A control and flooding system and oil displacement method suitable for carbonate weathering crust reservoirs

A weathering shell and carbonate technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor stability of the two-phase interface, poor dispersion and stability, inability to stabilize adsorption, etc. Dispersion stability can be improved, and the effect of increasing the swept volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a control and flooding system suitable for carbonate weathering crust reservoirs, comprising the following steps:

[0044] At room temperature (20±5°C), first add nano-silica to water, stir for 3-5 minutes and then ultrasonically 60-70 minutes to disperse nano-silica in water; then add quaternary ammonium salt surfactant, stir The surfactant is fully dissolved in 3-5 minutes to obtain a control and flooding system suitable for carbonate weathering crust deposits.

[0045] An oil displacement method suitable for carbonate weathering crust reservoirs. When the water content of the oil well corresponding to the water injection well increases significantly, the water flooding is inefficient or ineffective and the development effect becomes poor, and a large amount of remaining oil remains in the formation, the described method is adopted. The control and flooding system suitable for carbonate weathering crust reservoirs is used for oil displacement, i...

Embodiment 1

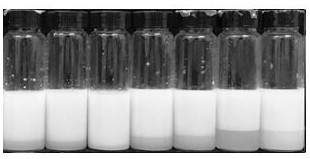

[0058] This example evaluates the high-temperature and high-salt emulsification performance of the control and flooding system suitable for carbonate weathering crust reservoirs.

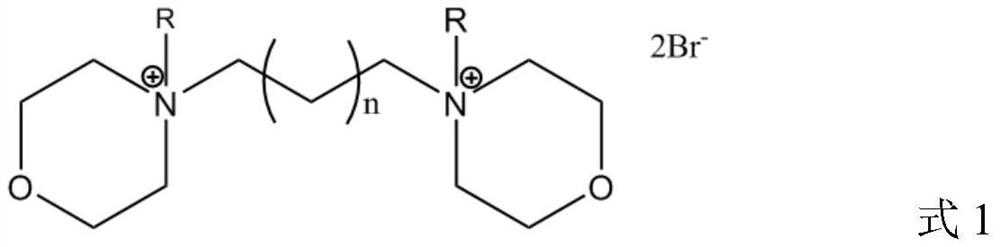

[0059] At room temperature (20±5°C), configure 10 mL of a composite system solution with a mass fraction of nano-silica of 2.0%, quaternary ammonium salt surfactants of different mass fractions, and water as the balance. The surfactant has formula 1 The structure shown:

[0060] Formula 1

[0061] In formula 1, R is C 10 h 21 The linear carbon chain, n is 1.

[0062] The water is treated oilfield reinjection sewage, the pH value is 5.6, the total salinity is 20 000 mg / L, ρ 油 悬浮物 <30mg / L.

[0063] The mass fractions of the surfactants are 0.03%, 0.06%, 0.1%, 0.25%, 0.5%, 0.75%, and 1%, respectively.

[0064] The above solution was mixed with 10 mL of n-dodecane at a volume ratio of 1:1 and put into a glass bottle, and stirred continuously at a speed of 10,000 r / min for 4 min by a high-speed h...

Embodiment 2

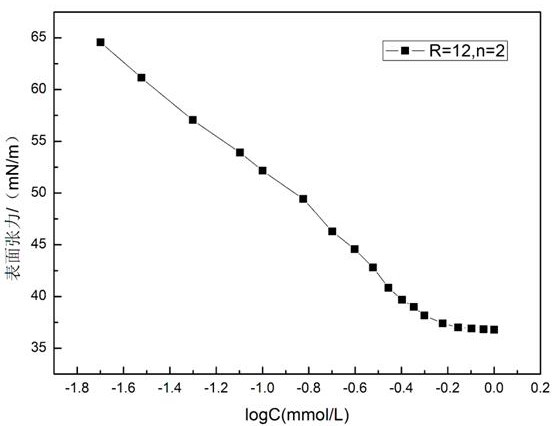

[0066] At room temperature (20±5°C), configure a composite system in which the mass fraction of nano-silica is 2.0%, the mass fraction of quaternary ammonium salt surfactant ranges from 0.02% to 1.0%, and the balance is water. The trend of the interfacial tension of the composite system changing with the mass fraction of surfactant was determined. Described tensio-active agent has the structure shown in formula 1:

[0067] Formula 1

[0068] In formula 1, R is C 12 h 25 The linear carbon chain, n is 2.

[0069] The water is treated oilfield reinjection sewage, the pH value is 6.7, the total salinity is 45 000 mg / L, ρ 油 悬浮物 <50mg / L.

[0070] like figure 2 Shown, the abscissa is the concentration of surfactant, and the ordinate is the surface tension, which is measured by the ring method. It can be seen that when the mass fraction of quaternary ammonium salt surfactant is greater than 0.5%, the interfacial tension of the system no longer decreases.

[0071] Based on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com