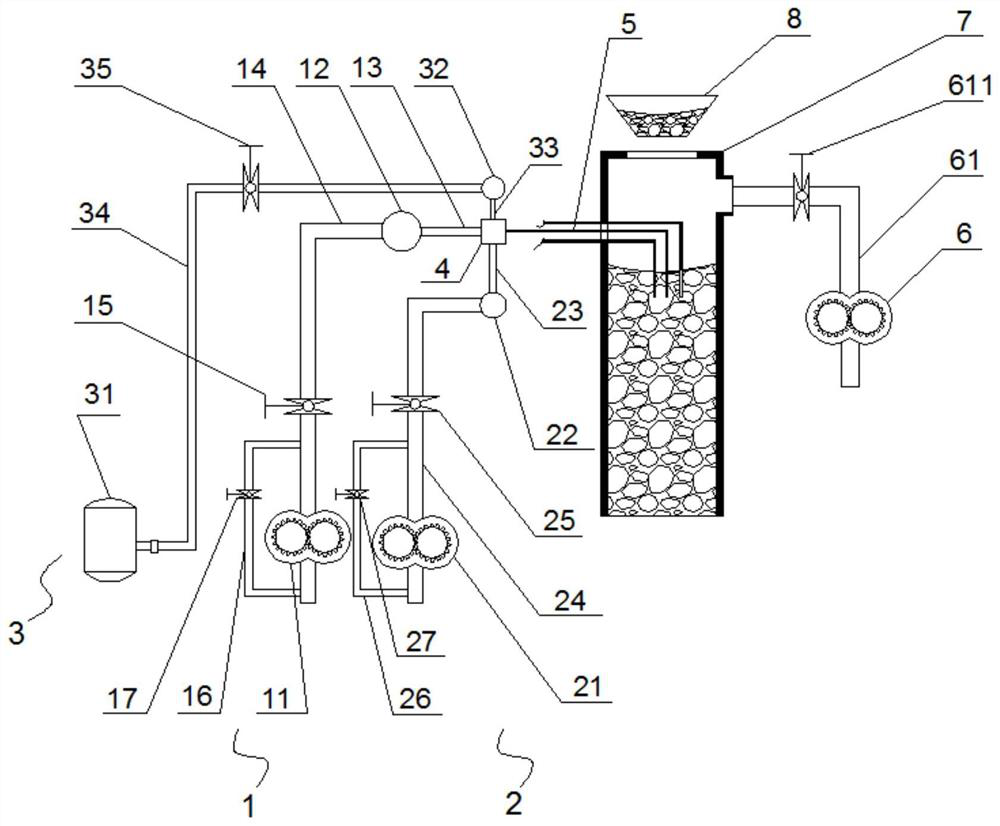

Lime kiln and control method thereof

A kiln chamber and gas technology, applied in the lime kiln field, can solve the problems of single fuel type and poor production adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

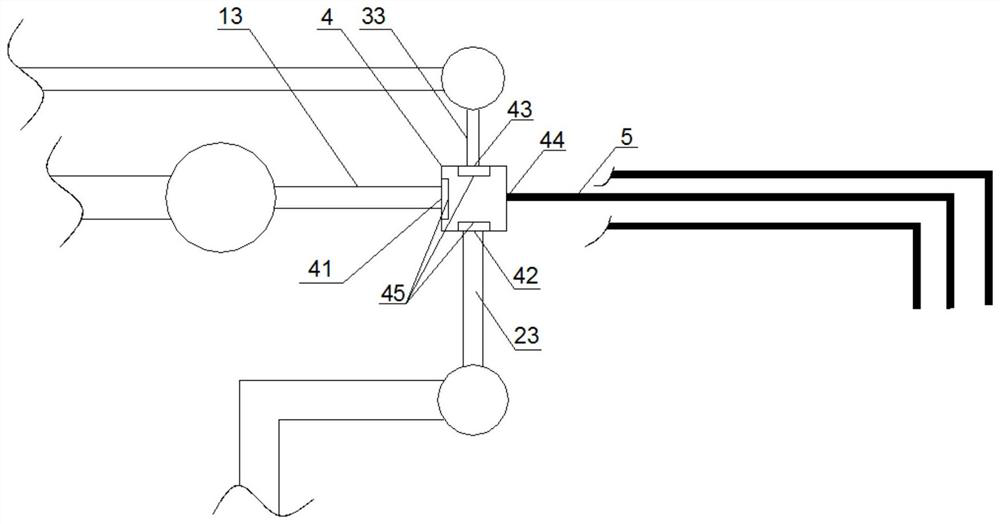

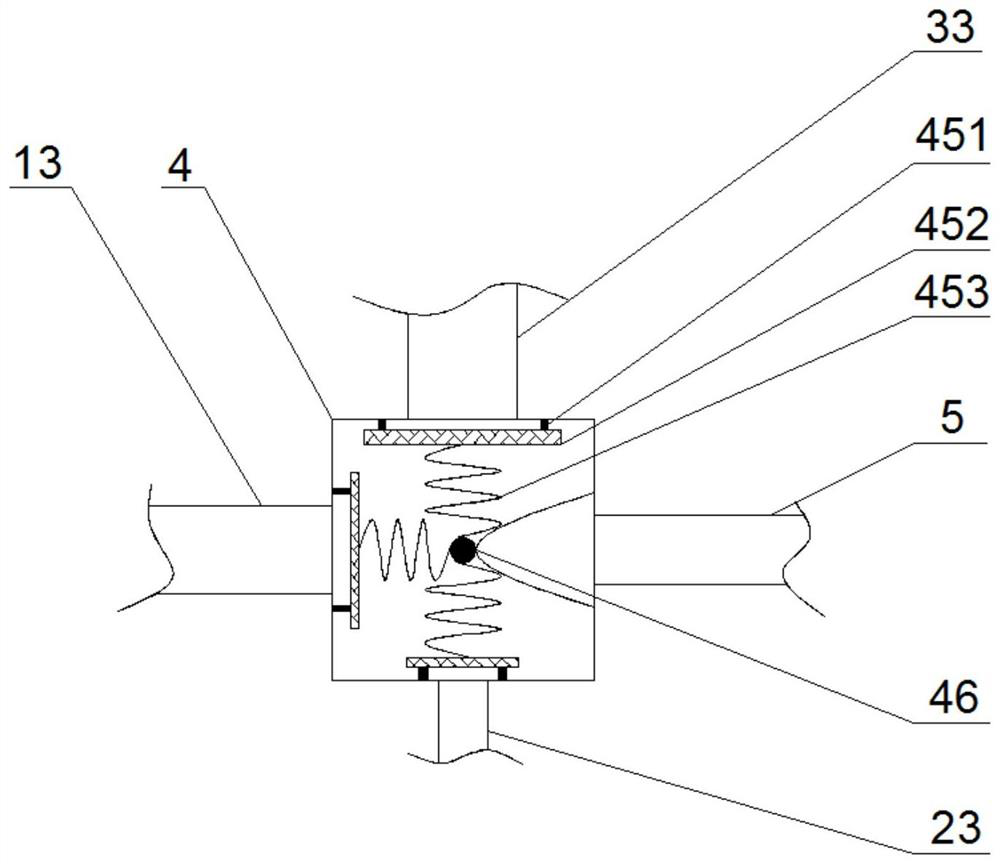

Embodiment 1

[0077] In the first embodiment, the mutually independent gas supply device 1 and the pulverized coal supply device 2 share a set of spray gun groups composed of N spray guns 5. When coal gas is used for heating with priority, when the gas pressure is too low due to large gas fluctuations, It is possible to determine whether to switch some of the N spray guns to pulverized coal fuel by detecting the pressure of the gas ring pipe and the internal pressure of the kiln, and obtain the position of the spray gun for switching the pulverized coal fuel and the number of spray guns N x , N x is less than the total number of spray guns N, so as to realize the composite and uniform heating of the two fuels. The specific implementation method can refer to other patent documents submitted on the same day as this application, and will not be repeated in this application specification. This gas-coal composite heating mode not only requires that the fuel of N spray guns can be switched synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com