Patents

Literature

52results about How to "Realize online switching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

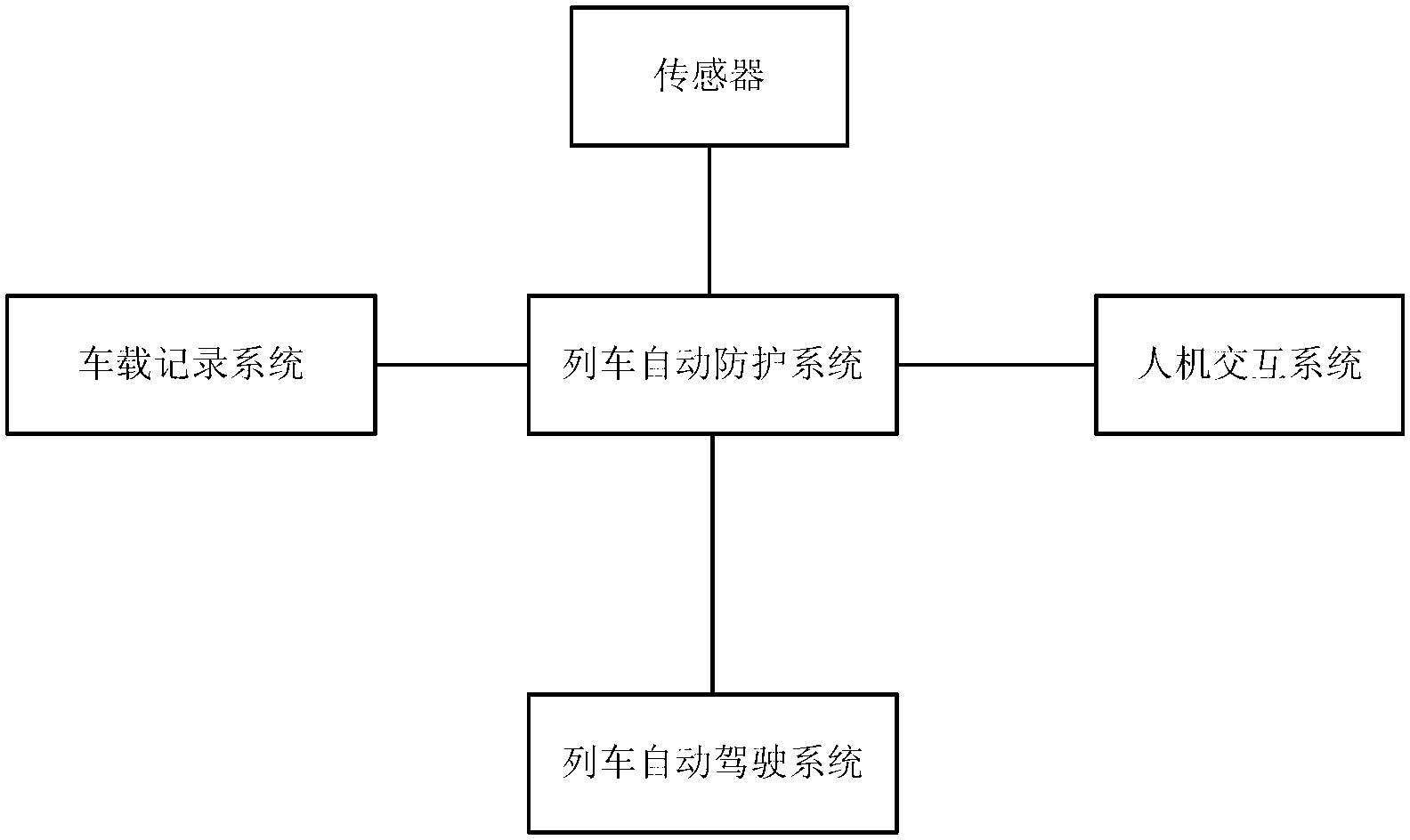

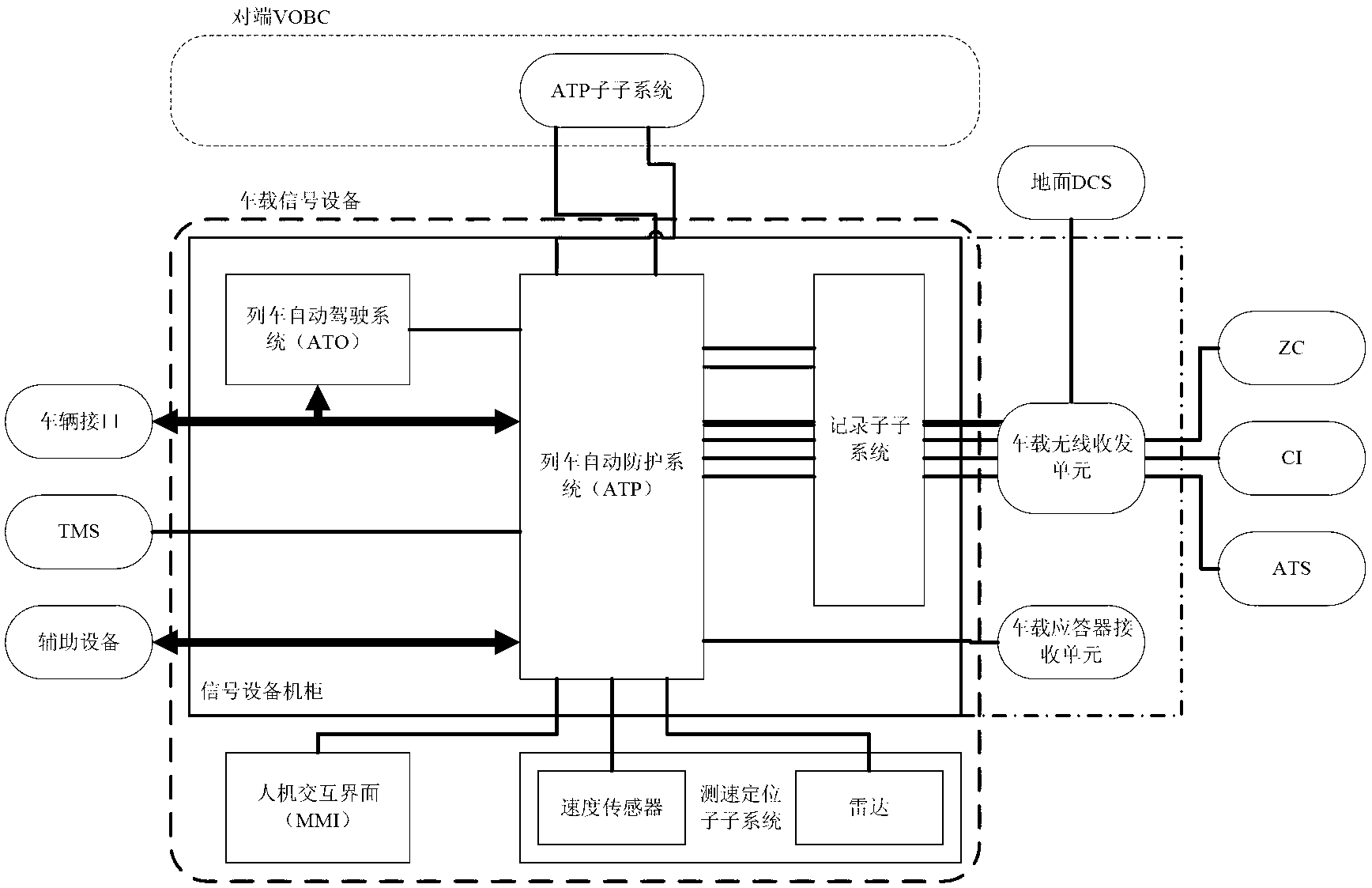

Train unmanned system and method

ActiveCN103010230AReal-time reflection analysisEasy to analyzeLocomotivesDriver/operatorInterference resistance

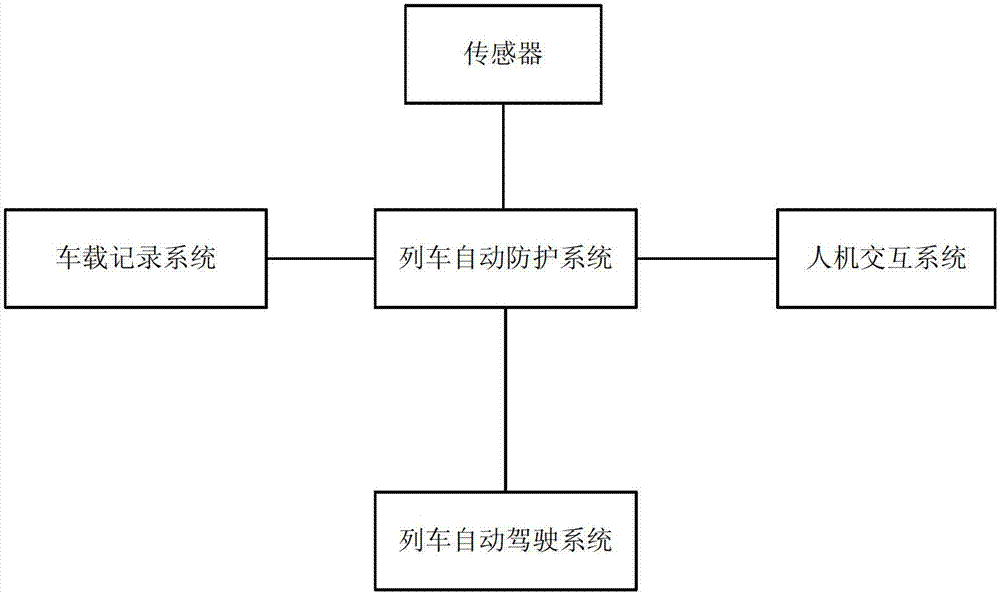

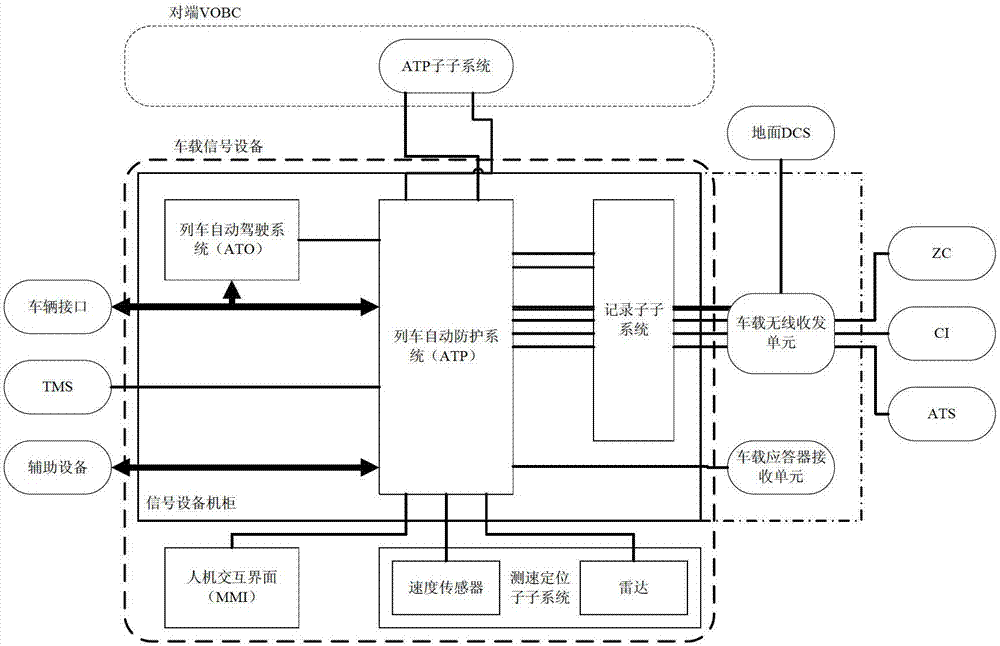

The invention discloses a train unmanned system and a train unmanned method, belonging to the field of traffic control. The system comprises a sensor, an automatic train protecting system connected with the sensor, a train-mounted recording system connected with the automatic train protecting system, an automatic train driving system connected with the automatic train protecting system, and a man-machine interaction system connected with the automatic train protecting system. By utilizing the system and the method, the precise control on the unmanned operation process of a train is realized, misoperation caused by artificial factors is reduced, the interference resistance is good, the working intensity of drivers is reduced, the security in train operation is improved, the departure interval of trains is shortened, and the operation efficiency of train routes is improved.

Owner:TRAFFIC CONTROL TECH CO LTD

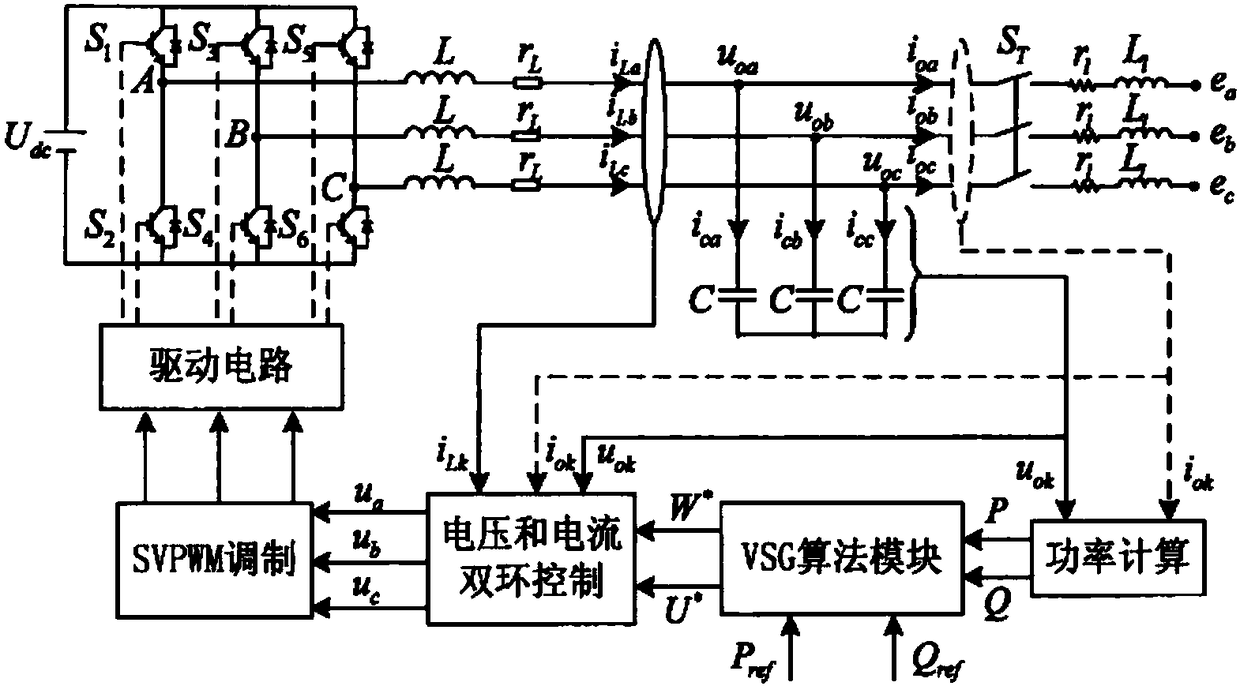

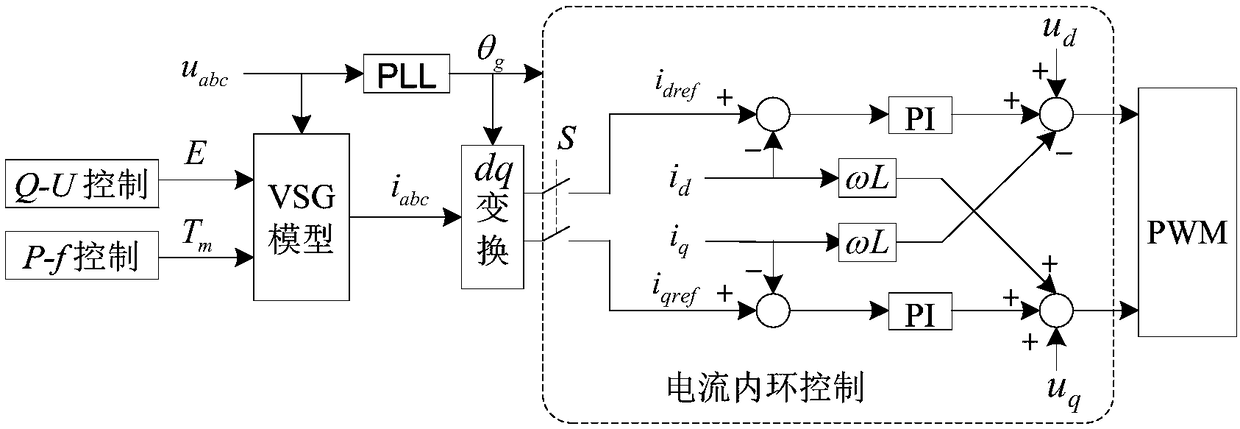

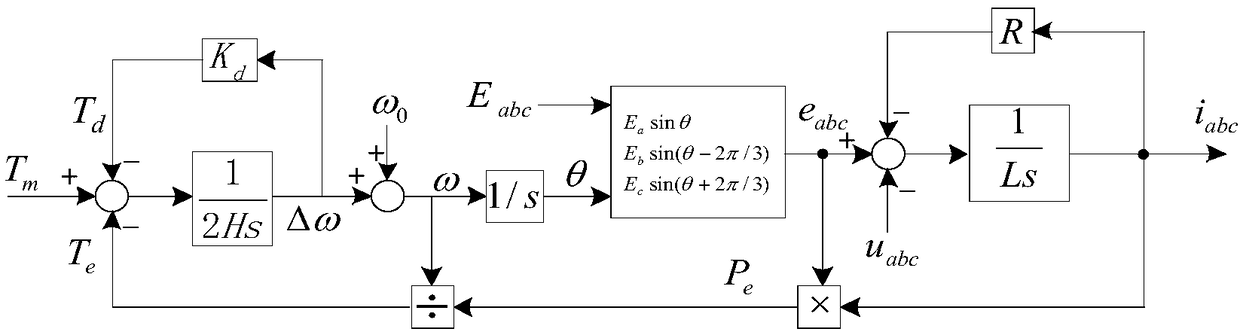

Converter based on virtual synchronous generator and control method thereof

ActiveCN108429431AEasy to controlFlexible controlAc network circuit arrangementsPower conversion systemsVirtual synchronous generatorFrequency stabilization

The invention relates to a converter based on a virtual synchronous generator and a control method thereof. When a VSG function module is cut in, three-phase stator current outputted by the VSG function module is used as an instruction value of a converter current inner ring, a power grid voltage phase angle of power grid voltage through a phase-locked loop is used as a phase angle instruction value of the converter current inner ring, and through power grid voltage directional vector control, PWM waves are generated for control. On the basis of reserving the characteristics of accurate and flexible current control, stable frequency and the like of the conventional converter, the converter has a voltage source output characteristic similar to that of a synchronous generator. The VSG function of the converter can be input and cut out seamlessly, the switching is simple, and the method is particularly suitable for multifunctional online switching of the converter with the VSG function and power grid fault ride through control.

Owner:XUJI GRP +4

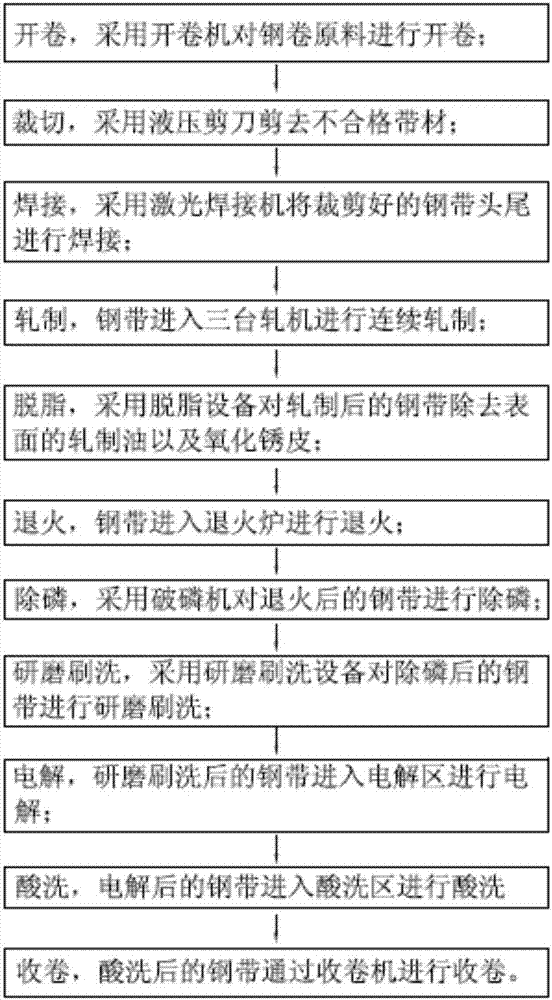

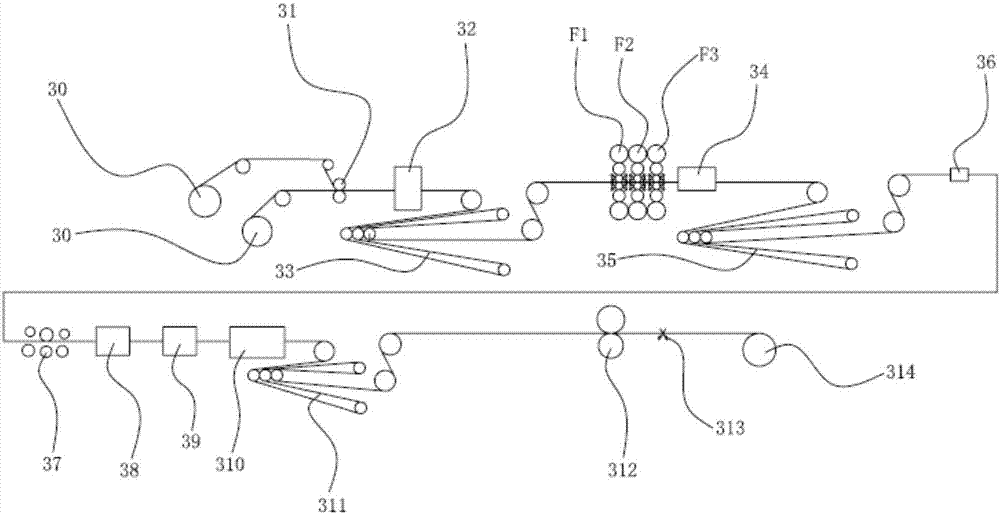

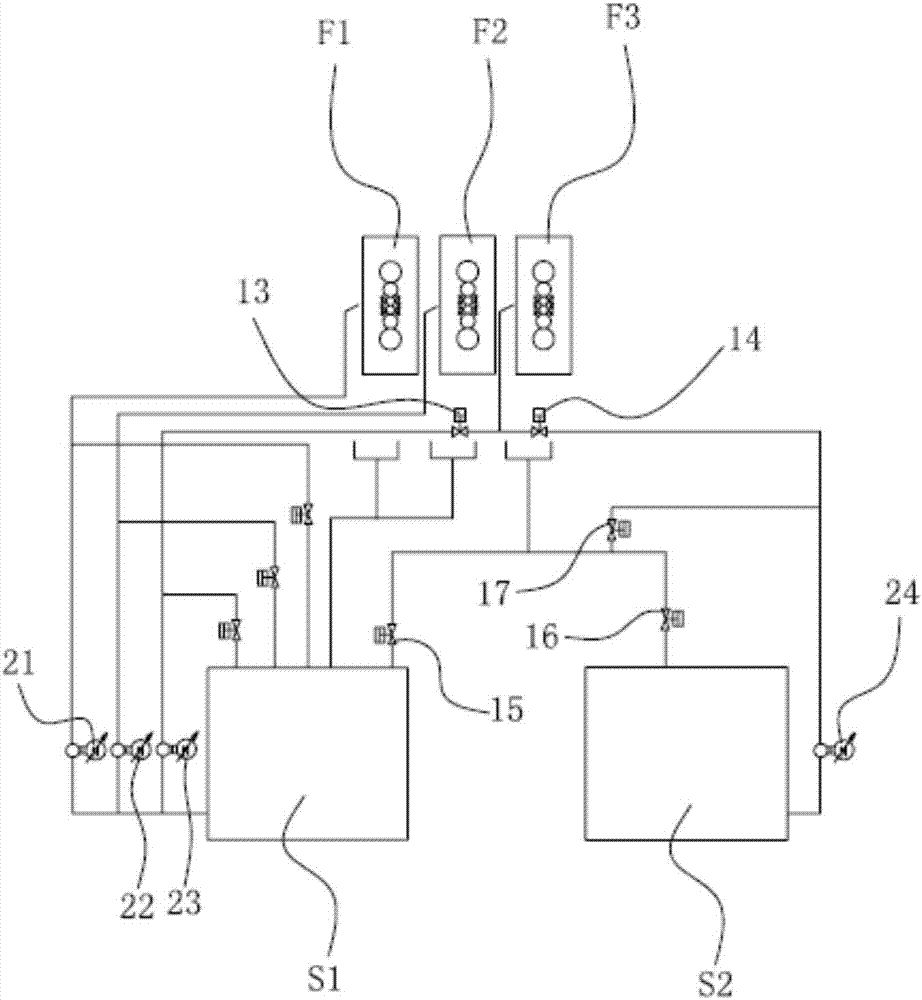

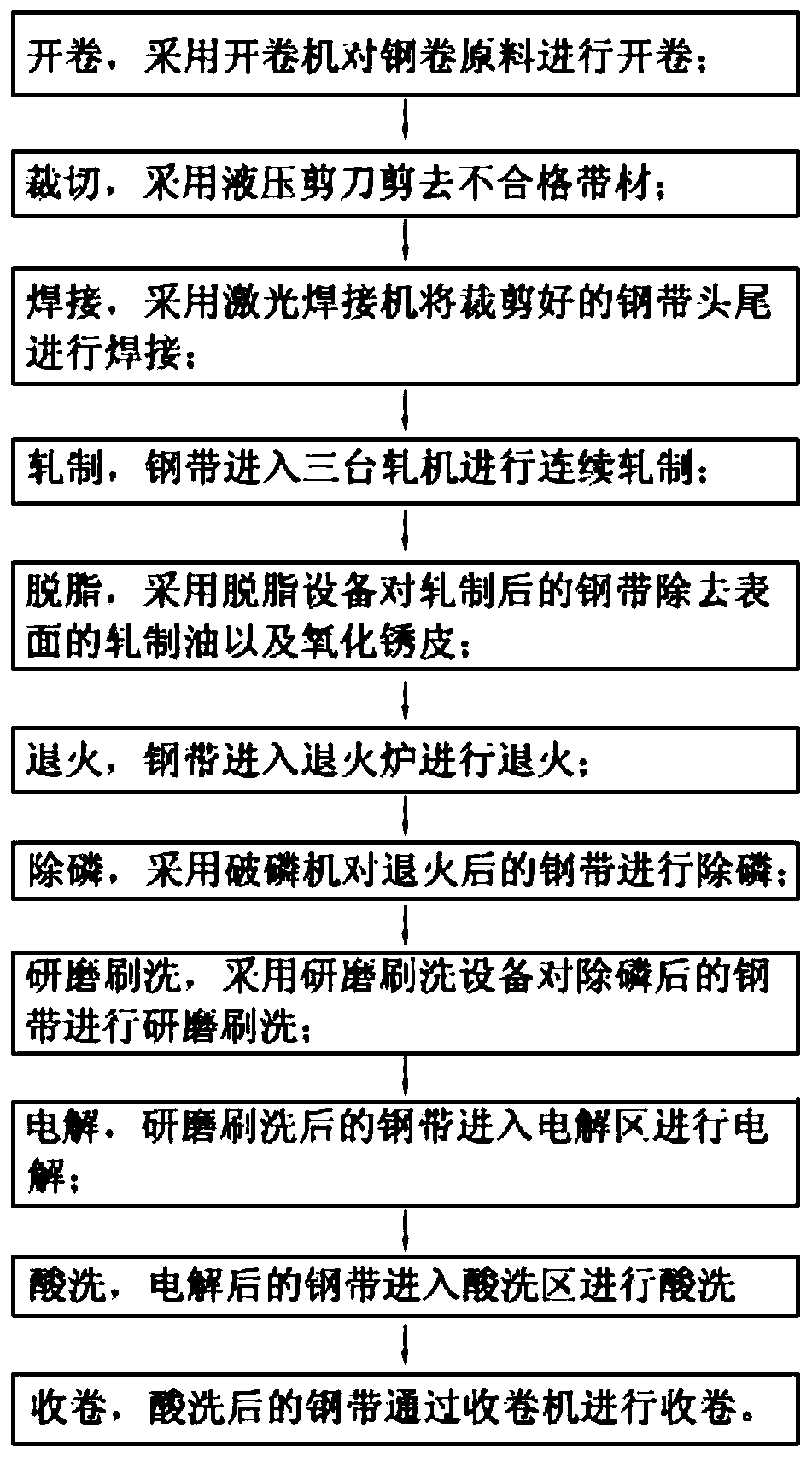

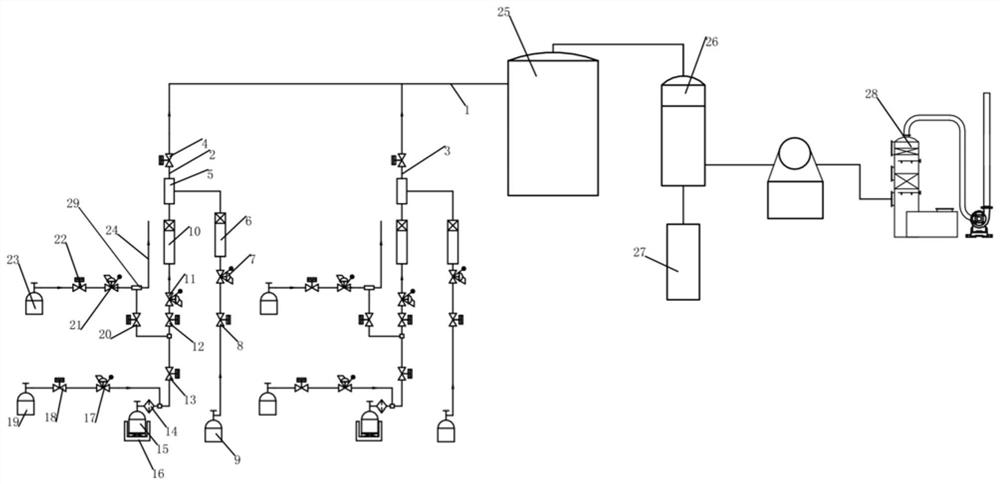

Hot acid pickling production process of stainless steel

ActiveCN107983770ARealize online switchingReduce manufacturing costWork treatment devicesMetal rolling arrangementsElectrolysisPollution

The invention provides a hot acid pickling production process of stainless steel. The hot acid pickling production process comprises the following steps of (1) uncoiling, wherein uncoilers are adoptedfor uncoiling a steel coil raw material; (2) cutting, wherein hydraulic scissors are adopted for shearing off unqualified steel strips; (3) welding, wherein a laser welding machine is adopted for welding the heads and the tails of steel strips obtained through shearing; (4) rolling, wherein the steel strips enter three rolling machines to be continuously rolled; (5) degreasing, wherein degreasingequipment is adopted for removing surface rolling oil and oxidized scales for the rolled steel strips; (6) annealing, wherein the steel strips enter an annealing furnace for annealing from a middle loop; (7), scale removal, wherein a scale breaker is adopted for carrying out scale removal on the annealed steel strips; (8) grinding and cleaning, wherein grinding and cleaning equipment is adopted for grinding and cleaning the steel strips obtained after scale removal; (9) electrolysis, wherein the ground and cleaned steel strips enter an electrolytic area to be electrolyzed; (10) acid pickling,wherein the electrolyzed steel strips enter an acid pickling area for acid pickling; and (11) coiling, wherein the steel strips obtained after acid pickling are coiled through a coiling machine. According to the hot acid pickling production process, the acid amount is reduced, environment pollution is relieved, and the product surface is smooth and full of gloss.

Owner:福建宏旺实业有限公司

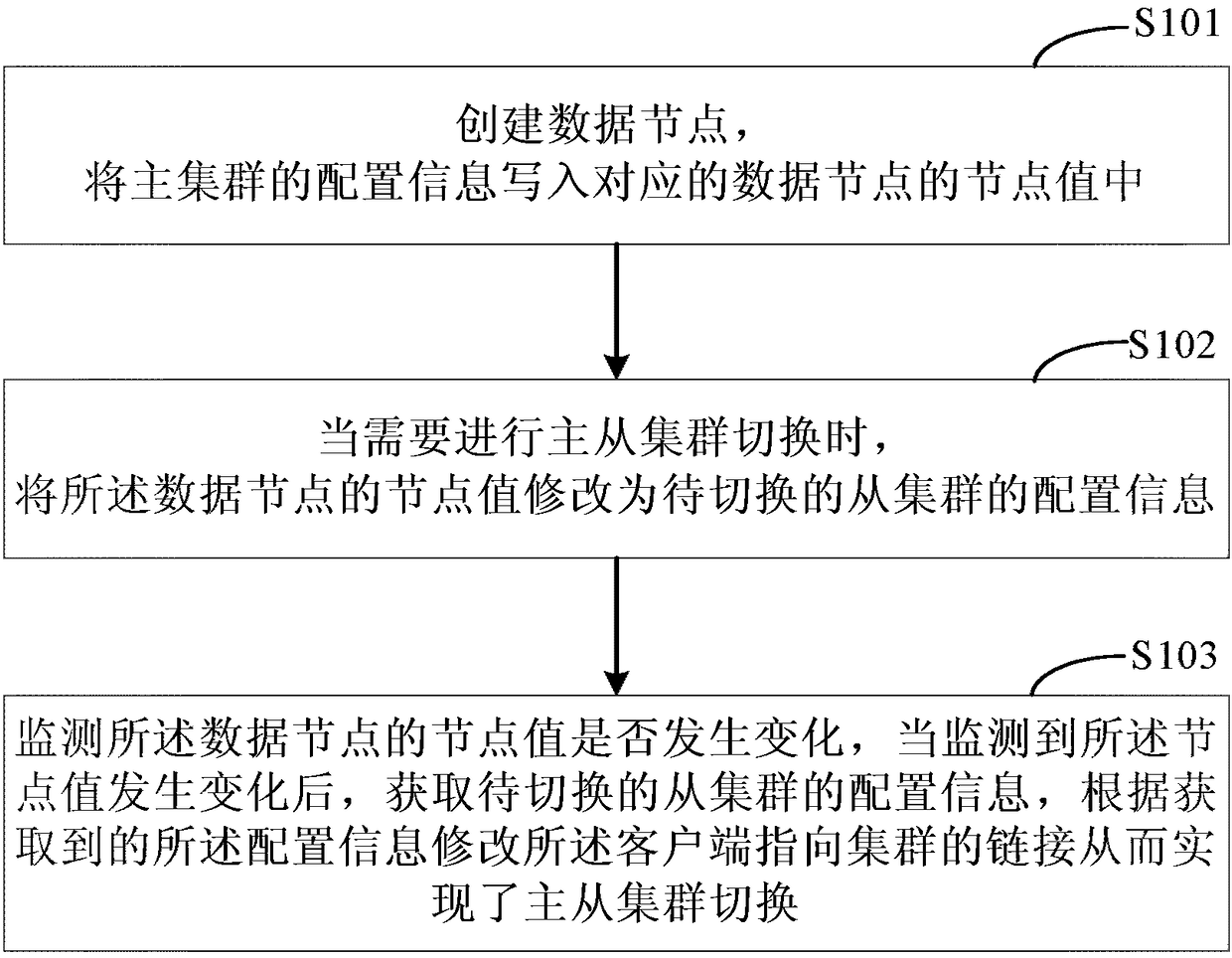

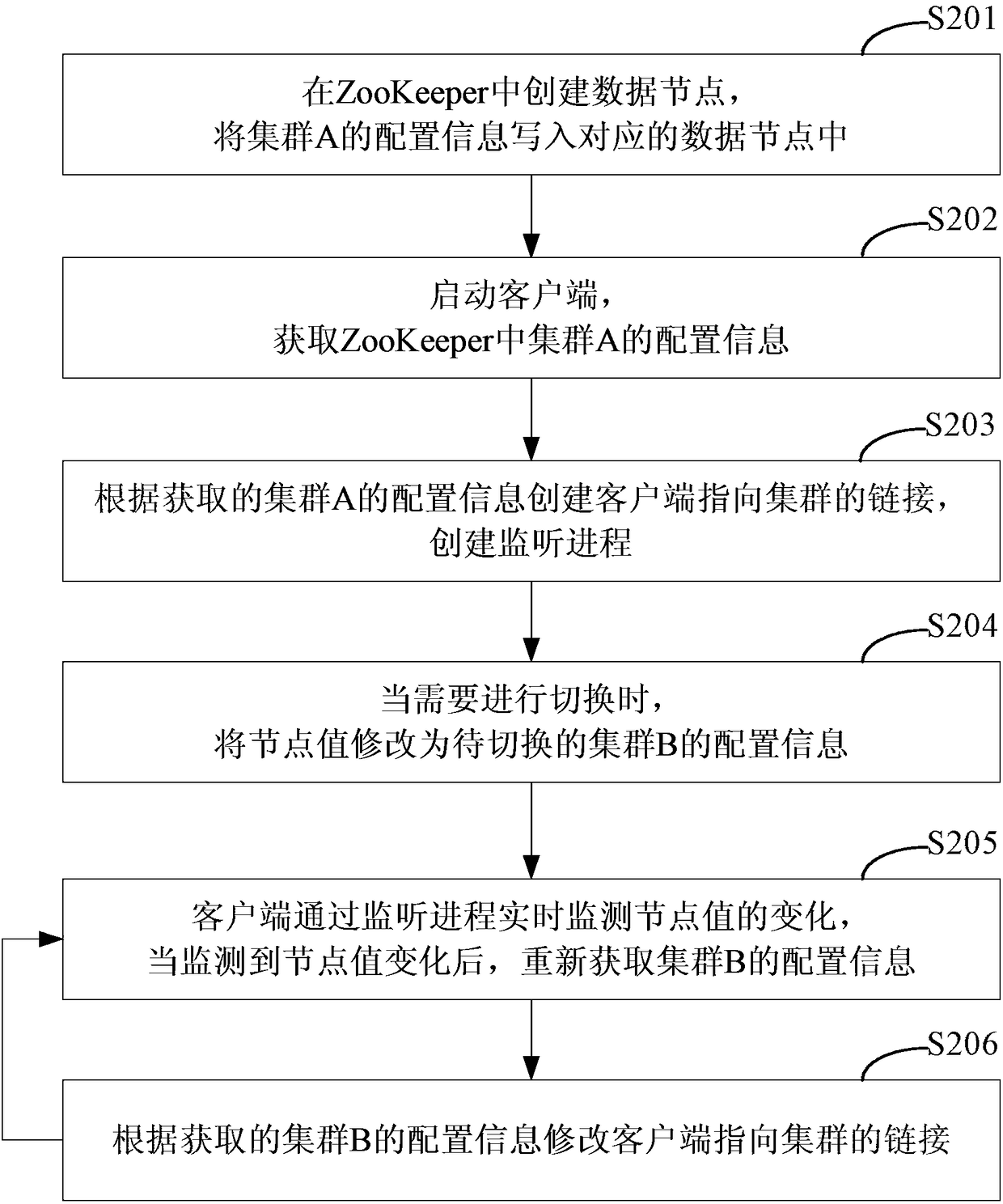

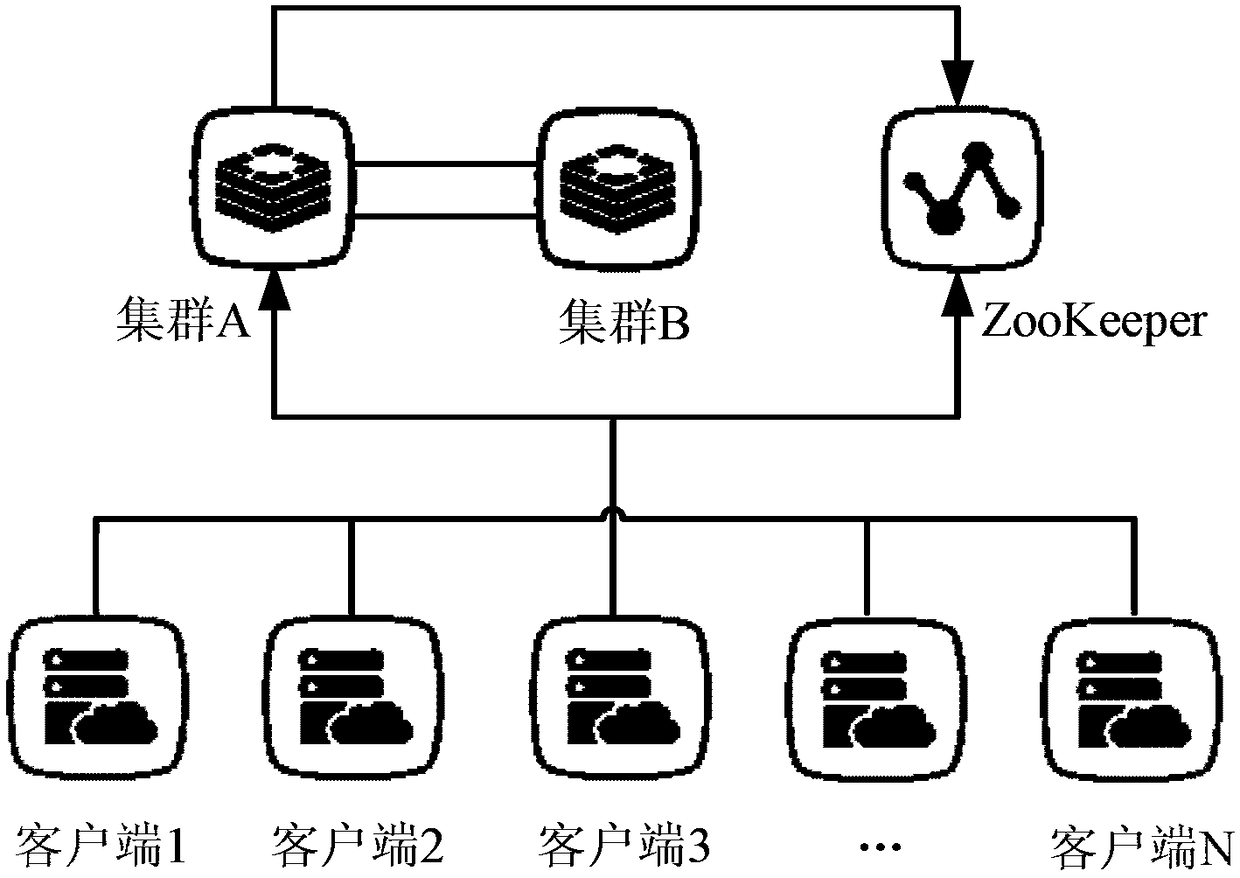

Master-slave cluster switching method and device

ActiveCN109245908ARealize online switchingQuick switchData switching networksClient-sideDistributed computing

The embodiment of the invention provides a master-slave cluster switching method and device, and relates to the technical field of computers. According to the embodiment of the invention, the method comprises the steps: creating data nodes, and writing the configuration information of a master cluster into a node value of a corresponding data node; modifying the node value of the data node into the configuration information of a slave cluster to be switched during the switching of the master-slave clusters; monitoring whether the node value of the data node changes or not: obtaining the configuration information of the slave cluster to be switched when the node value is monitored to change, and modifying the link, pointing to the cluster, of a client according to the obtained configurationinformation, thereby achieving the switching of the master-slave clusters. According to the embodiment of the invention, the configuration information is written into the node value of the data node.When the client monitors that the node value of the data node changes, the configuration information of the slave cluster is obtained after the node value is monitored to change, and the link from the client to the cluster is modified, thereby achieving the online switching of the master-slave clusters.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

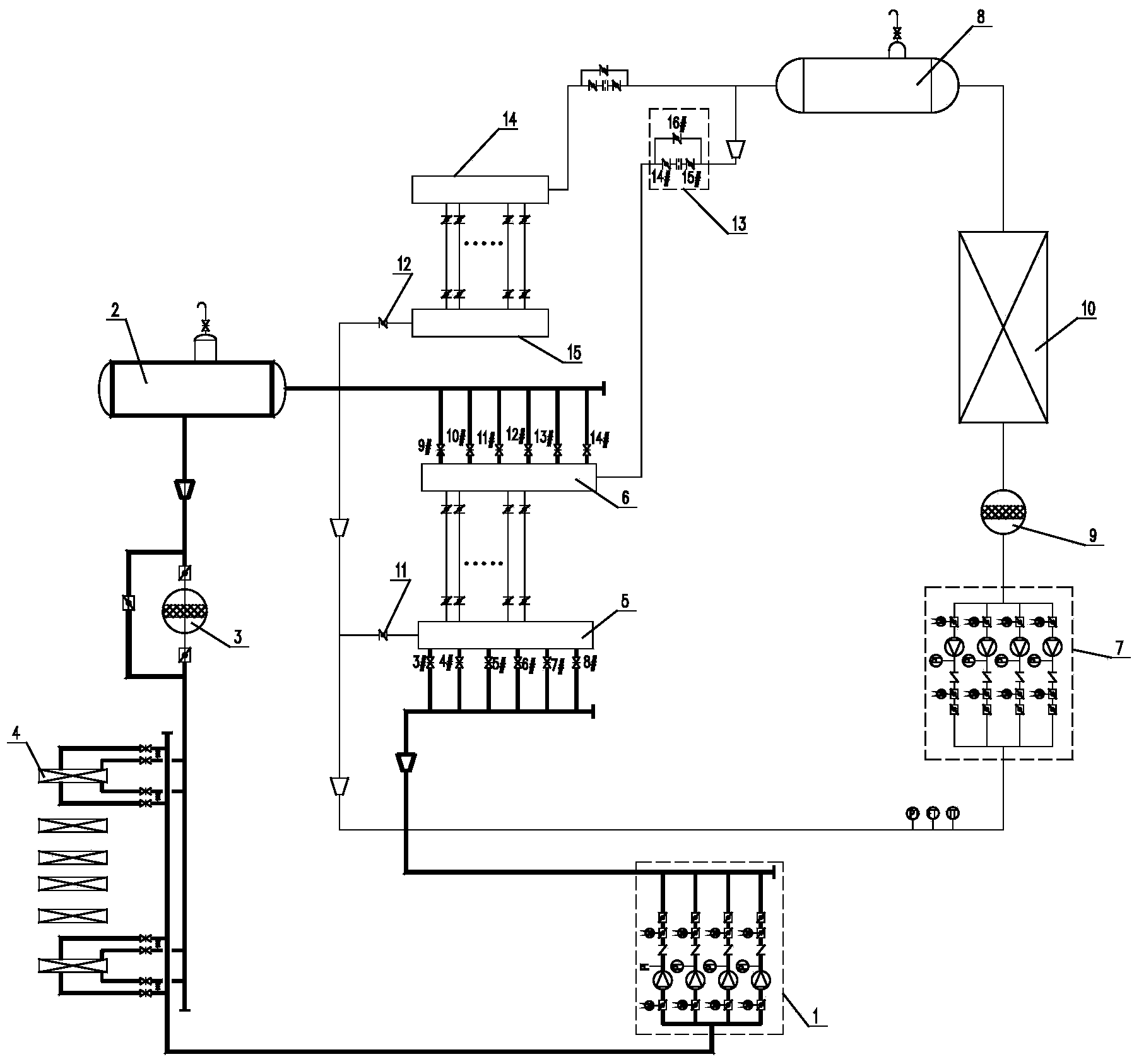

Direct high back pressure heat supply system of indirect air cooling unit

InactiveCN105910454ASolve the problem that the electrical load is limited by the thermal loadEnsure safetySteam/vapor condensersCooling towerNuclear engineering

The invention relates to the technical field of unit heat supply, in particular to a direct high back pressure heat supply system of an indirect air cooling unit. The direct high back pressure heat supply system comprises a condenser and is characterized in that recycled water pipelines in the condenser are uniformly divided into two separate parts: on one side, a water inlet pipe communicates with a heat supply network water return pipe, and a water outlet pipe communicates with a heat supply network water heater by virtue of a heat supply network circulating pump; on the other side, the water inlet pipe communicates with an indirect cooling tower through a frequency conversion circulating water pump, and the water outlet pipe communicates with the water inlet pipe of the indirect cooling tower. The direct high back pressure heat supply system is small in investment and simple in structure, takes effect quickly, and can realize operation under pure condensing and back pressure modes; in addition, in case that the heat supply network is abnormal, the unit can switch over two operational modes without halt to ensure operating safety of the unit.

Owner:SHANDONG HONGAO POWER TECHNOLOGY CO LTD

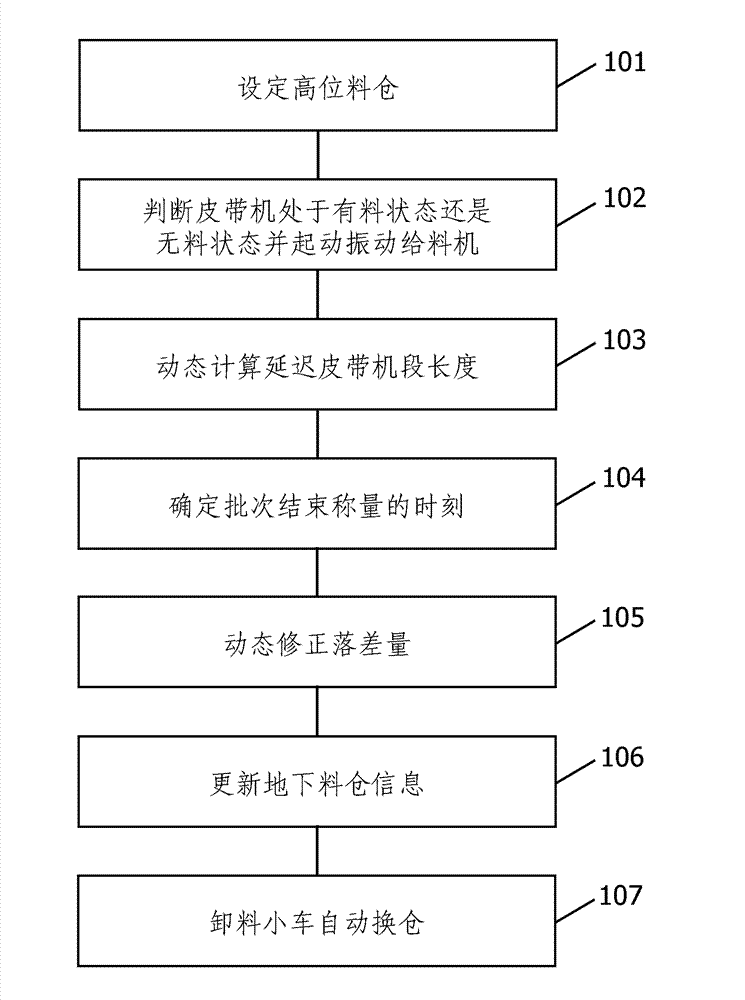

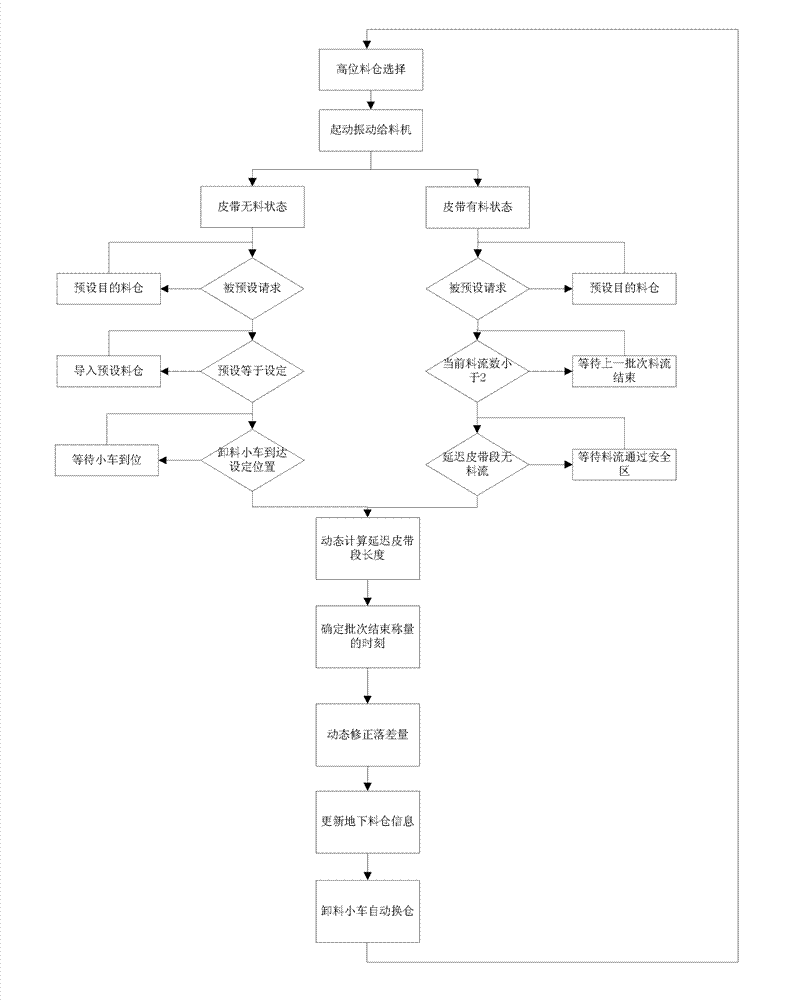

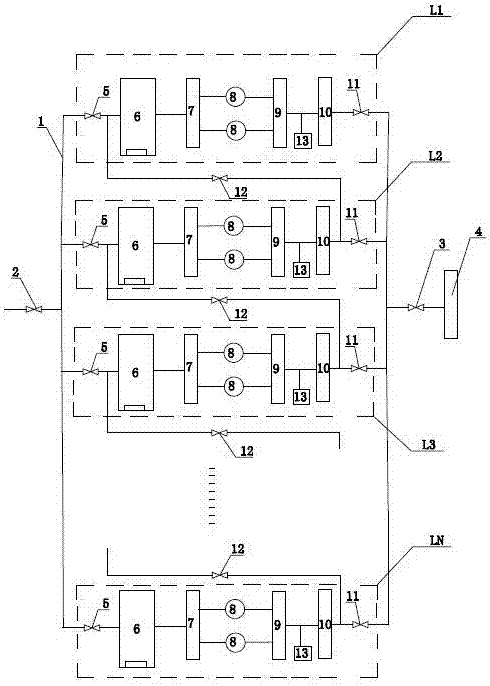

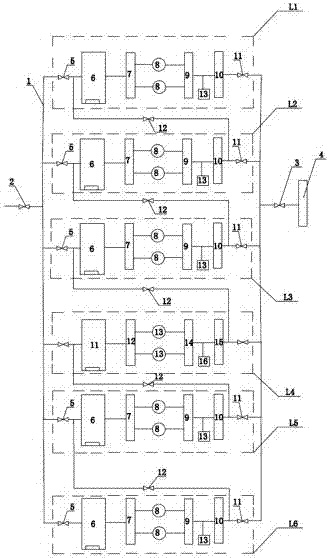

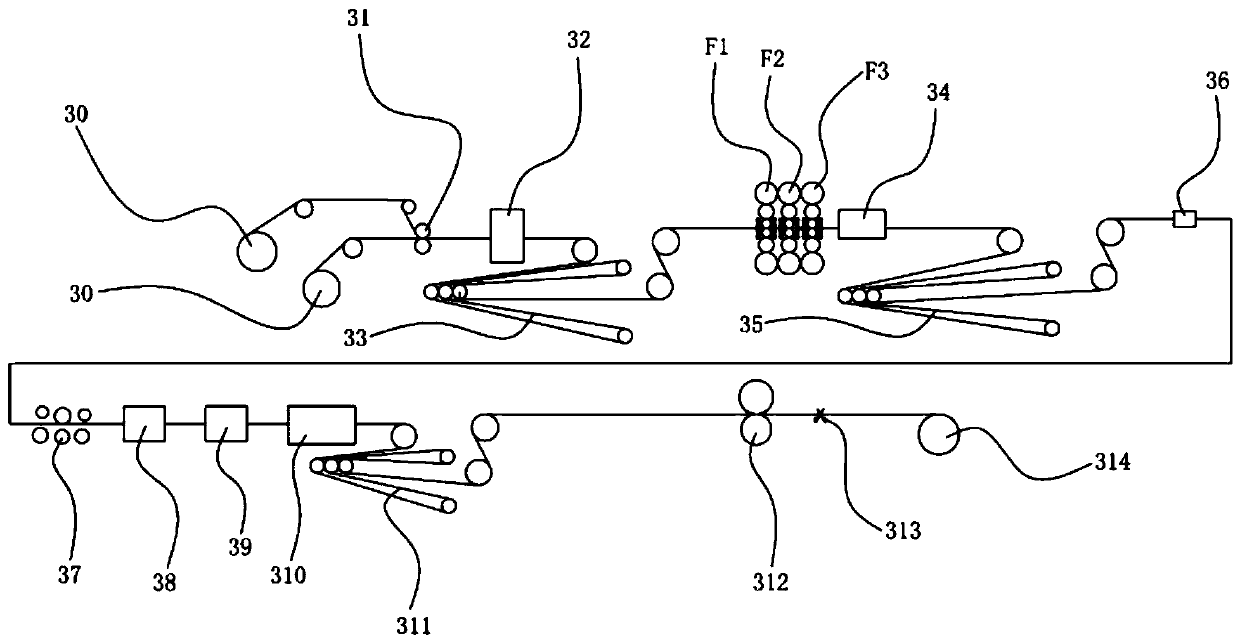

Multi-type material continuously feeding method for

ActiveCN103090679AAccurate location in real timeRealize online switchingCharge manipulationEngineeringBelt conveyor

The utility model discloses a multi-type material continuously feeding method. The method comprises the following steps of: firstly, setting high position bunker which comprises setting current bunker and setting preset bunker, wherein the current bunker is the final high position bunker of current batch of material and the preset bunker is the final high position bunker of next batch of material; secondly, judging whether there are material on belt conveyor or not and starting vibration feeder; thirdly, dynamically calculating the belt length which needed to be postponed; fourthly, determining the moment for finishing the weighting of the batch material and seeking the position where the end of material flow of a batch of material arrives and determining the moment of finishing weighting of a batch of material; fifthly, dynamically correcting amount of gap and dynamically correcting the weighting results of current batch material according to the cumulative weight of the actual weight of a patch of material and set laying-off quantity; sixthly, updating the information of underground bunker; finally, material-discharging trolley automatically changes bunker and material-discharging trolley automatically goes to the position of preset bunker after the current patch of material finishes material-loading.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

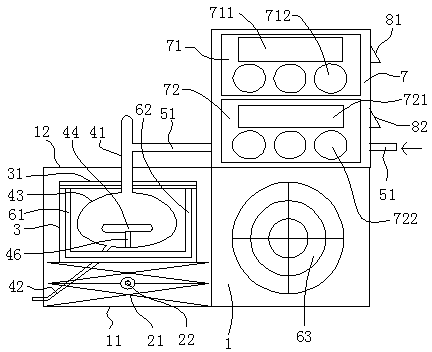

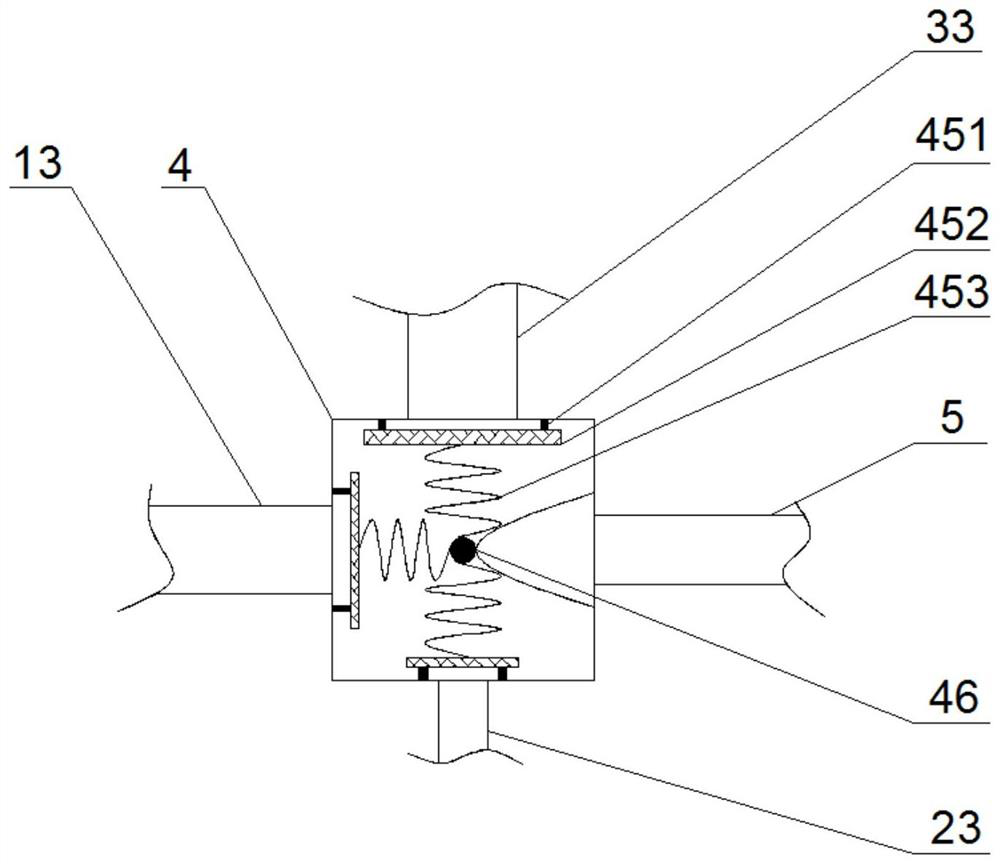

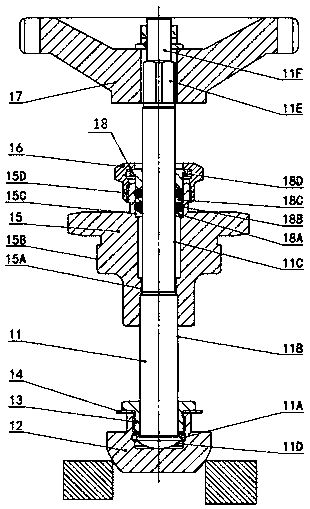

Inductively coupled plasma-atomic emission spectrometry/mass spectrometry (ICP-AES/ MS) switching-free type organic sampling device

The invention relates to the field of chemical test instruments, and in particular relates to an inductively coupled plasma-atomic emission spectrometry / mass spectrometry (ICP-AES / MS) switching-free type organic sampling device which comprises a box body. The organic sampling device is characterized in that the box body is internally provided with a height adjusting device; a box-type fixed rack is connected above the height adjusting device; the box-type fixed rack is internally provided with an atomization device; the upper part of the atomization device is connected with an aerosol discharge pipe which penetrates through a top plate of the fixed rack and a top plate of the box body and extends out of the box body; the bottom of the atomization device is provided with a waste liquid discharge pipe which penetrates through the side wall of the box body and extends out of the box body; the side wall of the upper part of the aerosol discharge pipe is also communicated with a gas inlet pipe; the gas inlet pipe is provided with a gas flow rate control device. The device is simple and compact in structure, an aerosol outlet of an atomizing chamber can be conveniently adjusted to be matched with the height of a central moment pipe, the atomization efficiency of the atomizing chamber is improved, and the device is avoided from being disassembled; after the device is adopted, two sampling modes including organic phase and aqueous phase can be switched in an online way.

Owner:FUZHOU UNIVERSITY

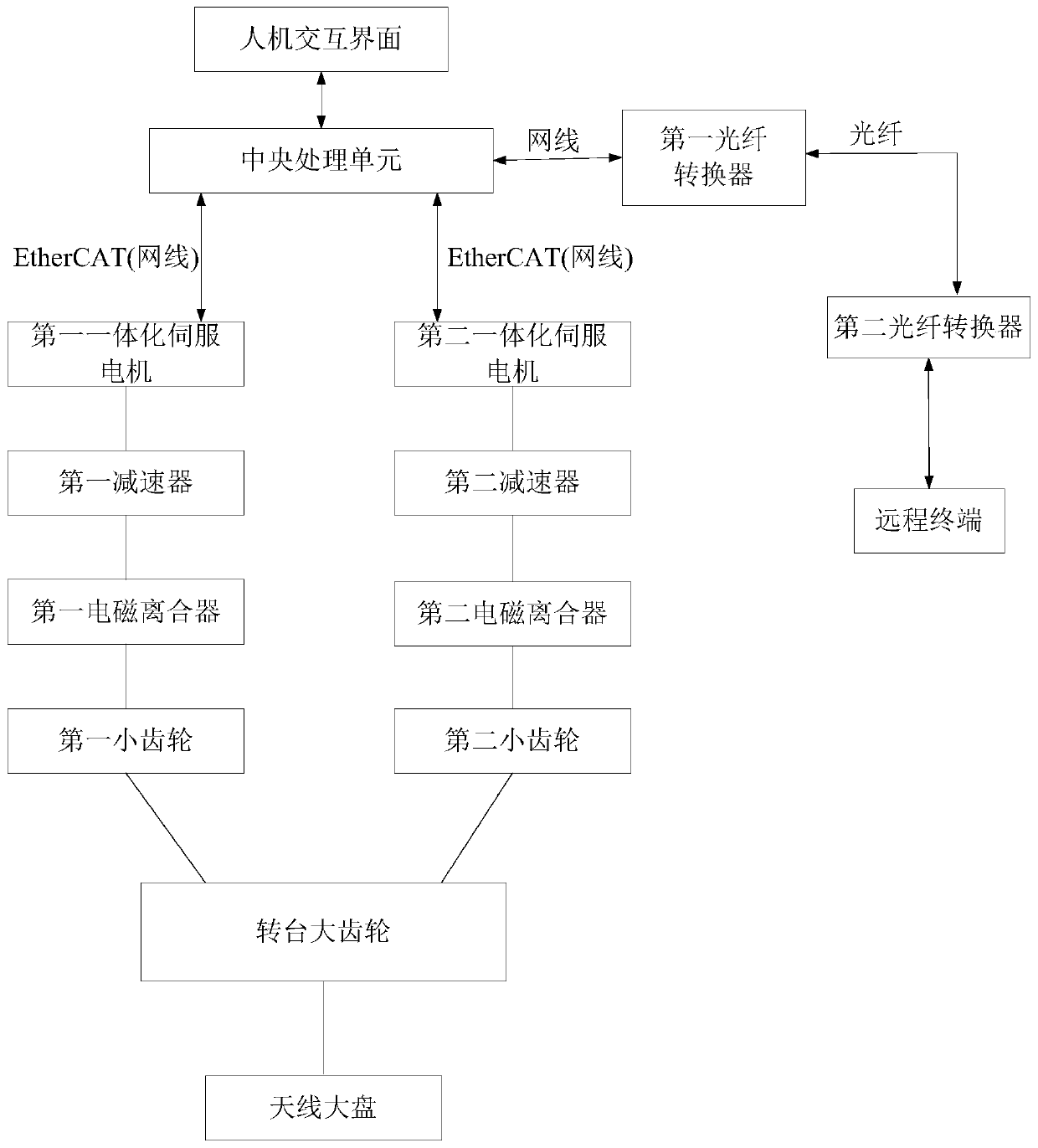

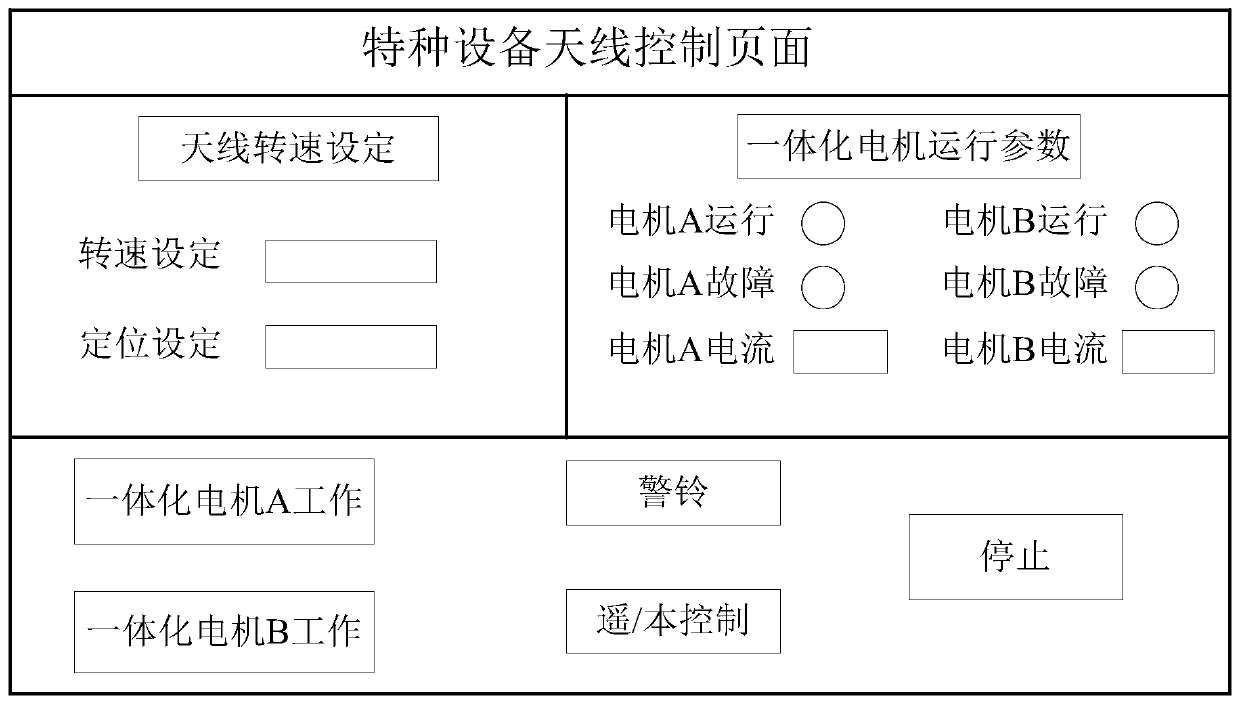

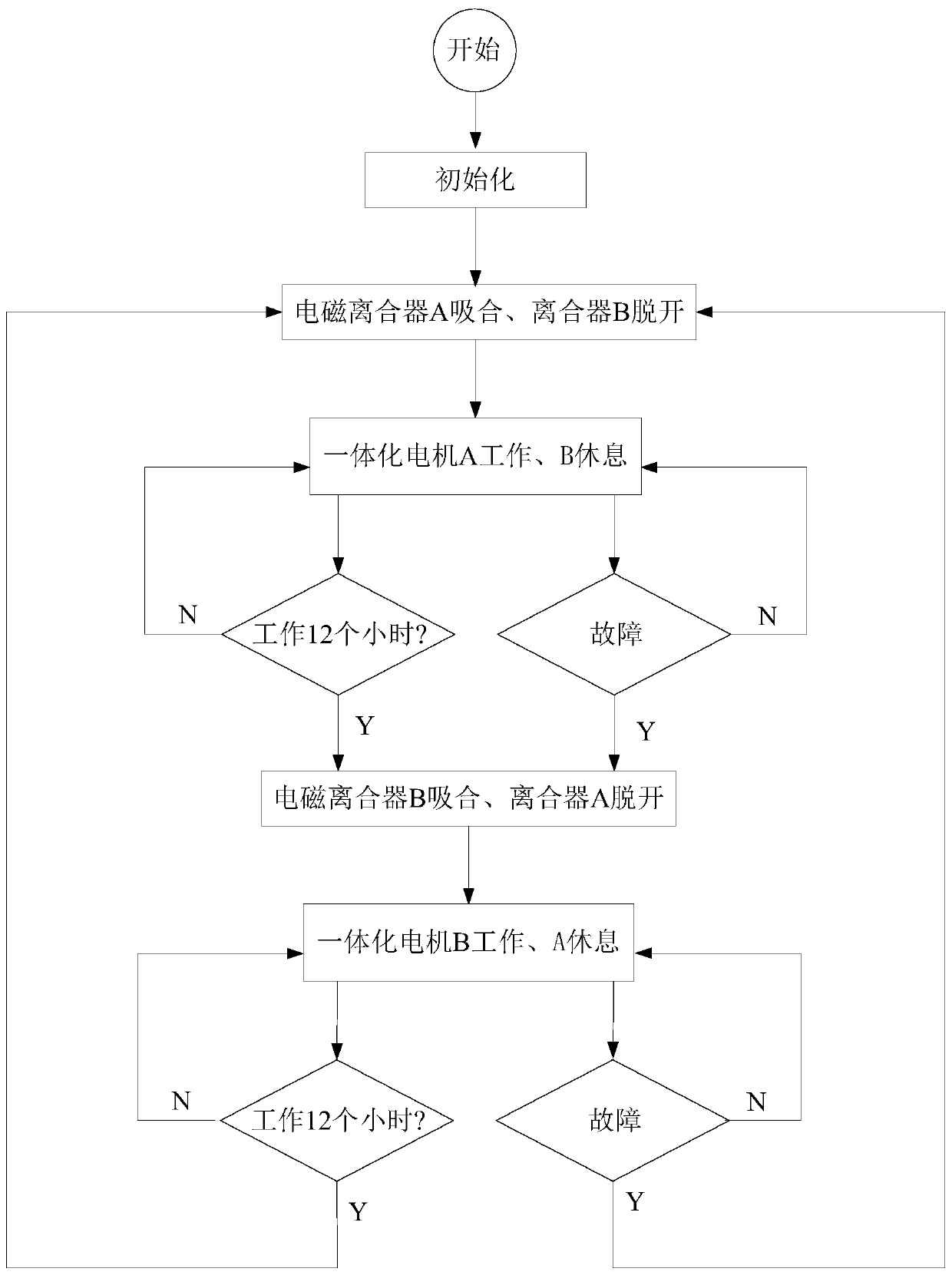

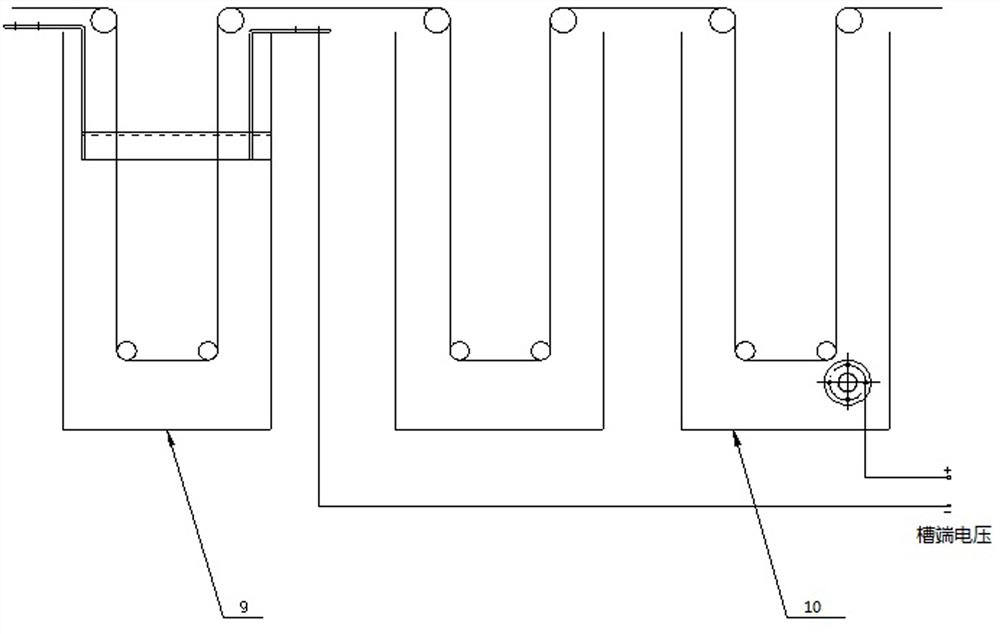

Special equipment antenna turntable dual-motor control system and method

ActiveCN110544828ARealize online switchingExtend your lifeAntennasElectromagnetic clutchElectric machinery

The invention discloses a special equipment antenna turntable dual-motor control system, which mainly includes a central processing unit, and a group consisting of a human-machine interaction interface, an optical fiber transmission unit, a first motor system, and a second motor system which are connected with the central processing unit. The first motor system and the second motor system are eachcomposed of an integrated servo motor, a reducer, an electromagnetic clutch, and a pinion which are successively connected. The two pinions rotate a turntable large gear and an antenna plate to change an antenna azimuth. A dual-motor control method of the system is also disclosed. The system uses a single central processing unit to control the dual motors. The two integrated servo motors operatealternately every 12 hours, thereby greatly prolonging the service lives of the integrated servo motors, reducing the maintenance frequency of workers, improving the reliability of the system, achieving the online switching of the motors, guaranteeing the 24-hours continuous operation of the special equipment antenna.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

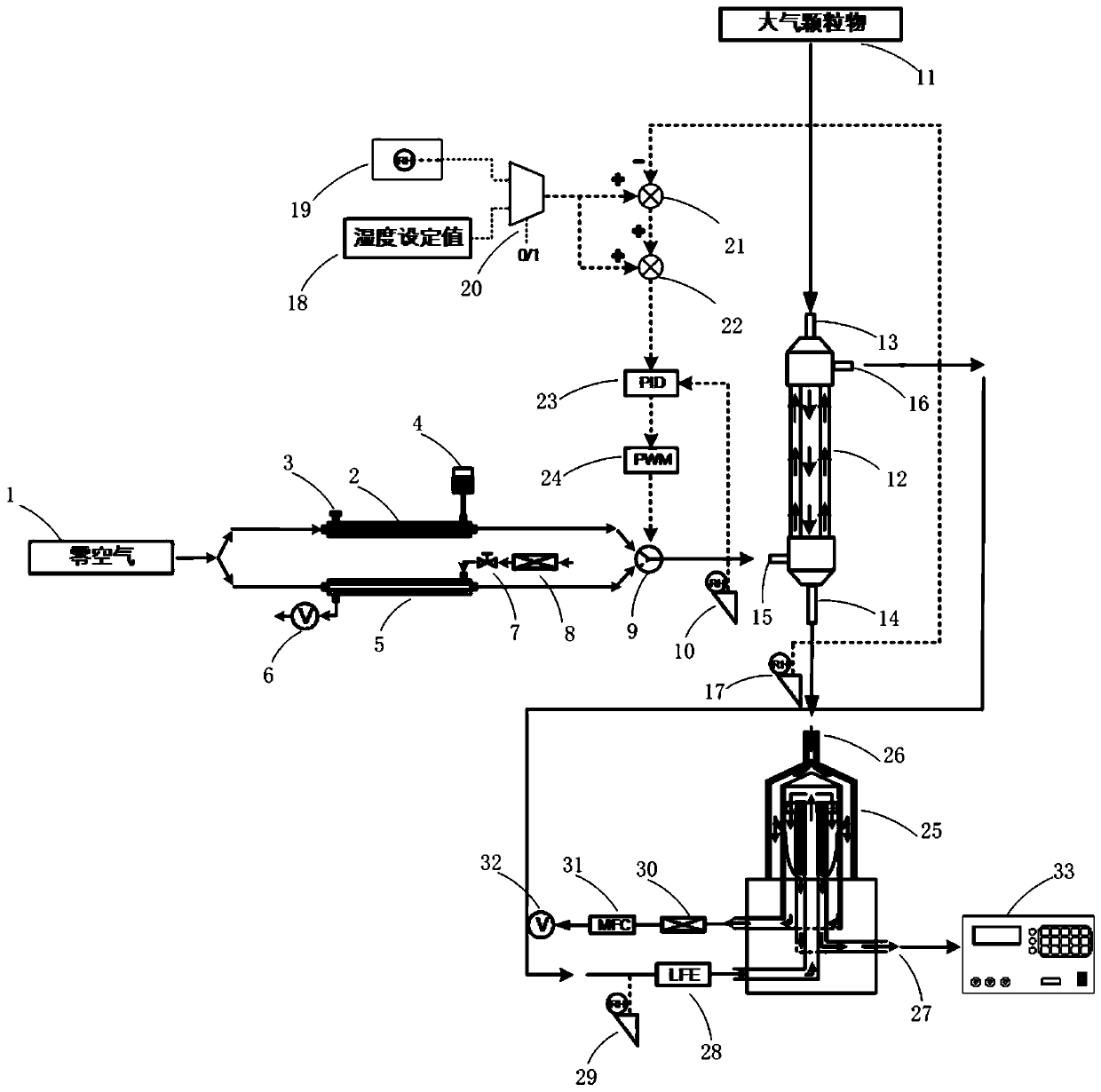

Device and method for rapidly measuring water content of nanoscale particles

ActiveCN110954446AQuick response to humidityReduce complexityNanoparticle analysisParticle suspension analysisWater contentAtmospheric sciences

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

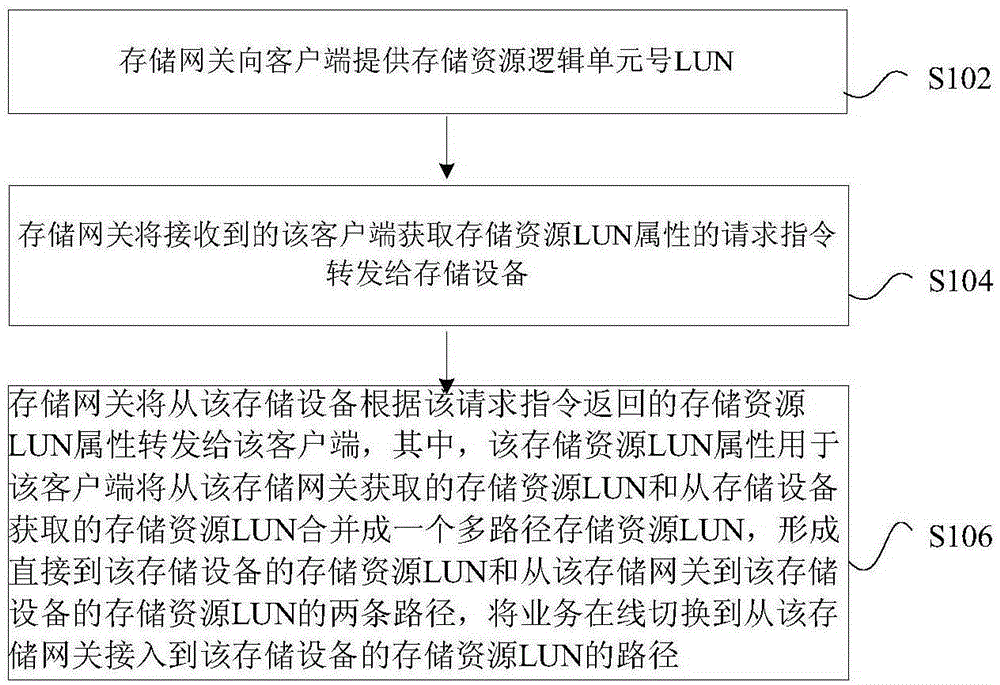

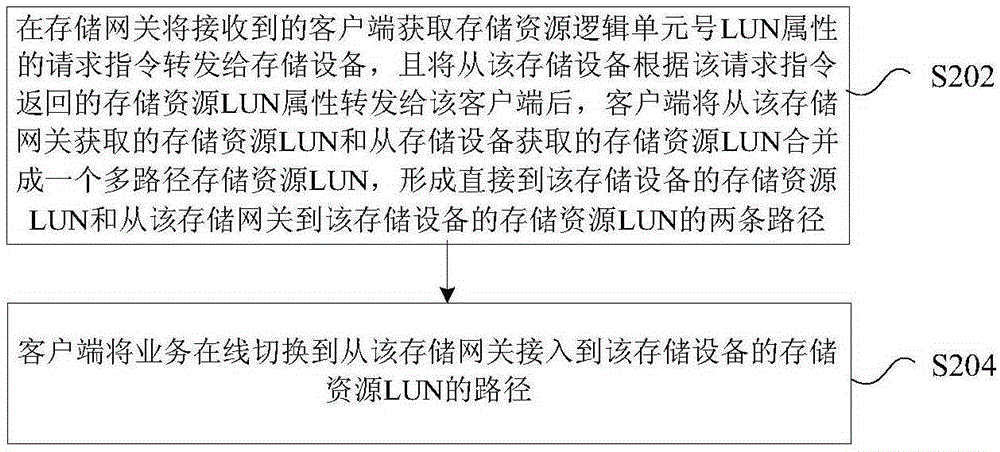

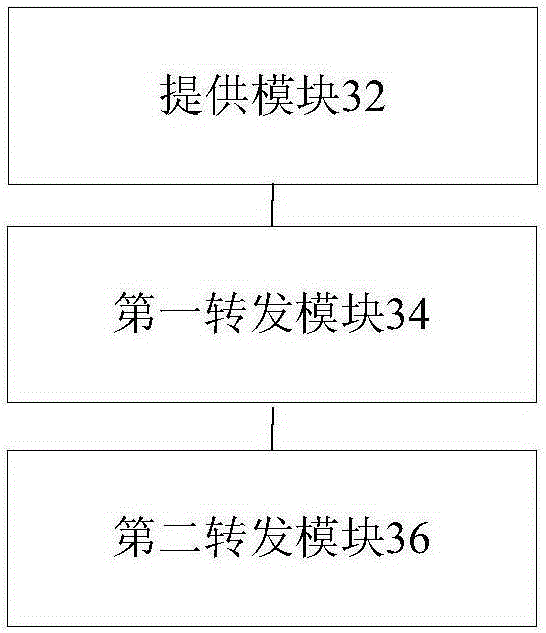

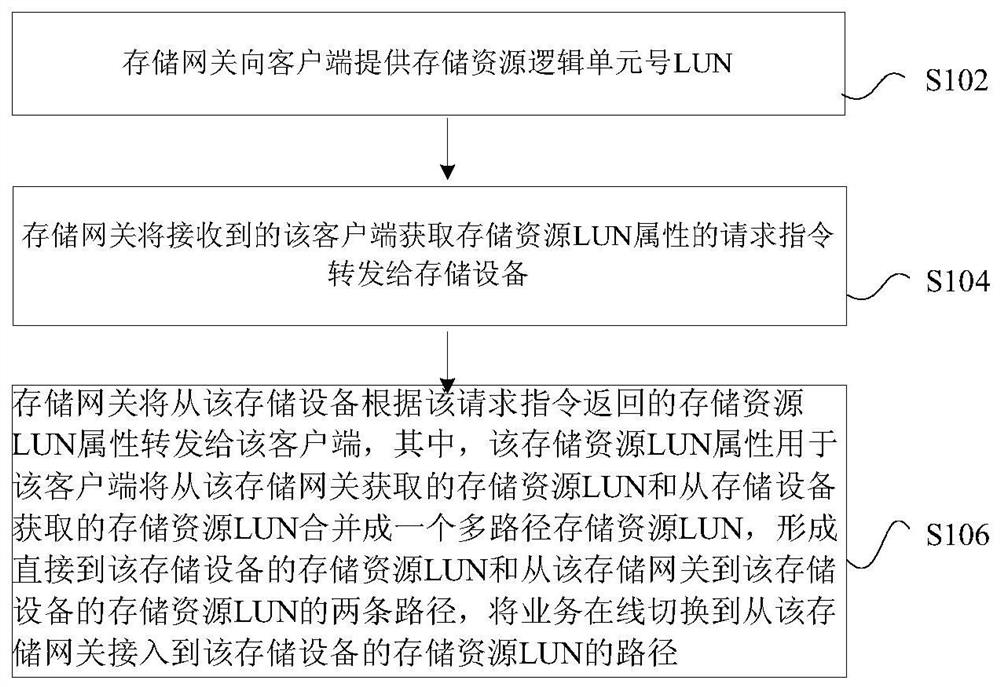

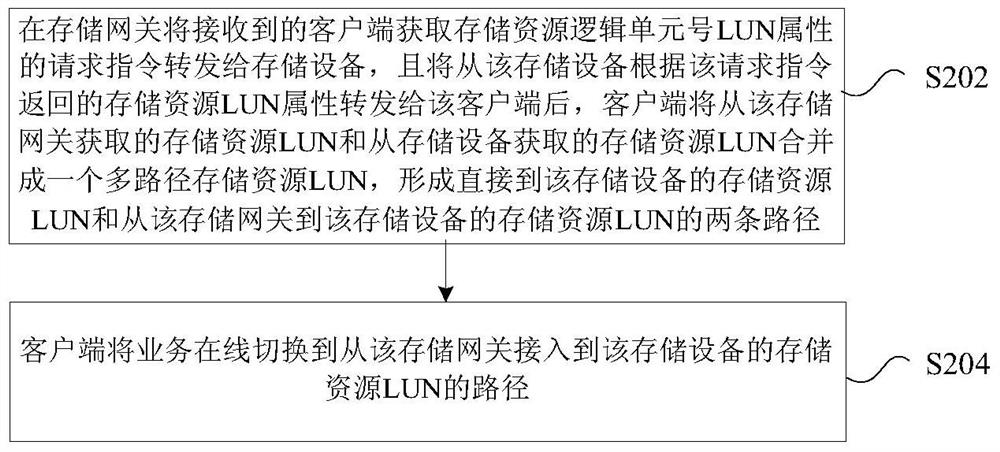

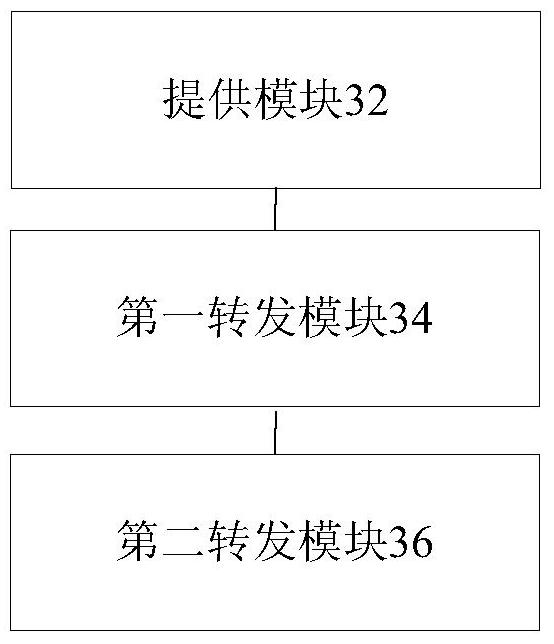

Storage take-over and switching processing method and device

ActiveCN106557276ARealize online switchingFix bugsInput/output to record carriersMemory adressing/allocation/relocationClient-sideMulti path

The present invention discloses a storage take-over and switching processing method and device. The method comprises: a storage gateway providing a storage resource logical unit number LUN for a client side; the storage gateway forwarding a received request instruction by which the client side obtains the attribute of the storage resource LUN to a storage device; the storage gateway forwarding the attribute of the storage resource LUN which is returned by a storage device according to the request instruction to the client side, wherein the attribute of the storage resource LUN is used for merging the storage resource LUN obtained from the storage gateway by the client side and another storage resource LUN obtained from the storage device into a multi-path storage resource LUN, to form two paths, and the operation is online switched to the path through which the access to the storage resource LUN of the storage device from the storage gateway is made. The problem that in the prior art the storage gateway comes online and supports the online switching of the client side and thus defects are caused is solved, and online switching of the client side can be realized.

Owner:ZTE CORP

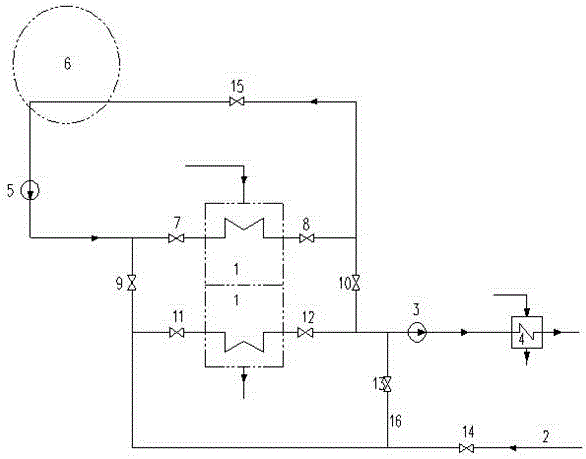

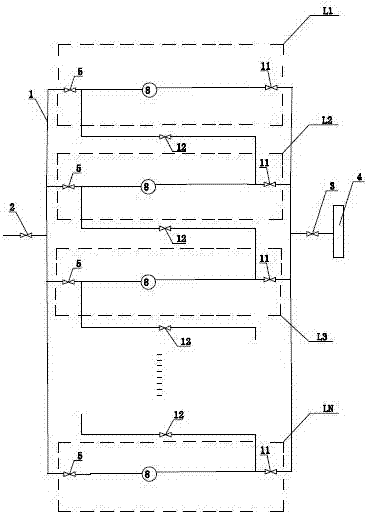

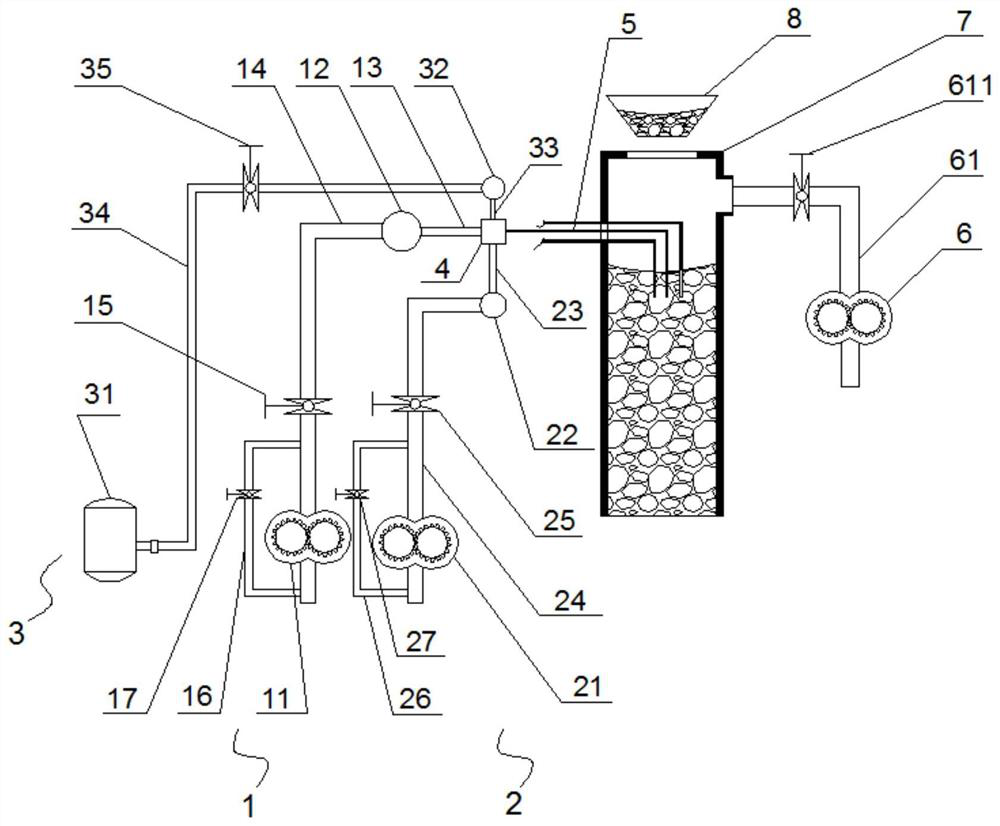

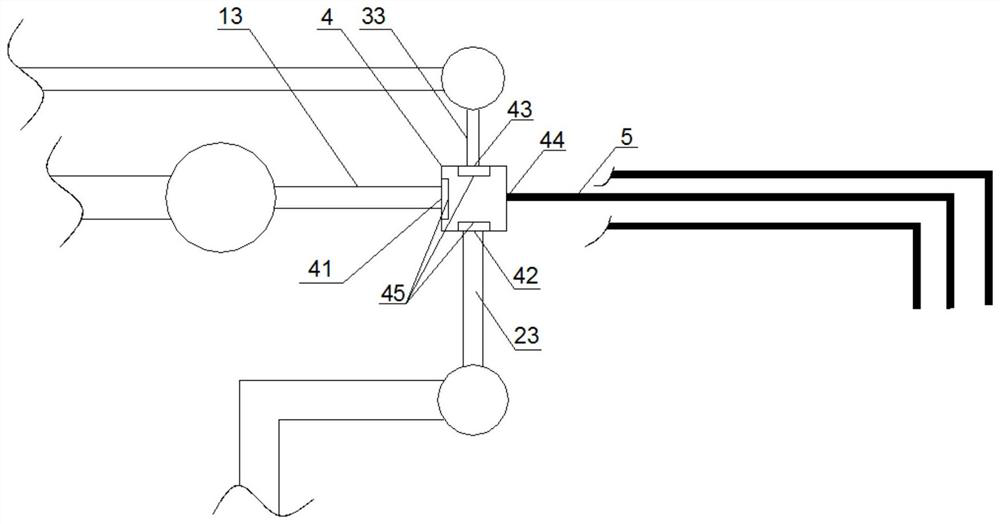

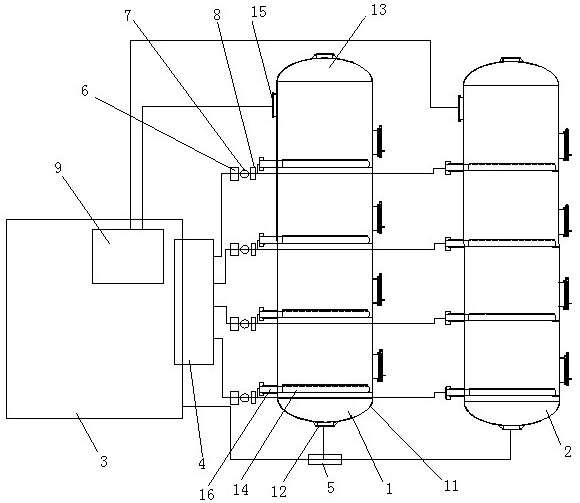

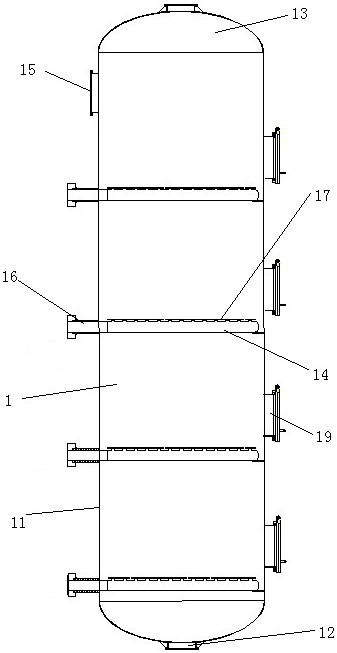

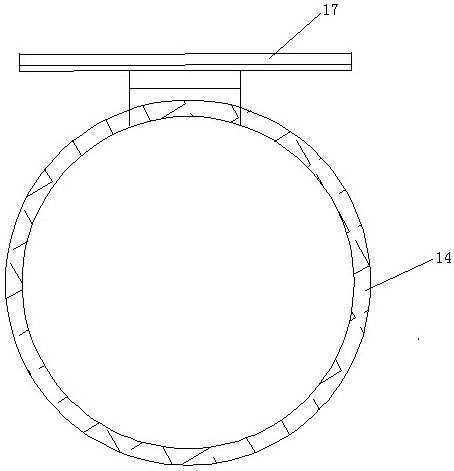

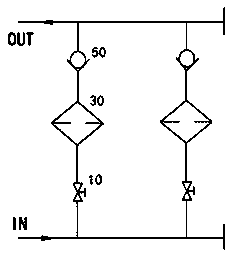

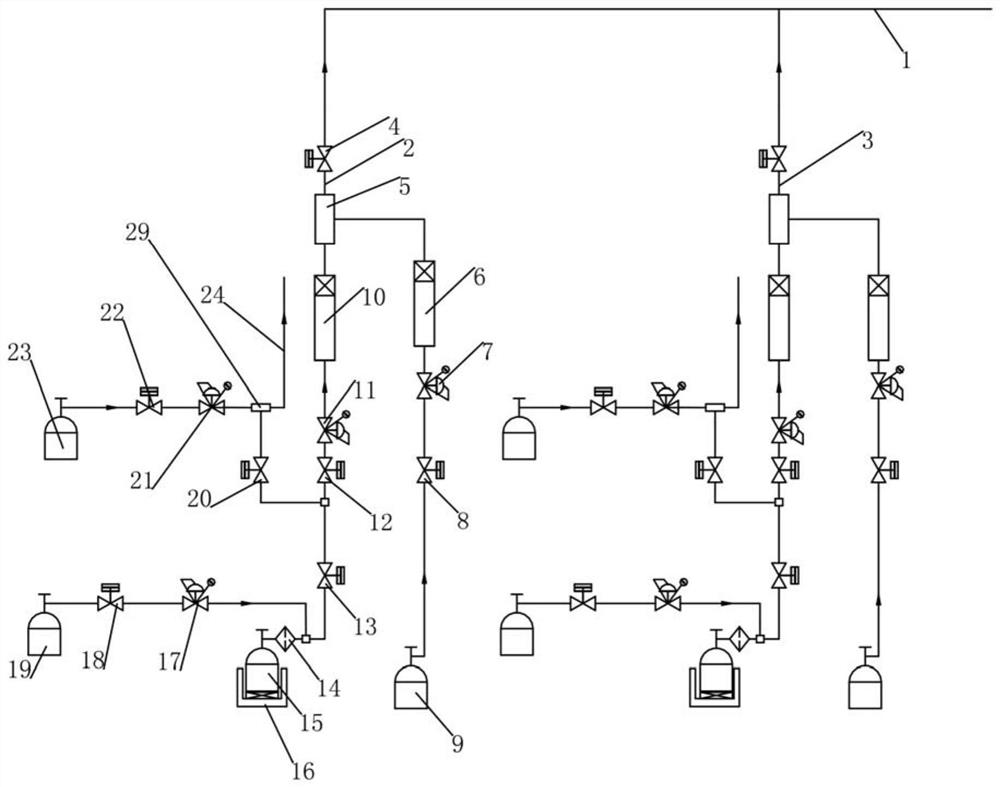

Closed circulation cooling system of blast furnace and non-shutdown online switching method of closed circulation cooling system

InactiveCN103882170ARealize online switchingIncrease cooling intensityCooling devicesEqualizationBlast furnace

The invention relates to a closed circulation cooling system of a blast furnace and a non-shutdown online switching method of the closed circulation cooling system. The closed circulation cooling system comprises an air cooler I, an air cooler II, a filter I, a filter II, a degassing tank I, a degassing tank II, a drainage ring pipe I, a drainage ring pipe II, a water supply ring pipe I, a water supply ring pipe II, a circulating water pump I and a circulating water pump II, wherein the degassing tank I, the air cooler I, the filter I, the circulating water pump I, the water supply ring pipe I, the drainage ring pipe I and the degassing tank I are connected with one another; the circulating water pump I is also connected with the water supply ring pipe II; and the water supply ring pipe II, the circulating water pump II, the air cooler II, the filter II, the degassing tank II, the drainage ring pipe II and the water supply ring pipe II are connected with one another. The closed circulation cooling system has the advantages that the non-shutdown online switching of the circulation cooling system is realized through pressure equalization and parallel operation, and the cooling intensity of cooled equipment is improved, so that the service life of the cooled equipment is prolonged, and the aim that the production is not influenced and the cooled equipment is not damaged during switching is achieved.

Owner:鞍钢集团工程技术有限公司

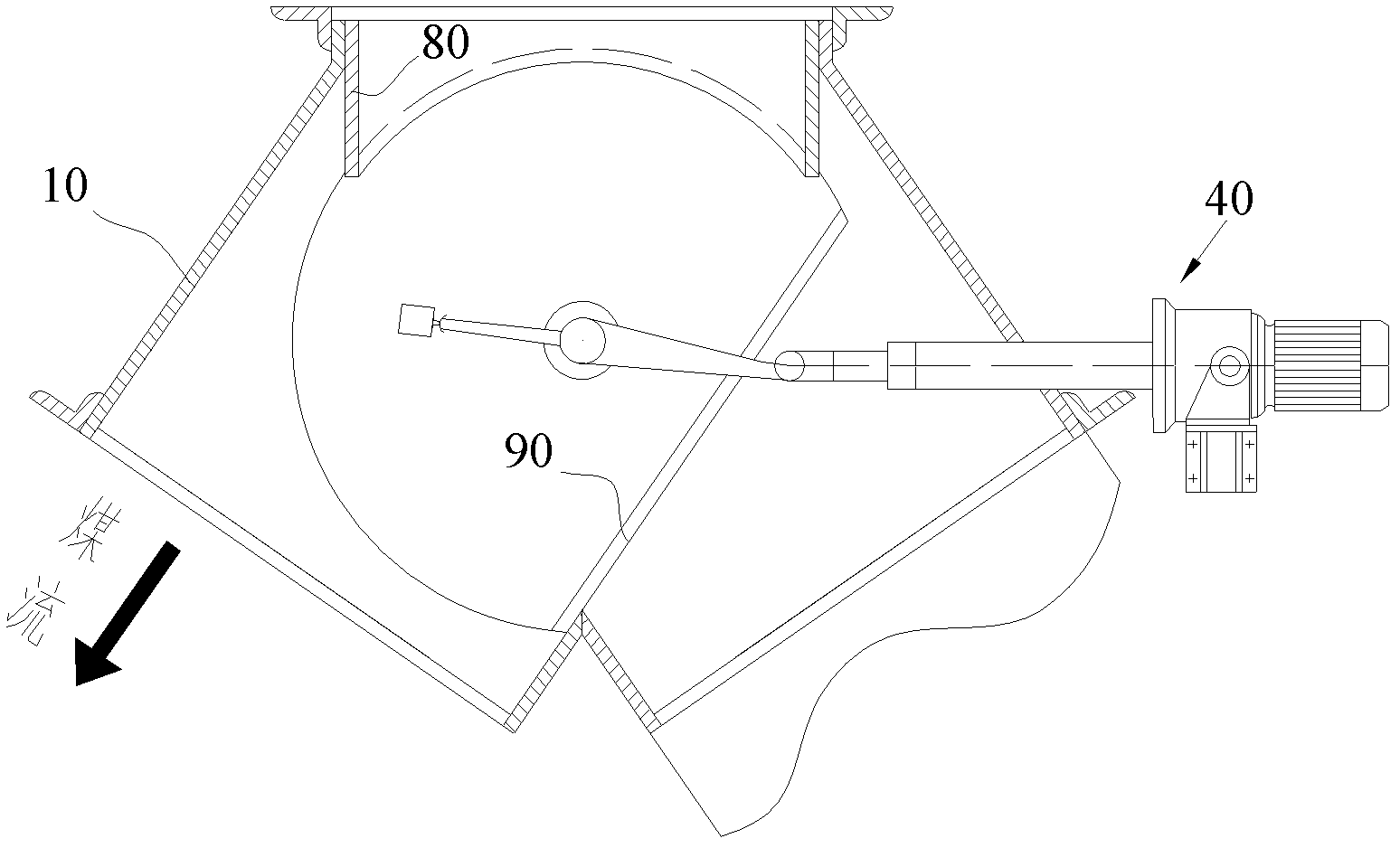

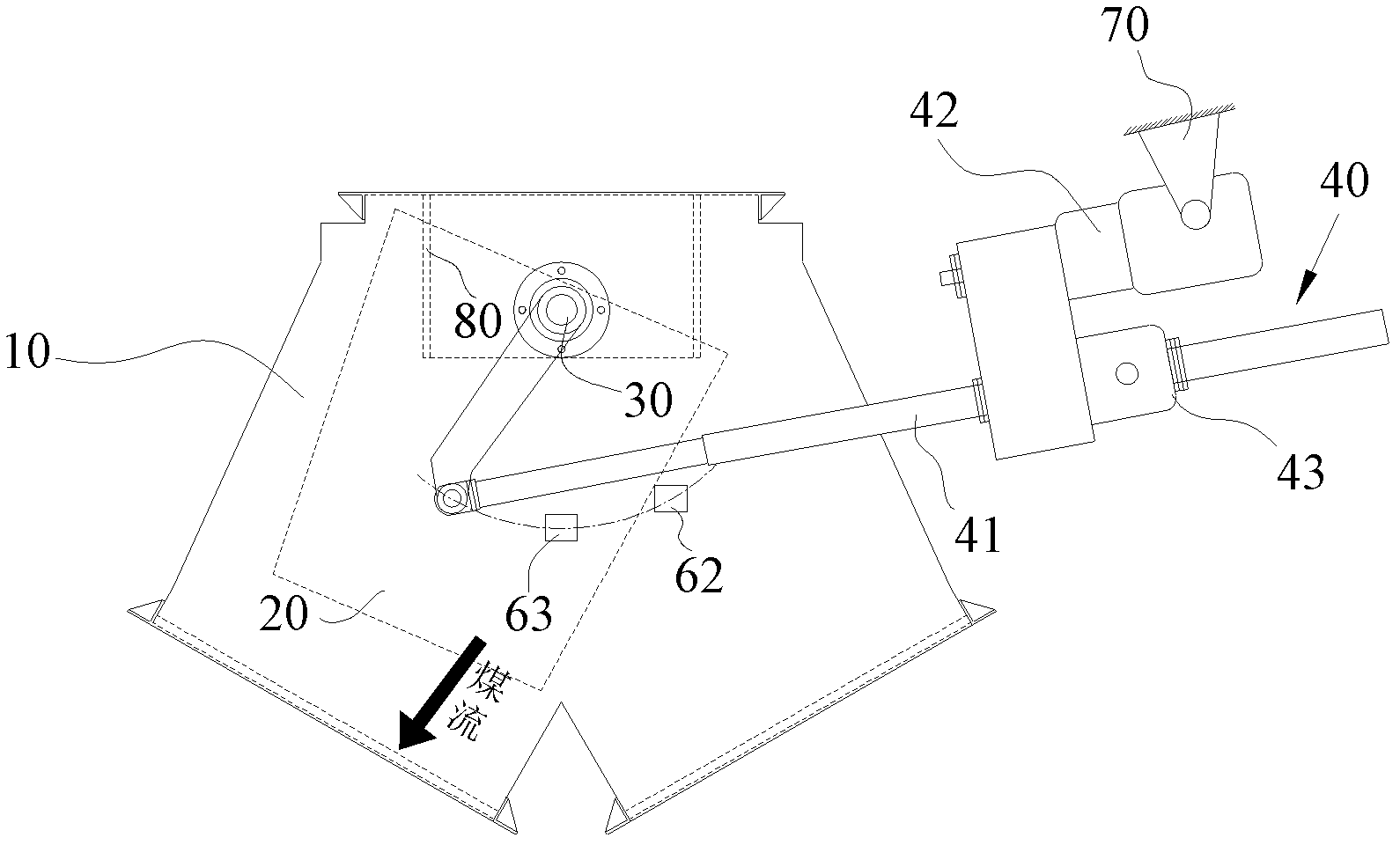

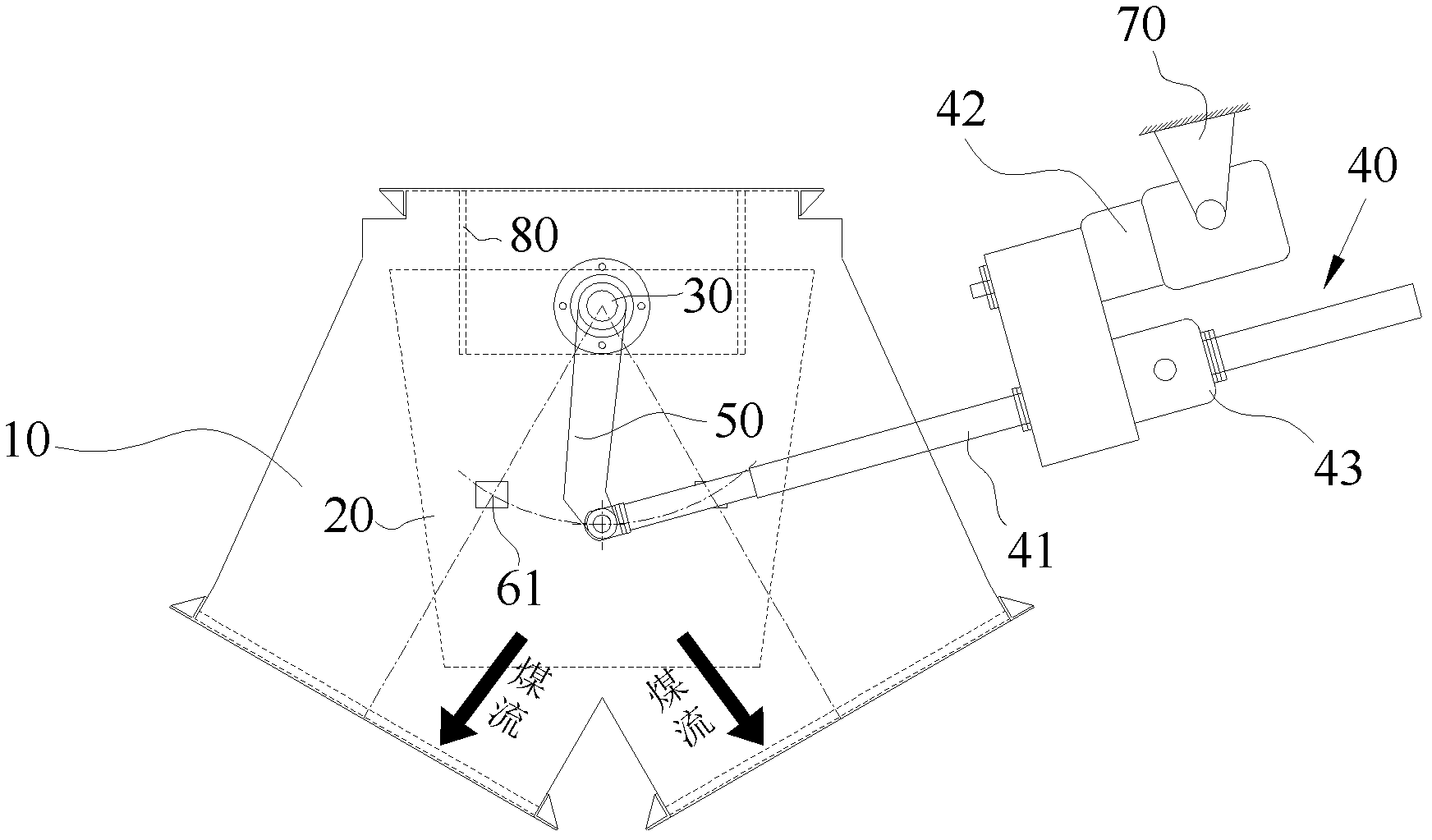

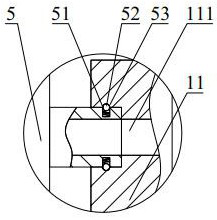

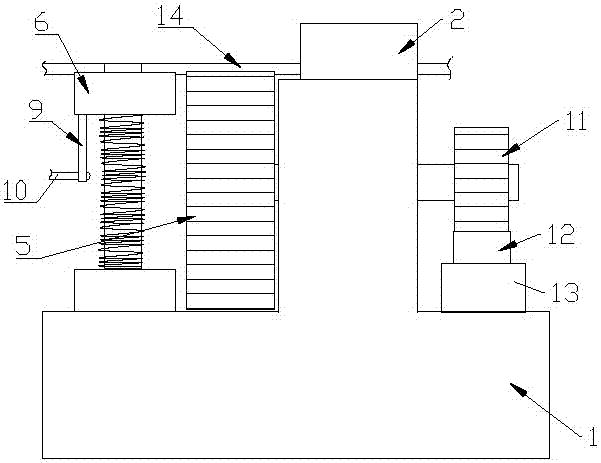

Material distribution device

InactiveCN102616560ARealize online switchingNo clogging will occurConveyor partsEngineeringMaterial distribution

The invention discloses a material distribution device which comprises a three-way material distribution pipe (10), and a material distribution barrel (20) with two opened ends, arranged in the three-way material distribution pipe (10), wherein the inlet of the material distribution barrel (20) is communicated with the inlet of the three-way material distribution pipe (10); and the outlet of the material distribution barrel (20) is selectively communicated with one or two outlets of the three-way material distribution pipe. According to the invention, the material distribution barrel is arranged in the three-way material distribution pipe, material enters from the inlet of the material distribution barrel and flows out from the outlet of the material distribution barrel, and the material blockage phenomenon can be avoided, as a result, the on-line switch of the material transportation is realized. And besides, the outlet of the material distribution barrel is communicated with the two outlets of the three-way material distribution pipe at the same time, and as a result, on-load distribution is realized during the material transportation.

Owner:CHINA SHENHUA ENERGY CO LTD +2

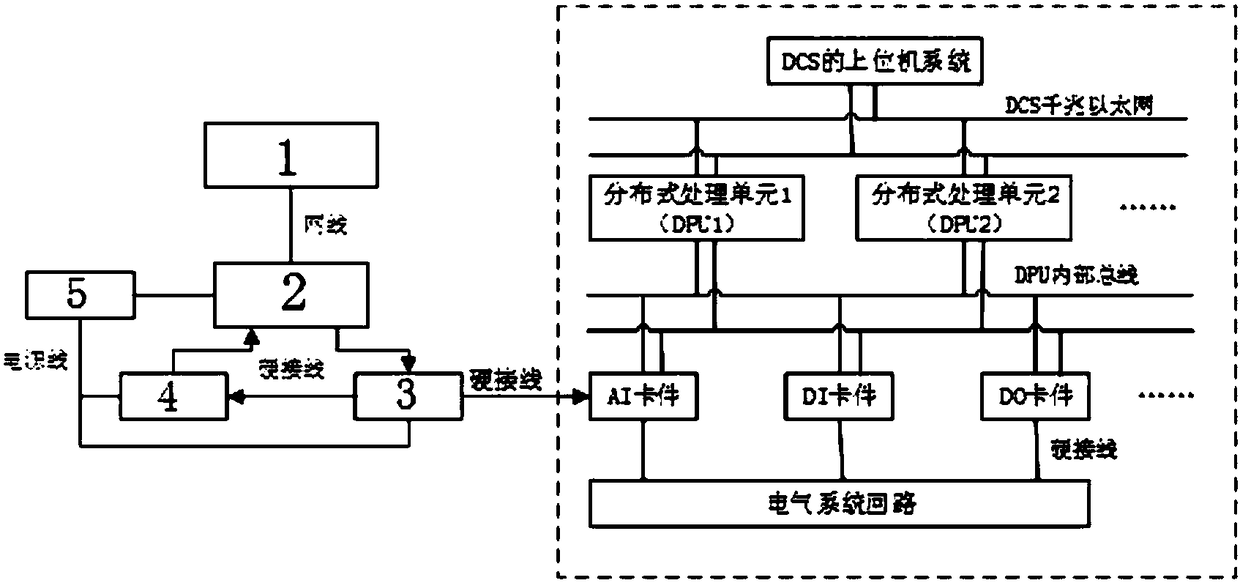

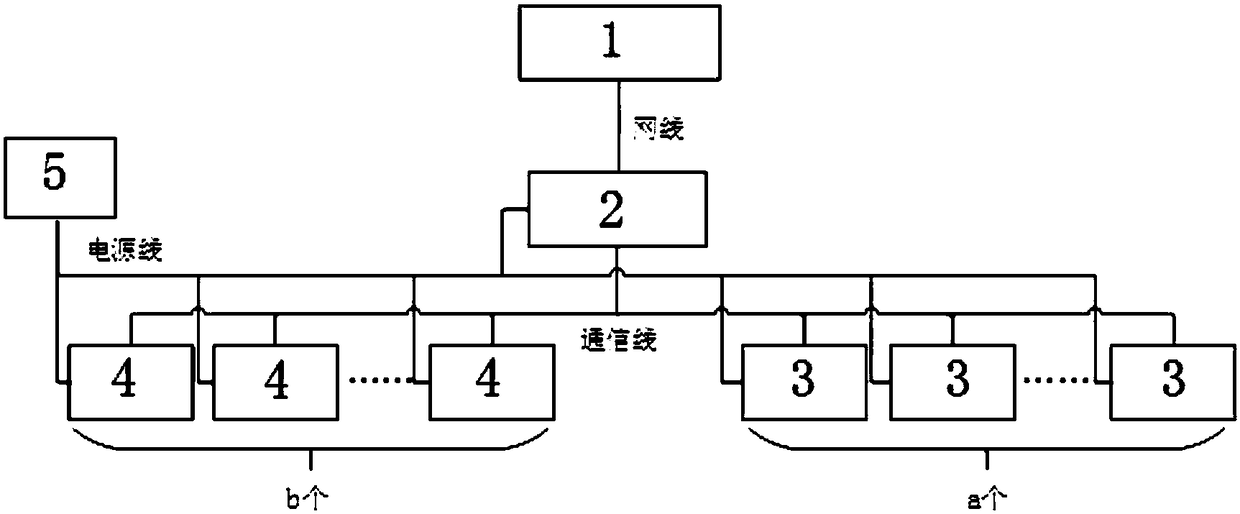

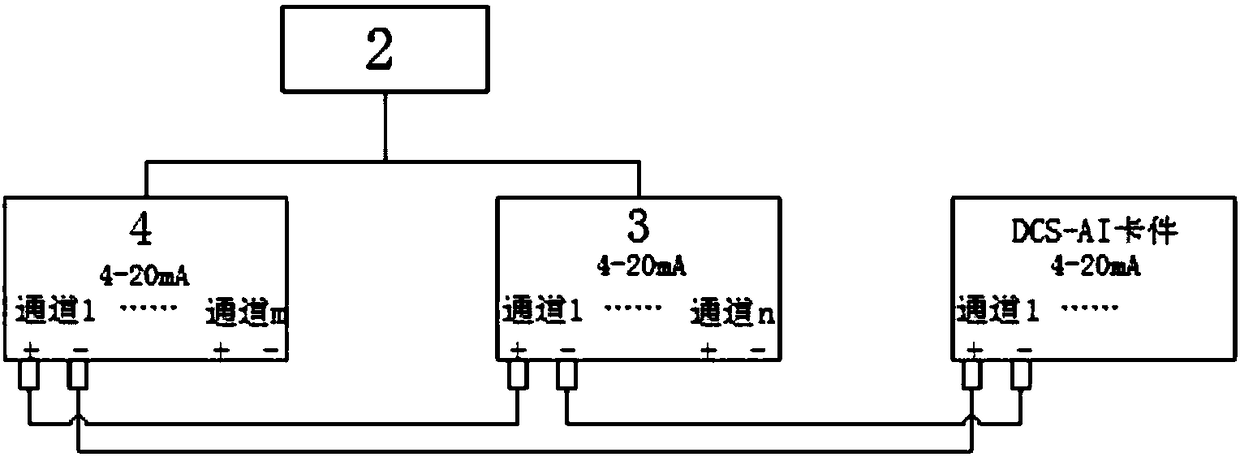

Detection system and method for validity of analog quantity output channel of power plant

PendingCN108508878ARealize online switchingReduce troubleshooting timeElectric testing/monitoringEngineeringControl theory

The invention discloses a detection system and a detection method for the validity of an analog quantity output channel of a power plant. The system comprises a controller upper computer (1), a controller (2), an analog quantity output module (3), an analog quantity input module (4) and a power source (5), wherein the controller (2), the analog quantity output module (3) and the analog quantity input module (4) are respectively connected with the power source (5) by power lines; the controller upper computer (1) is connected with the controller (2) by a cable; the analog quantity output module(3) and the analog quantity input module (4) are respectively connected with the controller (2) by an RS-485 or RS-232 serial port; and the analog quantity output module (3) and the analog quantity input module (4) are connected by hard wiring. The system and the method realize notification of the real-time state of each analog quantity output channel to the controller and a DCS, so that troubleshooting time is shortened. In addition, the invention also gives consideration to channel redundancy, and online switching is realized in malfunction of channels.

Owner:CHINA HUADIAN SCI & TECH INST

Compression level switchable compressor and use method thereof

InactiveCN106930927AExpand the scope of applicable working conditionsReduce equipment input costsPositive displacement pump componentsPipeline systemsParallel compressionComputer engineering

The invention discloses a compressor with switchable compression stages and a method for using the same, comprising a pipeline, an inlet valve and an outlet valve are arranged on the pipeline, and N parallel compressors are arranged on the pipeline between the inlet valve and the outlet valve. Pipelines, N≥2, each compression pipeline is provided with a front valve, a compression cylinder, and a rear valve in sequence; there is also a series-parallel regulating valve between any two adjacent compression pipelines, and the series-parallel regulating valve is located in the pipeline. One end is connected to the pipe between the compression cylinder and the rear valve of one of the compression lines, and the other end is connected to the pipe between the compression cylinder and the front valve of the other compression line. The compressor of the present invention can realize compression level switching.

Owner:SHANDONG KERUI COMPRESSOR

Lime kiln and control method thereof

ActiveCN111854458AAvoid mixingRealize online switchingControl devices for furnacesThermodynamicsCombustion

The invention discloses a lime kiln and a control method thereof. The lime kiln comprises an online fuel switching system, and the online fuel switching system comprises a coal gas supply device, a pulverized coal supply device, N fuel switchers and N spray guns; when fuel of all the spray guns is switched from pulverized coal to coal gas, valve bodies at pulverized coal inlets in the fuel switchers and a pulverized coal stop valve are sequentially closed, and a pulverized coal conveying fan is adjusted to be in a standby state; the operation frequency of a coal gas conveying fan is improved,after the coal gas air pressure meets the kiln entering requirement, a coal gas stop valve and the valve bodies at coal gas inlets in the fuel switchers are sequentially opened, and coal gas sequentially passes through a coal gas conveying pipeline, a coal gas ring pipe, coal gas inlets and fuel outlets of the N fuel switchers and the N spray guns and flows into a kiln chamber; and a combustion-supporting air stop valve is opened, the operation frequency of a combustion-supporting fan is adjusted, the combustion-supporting air volume is matched with the coal gas volume, and the switching process is finished. According to the lime kiln and the control method thereof, the defects that lime kiln fuel is single in type and poor in production adaptability are overcome, and lime kiln coal gas / pulverized coal online switching is achieved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

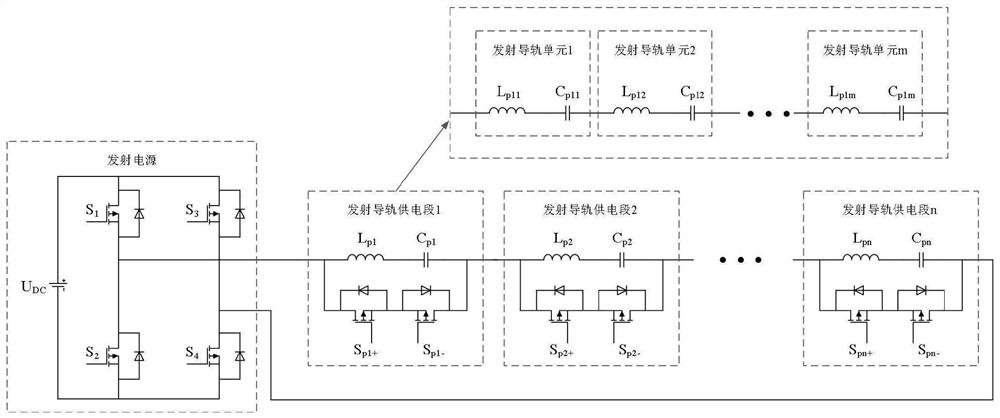

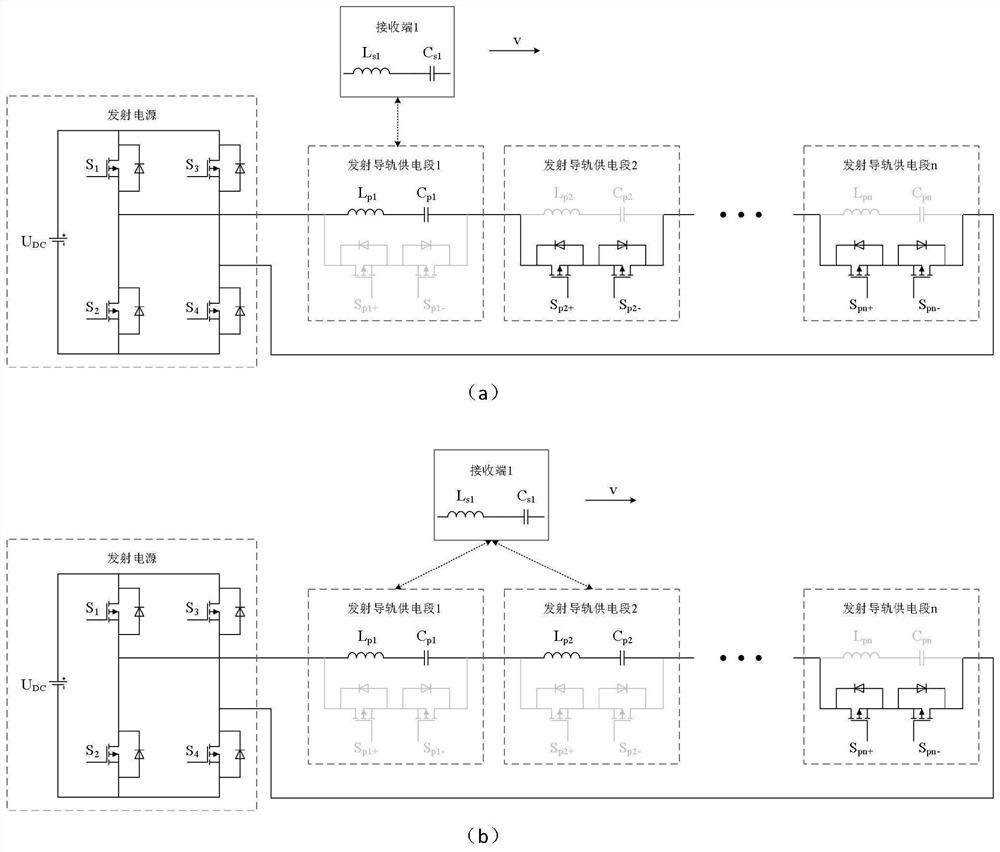

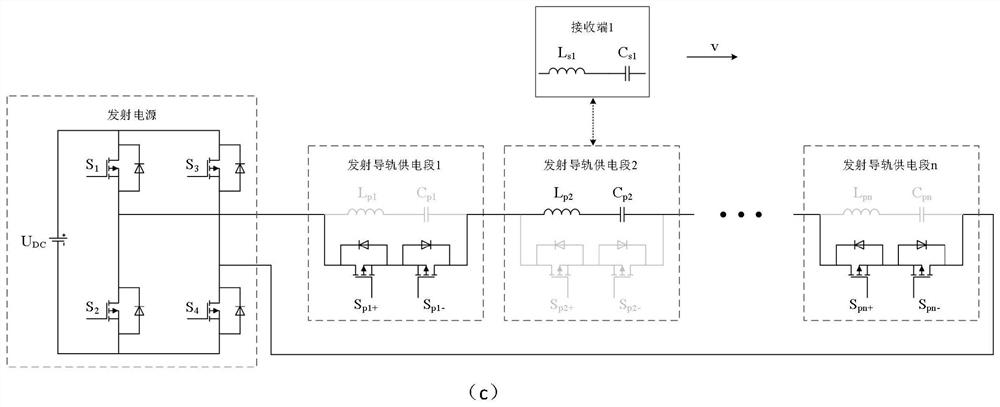

Integrated guide rail distribution switching power supply topology based on series compensation

PendingCN113595260AReduce usageLow costCharging stationsCircuit arrangementsTransmitter coilCapacitance

The invention provides an integrated guide rail distribution switching power supply topology based on series compensation. The power supply topology comprises a transmitting power supply and n transmitting guide rail power supply sections; each section of the n transmitting guide rail power supply sections comprises n transmitting guide rail units connected in series and a group of switching tubes Spn+ and Spn- which are connected in series reversely; each transmitting guide rail unit is formed by connecting a transmitting coil Lpnm and a compensation capacitor Cpnm integrated in the transmitting coil Lpnm in series; a group of switch tubes Spn+ and Spn- which are reversely connected in series are connected in parallel to the corresponding power supply sections of the transmitting guide rails; the multiplexing emission guide rail power supply section compensates for the adjacent power supply sections, and there is no need to configure a compensation inductor for each power supply section; and the multiplexing resonant capacitor compensates for the two power supply sections, and the number of capacitors is reduced. Due to high multiplexing of the system, the number of resonators is reduced, the size and cost of the system are reduced, loss is reduced, and the efficiency of the system is improved.

Owner:HARBIN INST OF TECH

External regeneration method and device for sulfur recovery device agent

PendingCN113198306AReduce processingRaise the renovation costDispersed particle separationProcess engineeringThermodynamics

The invention discloses an external regeneration method and device for a sulfur recovery device agent. Two independent external agent regenerators which are main and standby are arranged outside a reactor of the sulfur recovery device, and a regeneration distributor with a four-stage tower structure is arranged in each external agent regenerator; the regeneration distributor adopts a multi-ring equal-ratio gas distribution structure, a pore gas distribution disc and a gas distribution film are arranged on a gas distribution pipe of the regeneration distributor, and a solution flows out of a reactor reaction area of the sulfur recovery device and flows into an external agent regenerator from a downcomer for regeneration, and overflows to a reactor settling area of the sulfur recovery device through an agent outlet at the top of the external agent regenerator, so as to form agent absorption and regeneration cycle. The independent external regenerator is established, a special gas distribution disc, a gas distribution film regeneration distributor and a steam stripping technology are applied to complete agent circulation, and an external agent regeneration technology of the whole sulfur recovery device is formed, so that the utilization rate of regenerated air and the agent regeneration efficiency can be effectively improved, the sulfur blockage probability can be reduced, and the long-period operation of the sulfur recovery device can be realized.

Owner:扬州石化有限责任公司

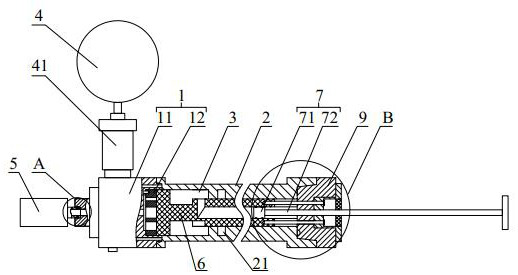

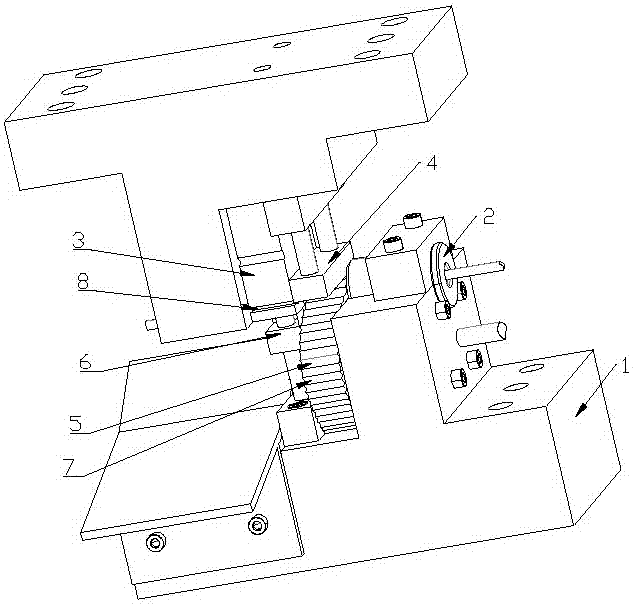

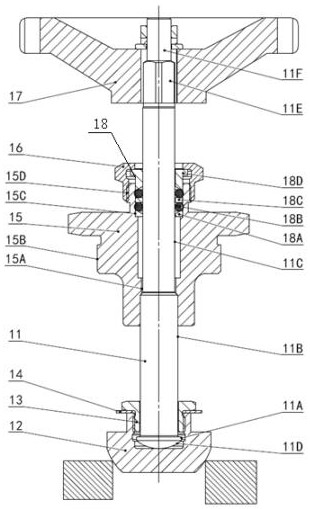

Valve grease injection tool

ActiveCN113751290AAchieve regulationRealize online switchingLiquid surface applicatorsCoatingsThermodynamicsVALVE PORT

The invention relates to the technical field of petroleum and natural gas pipeline valve maintenance, in particular to a valve grease injection tool which comprises a confluence mechanism and a grease injection cylinder which are rotationally connected, and further comprises a pressure monitoring mechanism, a plurality of runners are arranged in the confluence mechanism, a grease injection channel is arranged in the grease injection cylinder, and the confluence mechanism and the grease injection cylinder are coaxially rotated. The grease injection channel can communicate with one of the flow channels; and the pressure monitoring mechanism is used for monitoring the pressure in the grease injection channel, so that the grease injection flow can be adjusted by adjusting the grease injection channel to communicate with different runners, the grease injection flow can be adjusted in real time in the grease injection process, the operation procedure is simple, meanwhile, the overpressure condition is effectively avoided, it is guaranteed that the grease injection process is smoothly carried out, one grease injection tool can meet various valves with different sealing grease demands, the application range of the single grease injection tool is expanded, the number of parts is reduced, and the use reliability is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

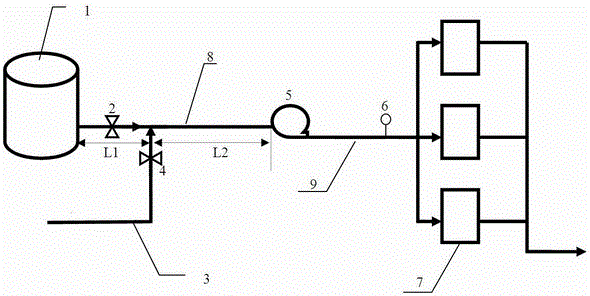

A slurry-water online switching method in a long-distance slurry pipeline transportation system

ActiveCN104197197BGuaranteed continuityImprove delivery efficiencyPipeline systemsSlurry pipelineLine switching

The invention provides an on-line switching method for slurry and water in a long-distance slurry pipeline transportation system. The method comprises the following steps that first, the flow of main pumps is reduced to the minimum value, and meanwhile the rotating speed of a feeding pump is increased to a full rotating speed; second, a stirring tank outlet valve is closed step by step, a water valve is opened, closing is suspended when the stirring tank outlet valve is closed by a half or so, and the water valve is continued to be opened; third, after the water valve is completely opened, the stirring tank outlet valve is closed; fourth, after the stirring tank outlet valve is completely closed, the rotating speed of the feeding pump is reduced, and the flow of the feeding pump is made to be matched with the flow of the main pumps; fifth, the flow of the main pump is increased to the normal working flow. According to the on-line switching method for the slurry and water in the long-distance slurry pipeline transportation system, the relation between the distance from the water valve to a stirring tank and the distance from the water valve to the feeding pump is taken into full consideration, innovation is carried out on the opening and closing relation between the water valve and the stirring tank outlet valve, slurry and water switching is stably achieved, the phenomenon that main pumps may be shut down during slurry and water switching is completely avoided, and slurry and water switching efficiency and slurry pipeline transportation efficiency are improved.

Owner:YUNNAN DAHONGSHAN PIPELINE

Rod punching and shearing die

The invention relates to a rod punching and shearing die and relates to the field of mechanical punching and shearing. The rod punching and shearing die comprises a base, a material guiding mechanism and a material breaking mechanism. The material guiding mechanism comprises a material guiding sleeve installed on the base. The material guiding sleeve is internally provided with a material guiding hole allowing a rod to penetrate through. An inlet of the material guiding hole is in a flaring shape. The material breaking mechanism comprises a dynamic material breaking mechanism body and a static material breaking mechanism body. The dynamic material breaking mechanism body is installed on a punch and comprises an upper punching and shearing block and an upper pressing unit. The upper pressing unit comprises an upper pressing block. The static material breaking mechanism body comprises a lower punching and shearing block and a lower pressing unit. The lower punching and shearing block is rotationally connected to the base and is round. Punching and shearing grooves are circumferentially formed in the edge of the lower punching and shearing block. A rotating shaft is fixedly connected to the center of the lower punching and shearing block. A driven gear is coaxially connected to the rotating shaft. A rack is arranged on the driven gear in an engaged mode. An air cylinder is connected to the end of the rack. A lower pressing block is provided with a punching groove. By implementing the scheme, on-line switching of cutters and leveling of the rod sections in the prior art are achieved, and the problem that the cut positions of rods are deformed is solved.

Owner:重庆永丰精气汽车配件有限公司

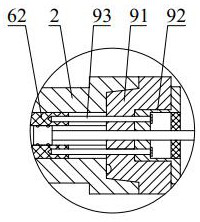

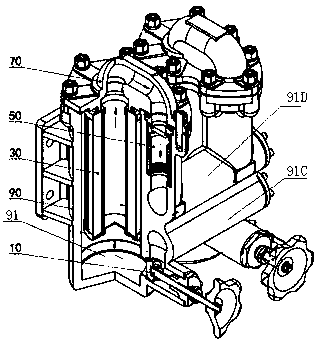

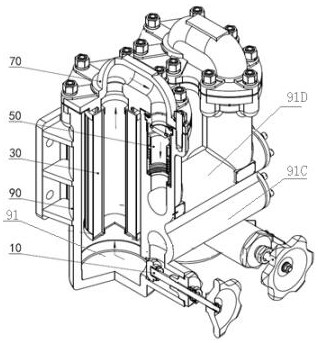

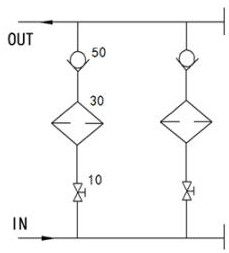

Fuel oil filter applied to gas turbine

ActiveCN109695507ACompact structureGuaranteed sealing performanceTurbine/propulsion fuel valvesGas turbinesFuel oil

The invention discloses a fuel oil filter applied to a gas turbine. The fuel oil filter applied to the gas turbine includes a filter shell body, the filter shell body is provided with an inlet main pipe and an outlet main pipe, the inlet main pipe is correspondingly connected with one ends of two stop valves installed in the filter shell body, the other ends of the stop valves are connected to thebottom ends of filter drums, filter elements are arranged in the filter drums, and the upper ends of the filter drums are connected to one ends of check valves through filter covers, the other ends of the check valves are connected with the outlet main pipe, the number of the filter drums, the filter elements, the filter covers and the check valves are all two, and the filter drums, the filter elements, the filter covers and the check valves are all symmetrically arranged in the filter shell body. According to the fuel oil filter applied to the gas turbine, the problems of a large size, poorreliability, high noises during vibration, no shock and vibration resistance design and the like of an existing filter structure are solved, and the requirements of filtering performance, a compact structure, on-line switching and replacement of the filter elements, shock and vibration resistance, high reliability and the like of a gas turbine fuel oil system are met.

Owner:中国船舶重工集团公司第七0七研究所九江分部

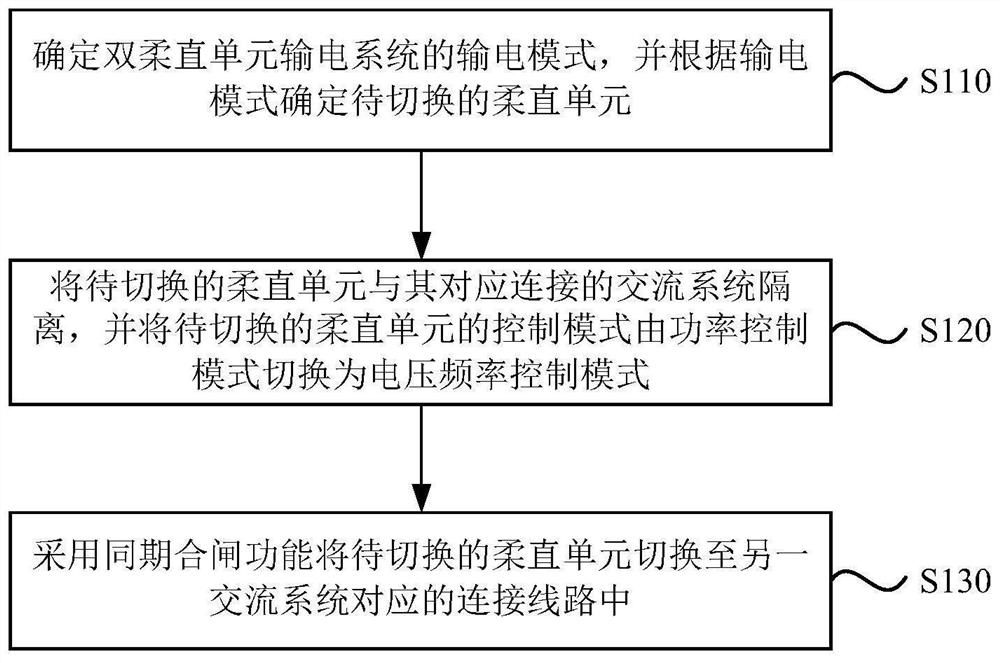

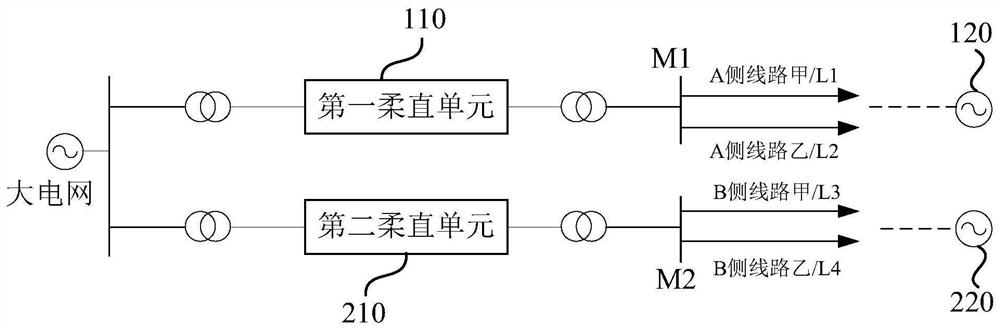

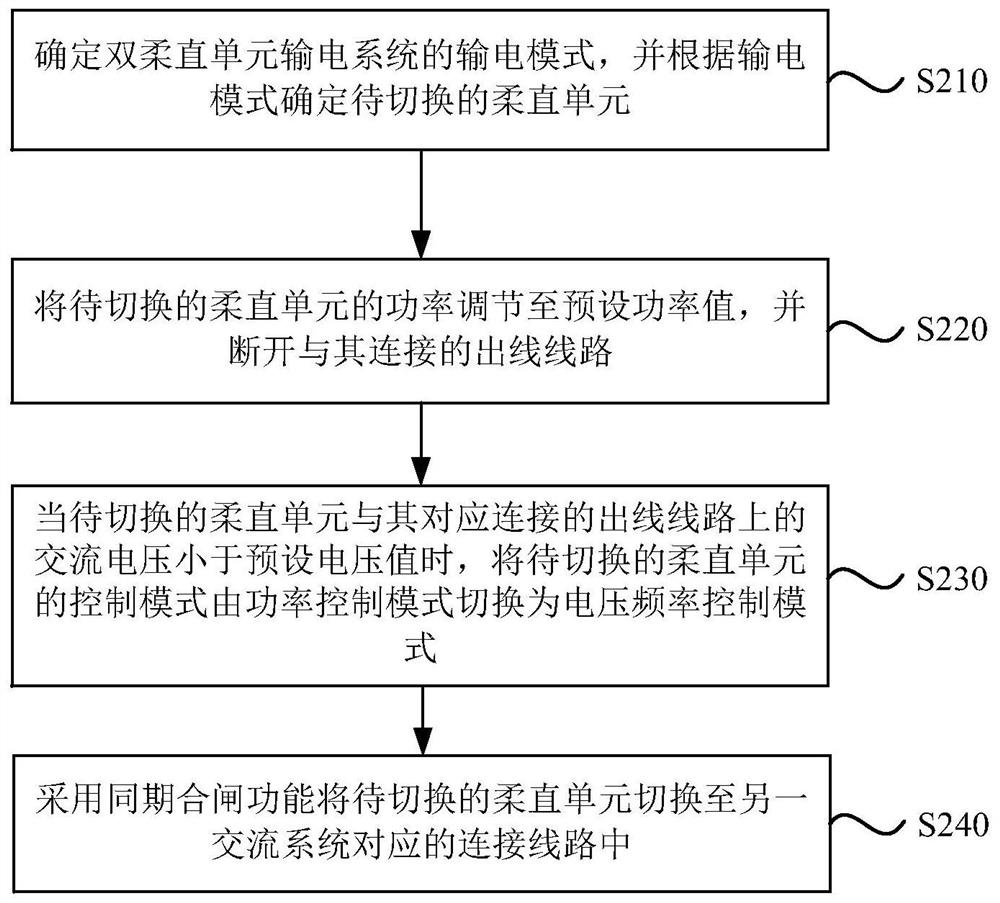

Double flexible direct current unit power transmission system and power transmission mode switching method thereof

PendingCN113746195AAvoid latching operationsReduce switching complexityElectric power transfer ac networkDc source parallel operationPower controlEngineering

The invention discloses a double flexible direct current unit power transmission system and a power transmission mode switching method thereof. The switching method comprises the following steps: determining a power transmission mode of the double flexible direct current unit power transmission system, and determining a to-be-switched flexible direct current unit according to the power transmission mode, wherein the power transmission mode comprises a distribution mode and a combined transmission mode; isolating the flexible direct current unit to be switched from an alternating current system correspondingly connected with the flexible direct current unit, and switching the control mode of the flexible direct current unit to be switched from a power control mode to a voltage frequency control mode; and switching the flexible direct current unit to be switched to a connecting line corresponding to another alternating current system by adopting a synchronous switching-on function. Compared with the prior art, the technical scheme provided by the invention can realize on-line switching of the power transmission mode of the double-flexible direct-current unit power transmission system, avoids locking operation on the flexible direct-current units, and is beneficial to reducing the switching complexity, so that the operation efficiency of an operator can be improved, and the operation burden of the operator is reduced.

Owner:GUANGDONG POWER GRID CO LTD +1

A hot pickling production process for stainless steel

ActiveCN107983770BRealize online switchingReduce manufacturing costWork treatment devicesMetal rolling arrangementsElectrolysisStrip mill

The invention provides a hot acid pickling production process of stainless steel. The hot acid pickling production process comprises the following steps of (1) uncoiling, wherein uncoilers are adoptedfor uncoiling a steel coil raw material; (2) cutting, wherein hydraulic scissors are adopted for shearing off unqualified steel strips; (3) welding, wherein a laser welding machine is adopted for welding the heads and the tails of steel strips obtained through shearing; (4) rolling, wherein the steel strips enter three rolling machines to be continuously rolled; (5) degreasing, wherein degreasingequipment is adopted for removing surface rolling oil and oxidized scales for the rolled steel strips; (6) annealing, wherein the steel strips enter an annealing furnace for annealing from a middle loop; (7), scale removal, wherein a scale breaker is adopted for carrying out scale removal on the annealed steel strips; (8) grinding and cleaning, wherein grinding and cleaning equipment is adopted for grinding and cleaning the steel strips obtained after scale removal; (9) electrolysis, wherein the ground and cleaned steel strips enter an electrolytic area to be electrolyzed; (10) acid pickling,wherein the electrolyzed steel strips enter an acid pickling area for acid pickling; and (11) coiling, wherein the steel strips obtained after acid pickling are coiled through a coiling machine. According to the hot acid pickling production process, the acid amount is reduced, environment pollution is relieved, and the product surface is smooth and full of gloss.

Owner:福建宏旺实业有限公司

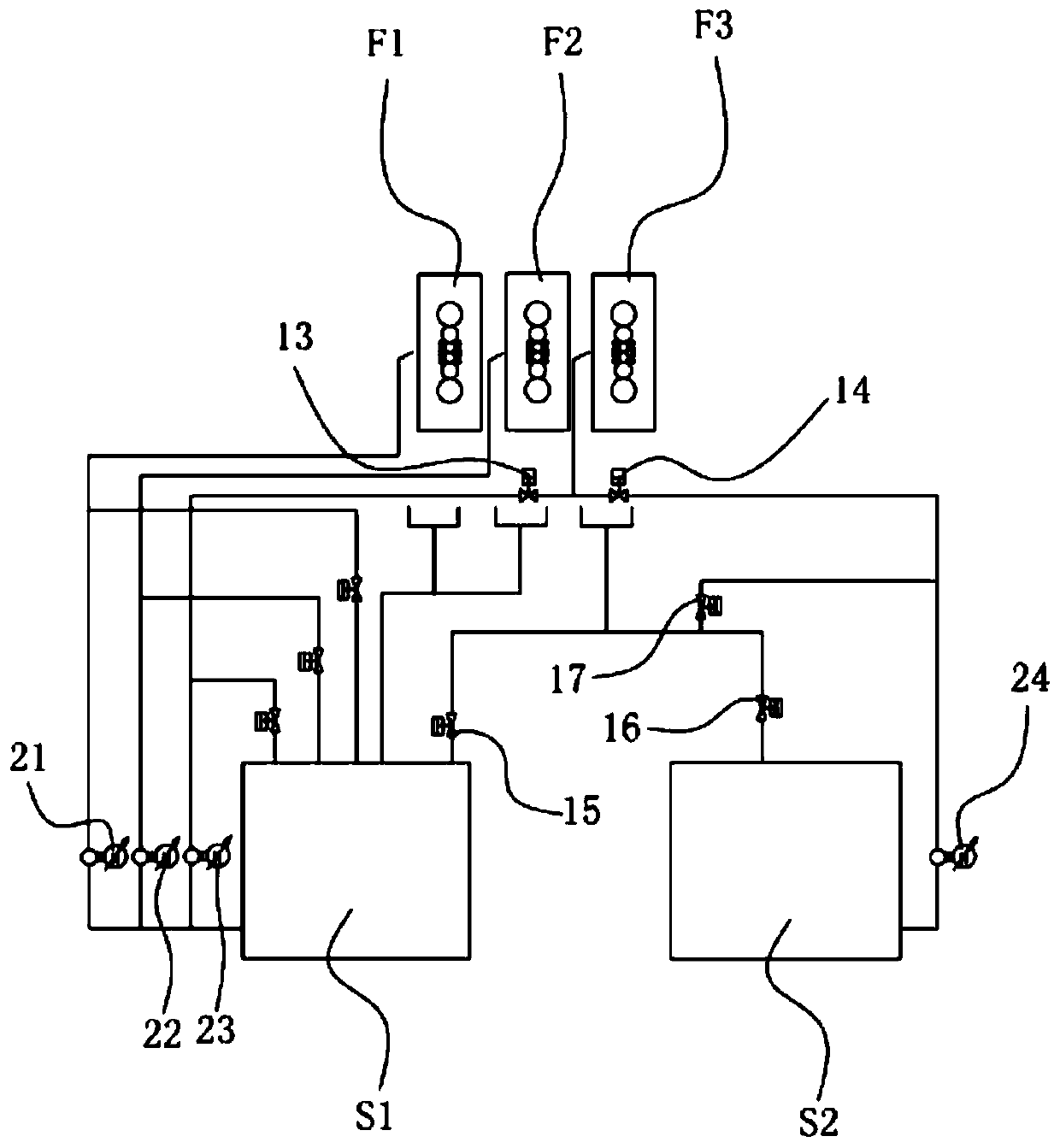

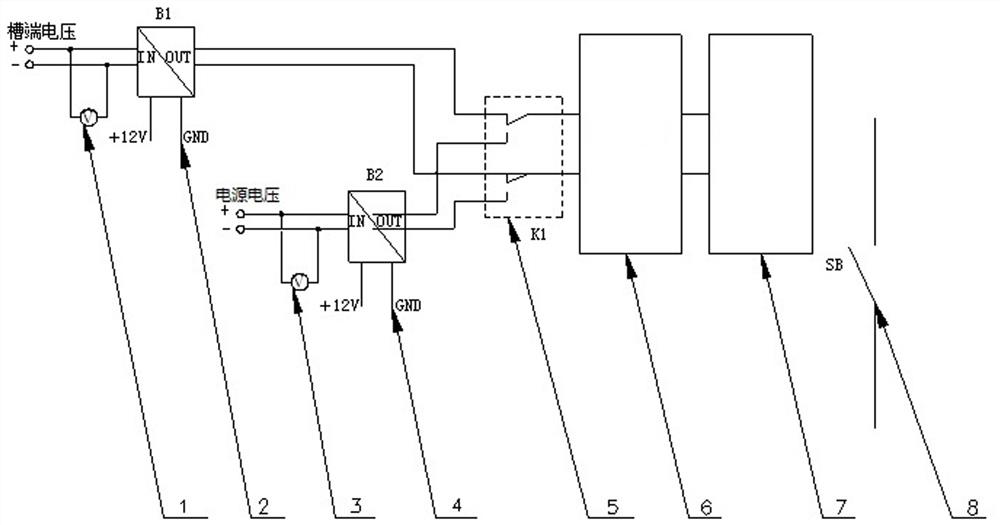

Feedback system of aluminum foil last-stage formation electrolysis power supply and feedback method thereof

PendingCN114415500ASimple structureReasonable designAnodisationAdaptive controlControl systemDc voltage

The invention discloses a feedback system and a feedback method of an aluminum foil last-stage formation electrolysis power supply. The system comprises a cell end voltmeter, a cell end voltage electric quantity isolation sensor, a machine end voltmeter, a machine end voltage electric quantity isolation sensor, a relay, a circuit unit adjusting unit, a change-over switch SB, an electrolytic cell A and an electrolytic cell B, when in use, the cell end voltage is connected to the cell end voltmeter and the cell end electric quantity isolation sensor and then is connected with the relay, a high-voltage direct-current voltage signal of the cell end voltage is converted into a direct-current low-voltage signal of 0-10V through the cell end electric quantity isolation sensor, and the direct-current low-voltage signal is input into the circuit unit of the electrolytic power supply for processing; and then the voltage is transmitted to the adjusting unit for comparison processing, the feedback voltage value is compared with the given voltage of the electrolytic power supply, and the adjusting control system of the electrolytic power supply adjusts the magnitude of the pulse trigger signal of the electrolytic power supply according to the compared data, so that the voltage-stabilized or current-stabilized operation of the electrolytic power supply is realized.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

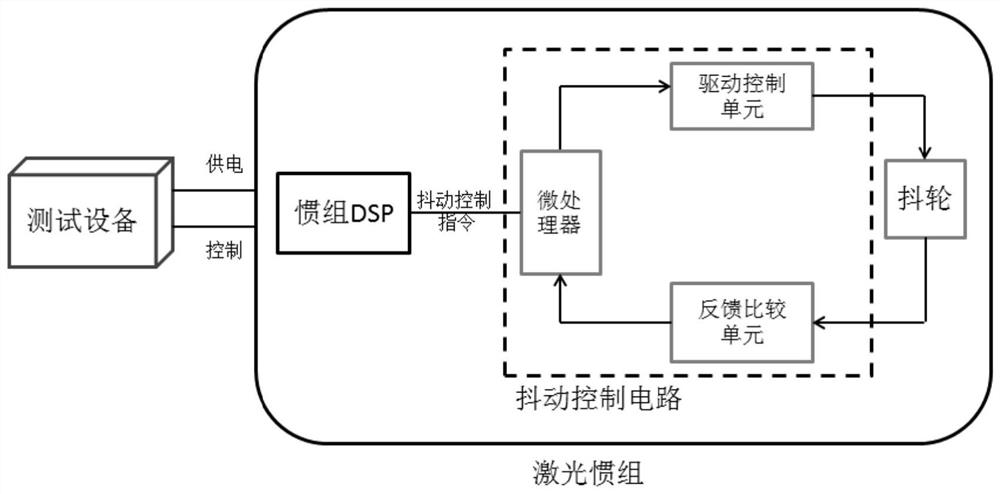

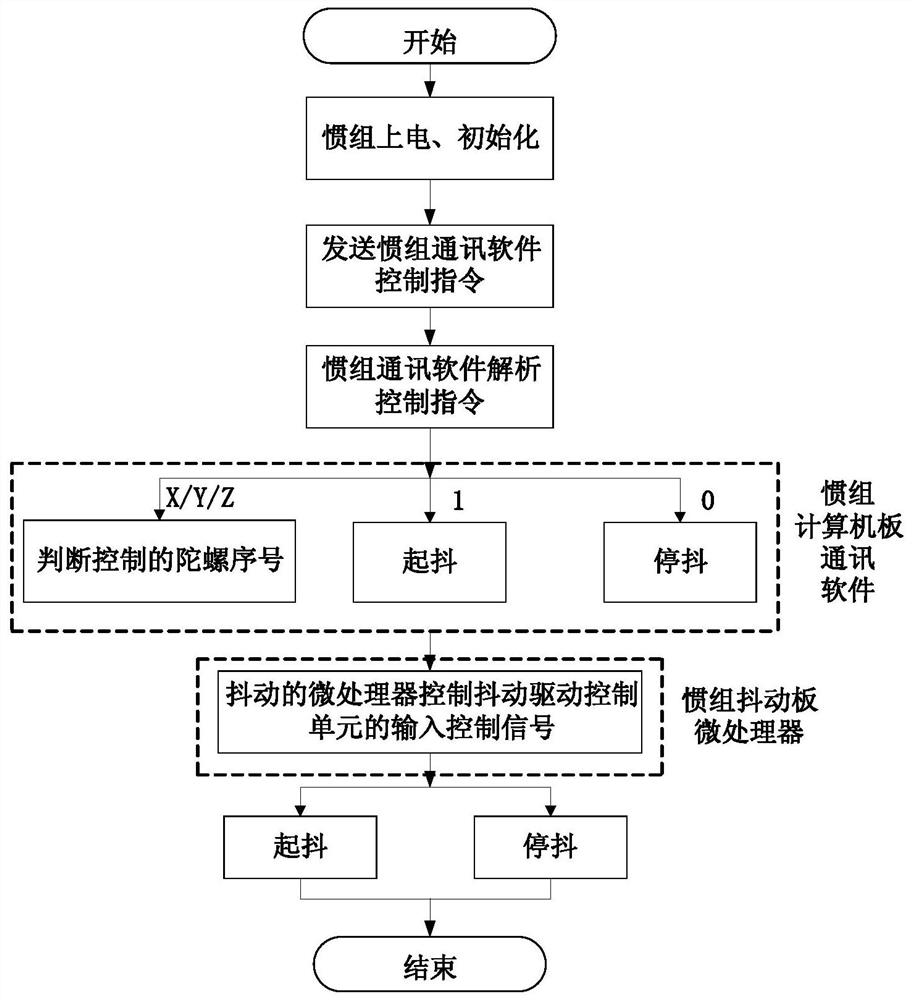

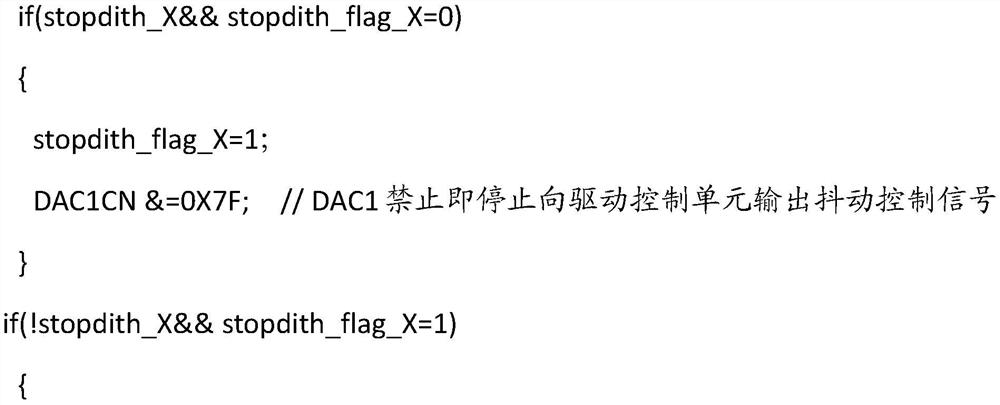

Jitter control method of laser inertial measurement unit

ActiveCN112284411AAchieve autonomous controlEasy to testMeasurement devicesTotal factory controlGyroscopeControl signal

The invention discloses a jitter control method of a laser inertial measurement unit. The method comprises the following steps: (1) a laser inertial measurement unit communication protocol is designed; (2) test equipment sends a control instruction to inertial measurement unit communication software; (3) the inertial measurement unit communication software sends a control instruction to a jitter control circuit according to the received control instruction; (4) a microprocessor of the jitter control circuit judges the gyro serial number and the jitter control content according to the control instruction of the inertial measurement unit communication software; and (5) the microprocessor of the jitter control circuit realizes the independent jitter control of three gyroscopes by controllingthe on-off of jitter control signals of three drive control units. By sending a jitter control instruction to the laser inertial measurement unit communication software, the independent control over the online jitter of three laser gyroscopes is achieved, and the online switching of different jitter methods of the gyroscope is achieved.

Owner:BEIJING AEROSPACE ERA LASER NAVIGATION TECH CO LTD

A chemical vapor deposition system, gas supply device and gas supply method

ActiveCN110529736BRealize online switchingStable air supplyPipeline systemsThermodynamicsProcess engineering

The invention provides a chemical vapor deposition system, a gas supply device and a gas supply method, the gas supply device includes a terminal main pipe, a first gas supply pipeline and at least one spare gas supply pipeline; the first gas supply pipeline includes a mixed gas supply Branch line, process gas supply branch line, gas mixing container and sixth electromagnetic pneumatic valve, process gas supply branch line includes process gas storage container, high-purity filter, fourth electromagnetic pneumatic valve, fifth electromagnetic pneumatic valve, third pressure transmitter , a first mass flow meter, a first purge gas pipeline and a second purge gas pipeline; the spare gas supply pipeline is the same as the first gas supply pipeline. The gas supply device of the chemical vapor deposition system of the present invention can realize on-line switching and stable, safe and continuous gas supply, and ensure the stability of process gas supply during the chemical vapor deposition process.

Owner:安徽光智科技有限公司

Storage takeover and switching processing method and device

ActiveCN106557276BRealize online switchingFix bugsInput/output to record carriersMemory adressing/allocation/relocationComputer networkEngineering

Owner:ZTE CORP

Train unmanned system and method

ActiveCN103010230BReal-time reflection analysisEasy to analyzeLocomotivesDriver/operatorInterference resistance

The invention discloses a train unmanned system and a train unmanned method, belonging to the field of traffic control. The system comprises a sensor, an automatic train protecting system connected with the sensor, a train-mounted recording system connected with the automatic train protecting system, an automatic train driving system connected with the automatic train protecting system, and a man-machine interaction system connected with the automatic train protecting system. By utilizing the system and the method, the precise control on the unmanned operation process of a train is realized, misoperation caused by artificial factors is reduced, the interference resistance is good, the working intensity of drivers is reduced, the security in train operation is improved, the departure interval of trains is shortened, and the operation efficiency of train routes is improved.

Owner:TRAFFIC CONTROL TECH CO LTD

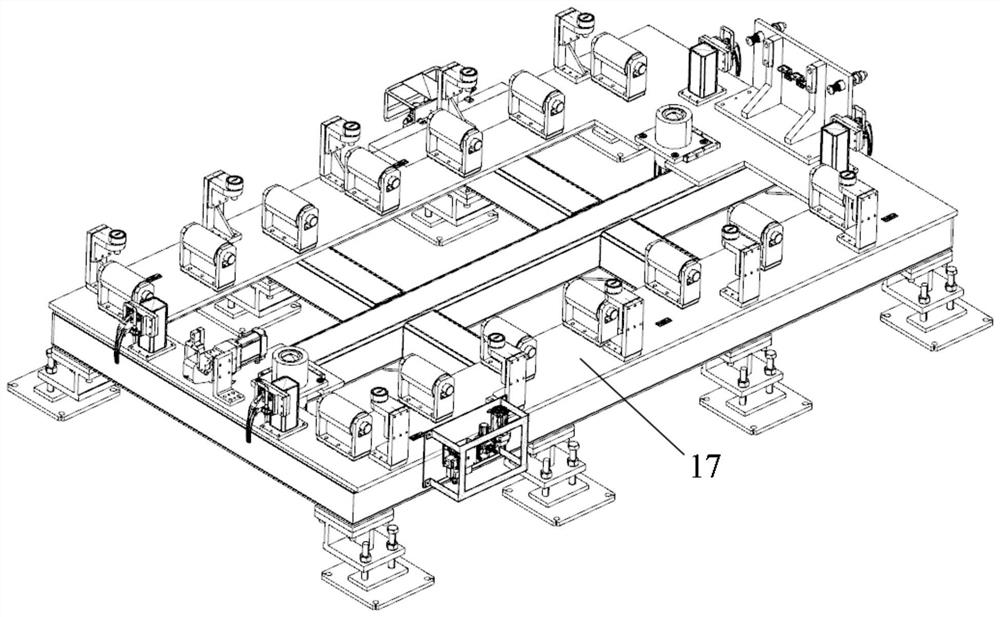

A Lightweight and Highly Flexible Roof Beam Tailored Welding Station

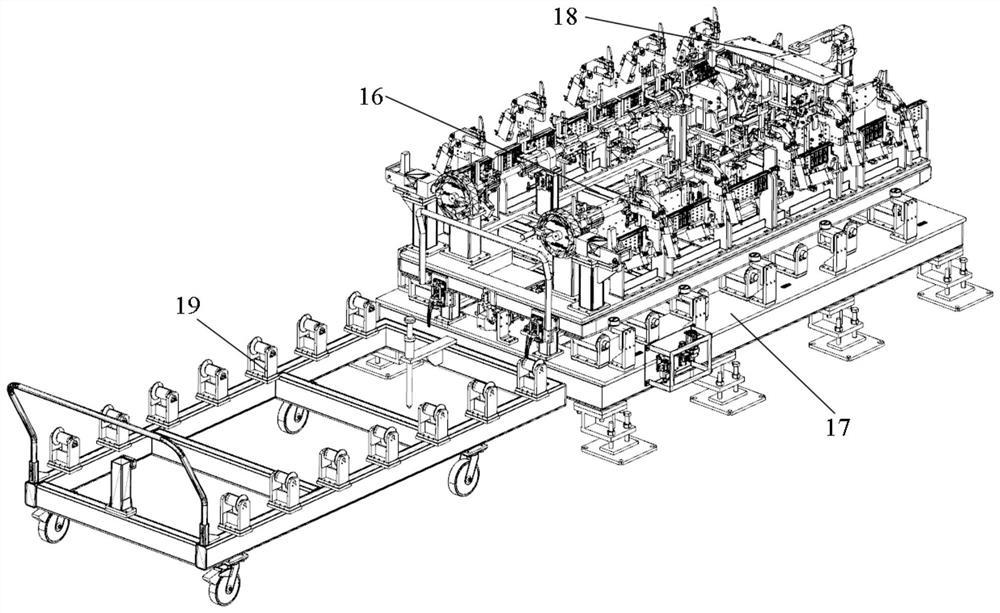

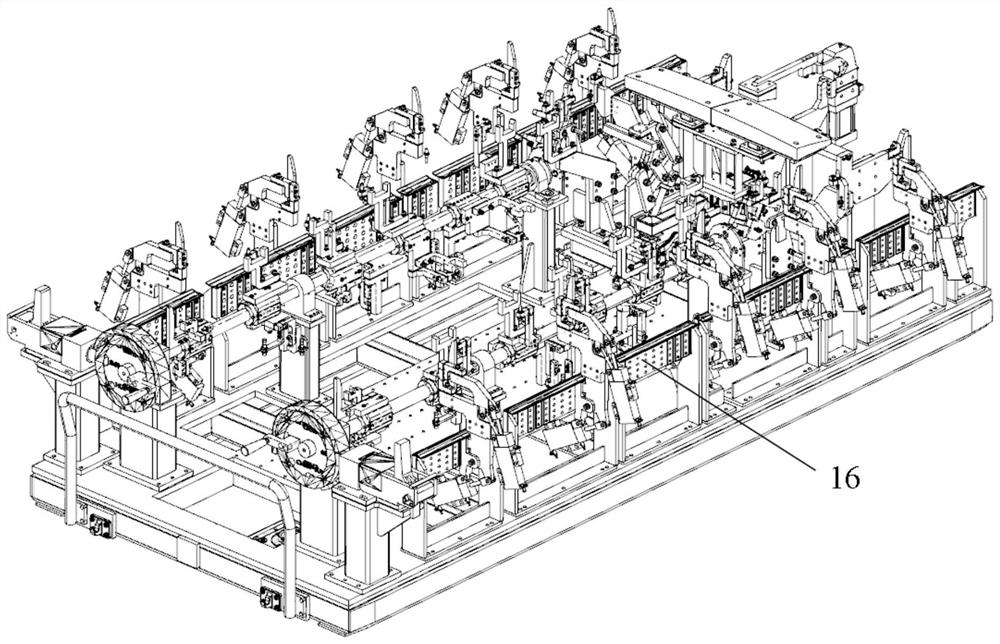

ActiveCN111774781BLower working heightCompact designWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSunroof

The invention discloses a light-weight and highly flexible top cover beam tailoring welding station, which comprises a rotary switching device, a skylight outer plate pressing mechanism, a skylight positioning assembly, a beam positioning assembly, a top cover outer plate positioning and pressing assembly, and a pushable flexible The bottom plate, two sets of rotary switching devices extend along the front and rear direction and are arranged on the left and right sides of the pushable flexible bottom plate, the positioning and pressing components of the outer plate of the top cover are set on the outside of the two sets of rotary switching devices and fixed on the pushable flexible bottom plate, The sunroof outer panel pressing mechanism is arranged between two sets of rotating switching devices and is arranged on the front part of the pushable flexible base plate. The skylight positioning assembly and the beam positioning assembly are switchably and symmetrically arranged on the two groups of rotating switching devices respectively. A light-weight and highly flexible roof beam tailor-welding station of the present invention is applicable to the welding of roof assemblies of various models and has a simplified structure, low cost, light weight, fast transfer of the whole line, and the working surface is off the ground The height is low, and the switching model is convenient and quick.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

A fuel filter applied to a gas turbine

ActiveCN109695507BRealize online switchingCompact structureTurbine/propulsion fuel valvesFuel filterControl theory

Owner:中国船舶集团有限公司第七零七研究所九江分部

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com