A slurry-water online switching method in a long-distance slurry pipeline transportation system

A pipeline transportation, long-distance technology, used in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problem of flow and pressure provided by the main pump in the latter stage, insufficient material sucked by the feeding pump, and insufficient material sucked by the main pump. and other problems to achieve the effect of ensuring fast pace, reducing the incidence of accidents and equipment failures, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

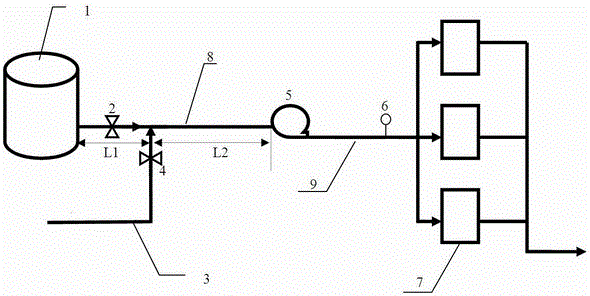

[0028] first combined with figure 1 Illustrate the long-distance slurry pipeline delivery system that adopts the slurry-water online switching method described in the present invention, as attached figure 1 As shown, it includes a stirring tank 1, a feeding pump 5 and a main pump 7. The stirring tank is used to store the upstream slurry and stir the slurry to be transported. The bottom outlet of the stirring tank 1 passes through the first slurry delivery pipeline 8 Connected to the pumping inlet of the feeding pump 5, the pumping outlet of the feeding pump 5 is connected to the pumping inlet of the main pump 7 through the second slurry delivery pipeline, and the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com