Groove surface acid mist source reduced clean production method and system in electrolysis workshop

An electrolysis workshop and clean production technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of limited application, difficult stripping, large ventilation volume, etc., and achieve the effect of reducing resource loss, avoiding secondary pollution, and reducing production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

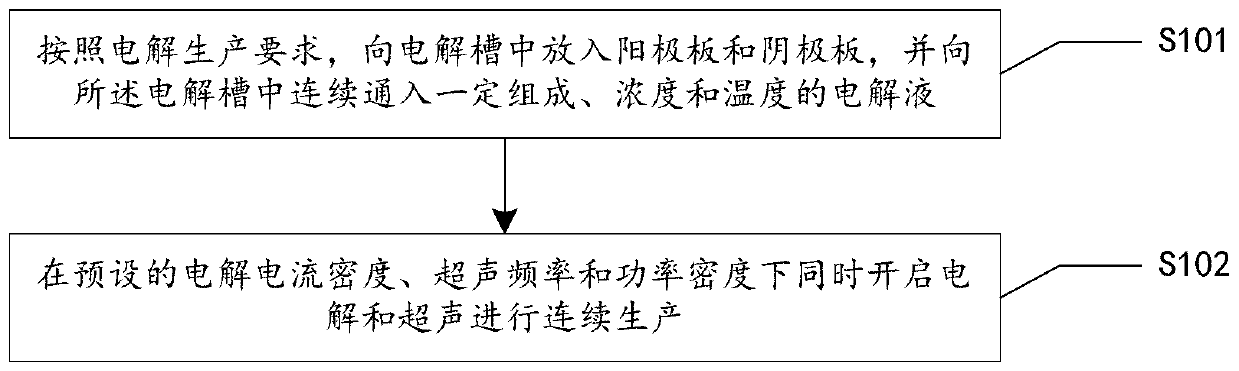

[0025] Such as figure 1 As shown, this embodiment proposes a clean production method for reducing the source of acid mist on the tank surface of the electrolytic workshop, and the method includes:

[0026] S101, according to the electrolytic production requirements, put anode plate and cathode plate into the electrolytic cell, and continuously pass into the electrolytic solution of certain composition, concentration and temperature in the electrolytic cell;;

[0027] S102. Under the preset electrolysis current density, ultrasonic frequency and power density, start electrolysis and ultrasonic at the same time to carry out continuous production.

[0028] Specifically, in this embodiment, the ultrasonic method is continuous ultrasonic, and the ultrasonic frequency is 20kHz to 500MHz; the ultrasonic power density is 5kw / m 3 up to 200kw / m 3 . And the process of ultrasonic application runs through the whole electrolysis process, that is, from the beginning of electrolysis until t...

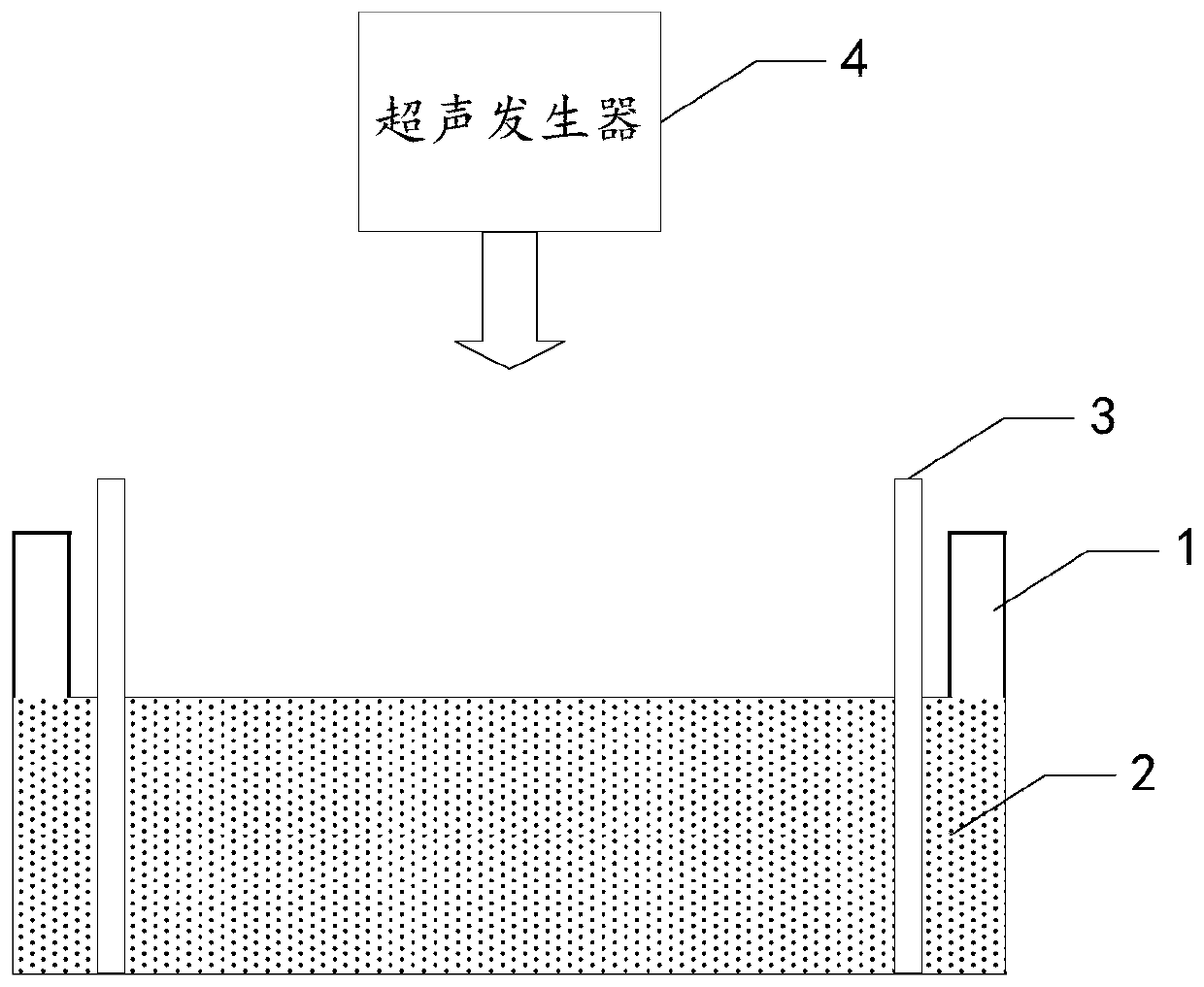

example 1

[0037] The ultrasonic generator is loaded on the cathode and anode plates of the electrolytic cell, and the ultrasonic power density is selected as 200.0kw / m3 , the ultrasonic frequency is 20kHz, the ultrasonic method is continuous ultrasonic, turn on the ultrasonic, and then turn on the electrolysis. After the parameters were basically stable, samples were taken at 1.0m above the electrolytic cell with a membrane holder equipped with a filter membrane at a sampling rate of 16.7L / min, 33min as a group, and 6 groups were collected continuously. After 48 hours of constant temperature and humidity, the quality of the filter membrane was weighed, and the emission intensity of the sulfuric acid mist was analyzed after pretreatment of the filter membrane.

[0038] Compared with the control group without ultrasonic treatment, the emission intensity of total suspended particulate matter and sulfuric acid mist was reduced by 80% to 100%, the power consumption was reduced by 3.4% to 5.7%...

example 2

[0040] The ultrasonic generator is loaded on the bottom of the electrolytic tank, and the ultrasonic power density is selected as 100.0kw / m 3 , the sound frequency is 40.0kHz, the ultrasonic method is continuous ultrasonic, turn on the ultrasonic, and then turn on the electrolysis. After the parameters were basically stable, samples were taken at 1.0m above the electrolytic cell with a membrane holder equipped with a filter membrane at a sampling rate of 16.7L / min, 33min as a group, and 6 groups were collected continuously. After 48 hours of constant temperature and humidity, the quality of the filter membrane was weighed, and the emission intensity of the sulfuric acid mist was analyzed after pretreatment of the filter membrane.

[0041] Compared with the control group without ultrasonic treatment, the emission intensity of total suspended particulate matter and sulfuric acid mist was reduced by 60% to 75%, the power consumption was reduced by 2.5% to 8.7%, and the power effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com