Atomized acid wellbore flow simulation device and working method for gas injection development of fractured-vuggy reservoirs

A flow simulation, fracture-cavity technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem of affecting the effective distance of the acid solution affecting the geometric size of the wormhole, affecting the liquid rheology and the acid-rock reaction rate. , Affecting the effective distance of wormholes, etc., to achieve excellent anti-blocking performance, good atomization effect, and the effect of improving atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

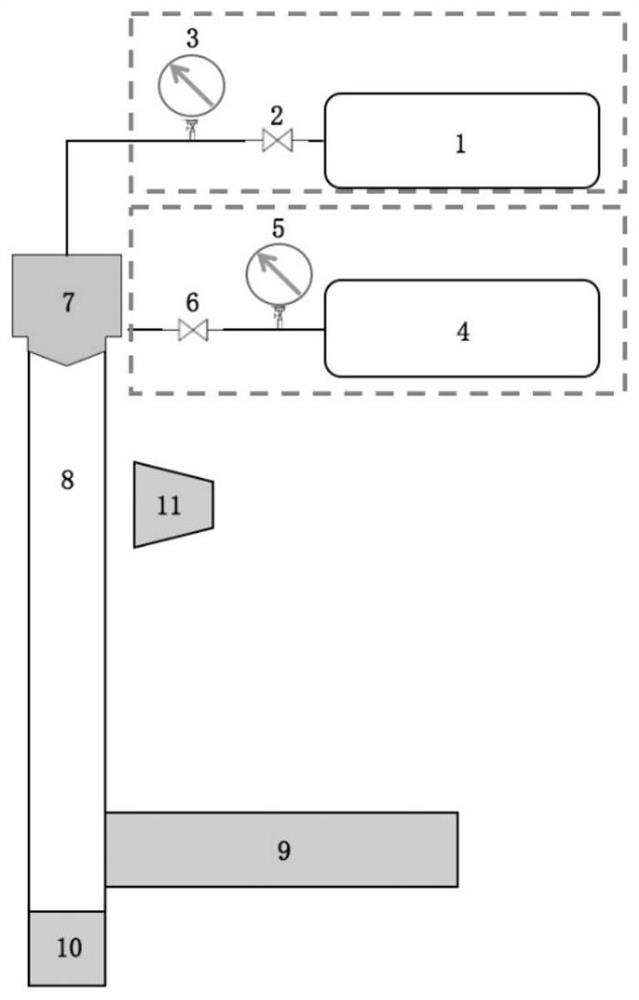

[0042] An acid atomization-wellbore flow simulation platform for deep acidification of fracture-cavity reservoirs, such as figure 1 As shown, it includes gas system, liquid system, atomization generator, simulated wellbore flow device and acid atomization evaluation device.

[0043] The air circuit system includes an air compressor 1, an air throttle valve 2, and a gas pressure gauge 3. The air compressor provides gas with adjustable injection speed for the atomization generating device. The air throttle valve is used to control the gas injection speed, and the gas pressure gauge is used for Measure gas injection pressure.

[0044] The liquid system includes a high-pressure acid-resistant pump 4, a liquid pressure gauge 5, and a liquid throttle valve 6. The high-pressure acid-resistant pump provides acid liquid with adjustable injection speed for the double-flow Venturi atomization generator, and the liquid pressure gauge is used to measure the liquid injection pressure. , Th...

Embodiment 2

[0049] Set the initial gas flow rate to 1.0m 3 / h, the initial fluid injection rate is 40mL / min, by changing the gas-liquid ratio under different conditions, the atomization rate under this condition is calculated as shown in Table 1 below.

[0050] Table 1 Initial Experimental Data Recording Form

[0051]

[0052]

[0053] Use serial number 1 as the experimental control group, control variables, and change the liquid flow rate and gas flow rate respectively. Through the comparison of serial numbers 1, 4, and 7, it is found that when the liquid flow rate is kept constant at 40mL / min, the gas flow rate is changed to 0.5m 3 / min, 1m 3 / min, 2m 3 / min, with the increase of liquid-gas ratio, the atomization rate increased from 4.00% to 33.33%.

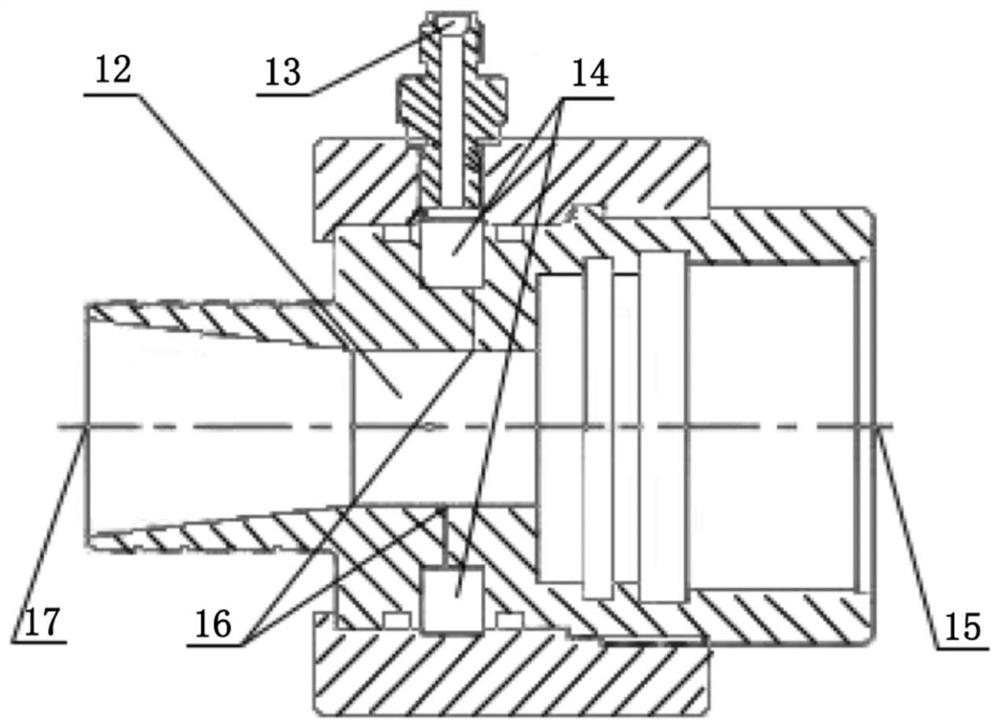

[0054] The atomization effect of the double-flow Venturi atomization generating device described in Table 1 is relatively low. Therefore, through the atomization principle of the Venturi tube, the atomization rate of the atomiza...

Embodiment 3

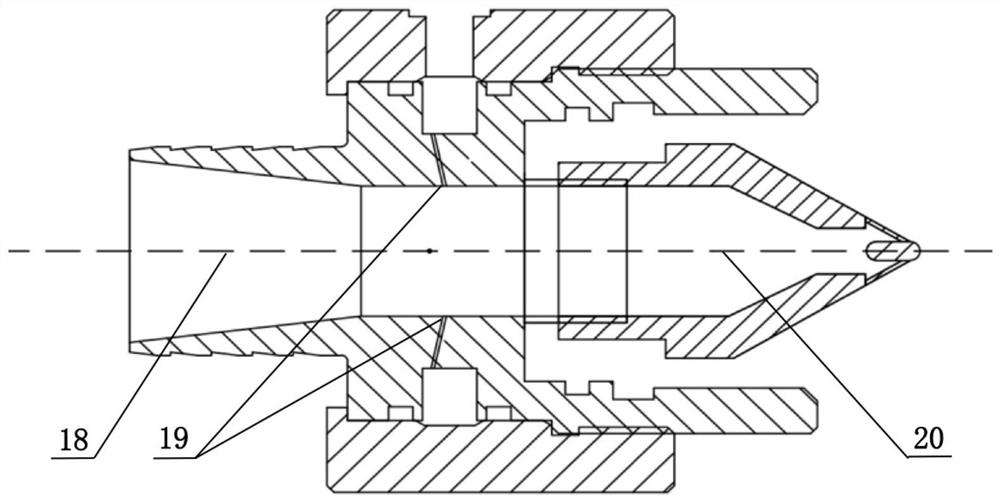

[0063] From Example 1, it can be seen that the atomization rate can be increased by changing the cross-sectional area of acid liquid injection, but at the same time, the pressure of the acid liquid injection port is increased, which is likely to cause damage to the equipment. Therefore, the atomization rate cannot be improved only by reducing the cross-sectional area of the acid liquid injection, but other methods should be selected to improve the atomization generating device. Embodiment 3 adopts a narrower and longer Venturi pipe, redesigns the acid liquid injection port, and improves the atomizing nozzle.

[0064] The improved double-flow Venturi atomization generating device is 120mm high, the gas inlet is 40mm high, the inner diameter is 20mm, the outer diameter is 32mm, the liquid inlet diameter is 8mm, the liquid outlet diameter is 0.5mm, and the total cross-sectional area is 1.57mm 2 , The length of the atomizing nozzle of the double-flow outlet is 53mm, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com