High-content water-based resistance reducing agent and preparation method thereof

A drag-reducing agent, high-content technology, applied in chemical instruments and methods, earth drilling, mining fluids, etc., to achieve the effect of shortening the action time, improving storage stability, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Preparation of high content water-based drag reducer:

[0061] 1.1 Raw materials:

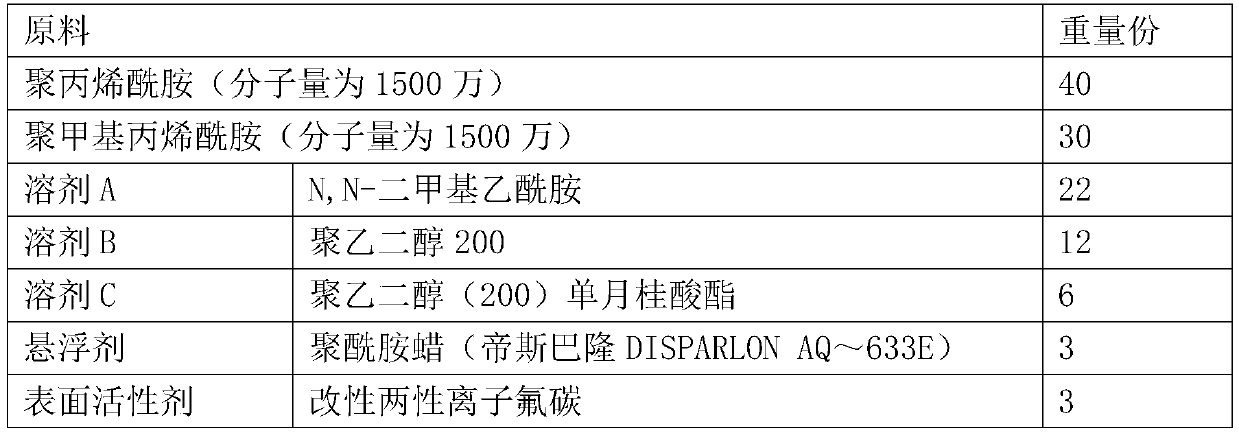

[0062] Each raw material is in parts by weight, as shown in Table 1 below:

[0063] Table 1 Embodiment 1 raw material list

[0064]

[0065] 1.2 Preparation method:

[0066] Include the following steps:

[0067] S1: Add solvent C and suspending agent to the reaction vessel, stir at a stirring rate of 1000r / min for 1h, and let stand for 1h;

[0068] S2: Add solvent A and solvent B to the reaction vessel and stir at a stirring rate of 100r / min for 1h, and let stand for 1h;

[0069] S3: Add the surfactant and the water-soluble polyacrylamide polymer into the reaction vessel and stir for 1 hour at a stirring rate of 100 r / min to obtain a finished high-content water-based drag reducing agent.

Embodiment 2

[0071] Preparation of high content water-based drag reducer:

[0072] 2.1 Raw materials:

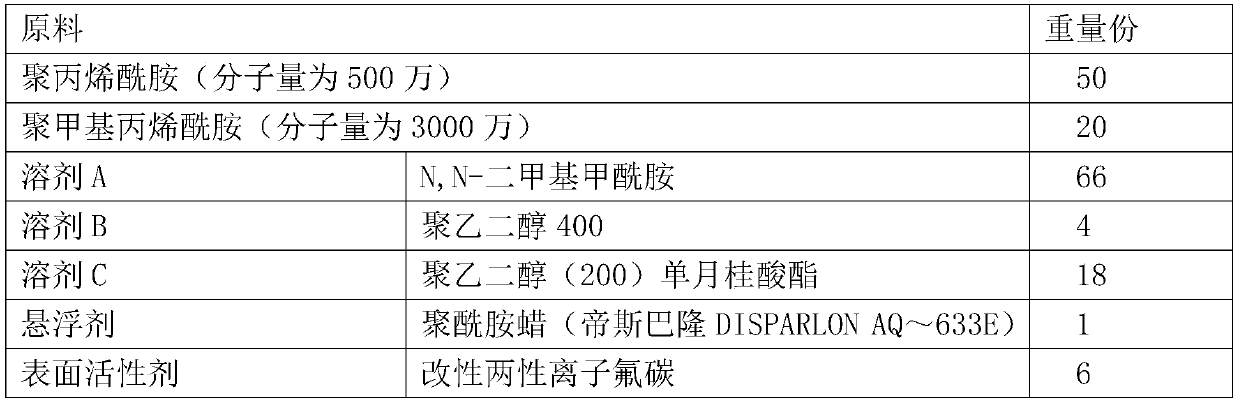

[0073] Each raw material is in parts by weight, as shown in Table 2 below:

[0074] Table 2 Embodiment 2 raw material table

[0075]

[0076] 2.2 Preparation method:

[0077] Include the following steps:

[0078] S1: Add solvent C and suspending agent to the reaction vessel, stir at a stirring rate of 900r / min for 1.2h, and let stand for 1.5h;

[0079] S2: Add solvent A and solvent B into the reaction vessel and stir at a stirring rate of 110r / min for 0.8h, and let stand for 0.8h;

[0080] S3: Add a surfactant and a water-soluble polyacrylamide polymer into the reaction vessel and stir for 1.2 hours at a stirring rate of 110 r / min to obtain a finished high-content water-based drag reducer.

Embodiment 3

[0082] Preparation of high content water-based drag reducer:

[0083] 3.1 Raw materials:

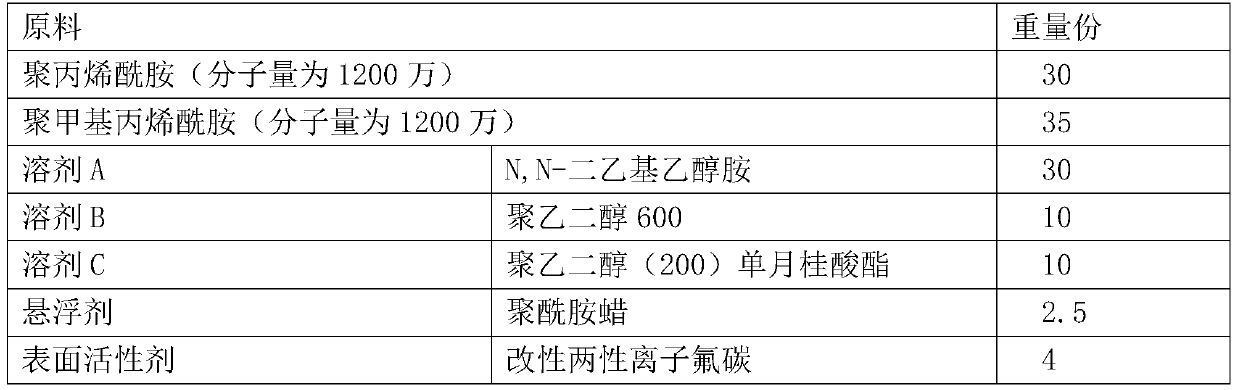

[0084] Each raw material is in parts by weight, as shown in the following table 3:

[0085] Table 3 Embodiment 3 raw material list

[0086]

[0087] 3.2 Preparation method:

[0088] Include the following steps:

[0089] S1: Add solvent C and suspending agent to the reaction vessel, stir at a stirring rate of 1100r / min for 0.8h, and let stand for 0.8h;

[0090] S2: Add solvent A and solvent B into the reaction vessel and stir at a stirring rate of 90r / min for 1.2h, and let stand for 1.5h;

[0091] S3: Add a surfactant and a water-soluble polyacrylamide polymer into the reaction vessel and stir at a stirring rate of 90r / min for 0.8h to obtain a finished high-content water-based drag reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com