Graphene armor reinforced foam system for oil-gas field and preparation method of foam system

A foam system and graphene technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of foam stabilizer without surface activity, formation porous medium adsorption, no foaming ability, etc., to achieve the effect of increasing production Good, weakens the effect of rupture and reduces fluid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

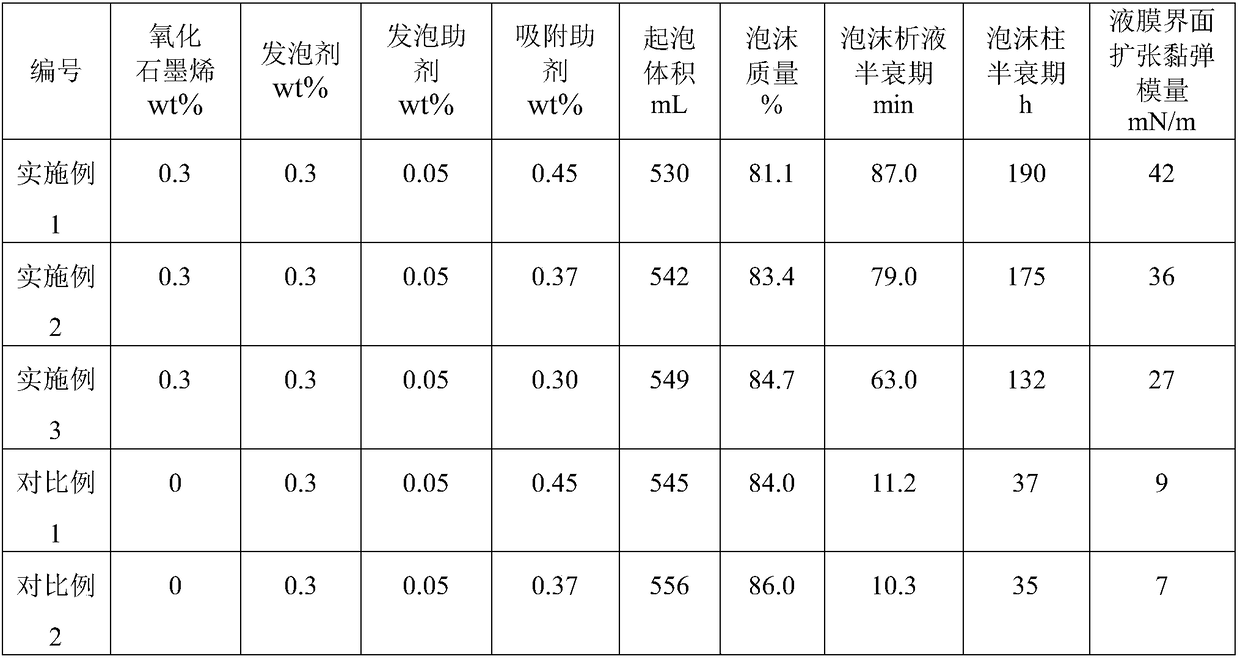

[0082] Embodiment 1-3, the foam system reinforced by graphene armor for oil and gas fields

[0083] The raw materials are gas phase, liquid phase and graphene oxide, and the specific components are as follows:

[0084] The gas phase is nitrogen.

[0085] The mass percent composition of liquid phase is as follows:

[0086] 0.3wt% blowing agent, 0.05wt% foaming aid, 0.45wt% adsorption aid, and the balance is water, wherein the blowing agent is di(2-ethylhexyl)sulfonate sodium succinate and fatty alcohol polyoxyethylene ether sodium sulfate in a mass ratio of 3:1; the foaming aid is lauryl alcohol; the adsorption aid is a mixture of camellia saponin and sodium bicarbonate, and the addition ratio is 4:1 ( quality).

[0087] Graphene oxide has a specific surface area of 300m 2 / g, the monolayer rate is 86%, the average thickness of the sheet is 3nm, the average diameter of the sheet is 7um, and the oxygen content is 30%; the added concentration of graphene oxide in the liquid...

Embodiment 4-6

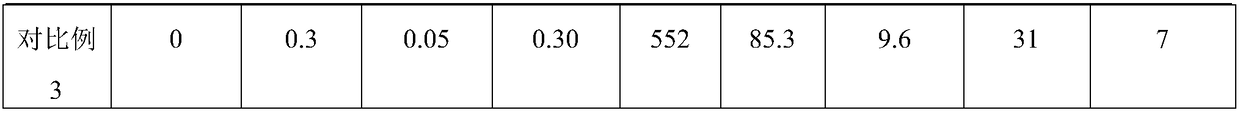

[0102] Embodiment 4-6, the foam system reinforced by graphene armor for oil and gas fields

[0103] The raw materials are gas phase, liquid phase and graphene oxide, and the specific components are as follows:

[0104] The gas phase is carbon dioxide.

[0105] The mass percent composition of liquid phase is as follows:

[0106] 0.3wt% blowing agent, 0.05wt% foaming aid, 0.45wt% adsorption aid, and the balance is water, wherein the blowing agent is di(2-ethylhexyl)sulfonate sodium succinate and fatty alcohol polyoxyethylene ether sodium sulfate in a mass ratio of 3:1; the foaming aid is lauryl alcohol; the adsorption aid is a mixture of camellia saponin and sodium bicarbonate, and the addition ratio is 4:1 ( quality).

[0107] Graphene oxide has a specific surface area of 300m 2 / g, the monolayer rate is 86%, the average thickness of the sheet is 3nm, the average diameter of the sheet is 7um, and the oxygen content is 30%; the added concentration of graphene oxide in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com