Patents

Literature

34results about How to "Reduce coalescing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

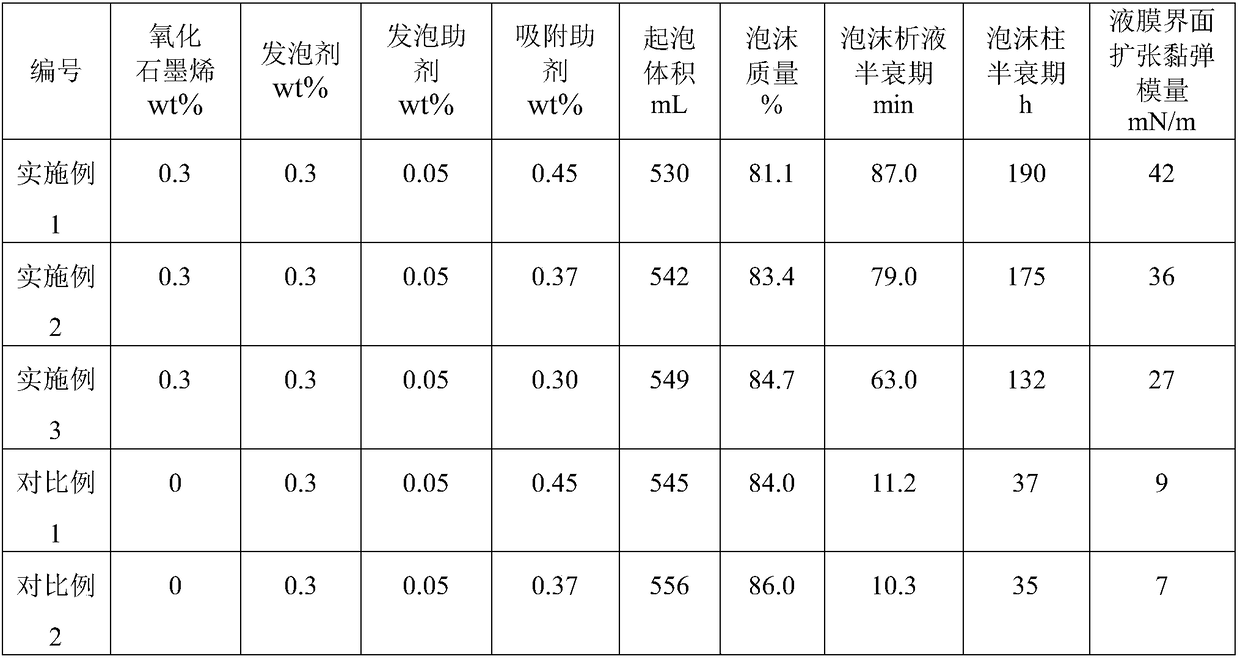

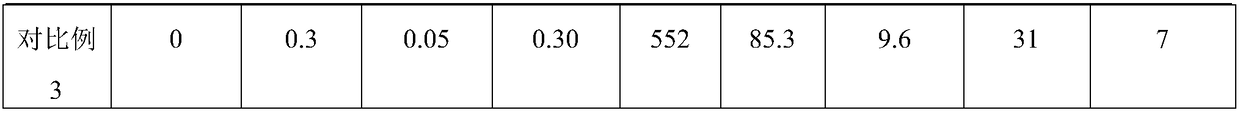

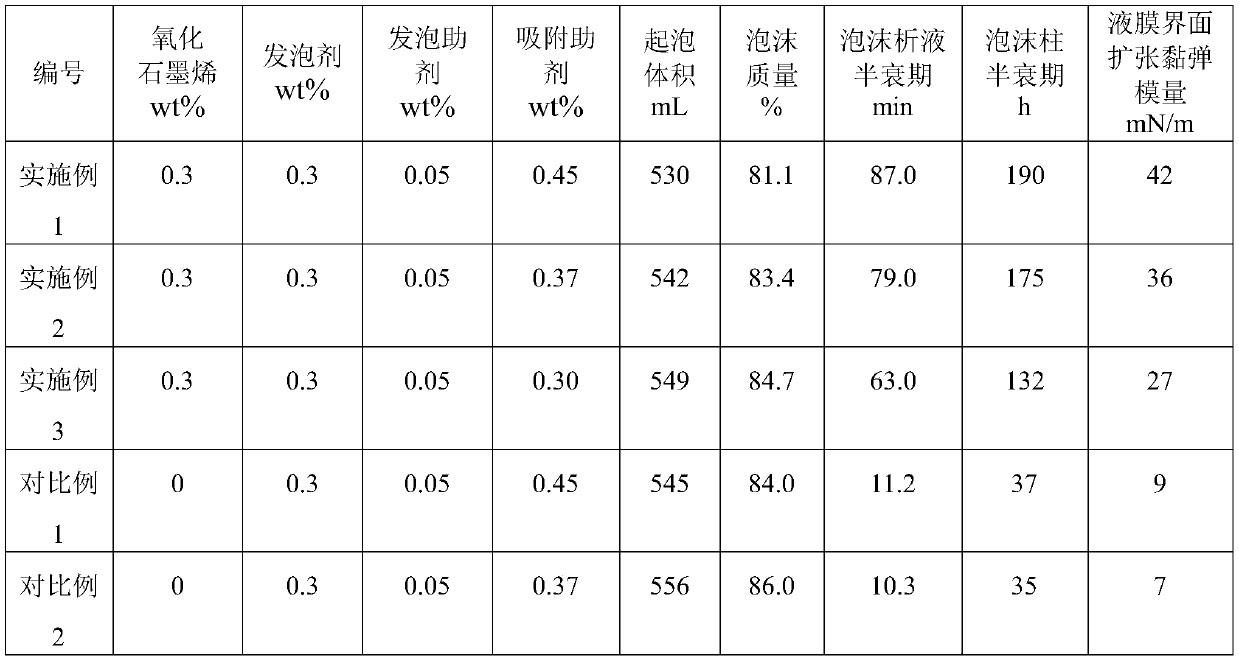

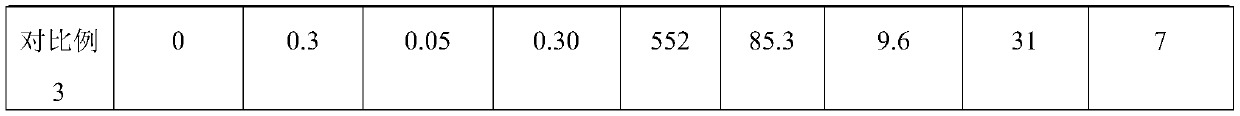

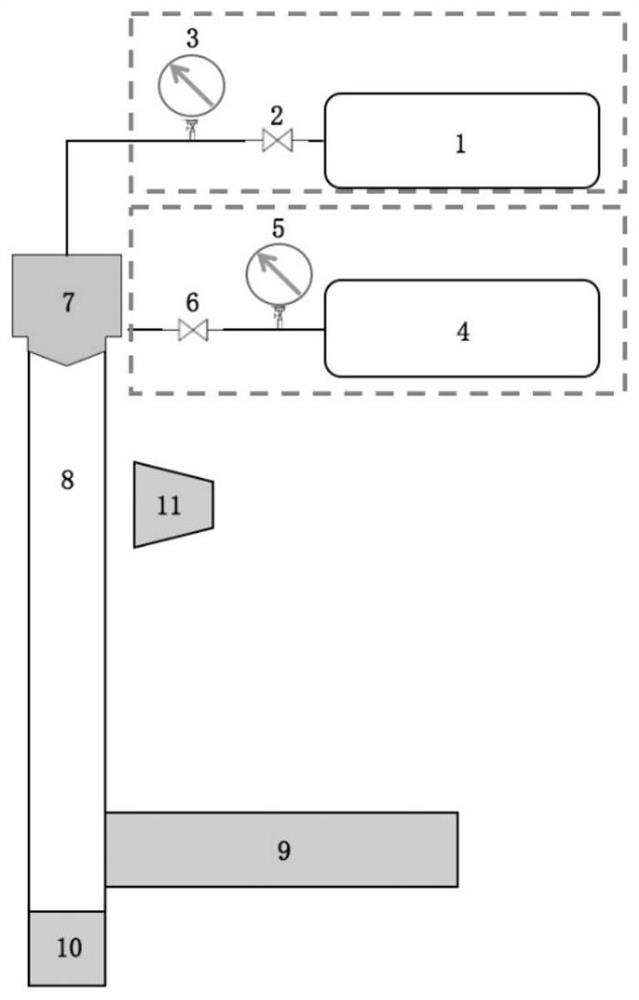

Graphene armor reinforced foam system for oil-gas field and preparation method of foam system

ActiveCN109439307AImprove stabilityReduce coalescingDrilling compositionCvd grapheneEnvironmental resistance

The invention discloses a graphene armor reinforced foam system for an oil-gas field and a preparation method of the foam system. The foam system is prepared from a gas phase, a liquid phase and graphene oxide, wherein the gas phase is nitrogen, carbon dioxide, natural gas or air; the liquid phase is an aqueous solution of a foaming agent, a blowing promoter and an adsorption assistant. Graphene oxide in foam can be strongly adsorbed on the gas-liquid interface of the foam, then a stable graphene armor layer is formed on an air bubble film and can effectively inhibit diffusion of gas in the foam through a liquid film and weaken of bubble coalescence, and meanwhile, the graphene armor layer can reduce loss of the liquid in the liquid film. Besides, the graphene armor layer can substantiallyimprove mechanical strength of the liquid film and effectively reduce breakage of the liquid film. By means of the graphene armor layer in the foam system, the foam has good stability. The graphene armor reinforced foam system is non-toxic and non-pollution, produces little formation damage and has the green and environment-friendly characteristics.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

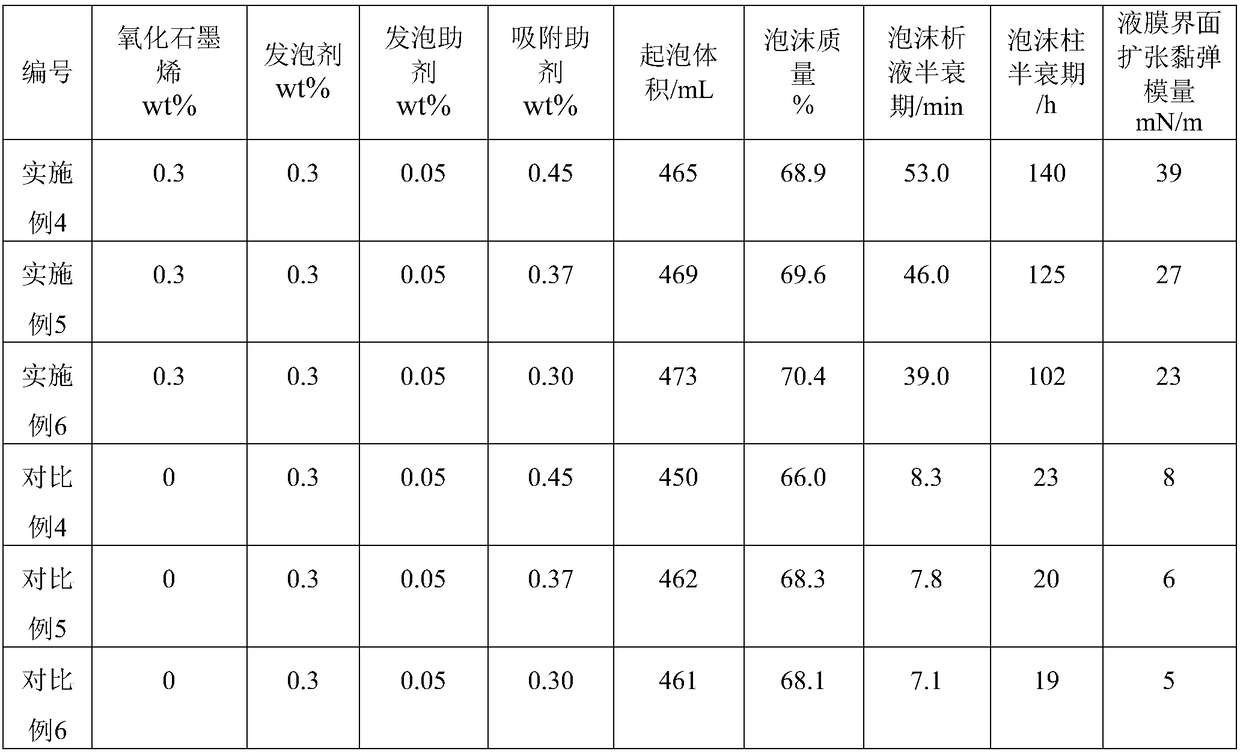

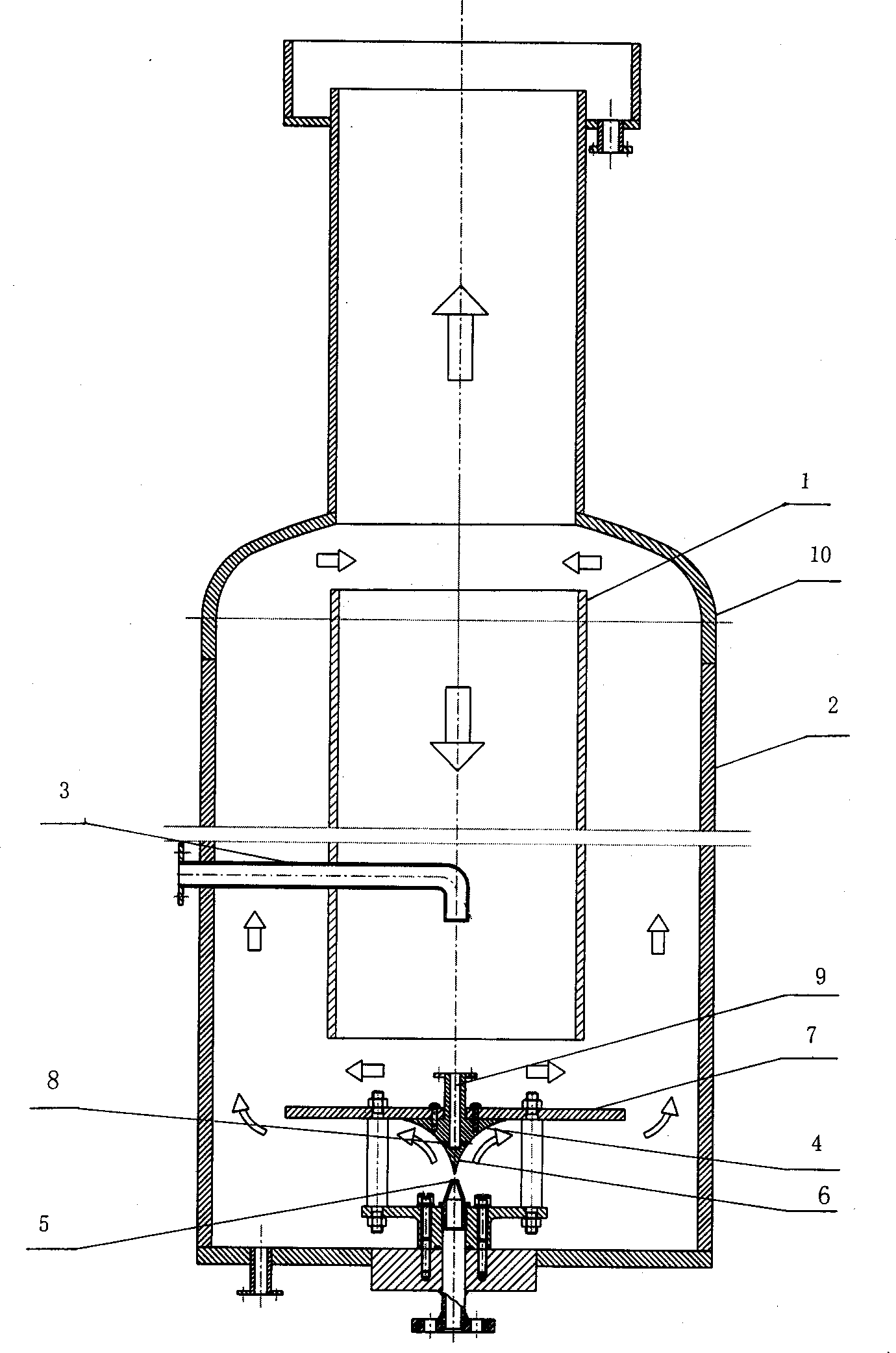

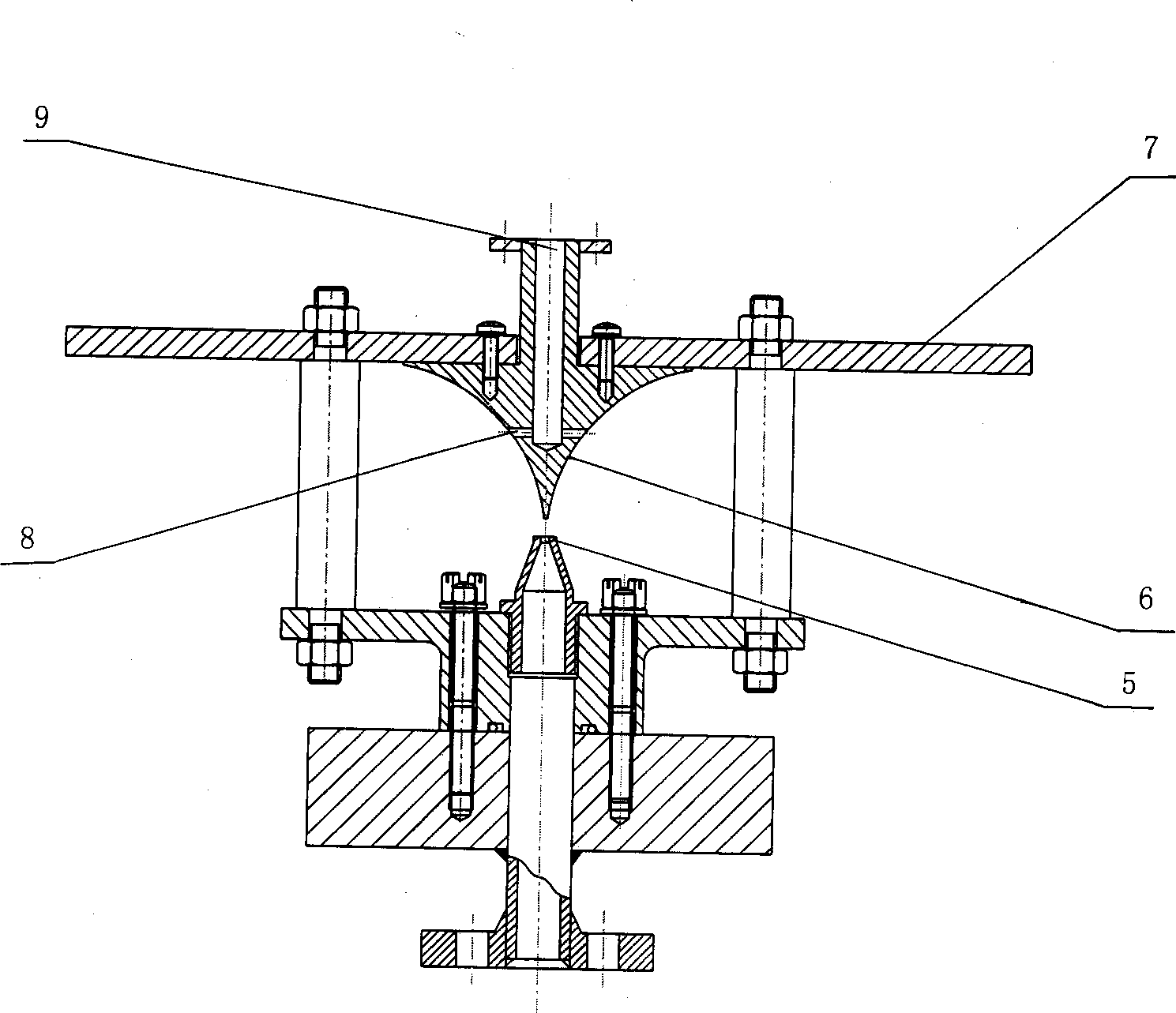

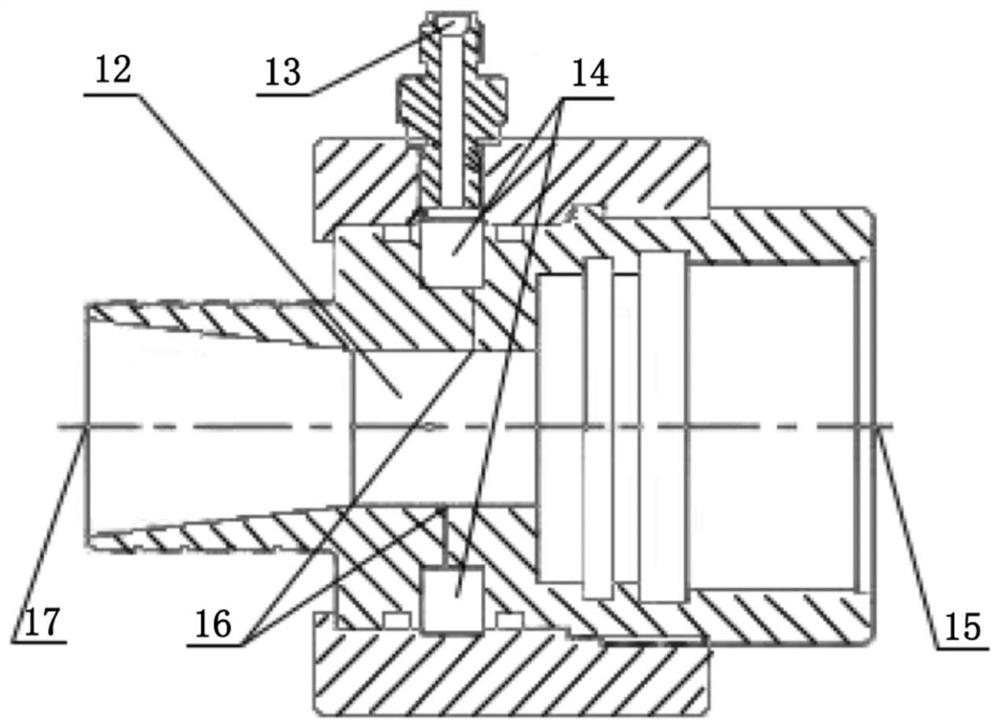

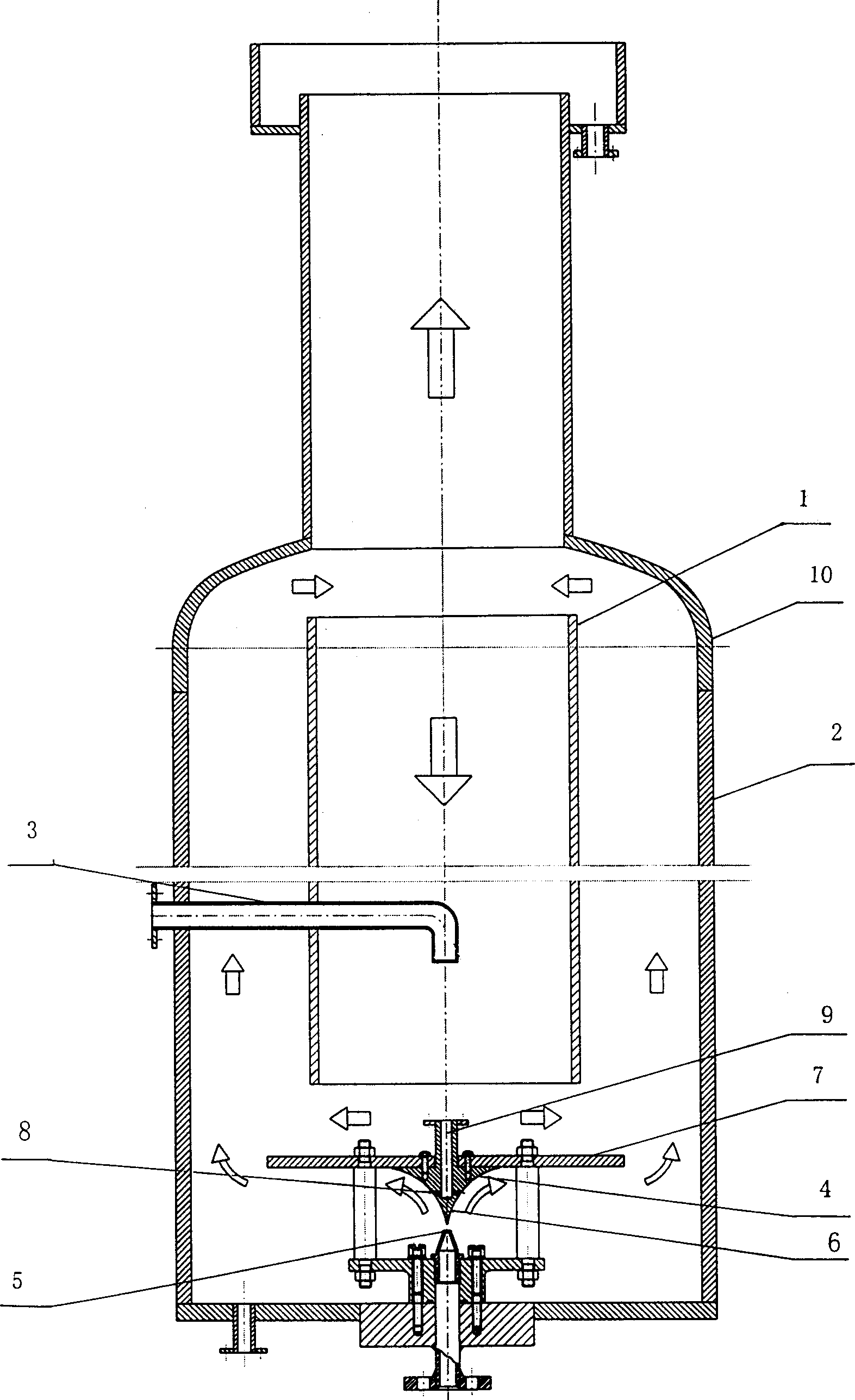

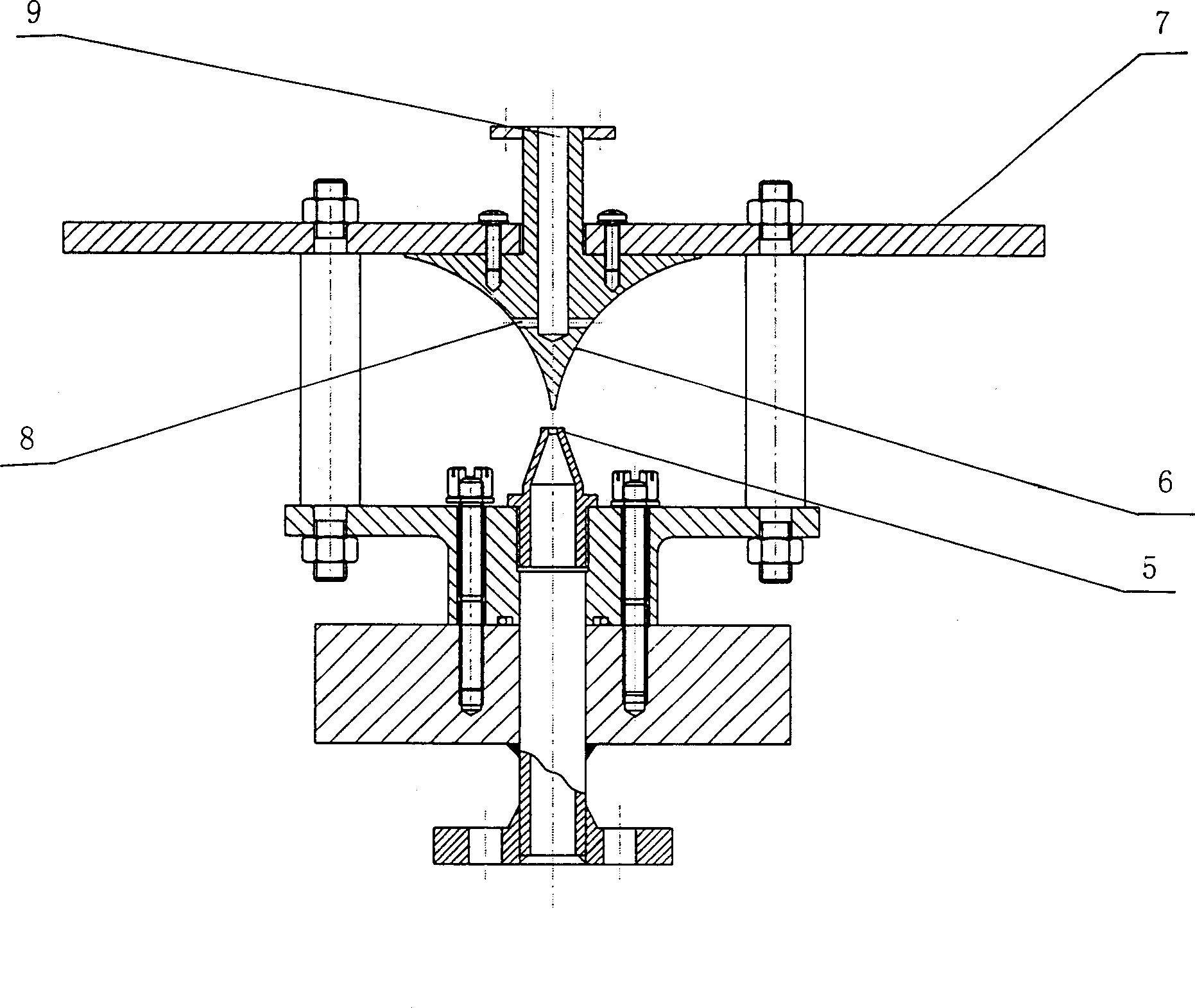

Jet aeration reactor used in active sludge method and its jet aeration process

InactiveCN1364731AOptimize spatial distributionReduce coalescingFlow mixersSustainable biological treatmentActivated sludgeProcess engineering

The present ivnention relates to aeration mode and equipment in waste water treatment. A new kind of jet aeration reactor and jet aeration process is provided. The present invention features that at the bottom of the reactor, a coaxial jet aerator with liquid driven jet, fixed cone, distributing plate and annular gap and a knocking plane in the upper part of the reactor are installed. The two phase gas-liquid flows knock oppositely to form gas-liquid circulation from output to inner, and this can improve the space distribution of bubbles, decrease bubbles aggregation, increase the service area of the jet aerator, maintain the homogeneous energy distribution rate in whole reactor and raise the mass transferring the energy transferring efficiency.

Owner:TSINGHUA UNIV +1

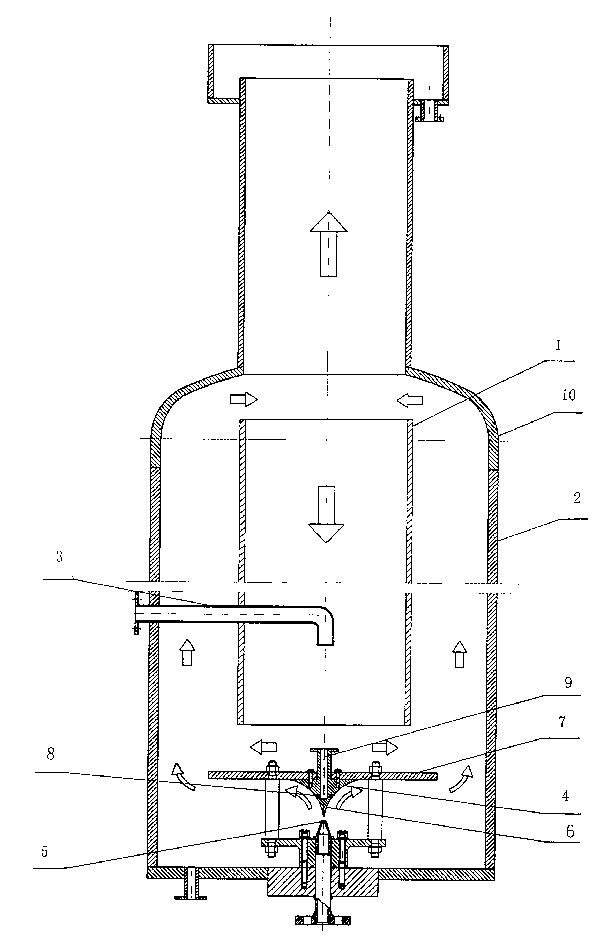

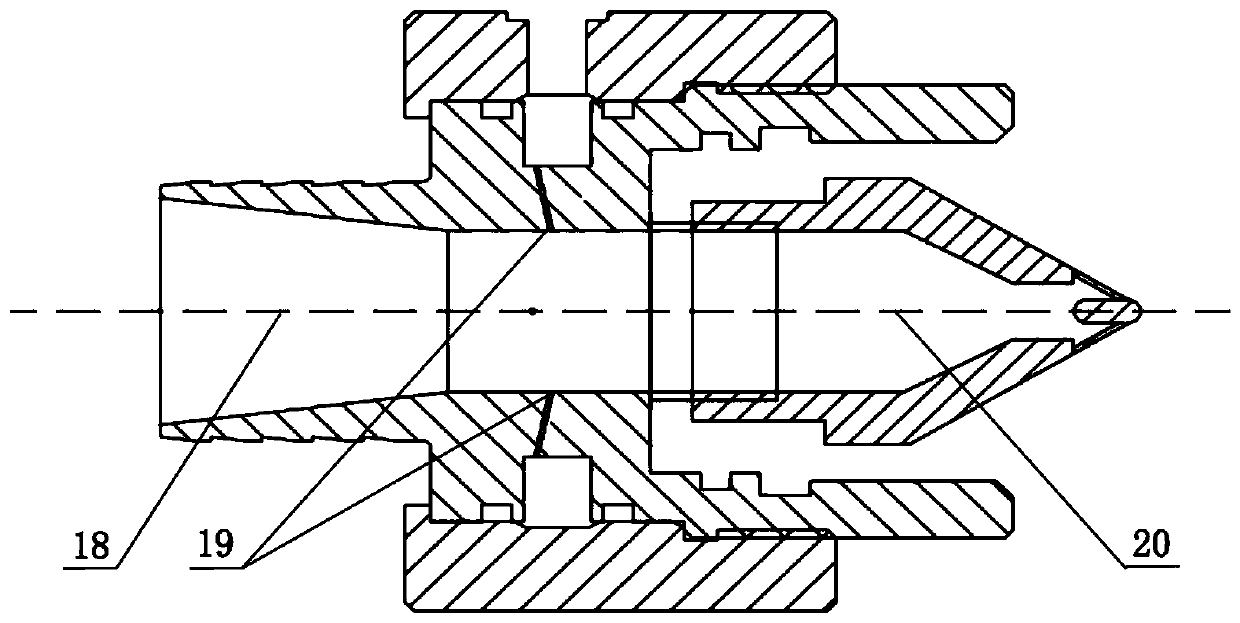

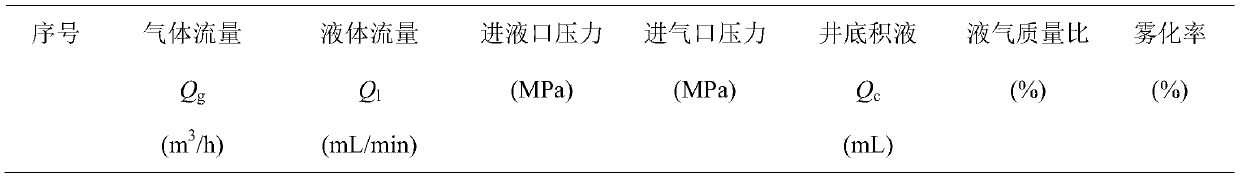

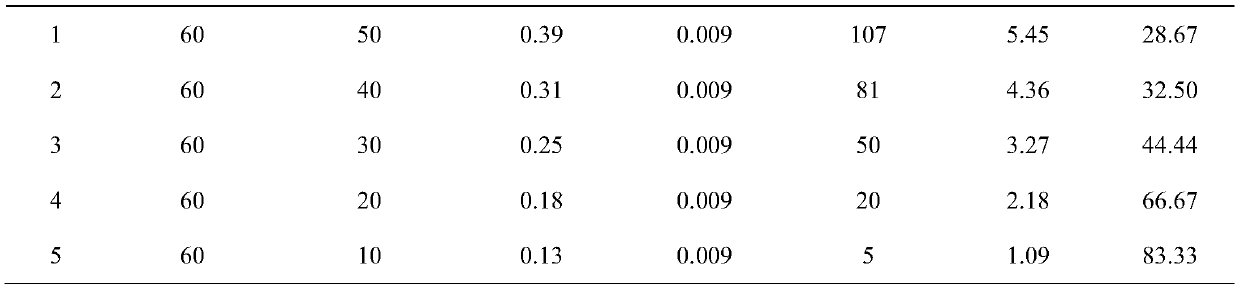

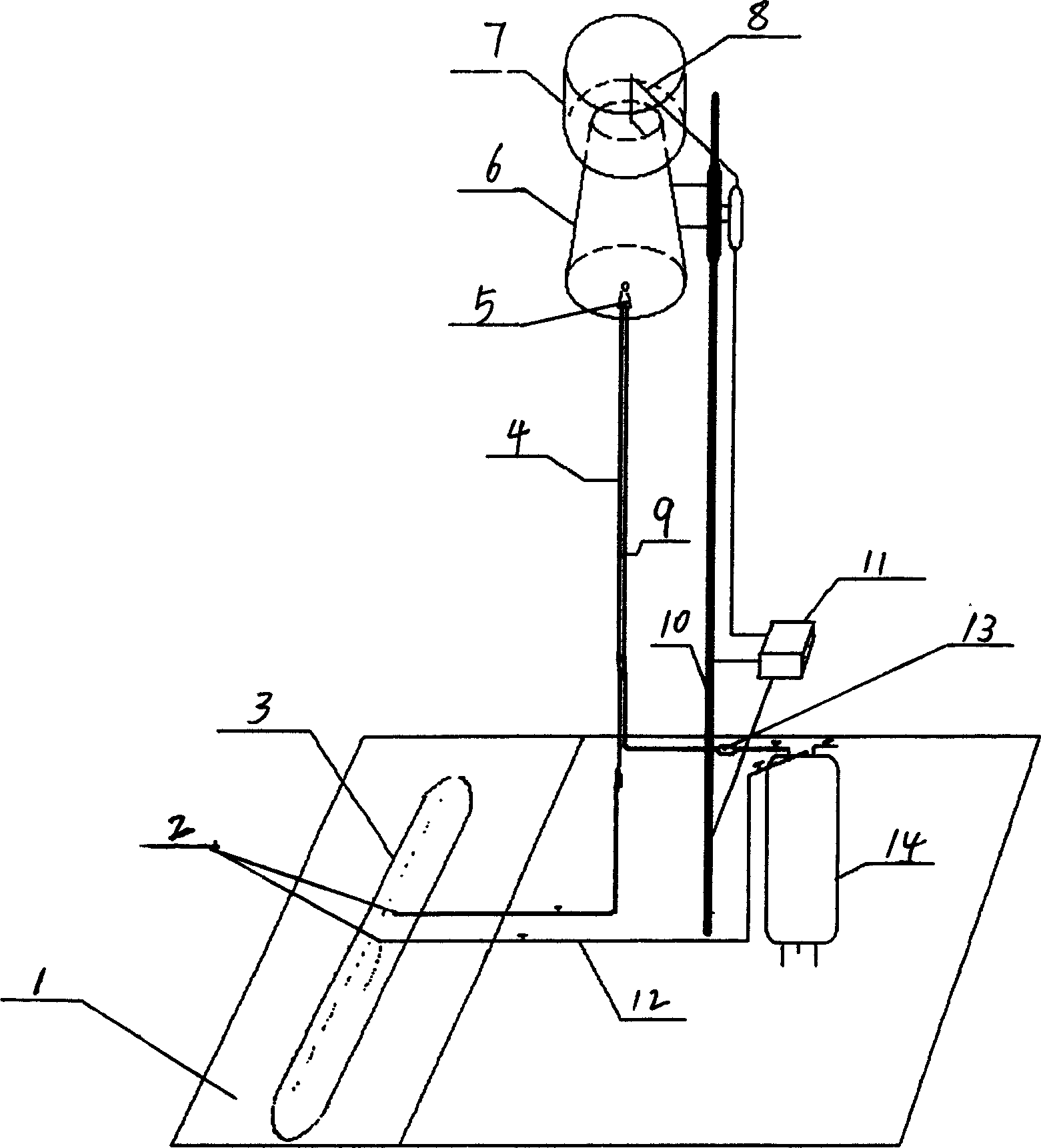

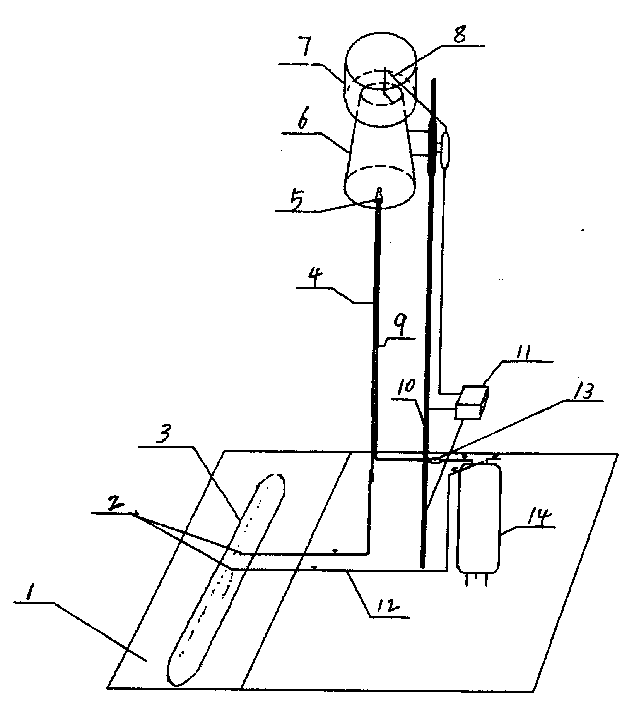

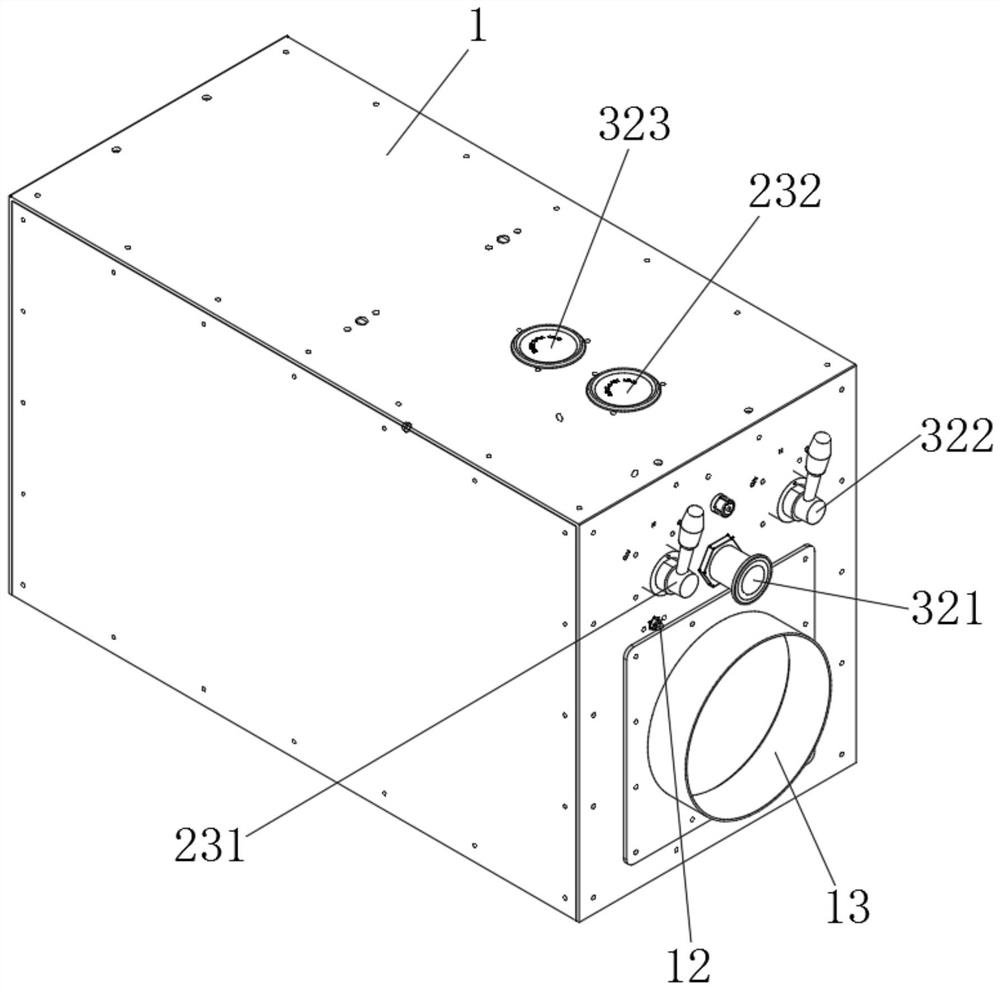

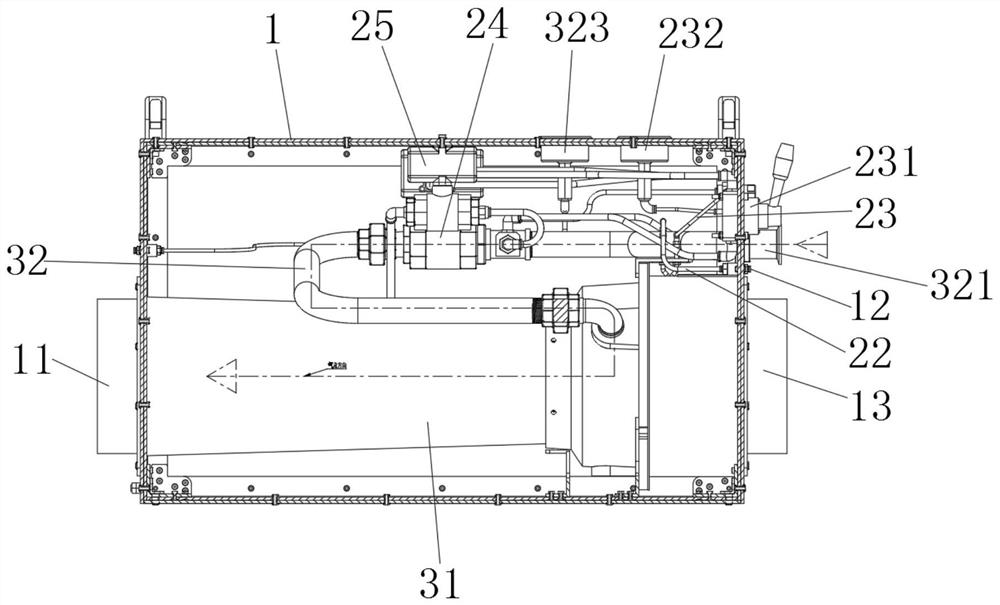

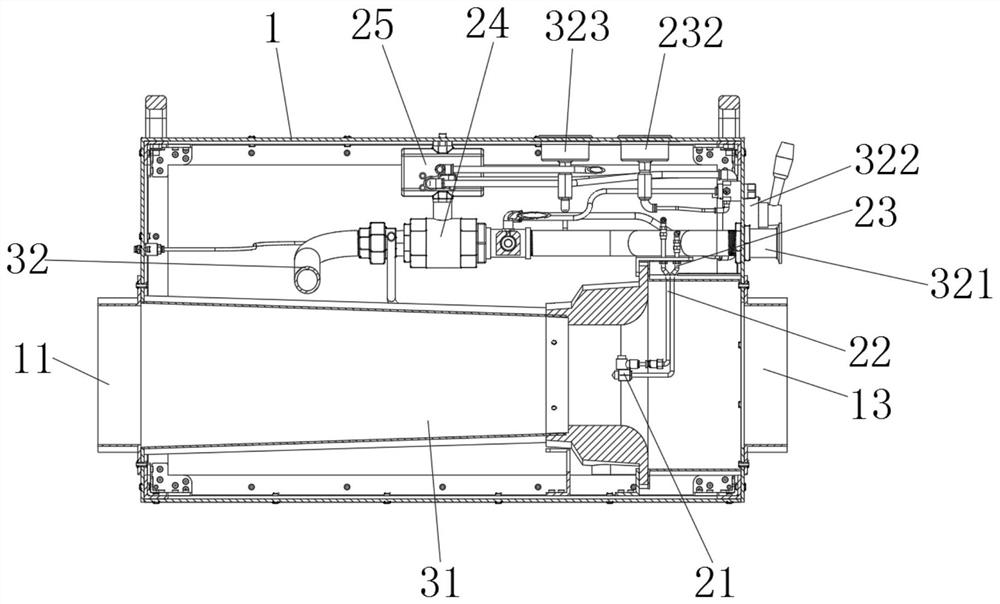

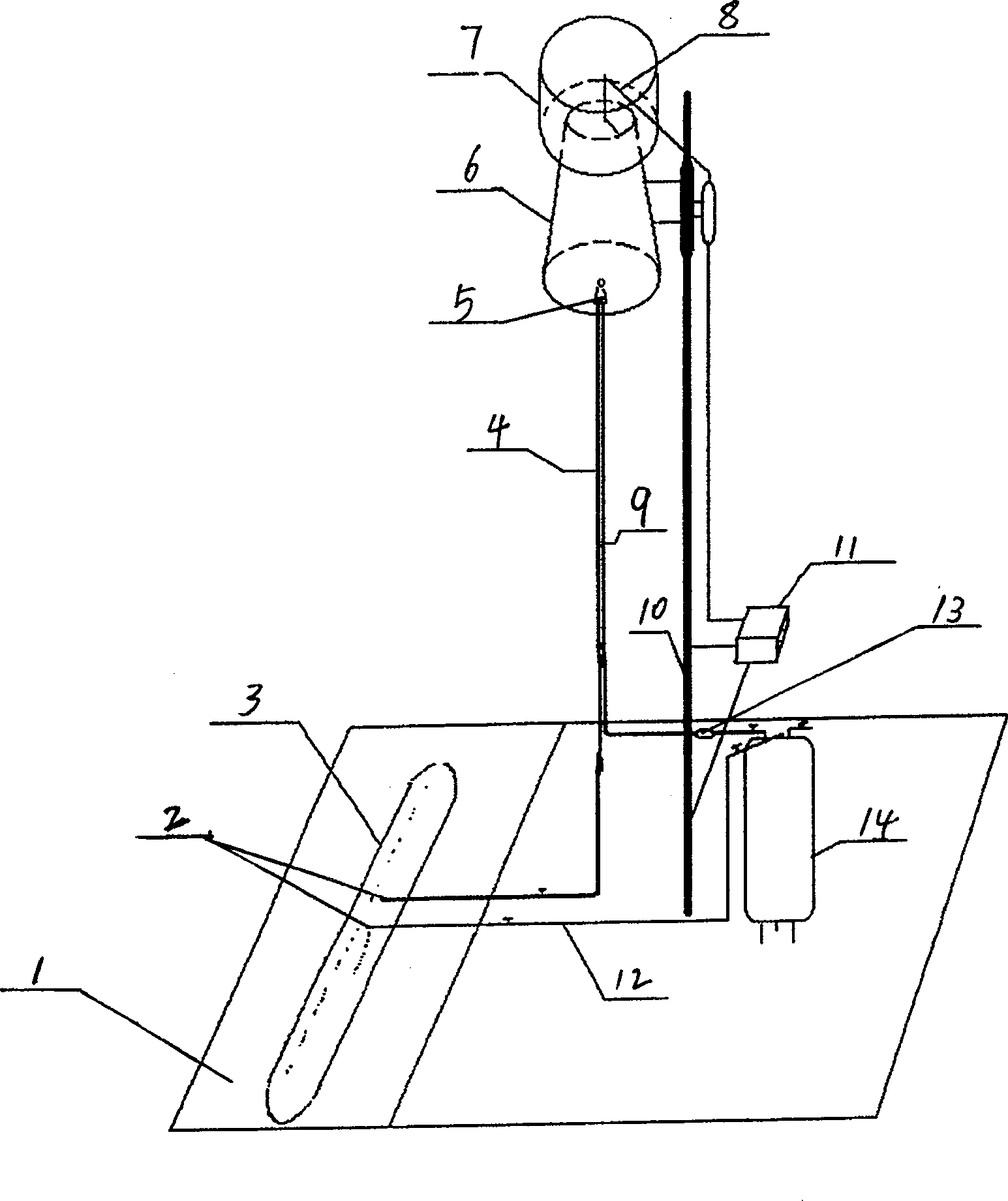

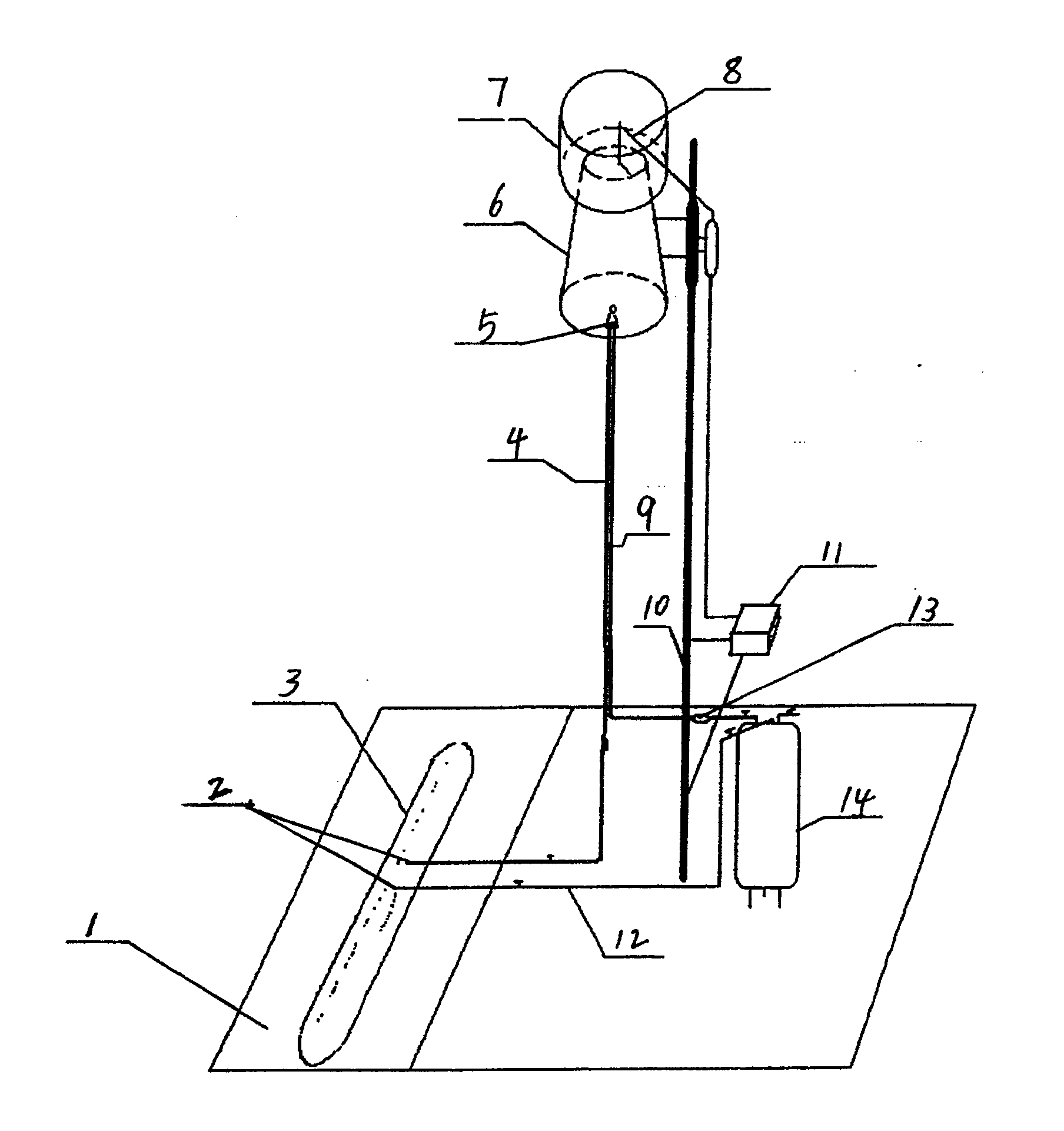

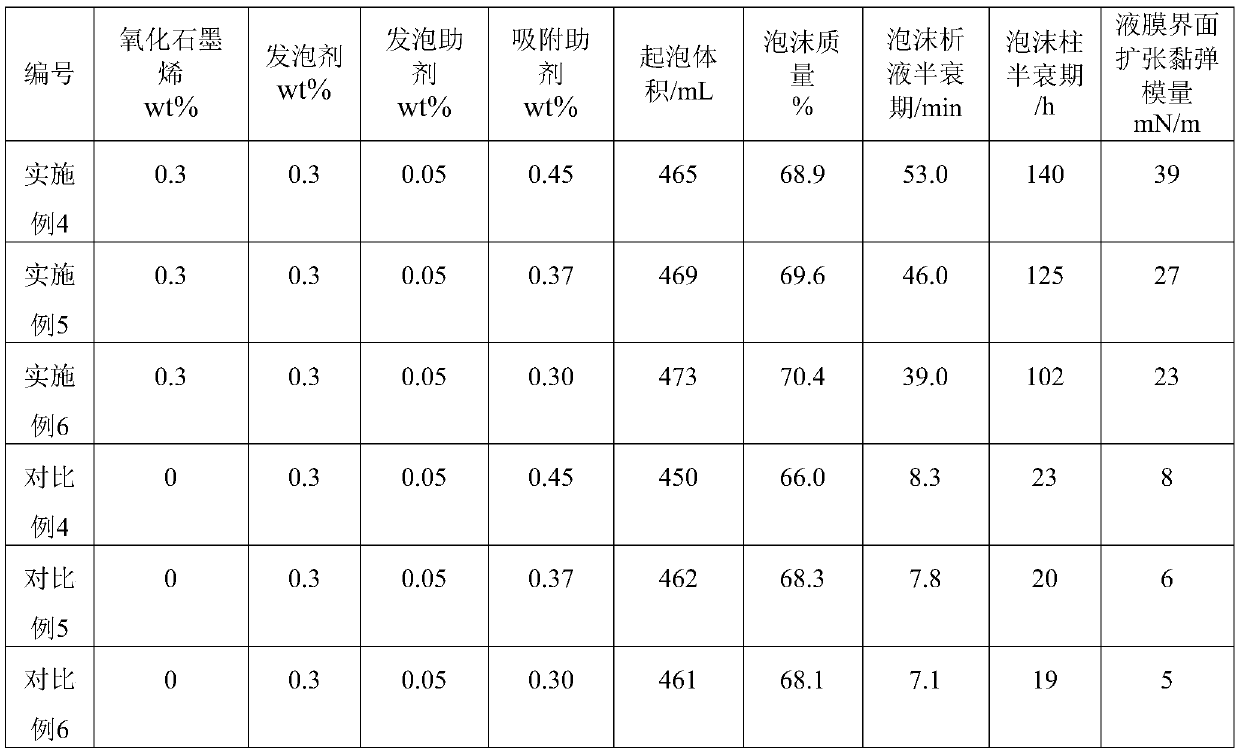

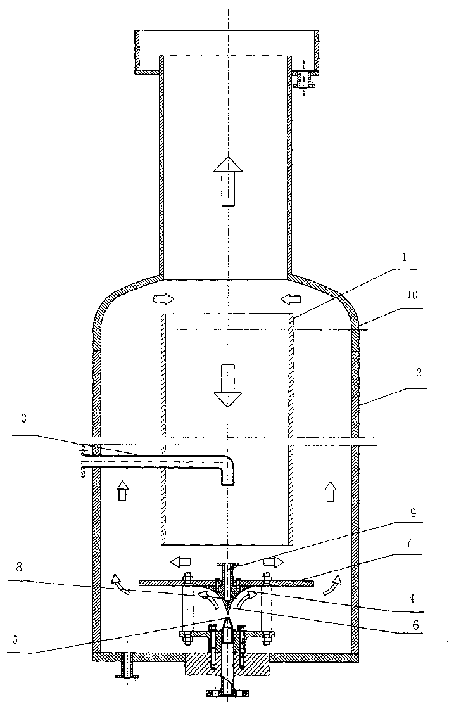

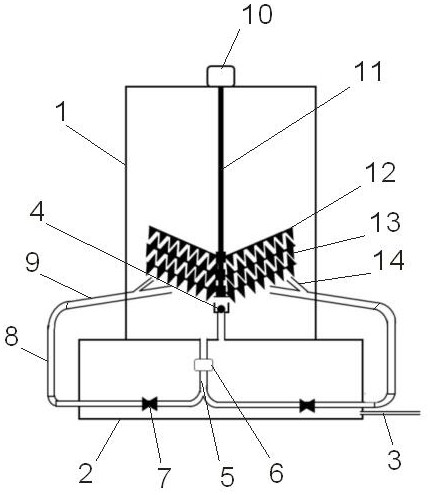

Atomized acid shaft flow simulation platform for gas injection development of fracture-cavity type oil reservoir and working method thereof

The invention discloses an atomized acid shaft flow simulation platform for gas injection development of a fracture-cavity type oil reservoir. The atomized acid shaft flow simulation platform mainly comprises a double-flow venturi atomization generation device, a shaft flow simulation device and an atomization evaluation device. The atomization generation device comprises an air path system, a liquid path system and an atomization generator; the airpath system comprises an air compressor, an air throttle valve and an air pressure gauge; the liquid path system comprises a high-pressure acid-proof pump, a liquid throttle valve and a liquid pressure gauge; the simulation wellbore is used for being connected with the double-flow venturi atomization generation device and comprises a vertical wellbore, a horizontal simulation stratum and an effusion collecting device. The observation system comprises a nano laser particle size analyzer. The invention also discloses a working method of the atomized acid shaft flow simulation platform for gas injection development of the fracture-cavity type oil reservoir. The simulation platform can be applied to an oil field site, the injection displacement is controlled through the air path system and the liquid path system, the high acid liquor atomization rate is kept according to site construction requirements, the acidification effect of the fracture-cavity type oil reservoir is improved and effective communication of the fracture-cavity type storage and collection unit bodies can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

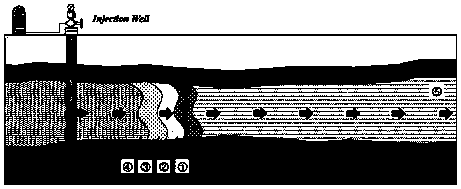

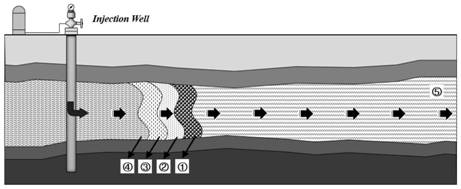

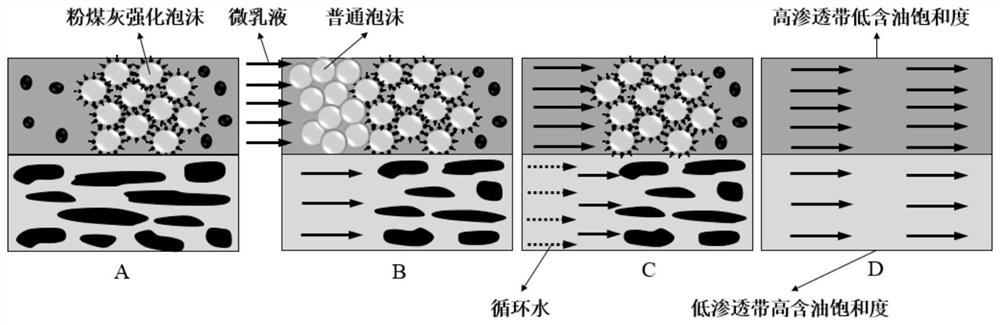

Oil field ultra-high water cut stage fly ash reinforced multiphase composite profile control and flooding method

ActiveCN110984933AEnhanced overall recoveryImprove microscopic heterogeneityFluid removalDrilling compositionActive agentOil phase

The invention discloses an oil field ultra-high water cut stage fly ash reinforced multiphase composite profile control and flooding method. The method comprises the following step: sequentially adopting fly ash reinforced foam, surfactant foam, microemulsion and water for profile control and flooding, wherein the fly ash reinforced foam is prepared from a gas phase and a liquid phase I; the liquid phase I is an aqueous solution of a foaming agent I, fly ash and a gas-liquid interface regulator; the surfactant foam is prepared from a gas phase and a liquid phase II; the liquid phase II is an aqueous solution of a foaming agent II; the microemulsion consists of a compound surfactant, a cosurfactant, an oil phase, an inorganic salt and water; and the compound surfactant is a compound of SDSand Tween 80. According to the method, through the action among the fly ash reinforced foam slug, the surfactant foam slug and the microemulsion slug, the opening and closing of a large pore channel can be regulated and controlled, the flow resistance is reduced, the regulation and flooding effect of blocking without blocking off is realized, the flow and production of crude oil are facilitated, and the purpose of economic and efficient development of an oil reservoir is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

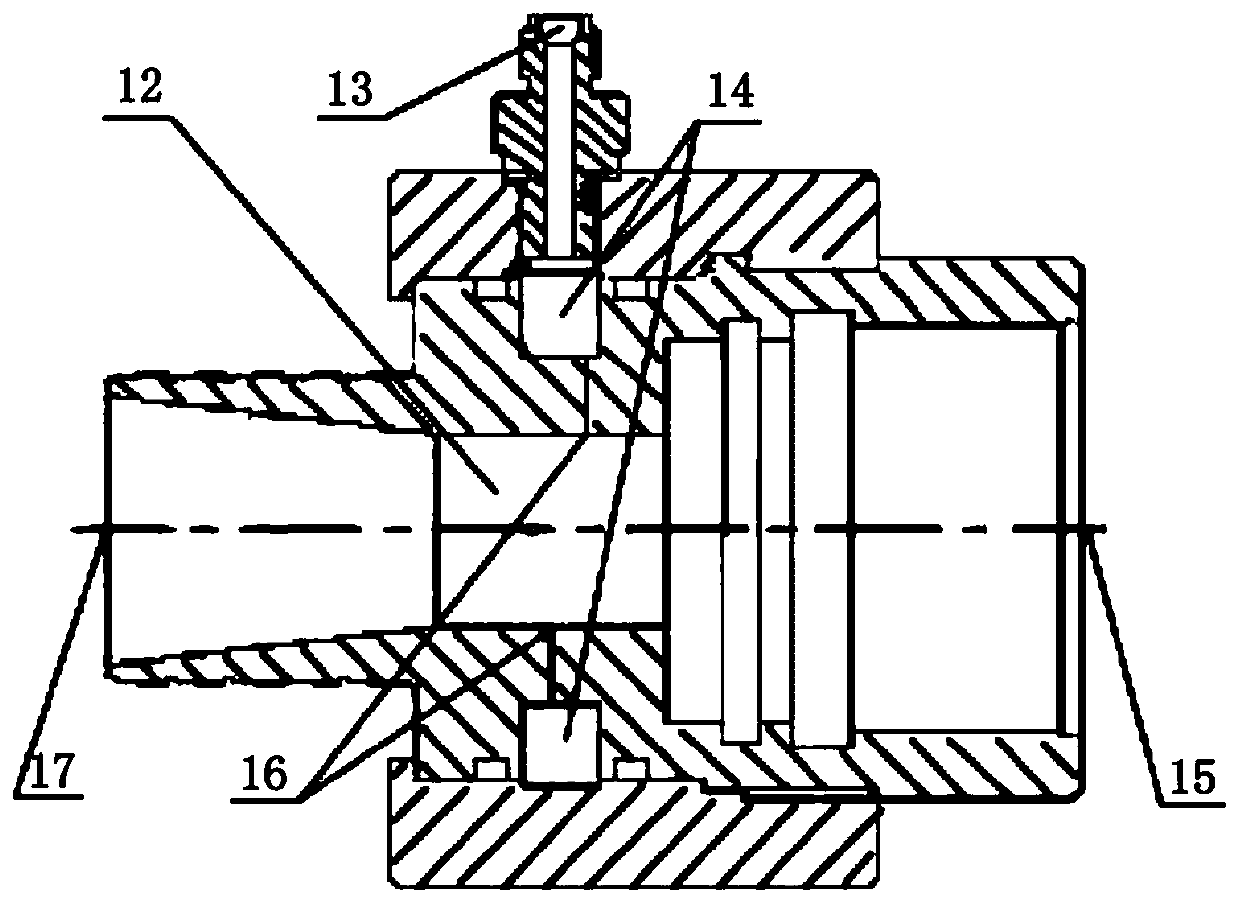

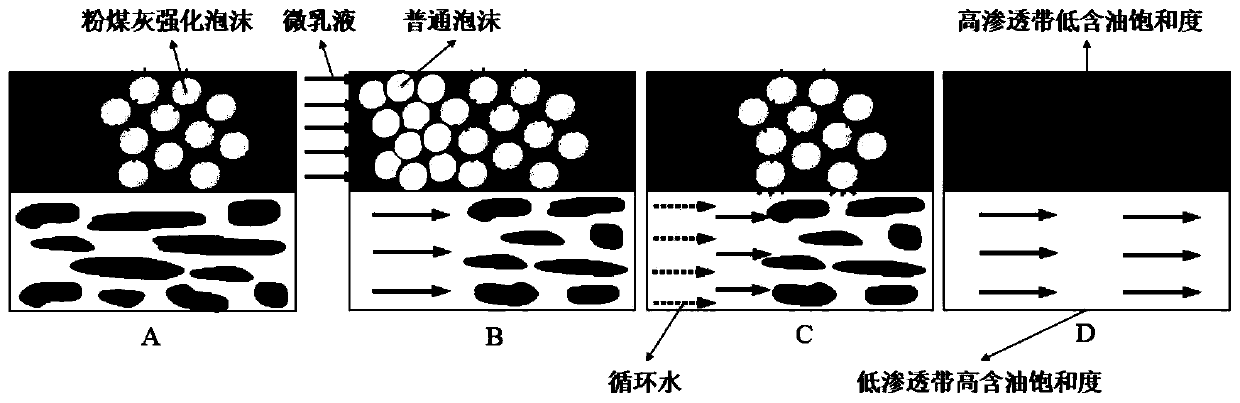

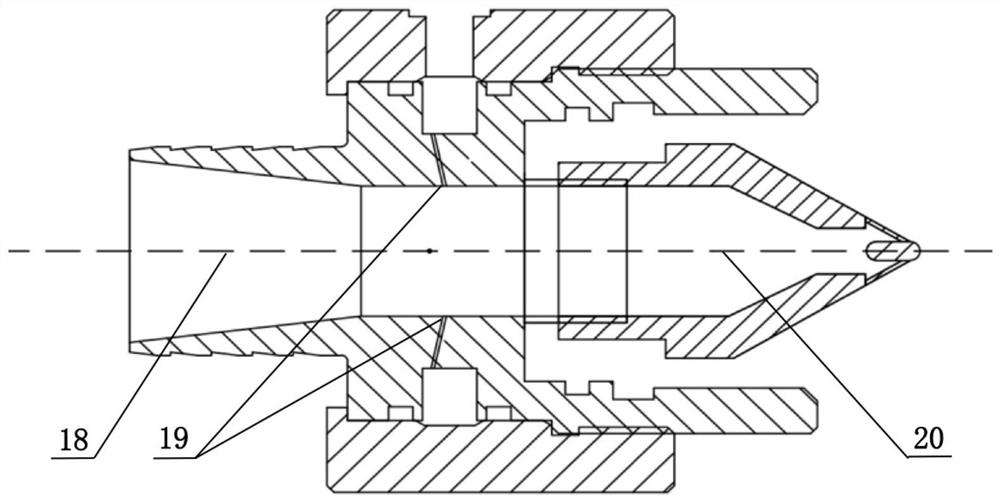

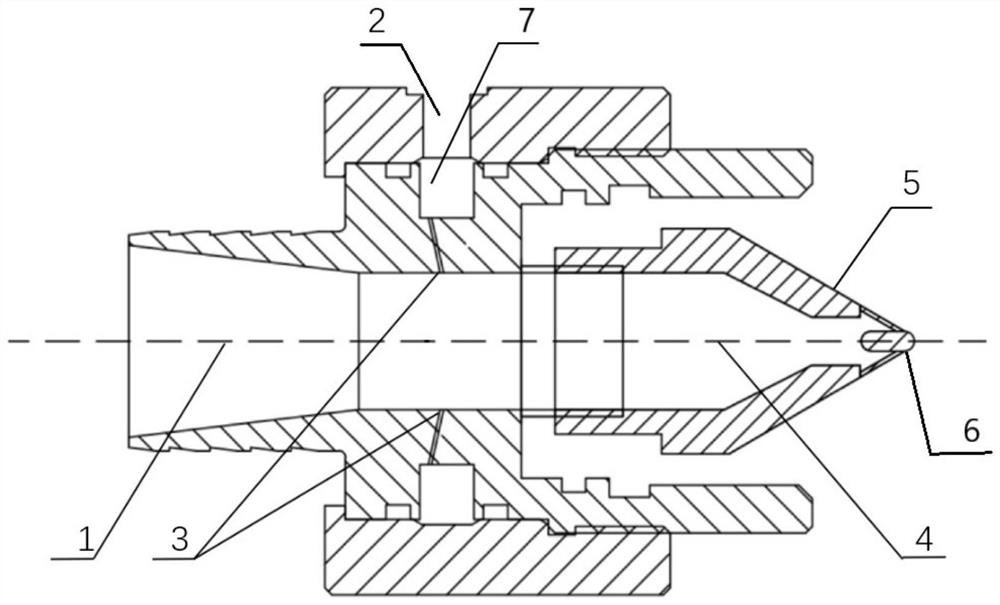

Acid liquid atomization device for deep acidification of fractured-vuggy reservoir and atomization method thereof

ActiveCN111085349AInto the uniformEasy to assembleFluid removalDrilling compositionAtomizer nozzleAir compressor

The invention discloses an acid liquid atomization device for deep acidification of a fractured-vuggy reservoir. The acid liquid atomization device for deep acidification of the fractured-vuggy reservoir comprises a gas path system, a liquid path system and an atomization nozzle; the gas path system comprises a gas inlet and an air compressor; the liquid path system comprises acid liquid inlets, ahigh-pressure acid-proof pump and a double-flow type Venturi tube; air is pressurized by the air compressor and then enters the gas inlet; and acid liquid is pressurized by the high-pressure acid-proof pump and then enters an annular cavity, the annular cavity is used for accumulating the acid liquid, the acid liquid in the annular cavity enters a cylindrical cavity through the acid liquid inletsformed in the wall, acid mist is formed in the cylindrical cavity as the hydrodynamic cavitation effect, the acid mist is constrained by the cylindrical cavity to form acid mist columnar fluid, the acid mist columnar fluid moves at high speed in an atomization generator and is finally sprayed out from the atomization nozzle of the atomization generator, and the atomization nozzle is directly connected with a shaft. The acid liquid atomization device for deep acidification of the fractured-vuggy reservoir has the good high temperature resistance, high pressure resistance and acid resistance, the injection displacement can be controlled through the gas path system and the liquid path system, the high acid liquid atomization rate is kept, and the acidification effect of the fractured-vuggy reservoir is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

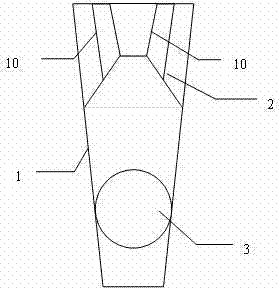

Silver iodide acetone solution above-ground combustion equipment and its combustion method

InactiveCN1515146AImprove atomization effectMeet the requirements of scaleWeather influencing devicesSilver iodideAbove ground

The present invention discloses a silver iodide acetone solution above-ground combustion equipment, including liquid storage tank, air compressor, liquid-supplying and gas-supplying pipelines, filter, atomizer, pulse high-voltage igniter, combustion chamber and wind-proofing device, the above-mentioned components are placed on a base seat. The liquid storage tank is communicated with liquid inelt of atomizer by means of filter, the air outlet of air compressor is communicated with air inlet of the atomizer, the combustion chamber is a circular truncated cone shaped cylinder body whose upper portion is larger and lower portion is smaller, and is placed on a vertical rod. It can make combustion temp, be up to 1000 deg.C, after having been cooled in atmosphere the combustion substance can be formed into silver iodide iced airosol.

Owner:BEIJING WEATHER MODIFICATION OFFICE

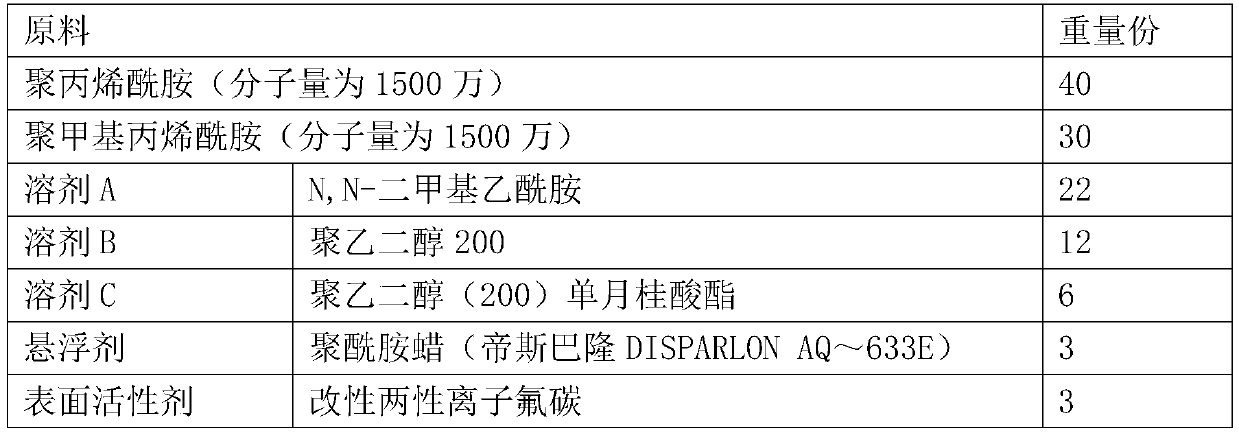

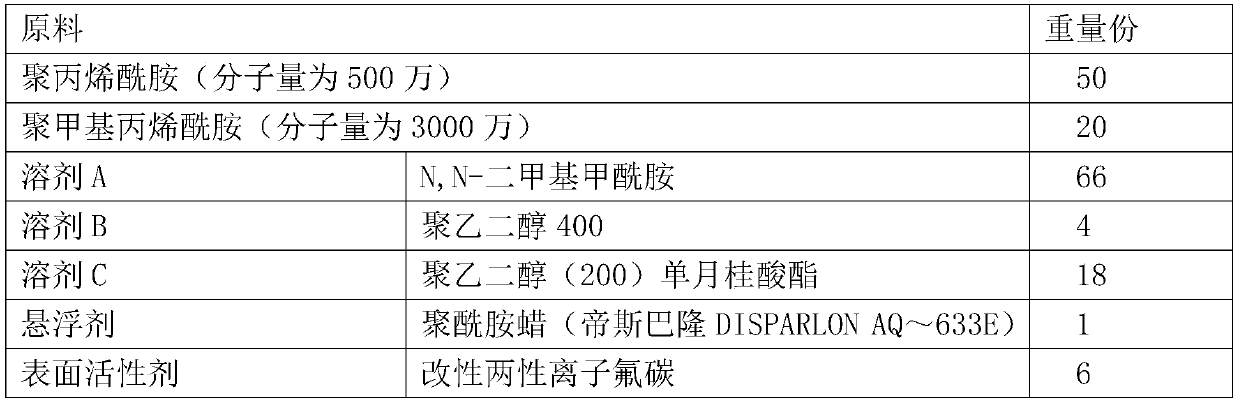

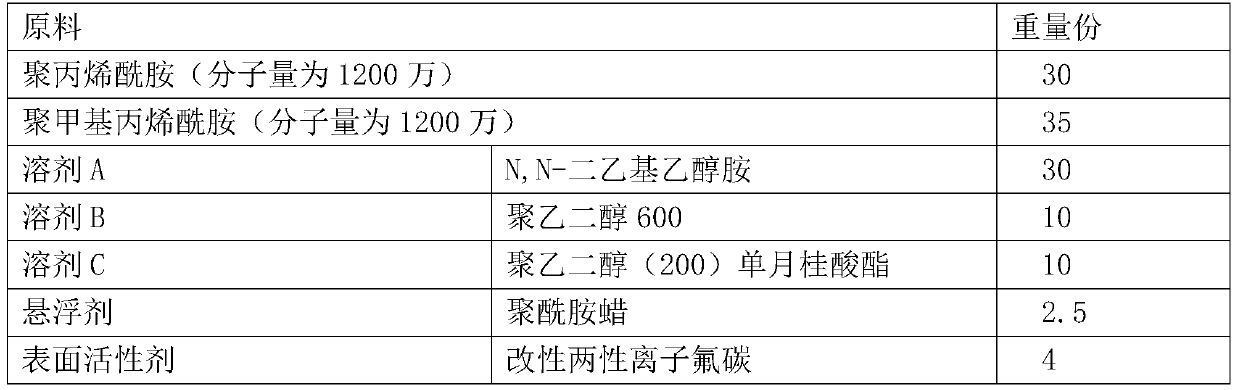

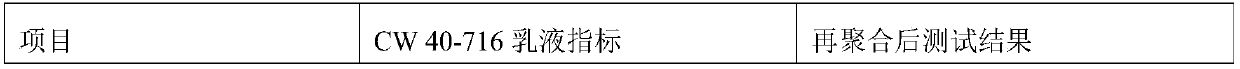

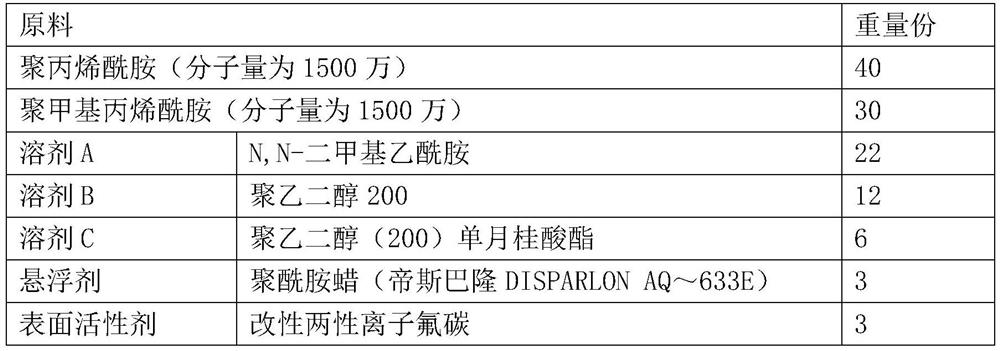

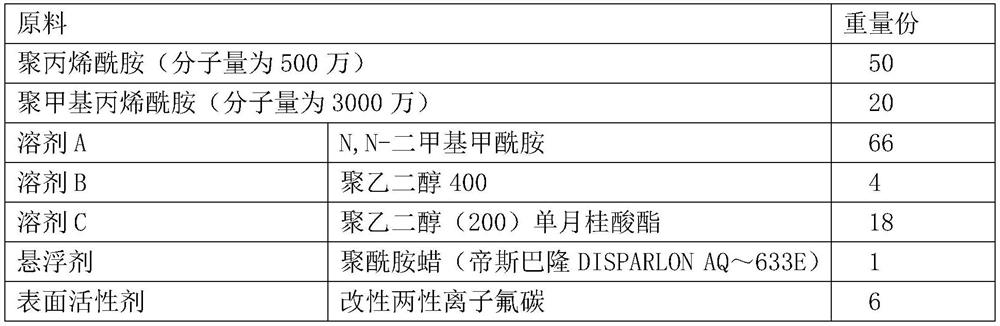

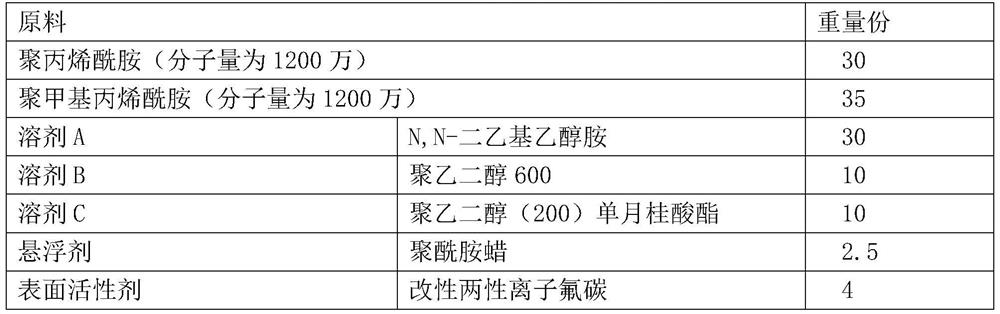

High-content water-based resistance reducing agent and preparation method thereof

ActiveCN111394085AEliminates slow dissolutionEliminate oil phase damage problemsFluid removalDrilling compositionMethacrylamideSolvent

The invention provides a high-content water-based resistance reducing agent and a preparation method thereof, and solves the technical problems in the prior art that a powder resistance reducing agentis low in hydration speed, oily residues exist after gel breaking of an oily suspension resistance reducing system, environmental friendliness is not achieved and the powder content of a water-basedresistance reducing suspension system is low. The preparation comprises the following raw materials in parts by weight: 20-50 parts of polyacrylamide; 20-40 parts of polymethacrylamide; 22-66 parts ofa solvent A; 4-12 parts of a solvent B; 6-18 parts of a solvent C; 1-3 parts of a suspending agent; and 3-6 parts of a surfactant, wherein the solvent A is alkyl amides; the solvent B is polyethyleneglycol; and the solvent C is polyhydric alcohol or polyhydric alcohol esters. The high-content water-based resistance reducing agent not only has the characteristics of high hydration speed, high powder content and good storage stability, but also can realize integrated operation and online blending.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD +1

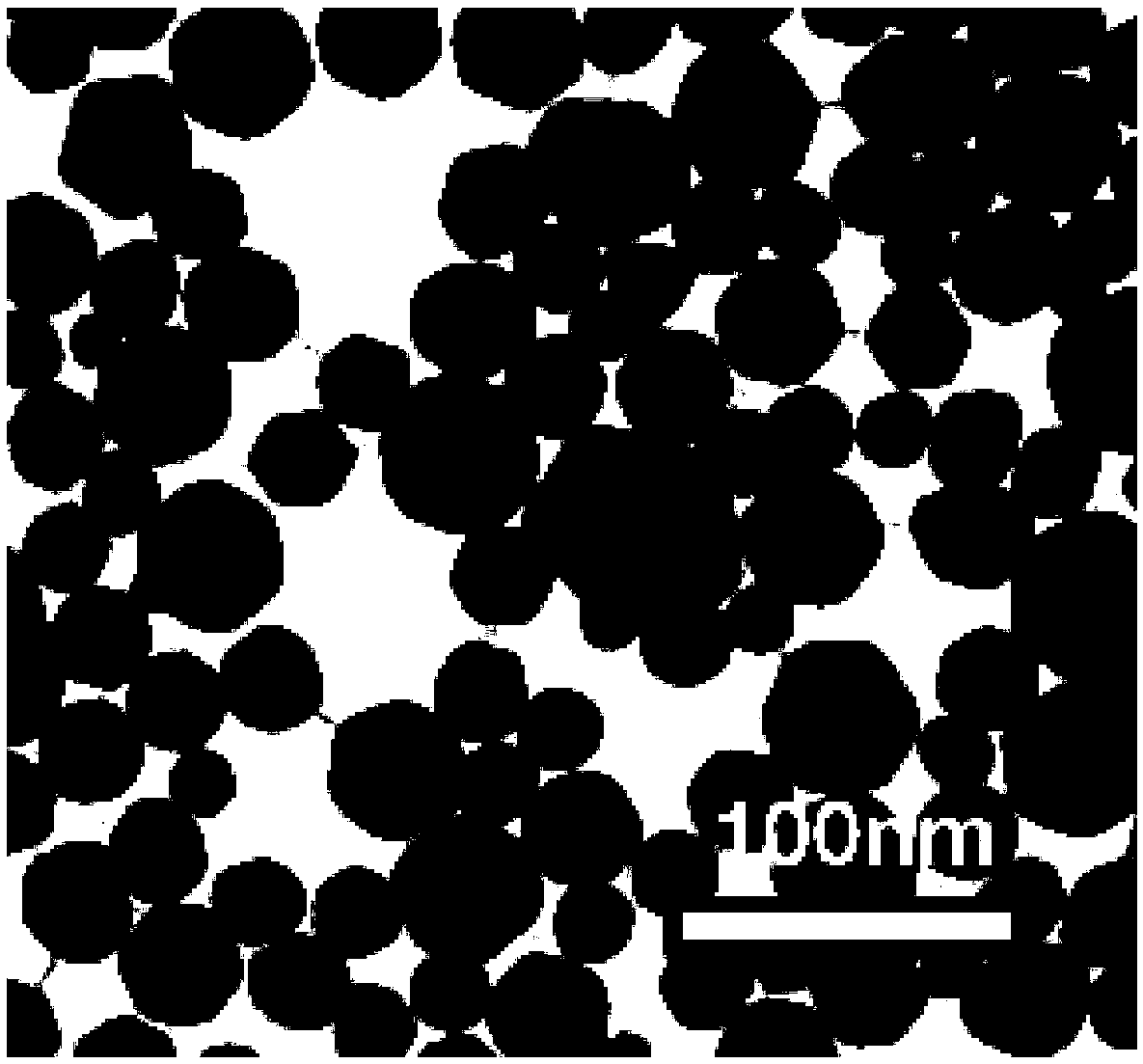

Nano-foam oil-displacing agent and preparation method thereof

ActiveCN112375554AReduce coalescingShorten speedFluid removalDrilling compositionNanofoamActive agent

The invention belongs to the technical field of oil extraction in oil fields, and particularly relates to a nano-foam oil-displacing agent and a preparation method thereof. The oil-displacing agent comprises the following components in percentage by weight: 10-45% of an anionic surfactant, 7-15% of a zwitterionic surfactant, 6-12% of oily nanoparticles, 5-10% of a stabilizer, 1-2% of a dispersingagent and the balance of water. The preparation method of the oil-displacing agent comprises the following steps: preparing oily nanoparticles from solid paraffin and isocaprylic acid, dispersing theoily nanoparticles in water, conducting uniform mixing with a surfactant, and adding a stabilizer and water to prepare the nano-foam oil-displacing agent. The nano-foam oil-displacing agent can effectively inhibit gas diffusion, enhance the mechanical stability and viscosity of a liquid film, effectively prevent external heat from being transferred to the inside, reduce the molecular thermal motion rate, greatly reduce the liquid separation rate of a foam liquid film, enhance the stability of foam and further improve the oil-displacing efficiency.

Owner:滨州市广友石油科技有限公司

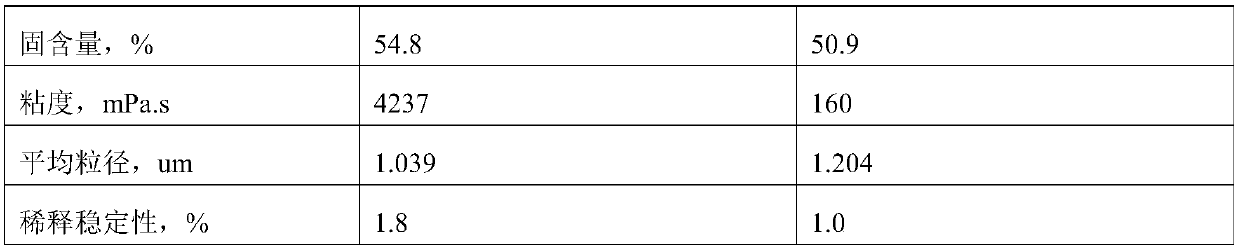

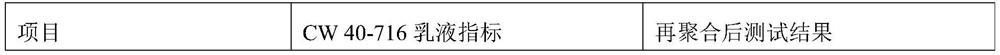

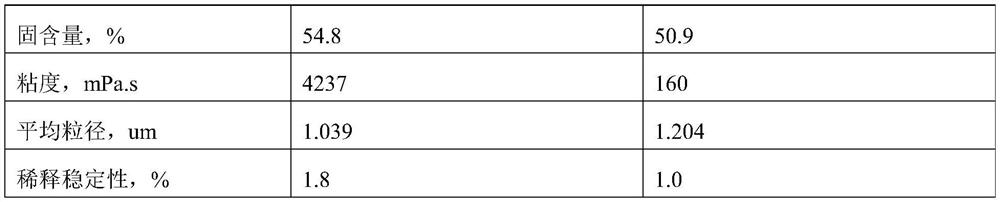

Low-viscosity high-speed cigarette adhesive and preparation method thereof

The invention provides a low-viscosity high-speed cigarette adhesive prepared from seed emulsion, a vinyl acetate monomer, an oxidant, an initiator, a capturing agent, an alcohol compound, a pH regulator and water, wherein the seed emulsion is one or combination of more of vinyl acetate-ethylene emulsion, vinyl acetate-acrylate emulsion, a vinyl acetate homopolymerized emulsion, the seed emulsionhaving solid content of 40.0-65.0% and viscosity of 500-5000 mPa*s. In the invention, firstly, the protective colloid in the emulsion is broken to reduce the viscosity, and then the stable emulsion system is reconstructed through polymerization, and the generation quantity of new emulsion particles is controlled, thus producing the emulsion. The viscosity of the emulsion can be lowered to 200 mPa*s, which not only satisfies the cigarette lap adhesion at the machine speed of 14,000-16,000 / min but also can be used for adhesion of common materials, such as paper processing, coating decoration, nonwoven clothes, carpets, etc. The adhesive is simple in preparation method and is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +2

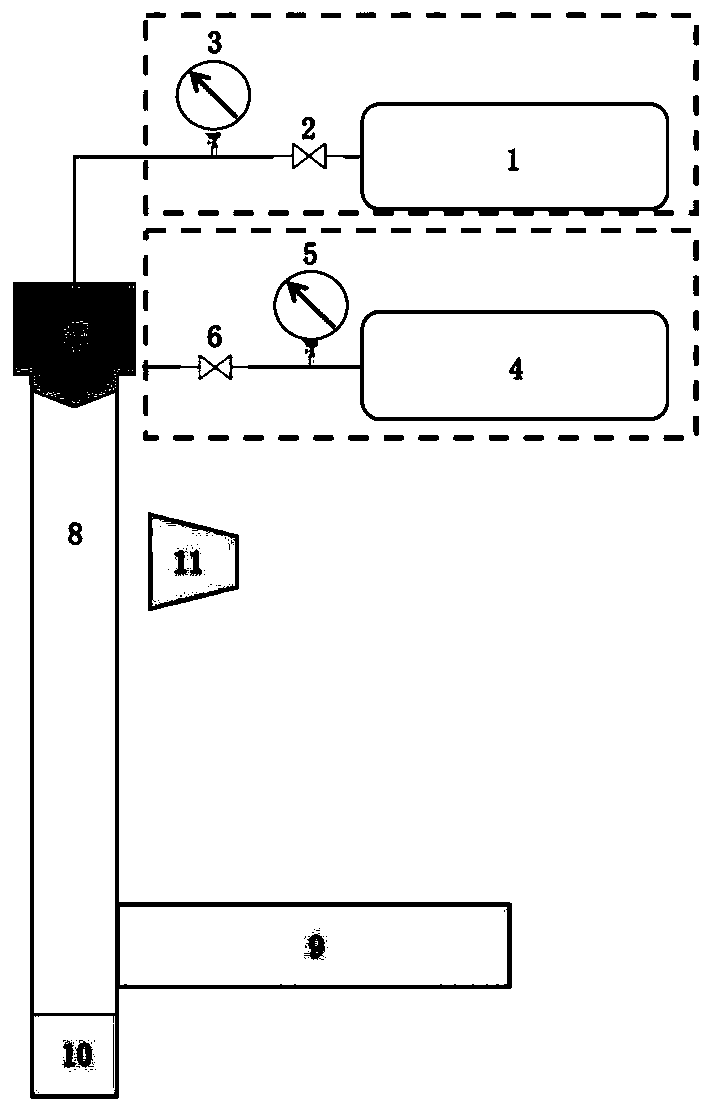

Multistage atomization method for inhibitor

InactiveCN112354711AReduce dosageReduce coalescingLiquid spraying apparatusProcess engineeringAir compressor

The invention discloses a multistage atomization method for an inhibitor. The multistage atomization method for the inhibitor comprises the following steps that an air compressor compresses air, and the compressed air is stored in an air storage tank; the compressed air in the air storage tank is purified through a purification assembly and then conveyed to the air inlet end of a first-stage atomizer, the inhibitor is conveyed to the liquid inlet end of the first-stage atomizer, and first-stage atomization is carried out on the inhibitor through the first-stage atomizer; and the inhibitor after first-stage atomization enters the liquid inlet end of a second-stage atomizer, the compressed air in the air storage tank is purified through the purification assembly and then conveyed to the airinlet end of the second-stage atomizer, and second-stage atomization is carried out on the inhibitor through the second-stage atomizer, and the inhibitor after second-stage atomization is sprayed intoa limited space from an outlet of the second-stage atomizer. According to the multistage atomization method for the inhibitor, second-stage atomization can be carried out on the inhibitor to achievea more sufficient atomization effect, coalescence of atomized liquid drops is effectively reduced, and the use efficiency of the oil-gas inhibitor is effectively improved.

Owner:QINGDAO NUOCHENG CHEM SAFETY SCI & TECH CO LTD

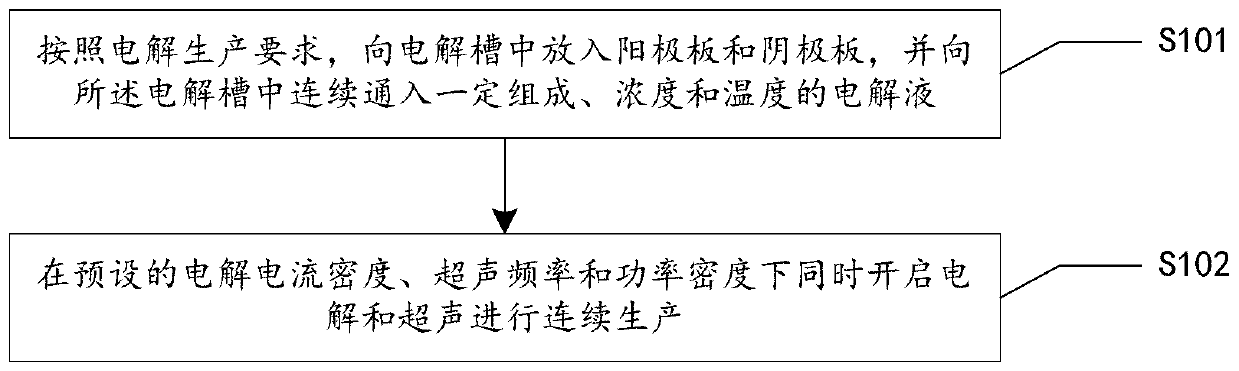

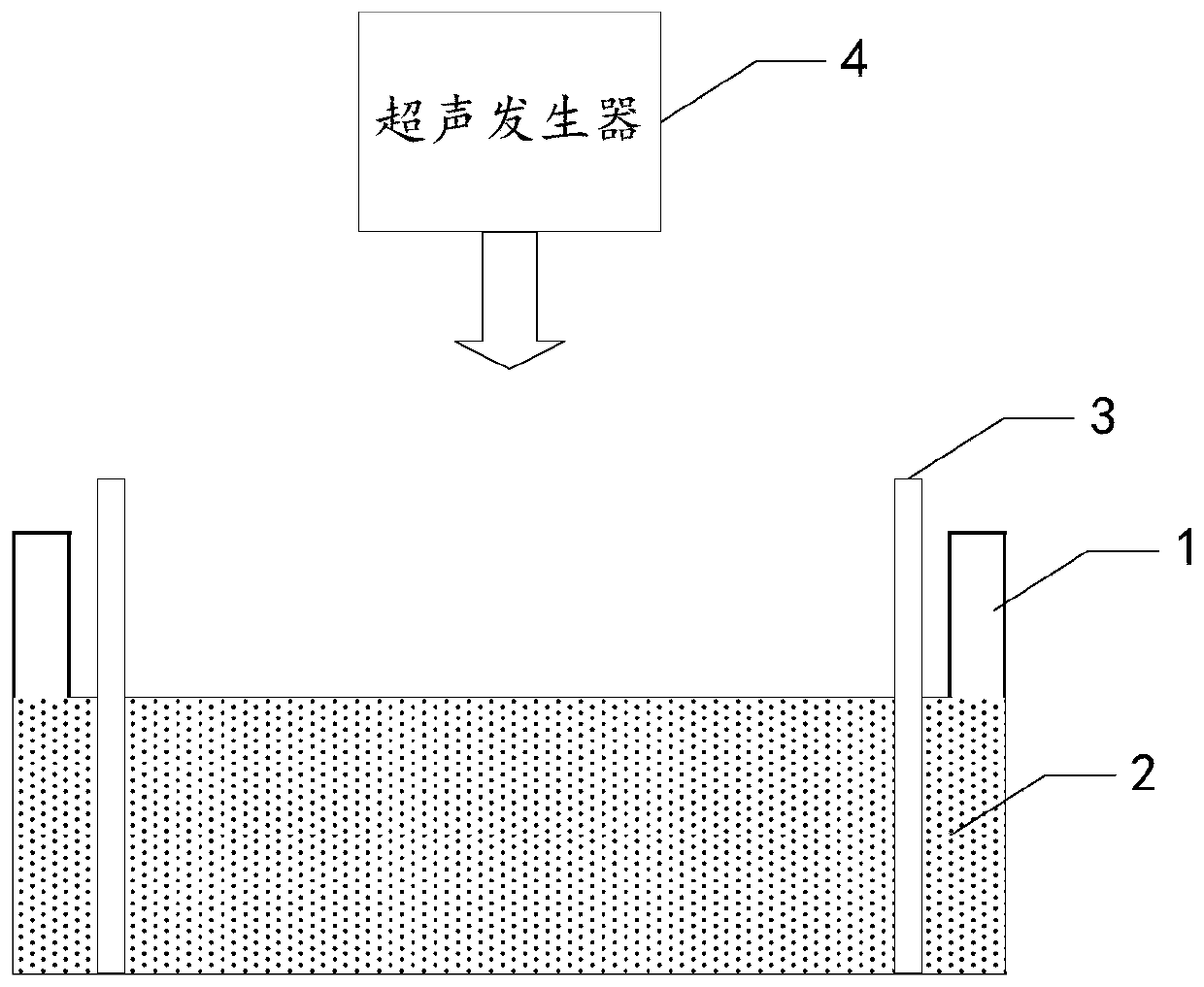

Groove surface acid mist source reduced clean production method and system in electrolysis workshop

InactiveCN110373686AReduce productionReduce coalescingElectrolysis componentsEcological environmentSlag

The invention provides a groove surface acid mist source reduced clean production method and system in an electrolysis workshop. According to the method, during normal electrolysis process, super sound with certain ultrasonic frequency and power density is applied to an electrolyte solution inside a groove and anode and cathode plates, thus achieving the purpose of controlling the size, quantity,motion speed and direction of oxygen and hydrogen bubbles which are separated out of the surface of the solution, and in this way, the subsequent process that the oxygen and hydrogen bubbles blast andrelease acid mist droplets on the free liquid surface of the electrolyte solution can be further controlled. By adopting the method, the occurrence of a large amount of acid mist caused by the blasting and sputtering of the bubbles on the free liquid surface of the electrolyte solution as well as the high-value resource loss can be reduced from the source, so that investment on end treatment facilities and high operation cost can be remarkably reduced, in this way, secondary pollution caused by acid mist treatment slag is avoided, and the damage of the groove surface acid mist to the health of workers in the workshop as well as to the ecological environment beyond the workshop can be relieved; and in addition, the electrolytic current efficiency is improved, and the electric energy consumption is reduced. The method is generally suitable for source prevention and control of the groove surface acid mist during zinc electrolysis, manganese electrolysis, nickel electrolysis, and other wet electrolytic processes.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

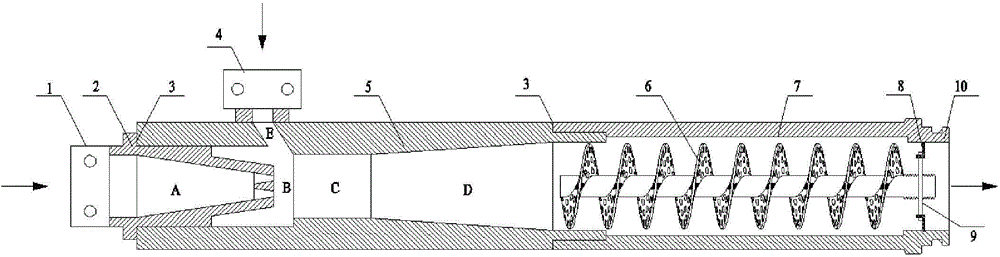

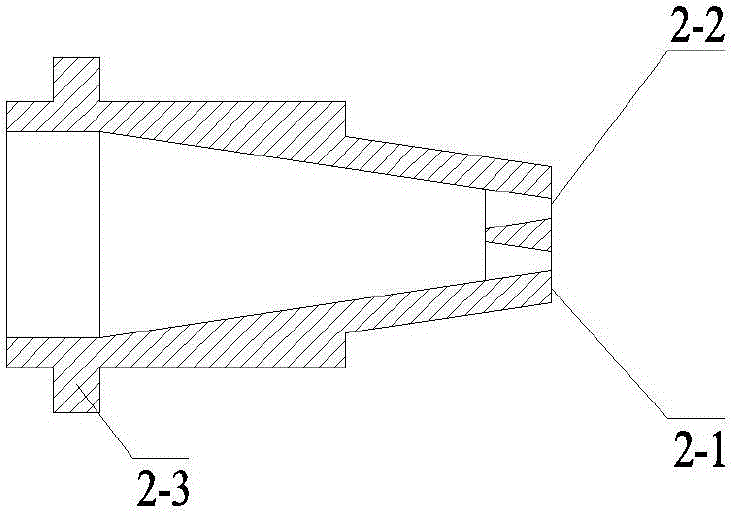

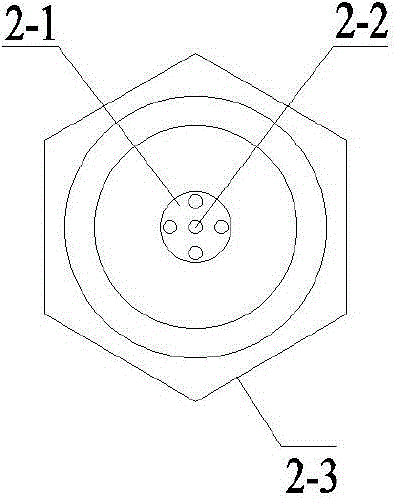

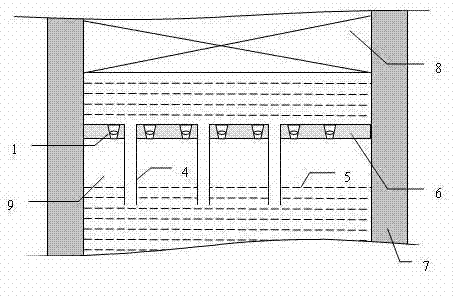

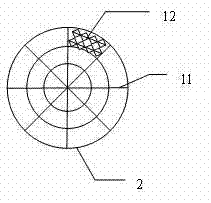

A mine-used porous spiral foam generating device

The invention discloses a mining porous spiral-type foam generating device. The mining porous spiral-type foam generating device comprises a compressed air joint (1), a nozzle body (2), a gas-liquid mixing chamber (5), porous spiral-type foamers (6), a foaming cylinder body (7) and a foam outlet joint (10), wherein the rear end of the nozzle body (2) is provided with at least one outlet nozzle; a nozzle cavity in the nozzle body (2) is of a circular truncated cone contracted shape; the compressed air joint is connected with the nozzle body; the nozzle body is installed at the inner side of the front end of the gas-liquid mixing chamber; the porous spiral-type foamers are installed in the foaming cylinder body. A multi-nozzle jet flow structure provided by the invention can achieve low-resistance high-efficiency mixing of a gas phase and a liquid phase. A wire surface high-multiple foaming and spiral low-resistance high-efficiency heat transfer mass transfer coupling mechanism is adopted for foaming, so that the foaming performance of the device is improved greatly; the generated foam is low in wind to foam ratio, is high in foaming quantity and is high in foam forming ratio; the resistance loss in the mixing and foaming process is reduced; the driving pressure of the device is improved; easily damage moving components in a turbulent flow foaming device are discarded; the device foaming reliability is improved.

Owner:CHINA UNIV OF MINING & TECH +1

Silver iodide acetone solution ground combustion equipment and its combustion method

InactiveCN100496217CMeet the requirements of scaleReduce coalescingWeather influencing devicesSilver iodideAbove ground

The present invention discloses a silver iodide acetone solution above-ground combustion equipment, including liquid storage tank, air compressor, liquid-supplying and gas-supplying pipelines, filter, atomizer, pulse high-voltage igniter, combustion chamber and wind-proofing device, the above-mentioned components are placed on a base seat. The liquid storage tank is communicated with liquid inelt of atomizer by means of filter, the air outlet of air compressor is communicated with air inlet of the atomizer, the combustion chamber is a circular truncated cone shaped cylinder body whose upper portion is larger and lower portion is smaller, and is placed on a vertical rod. It can make combustion temp, be up to 1000 deg.C, after having been cooled in atmosphere the combustion substance can be formed into silver iodide iced airosol.

Owner:BEIJING WEATHER MODIFICATION OFFICE

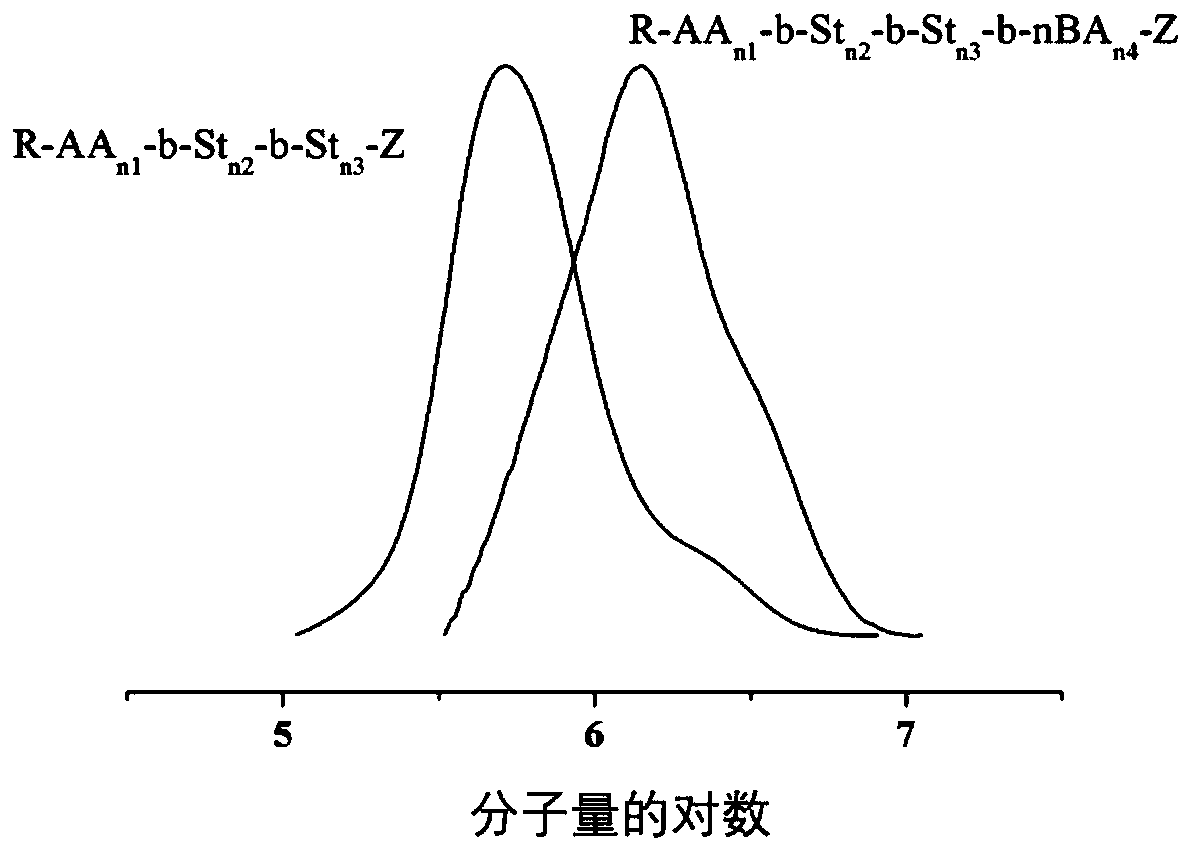

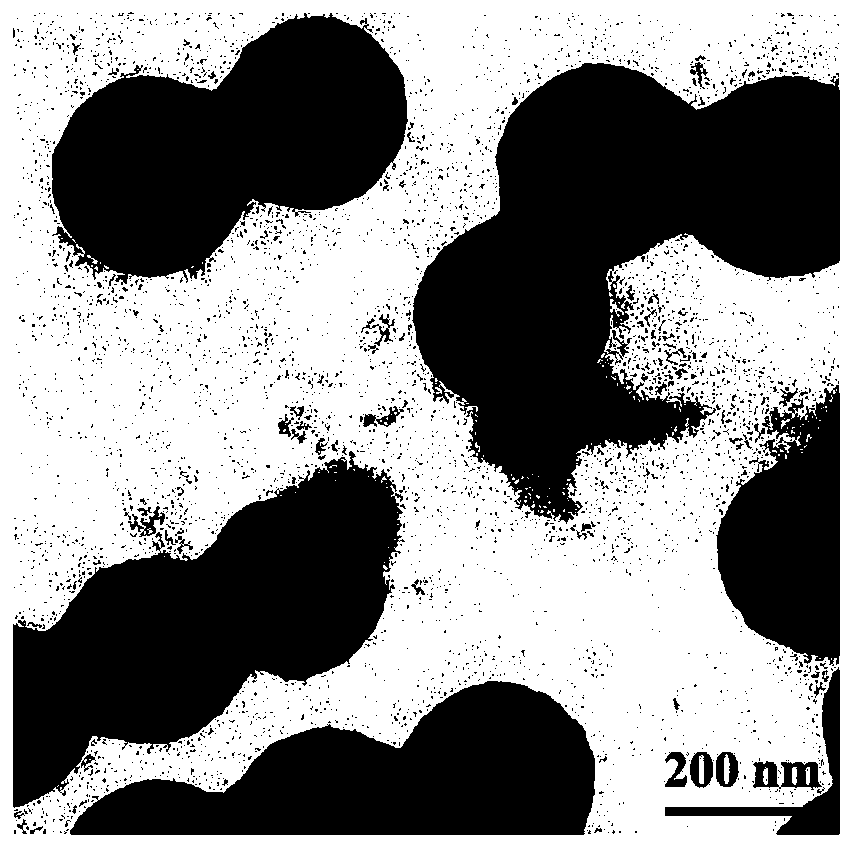

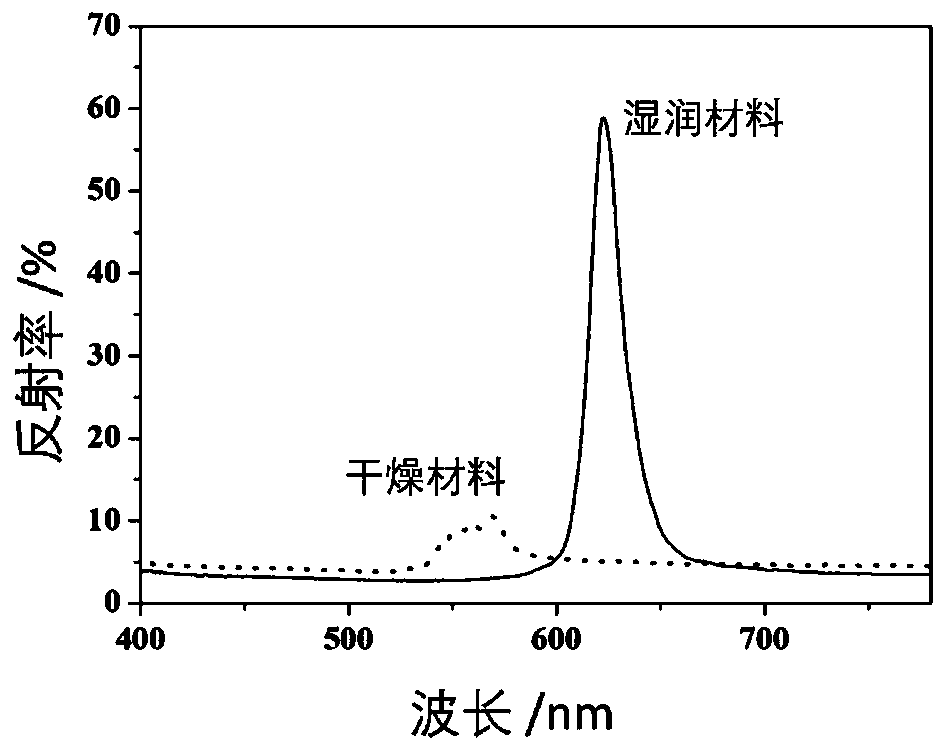

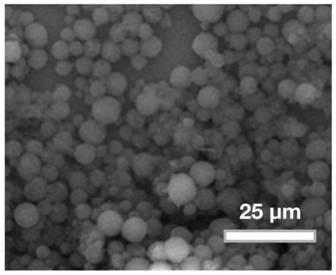

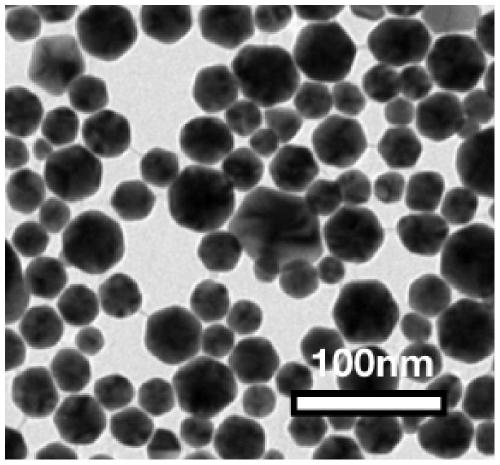

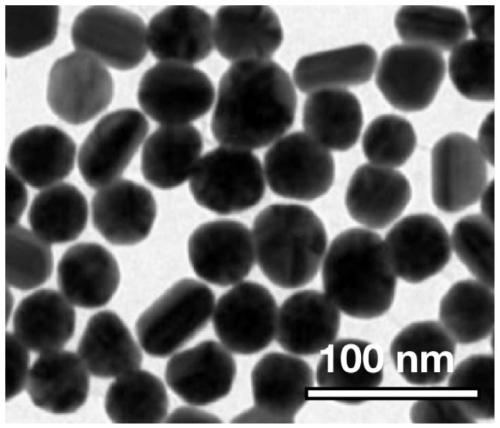

Preparation method of photonic crystal material with excellent mechanical properties

ActiveCN110330608AUniform sizeStable structureMaterial nanotechnologyPolycrystalline material growthEmulsionMicrostructure

The invention discloses a preparation method of a photonic crystal material with excellent mechanical properties. According to the preparation method, a emulsion polymerisation system is adopted, reversible addition-fragmentation chain transfer polymerization technology is adopted, a segmented copolymer nanoparticle rubber emulsion is prepared, after combination, amphiphilic high molecular reversible addition-fragmentation chain transfer reagent technology is adopted, so that three-layer polymer nanometer core-shell particles are obtained; and de-watering drying is carried out so as to obtainthe polymer photonic crystal material with uniform microstructures. The technical scheme used for preparing the polymer photonic crystal material is capable of saving energy, is friendly to the environment, and is simple in technology; the prepared photonic crystal material possesses following advantages: cracking is not easily caused, self supporting is realized, mechanical properties are excellent, and the application prospect is promising.

Owner:ZHEJIANG UNIV

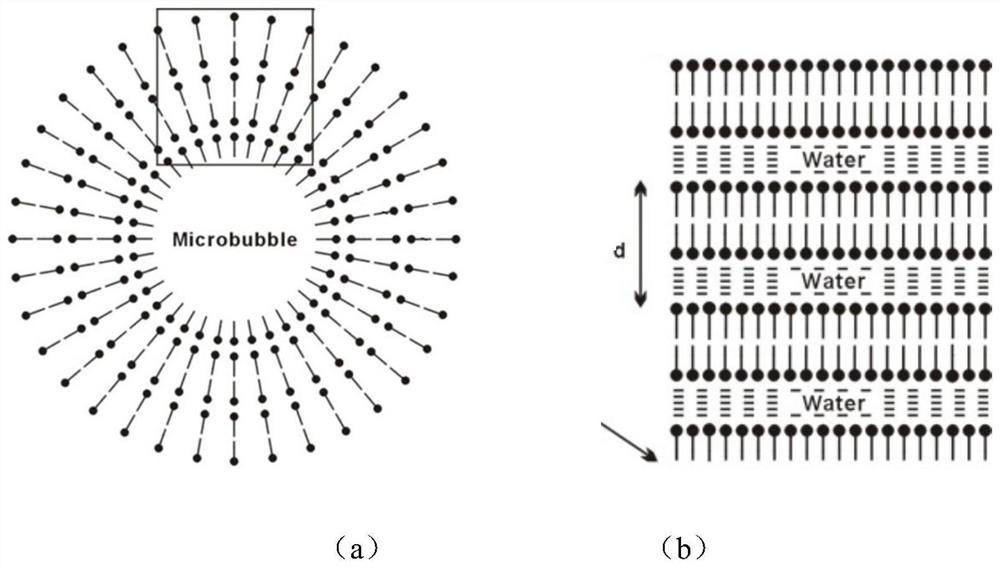

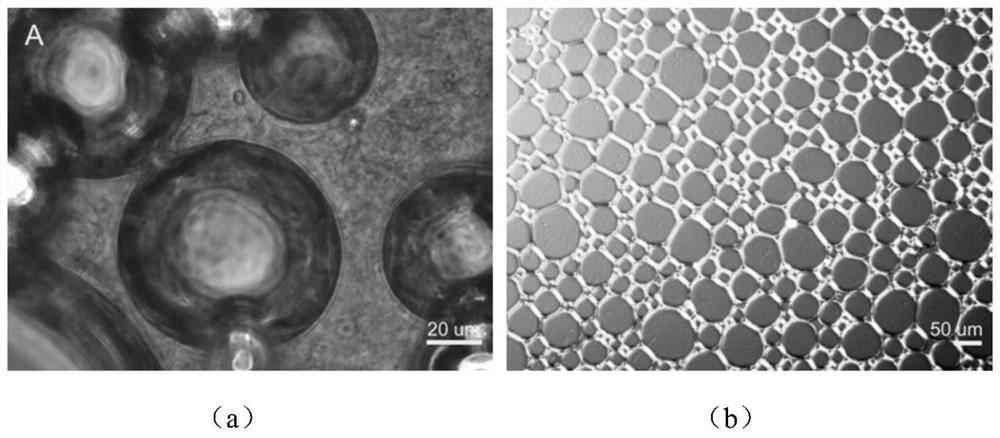

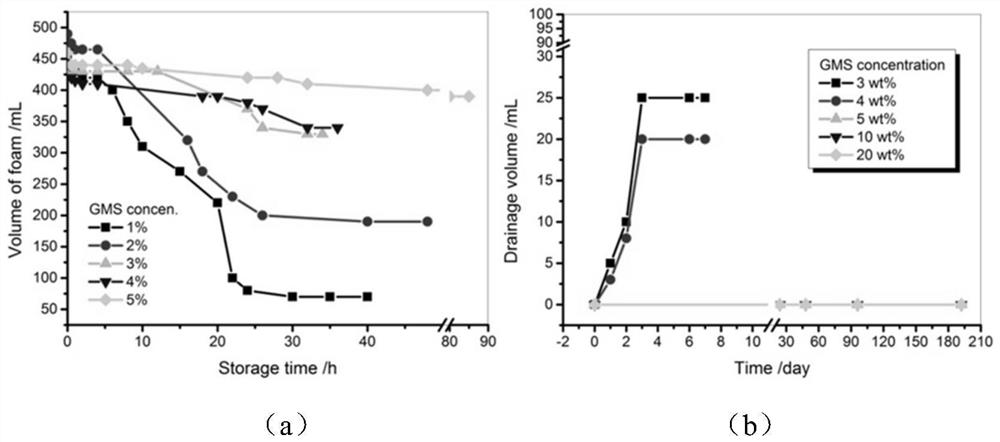

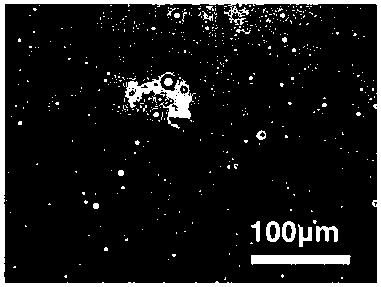

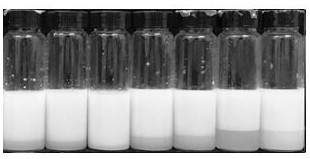

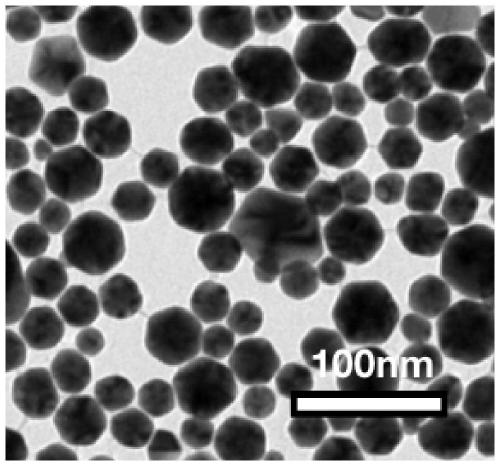

Preparation method of liquid crystal gel super-stable foam system

ActiveCN113999687AImprove stabilityReduce solubilityTransportation and packagingMixingFood industryActive agent

A preparation method of a liquid crystal gel super-stable foam system comprises the following steps: stirring a medium-chain fatty acid polyglycerol ester aqueous solution under heating until the medium-chain fatty acid polyglycerol ester aqueous solution becomes a semitransparent uniform dispersion system, so as to obtain a surfactant fatty acid polyglycerol ester-water mixed solution; and foaming the surfactant fatty acid polyglycerol ester-water mixed solution while stirring to obtain the liquid crystal gel super-stable foam system. The super-stable foam with the particle size of 40-70 microns prepared by the invention can be kept stable for 10 months or longer, and no obvious defoaming phenomenon occurs. The method for preparing the stable micro-foam from the single nonionic surfactant is simple, convenient, rapid and low in cost, and a new way is explored for preparation of the super-stable foam and application of the super-stable foam in the fields of daily chemicals, food industry, medicine delivery and the like.

Owner:XI'AN PETROLEUM UNIVERSITY

A kind of high-content water-based drag reducing agent and preparation method thereof

ActiveCN111394085BHigh powder contentFast hydrationFluid removalDrilling compositionMeth-Active agent

The invention provides a high-content water-based resistance reducing agent and a preparation method thereof, and solves the technical problems in the prior art that a powder resistance reducing agentis low in hydration speed, oily residues exist after gel breaking of an oily suspension resistance reducing system, environmental friendliness is not achieved and the powder content of a water-basedresistance reducing suspension system is low. The preparation comprises the following raw materials in parts by weight: 20-50 parts of polyacrylamide; 20-40 parts of polymethacrylamide; 22-66 parts ofa solvent A; 4-12 parts of a solvent B; 6-18 parts of a solvent C; 1-3 parts of a suspending agent; and 3-6 parts of a surfactant, wherein the solvent A is alkyl amides; the solvent B is polyethyleneglycol; and the solvent C is polyhydric alcohol or polyhydric alcohol esters. The high-content water-based resistance reducing agent not only has the characteristics of high hydration speed, high powder content and good storage stability, but also can realize integrated operation and online blending.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD +1

A kind of foam system reinforced with graphene armor for oil and gas fields and preparation method thereof

ActiveCN109439307BImprove stabilityReduce coalescingDrilling compositionAir liquid interfaceFoaming agent

The invention discloses a graphene armor reinforced foam system for an oil-gas field and a preparation method of the foam system. The foam system is prepared from a gas phase, a liquid phase and graphene oxide, wherein the gas phase is nitrogen, carbon dioxide, natural gas or air; the liquid phase is an aqueous solution of a foaming agent, a blowing promoter and an adsorption assistant. Graphene oxide in foam can be strongly adsorbed on the gas-liquid interface of the foam, then a stable graphene armor layer is formed on an air bubble film and can effectively inhibit diffusion of gas in the foam through a liquid film and weaken of bubble coalescence, and meanwhile, the graphene armor layer can reduce loss of the liquid in the liquid film. Besides, the graphene armor layer can substantiallyimprove mechanical strength of the liquid film and effectively reduce breakage of the liquid film. By means of the graphene armor layer in the foam system, the foam has good stability. The graphene armor reinforced foam system is non-toxic and non-pollution, produces little formation damage and has the green and environment-friendly characteristics.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Atomized acid wellbore flow simulation device and working method for gas injection development of fractured-vuggy reservoirs

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Upflow type reactor gas-liquid distribution disc and applications thereof

ActiveCN103100353BUniform quadratic distributionReduce solubilityHydrocarbon oil crackingHydrocarbon oils refiningGas phaseDouble phase

The present invention relates to an upflow type reactor gas-liquid distribution disc and applications thereof. According to the present invention, a suitable number of liquid lifting pipes are arranged on the distribution disc, the liquid lifting pipes are straight through pipes with openings on both ends, the opening on the upper end is connected with a distribution disc column plate, and is communicated with the upper portion of the column plate, the opening on the lower end extends into a liquid surface below the gas-liquid distribution disc, a space between the lower portion of the distribution disc column plate and the liquid surface and on the outer side of the liquid lifting pipe forms a gas collection chamber, and unidirectional valves are uniformly arranged in gaps surrounding the opening of the liquid lifting pipes on the distribution disc column plate, and control a stream to flow from bottom to top. With the upflow type reactor gas-liquid distribution disc, the gas phase can be distributed in the liquid phase in a micro bubble form so as to increase gas-liquid double phase mass transfer efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

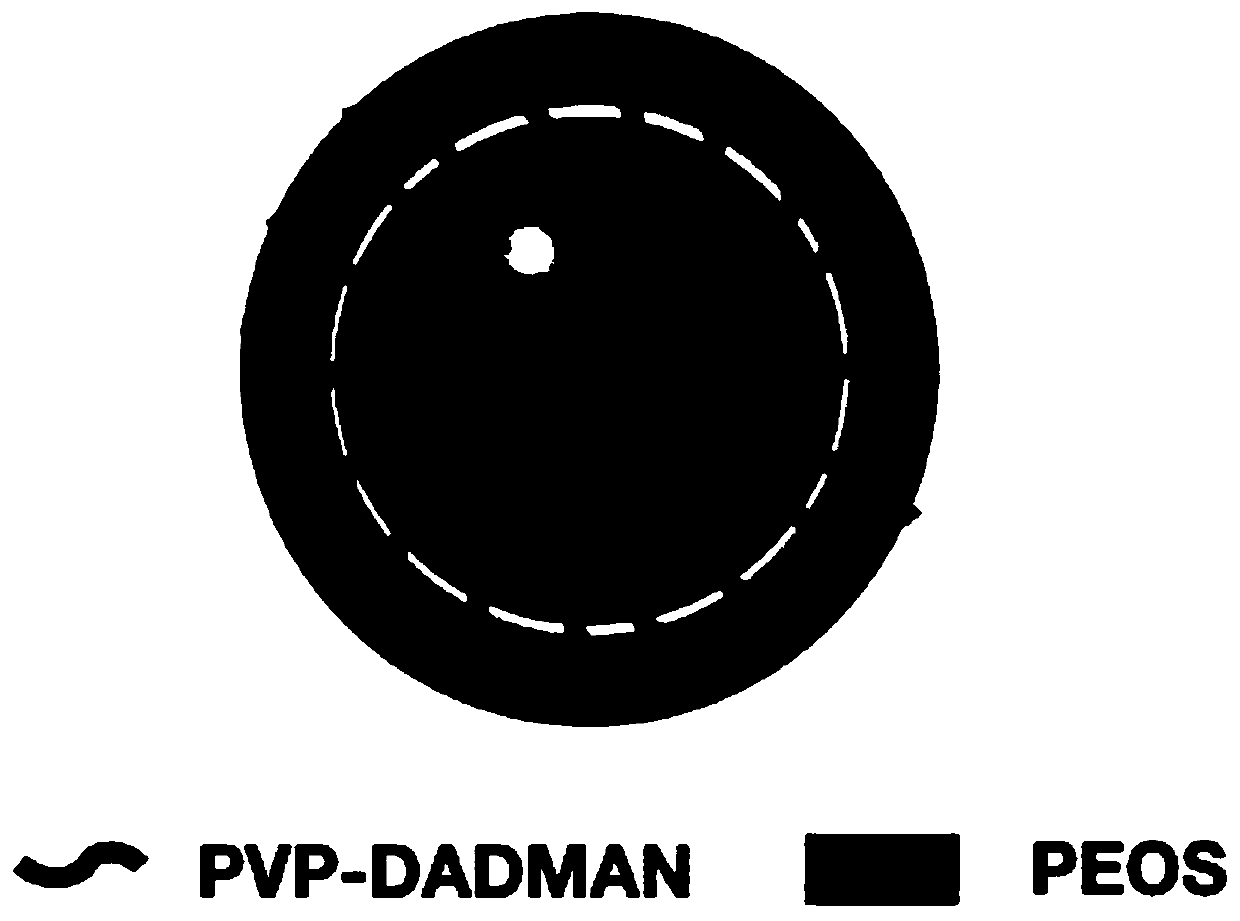

Preparation method and product of stress-sensitive paper anti-fake coating

ActiveCN108660852AImprove humidity stabilityImprove lipophilicityMaterial nanotechnologyCoatings with pigmentsPickering emulsionOil phase

The invention provides a preparation method of a stress-sensitive paper anti-fake coating. The preparation method includes: (1), dissolving HAuCl4 and PVP-DADMAN in water, boiling, adding a reducing agent, avoiding light for stirring reaction, centrifuging, and performing vacuum drying on supernatant to obtain modified nanogold particles; (2), diluting PEOS in ASA to serve as an oil phase; dissolving modified nanogold prepared in the step (1) in water, and adjusting pH to acidic to serve as an aqueous phase; ultrasonically stirring the aqueous phase and the oil phase while heating, and standing to obtain a Pickering emulsion of oil-in-water ASA, namely the stress-sensitive paper anti-fake coating. By the preparation method, the stable Pickering emulsion of oil-in-water ASA can be obtained,coalescence among ASA oil drops can be reduced effectively, and stability of the emulsion is improved substantially; no aqueous phase and oil phase are separated out after the emulsion is stable forseveral months, and no surfactant and other modifiers need to be added.

Owner:辽宁兴东科技有限公司

Jet aeration reactor used in active sludge method and its jet aeration process

InactiveCN1171809COptimize spatial distributionReduce coalescingFlow mixersSustainable biological treatmentActivated sludgeProcess engineering

The present ivnention relates to aeration mode and equipment in waste water treatment. A new kind of jet aeration reactor and jet aeration process is provided. The present invention features that at the bottom of the reactor, a coaxial jet aerator with liquid driven jet, fixed cone, distributing plate and annular gap and a knocking plane in the upper part of the reactor are installed. The two phase gas-liquid flows knock oppositely to form gas-liquid circulation from output to inner, and this can improve the space distribution of bubbles, decrease bubbles aggregation, increase the service area of the jet aerator, maintain the homogeneous energy distribution rate in whole reactor and raise the mass transferring the energy transferring efficiency.

Owner:TSINGHUA UNIV +1

A multi-phase compound control and flooding method with fly ash intensified in oilfield ultra-high water-cut period

ActiveCN110984933BEnhanced overall recoveryImprove microscopic heterogeneityFluid removalDrilling compositionActive agentOil phase

The invention discloses an oil field ultra-high water cut stage fly ash reinforced multiphase composite profile control and flooding method. The method comprises the following step: sequentially adopting fly ash reinforced foam, surfactant foam, microemulsion and water for profile control and flooding, wherein the fly ash reinforced foam is prepared from a gas phase and a liquid phase I; the liquid phase I is an aqueous solution of a foaming agent I, fly ash and a gas-liquid interface regulator; the surfactant foam is prepared from a gas phase and a liquid phase II; the liquid phase II is an aqueous solution of a foaming agent II; the microemulsion consists of a compound surfactant, a cosurfactant, an oil phase, an inorganic salt and water; and the compound surfactant is a compound of SDSand Tween 80. According to the method, through the action among the fly ash reinforced foam slug, the surfactant foam slug and the microemulsion slug, the opening and closing of a large pore channel can be regulated and controlled, the flow resistance is reduced, the regulation and flooding effect of blocking without blocking off is realized, the flow and production of crude oil are facilitated, and the purpose of economic and efficient development of an oil reservoir is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A kind of nano foam oil displacement agent and preparation method thereof

ActiveCN112375554BReduce coalescingShorten speedFluid removalDrilling compositionNanofoamActive agent

The invention belongs to the field of oil recovery technology, and in particular relates to a nano-foam oil displacement agent and a preparation method thereof. The oil displacement agent comprises the following components in weight percentage: 10-45% of anionic surfactant, 7-15% of zwitterionic surfactant, 6-12% of oily nanoparticles, 5-10% of stabilizer, and 1-10% of dispersant 2%, the balance is water. The preparation method of the oil-displacing agent is as follows: prepare oily nanoparticles through solid paraffin and isooctanoic acid, then disperse the oily nanoparticles in water and mix them with a surfactant, then add a stabilizer and water to make a nano-foam oil-displacing agent . The nano-foam oil displacement agent can effectively inhibit gas diffusion, enhance the mechanical stability and viscosity of the liquid film, effectively isolate the transfer of external heat to the interior, reduce the thermal movement rate of molecules, greatly slow down the liquid separation rate of the foam liquid film, and enhance the foam's stability. stability, thereby improving the oil displacement efficiency.

Owner:滨州市广友石油科技有限公司

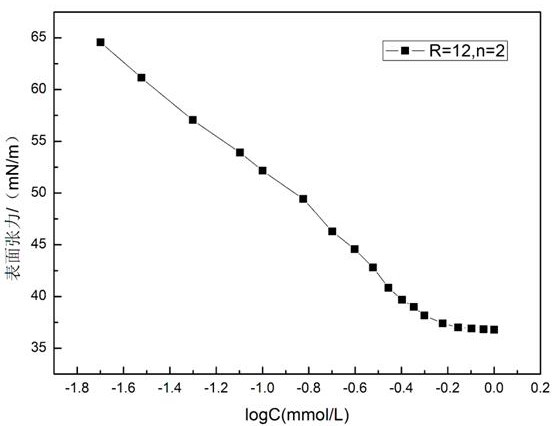

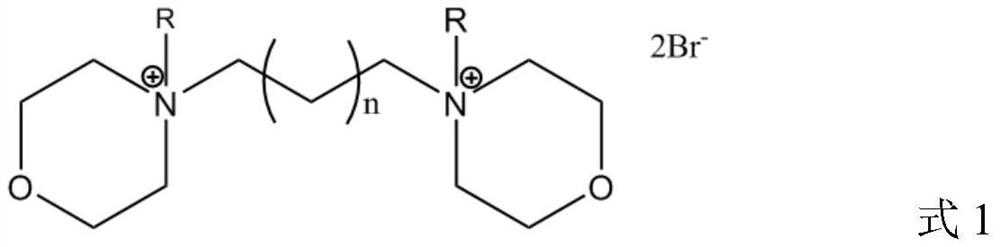

A control and flooding system and oil displacement method suitable for carbonate weathering crust reservoirs

ActiveCN109251740BHas the effect of displacing oilPlay the role of oil displacementDrilling compositionActive agentPhysical chemistry

The invention discloses a profile control and displacement system suitable for a carbonate weathered crust reservoir. The system comprises, by mass, 0.5-2% of nano-silica, 0.01-3.0% of a quaternary ammonium salt surfactant, and the balance of water. The invention also discloses a preparation method of the system. The preparation method comprises the following steps: adding the nano-silica into water at room temperature, performing stirring, and carrying out ultrasonic treatment to achieve uniform dispersion in water; and adding the quaternary ammonium salt surfactant, and performing stirring to fully dissolve the surfactant in order to obtain the system. The profile control and displacement system adopting the quaternary ammonium salt surfactant and the easily available silica nano-material has the advantages of certain decompression and augmented injection effect, good stability, good stratum injectivity, good interface stabilizing ability and good emulsification performance, plays arole in oil displacement, and also can be used for the profile control of the stratum.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

An acid atomization device and atomization method for deep acidification of fractured-vuggy reservoirs

ActiveCN111085349BIncrease aerodynamic forceImprove atomization rateFluid removalDrilling compositionAtomizer nozzleEngineering

An acid atomization device for deep acidification of fracture-cavity reservoirs, comprising a gas path system, a liquid path system, and an atomizing nozzle; the gas path system includes a gas inlet, an air compressor; the liquid path system includes an acid liquid inlet, a high-pressure acid-resistant Pump, double-flow venturi tube; air enters the gas inlet after being pressurized by the air compressor; acid liquid enters the annular cavity after being pressurized by the high-pressure acid-resistant pump, and the annular cavity is used to accumulate acid liquid, and the acid liquid in the annular cavity The acid liquid enters the cylindrical cavity through the acid liquid inlet on the wall, and acid mist is formed in the cylindrical cavity due to hydraulic cavitation, and the acid mist is constrained by the cylindrical cavity to become an acid mist columnar fluid, which occurs during atomization The high-speed movement inside the atomizer and finally sprayed out from the atomization nozzle of the atomization generator, which is directly connected with the wellbore. The device has good performance in high temperature resistance, high pressure resistance and acid resistance. It can control the injection displacement through the gas and liquid system, maintain a high atomization rate of acid liquid, and improve the acidizing effect of fracture-cavity reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of preparation method of AKD paper sizing agent and product thereof

ActiveCN108425275BImprove lipophilicityImprove stabilityWater-repelling agents additionCoatingsGold particlesActive agent

Owner:辽宁兴东科技有限公司

A controllable turbulent microalgae cultivation device that can effectively improve carbon sequestration efficiency

ActiveCN110777054BReduce sizeIncrease profitBioreactor/fermenter combinationsBiological substance pretreatmentsElectric machineEnvironmental engineering

The invention discloses a controllable flow-disturbing microalgae cultivation device which can effectively improve carbon fixation efficiency, comprising a reactor, an air chamber, a bubble generator and a diffuse flow swirling diffuser; the reactor is located on the air chamber On the side, the bubble generator is installed in the air chamber, which includes an octagonal tube, a water pump and a Venturi tube; the Venturi tube is connected to a connecting pipe, and the connecting pipe is connected to a hose after extending out of the air chamber; the hose It is connected with the bubble conveying pipe, and the bubble conveying pipe extends into the reactor; the diffuser swirling diffuser includes a motor, a transmission shaft and a cutting device; the cutting device includes a The three-layer cutting disc is provided with several thorns on the lower side of the upper cutting disc and the upper and lower sides of the middle cutting disc and the lower cutting disc. The present invention can CO 2 The formed bubbles are smaller in size and evenly distributed, thus greatly improving the carbon fixation and mass transfer efficiency of microalgae, which is very rich in the concept of energy saving and emission reduction.

Owner:CHONGQING UNIV

A kind of low-viscosity high-speed cigarette glue and its preparation method

ActiveCN110872478BLow viscosityLarge particle sizeGraft polymer adhesivesPolymer scienceLatex particle

The invention provides a low-viscosity high-speed cigarette gum, which is prepared from seed emulsion, vinyl acetate monomer, oxidant, initiator, capture agent, alcohol compound, pH regulator and water; the seed emulsion is vinyl acetate-ethylene One or more combinations of emulsion, vinyl acetate-acrylate emulsion, and vinyl acetate homopolymer emulsion; the solid content of the seed emulsion is 40.0%-65.0%, and the viscosity is 500-5000mPa.s. The invention obtains by first destroying the protective colloid of the emulsion, lowering the viscosity, then polymerizing to rebuild the emulsion stability system, and controlling the number of new latex particles generated. The viscosity of the emulsion prepared by the present invention can be lower than 200mPa.s, which can not only meet the needs of bonding of cigarettes with a machine speed of 14000-16000 pieces / min, but also be used for bonding of common materials, such as paper processing, paint decoration, non-woven fabrics, etc. Manufacturing industries such as textiles and carpets. The preparation method of the invention is simple and suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +2

A kind of early strength agent for concrete prefabricated parts and preparation method thereof

The invention discloses an early strength agent for concrete prefabricated parts and a preparation method thereof, comprising: soluble calcium salt, soluble silicon salt, anionic dispersant, nonionic dispersant, thickener and water; the preparation method is: soluble calcium salt , Soluble silicon salt, anionic dispersant, nonionic dispersant and thickener react compoundly in aqueous solution to generate organically doped calcium silicate hydrate gel suspension, which is the early strength agent for concrete prefabricated parts. The present invention uses anionic and nonionic composite dispersants to disperse calcium silicate hydrate gel particles, which can provide better dispersion; and add thickeners to early strength agents to reduce calcium silicate hydrate gel particles The aggregation between them further improves the stability.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com