Water-based resistance reducing agent and preparation method thereof

A drag-reducing agent and water-based technology, applied in the field of water-based drag-reducing agent and its preparation, can solve the problems of limited viscosity-increasing effect of inverse emulsion drag-reducing agent, poor base liquid cross-linking effect, and high processing cost, and can eliminate the dissolution rate. Slow and oil phase damage problem, avoid difficult handling, obvious effect of thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

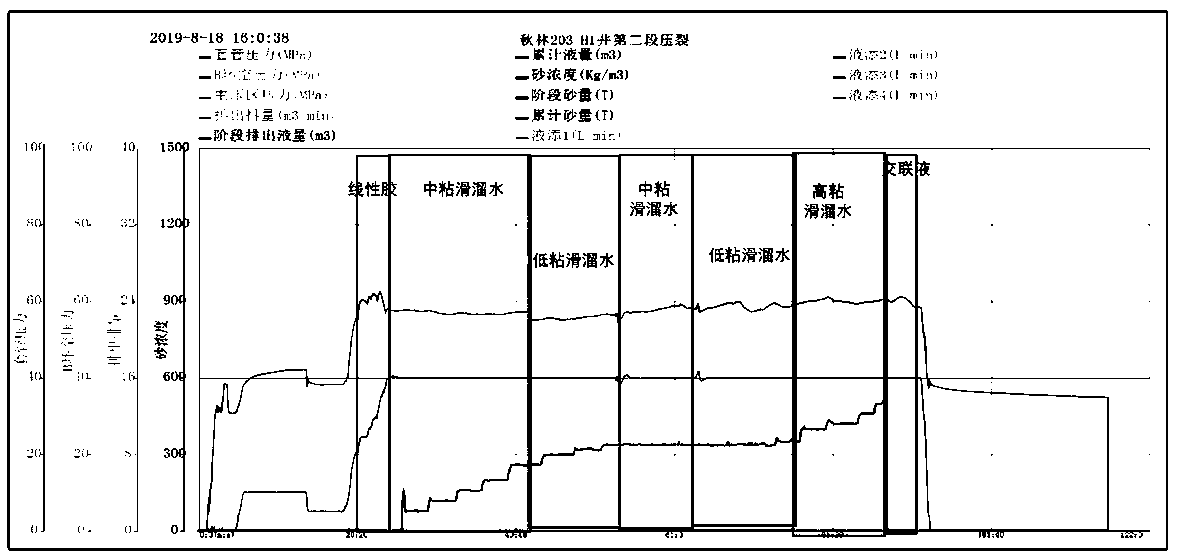

Image

Examples

Embodiment 1

[0041] Preparation of water-based drag reducer:

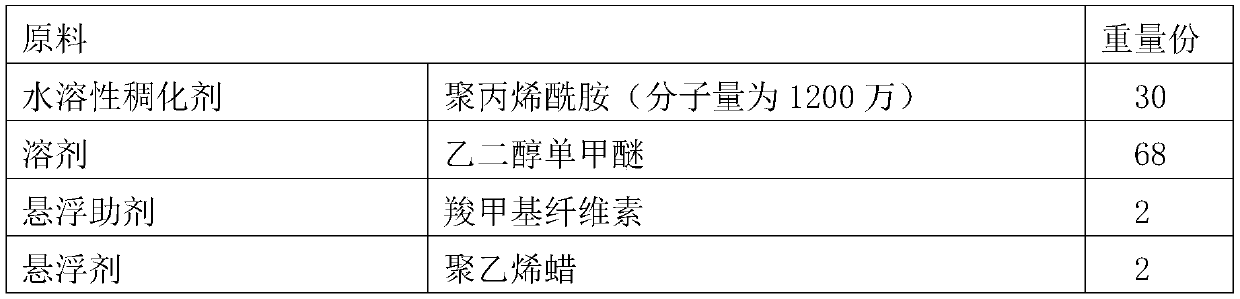

[0042] 1.1 Raw materials: each raw material is calculated in parts by weight, as shown in Table 1 below:

[0043] Table 1 Embodiment 1 raw material list

[0044]

[0045] 1.2 Preparation method:

[0046] Include the following steps:

[0047] S1: Add the solvent, suspending aid and suspending agent into the reaction kettle respectively, stir (stirring speed is 1000r / min) and circulate and shear through the emulsification pump for 1h;

[0048] S2: Add polyacrylamide into the reaction kettle, start stirring (stirring rate is 1300r / min) and circulate shearing by emulsification pump for 1h (circulating shearing speed is 2500r / min), and the finished product is obtained.

Embodiment 2

[0050] Preparation of water-based drag reducer:

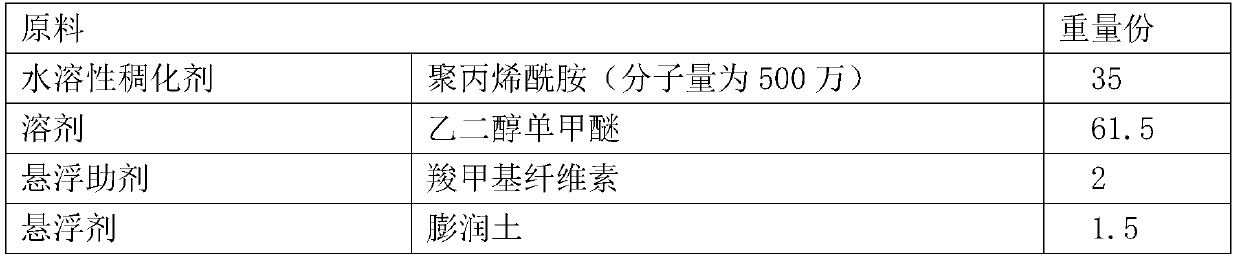

[0051] 2.1 Raw materials: each raw material is calculated in parts by weight, as shown in Table 2 below:

[0052] Table 2 Embodiment 2 raw material list

[0053]

[0054] 2.2 Preparation method: same as Example 1.

Embodiment 3

[0056] Preparation of water-based drag reducer:

[0057] 3.1 Raw materials: each raw material is calculated in parts by weight, as shown in Table 3 below:

[0058] Table 3 Embodiment 3 raw material list

[0059]

[0060] 3.2 Preparation method: Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com