An acid atomization device and atomization method for deep acidification of fractured-vuggy reservoirs

An atomization device, a fracture-cavity type technology, which is applied in liquid injection devices, chemical instruments and methods, injection devices, etc., can solve the problems of complex resonance characteristics and influencing factors, unfavorable application of acidizing deep wells in oil fields, complex ultrasonic atomization mechanism, etc. , to improve the acidification effect, reduce the surface tension and surface free energy, and improve the atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

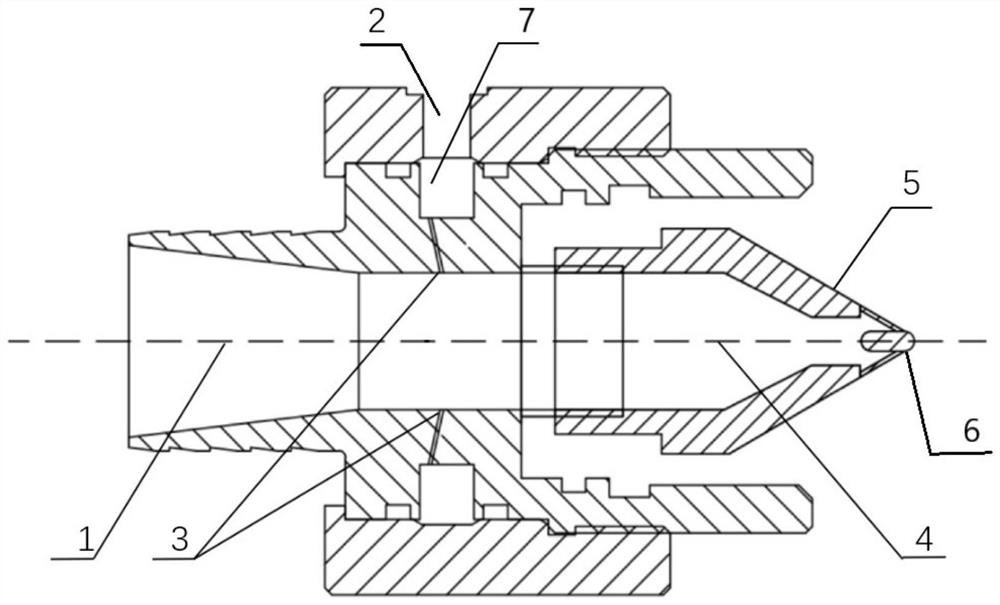

[0025] An acid atomization device for deep acidification of fracture-cavity reservoirs, comprising a gas path system, a liquid path system, and an atomizing nozzle; the gas path system includes a gas inlet, an air compressor; the liquid path system includes an acid liquid inlet, a high-pressure acid-resistant Pump, double-flow Venturi tube; air enters the gas inlet after being pressurized by the air compressor; acid liquid enters the annular cavity after being pressurized by the high-pressure acid-resistant pump, and the annular cavity is used to accumulate acid liquid, and the acid liquid in the annular cavity The acid liquid enters the cylindrical cavity through the acid liquid inlet on the wall, and acid mist is formed in the cylindrical cavity due to hydraulic cavitation, and the acid mist is constrained by the cylindrical cavity to become an acid mist columnar fluid, which occurs during atomization The high-speed movement inside the atomizer and finally sprayed out from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com