Oil field ultra-high water cut stage fly ash reinforced multiphase composite profile control and flooding method

A technology of ultra-high water content and fly ash, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problem of low sweep coefficient, achieve the suppression of channeling fingering, and the cost is easy to obtain , to achieve the effect of large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0067] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

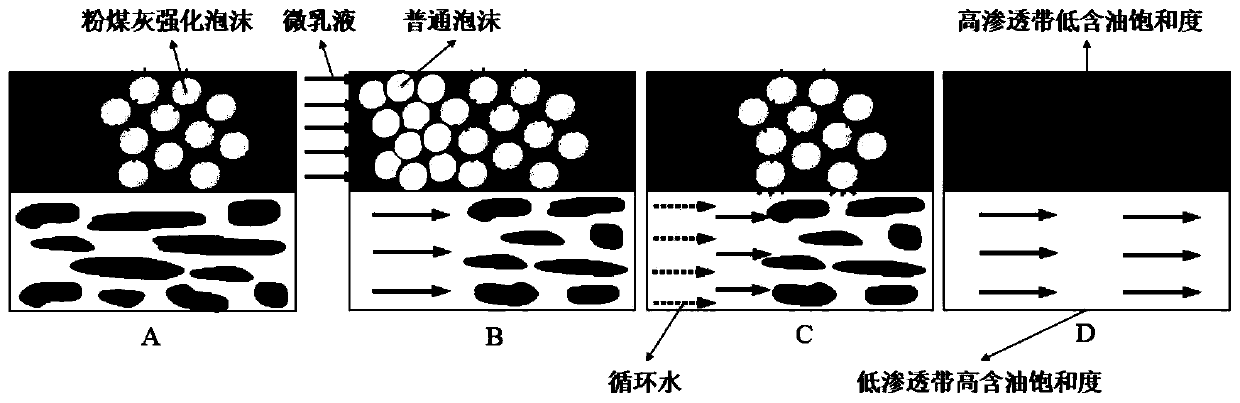

[0068] The present invention adopts fly ash-enhanced multi-phase composite control and flooding system to control and drive oilfields in ultra-high water-cut period. The injection method is as follows: figure 1 As shown, it can be seen that the injection sequence is as follows: enhanced blockage adjustment slug: injection of fly ash reinforced foam, isolation buffer slug: injection of surfactant foam, third slug: injection of microemulsion, hydrodynamic slug: injection Recycled water. The advantage of this injection sequence is that as time goes on, when the reaction time of the microemulsion and crude oil reaches the half-life of the surfactant foam, the surfactant foam begins to burst and disappear. At this time, the microemu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com