A Lightweight and Highly Flexible Roof Beam Tailored Welding Station

A highly flexible and lightweight technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult switching, high working surface height from the ground, and difficult migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

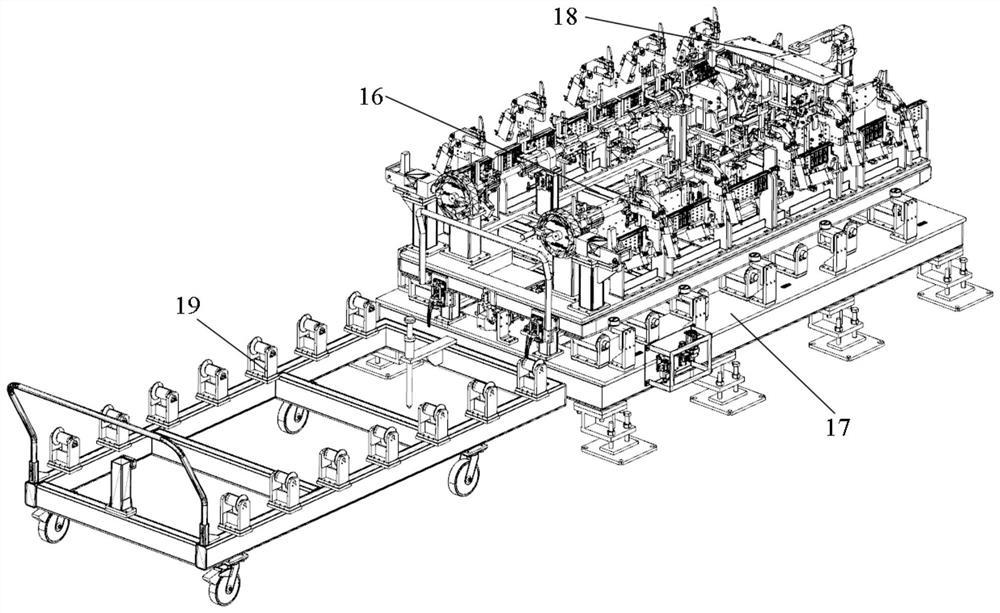

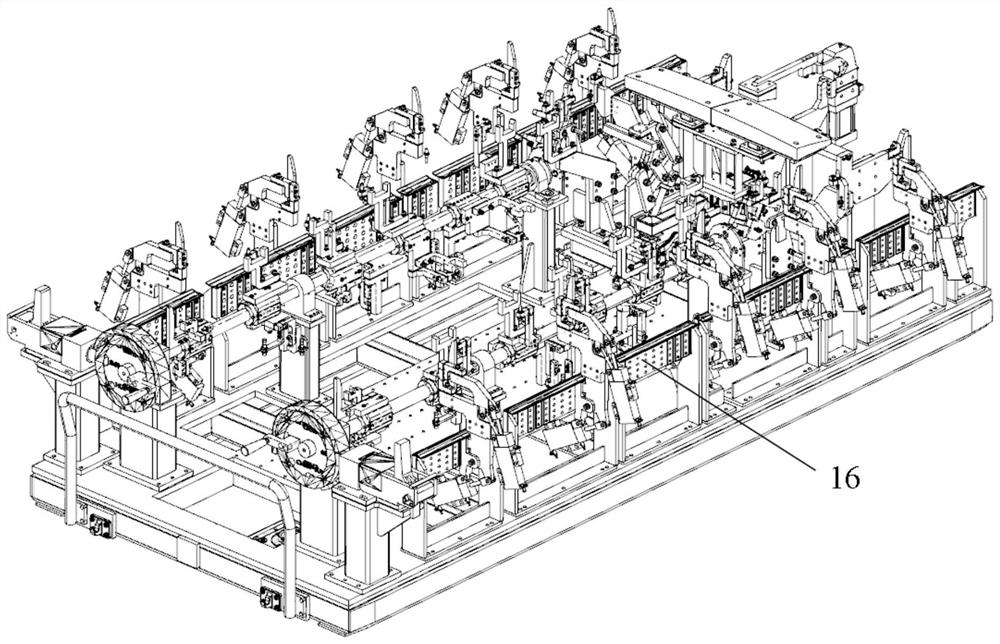

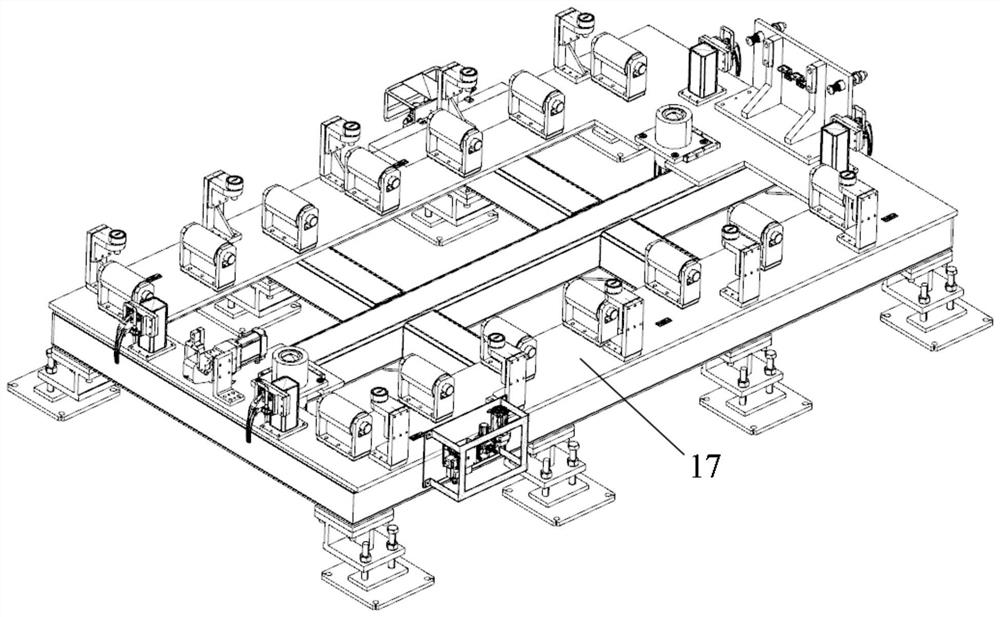

[0046] Combined below Figures 8 through 15 , a lightweight highly flexible top cover beam welding table of the present invention is further elaborated. The present invention describes the direction (up, down, left, right, front, back, inside and outside) when it is Figure 12 The structure shown in is described by reference, but the actual direction of use of the present invention is not limited thereto. Wherein, the dock is positioned to lock the mechanism 7 on the front side, the flexible base plate 1 can be pushed on the rear side; caster 12 on the inside, guide device 13 on the outside.

[0047] A lightweight highly flexible top cover beam soldering table of the present invention, please refer to Figures 8 through 15, including two sets of symmetrically set of rotary switching device 2, a set of skylight panel compression mechanism for positioning the compression of the roof window 3, a multi-group sunroof positioning component for locating the sunroof reinforcement frame of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com