Patents

Literature

41results about How to "Clear workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paint preparation technology

ActiveCN103540198AReasonable standardImprove standardsUnspecified rubber coatingsPolystyreneWaste rubber

The invention discloses a paint preparation technology, which is characterized by comprising the technological steps of: (1) raw material selection, wherein by weight percent, polystyrene foam, phenolic foamed plastics, waste rubber and nitrocellulose account for 65%, industrial alcohol, coal tar, acetone and water solvent account for 15%, pigment and filler account for 15%, and a wet dispersing agent, a defoaming agent, a delustering agent and a plasticizer account for 5%; (2) fusion refining; (3) primary fining; (4) dispersing; (5) blending and color modulation; (6) filtering; (7) packaging. The technology disclosed by the invention is reasonable and compact, technological process is reduced greatly, paint source is wide, the technology belongs to waste reuse, and production cost is reduced; meanwhile, according to the raw material ratio, the technology is convenient for preparing various functional paints and can meet the requirement of production technology of the paints, dosage and ratio are accurate, deviation is small, product quality is guaranteed, and yield of enterprises is improved effectively.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

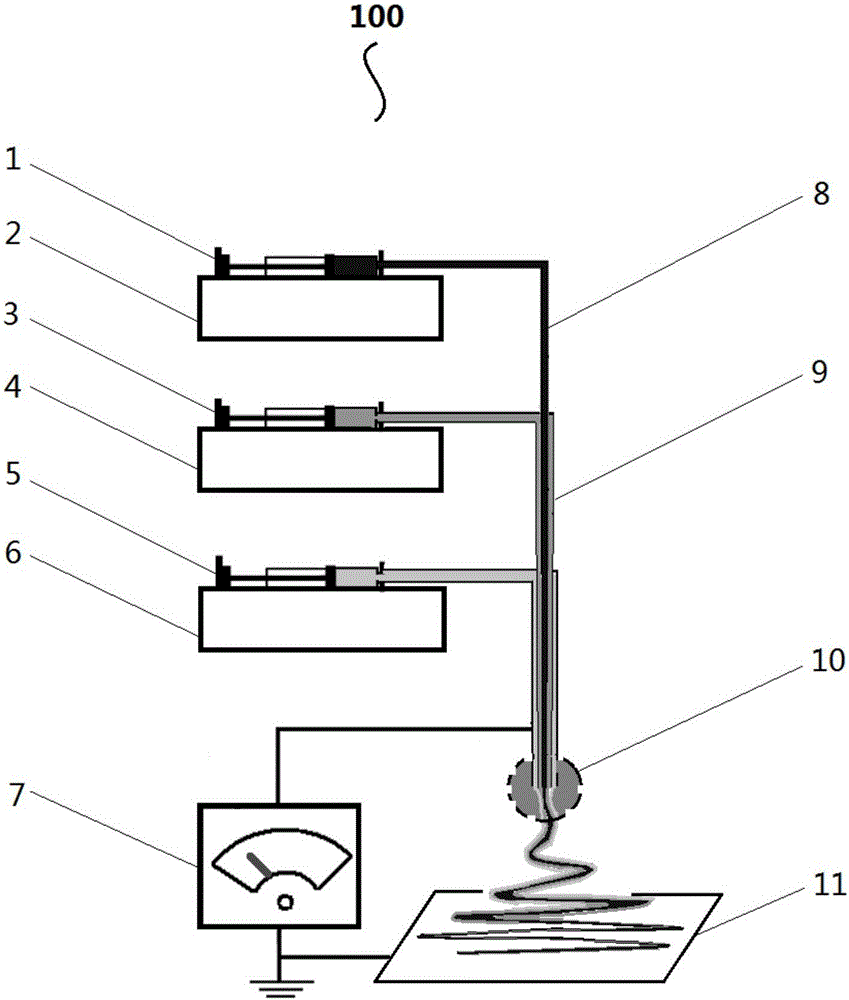

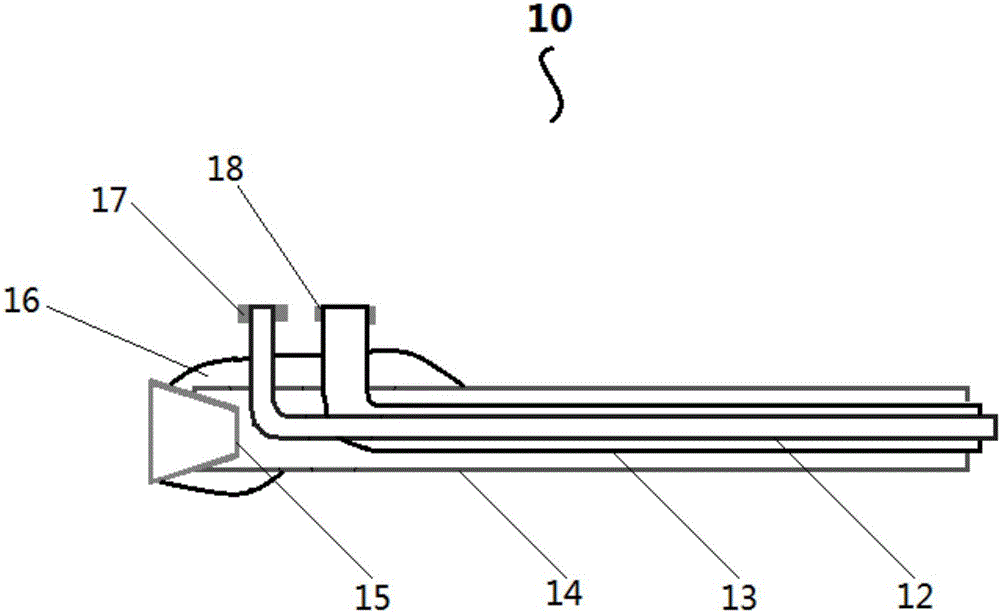

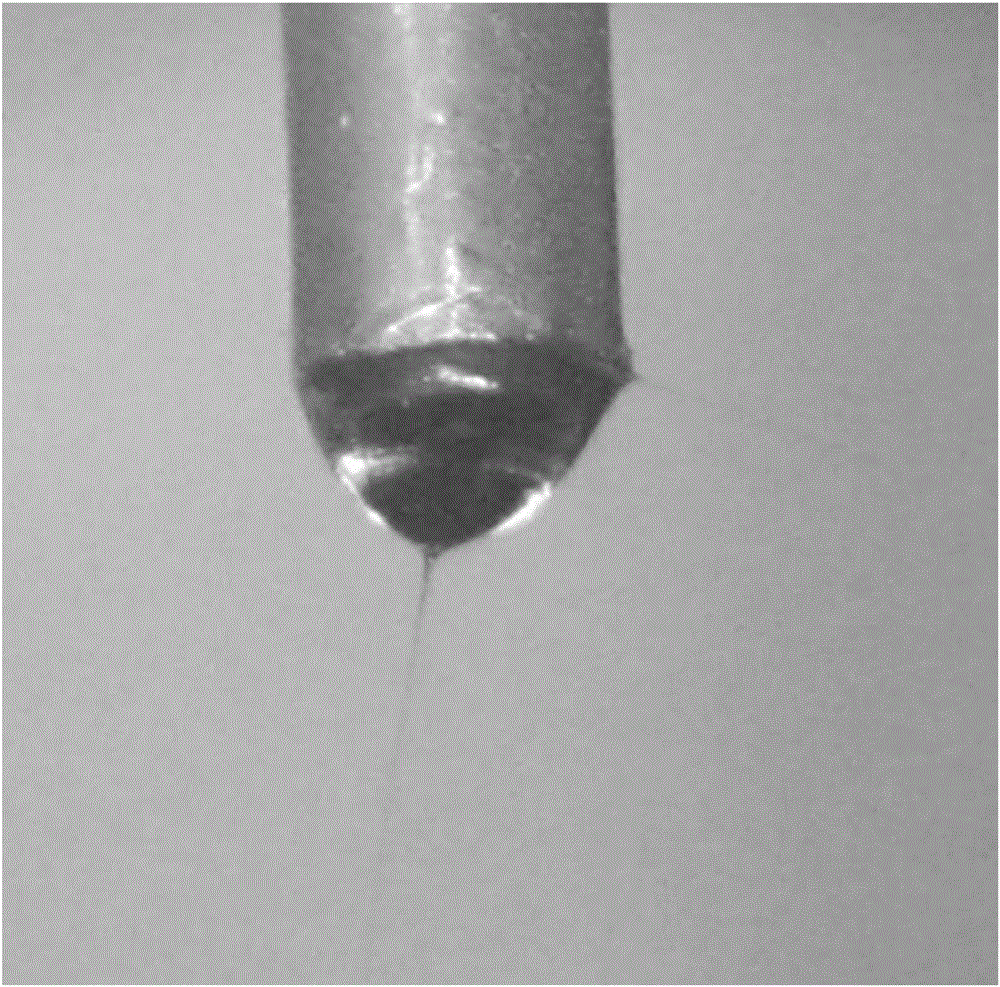

Core-sheath nano-fiber three-stage coaxial electrospinning preparation method and device

The invention provides a core-sheath nano-fiber three-stage coaxial electrospinning preparation method. The core-sheath nano-fiber three-stage coaxial electrospinning preparation method comprises the following steps: step one, respectively filling an inner layer fluid injector, a middle layer fluid injector and an outer layer fluid injector with inner layer fluid, middle layer fluid and outer layer fluid which are dispensed; step two, connecting a three-stage coaxial electrospinning head to a high voltage electrostatic generator, so that the three-stage coaxial electrospinning head is electrified, the inner layer fluid, the middle layer fluid and the outer layer fluid form a Taylor cone at the three-stage coaxial electrospinning head, and jet flow is sent out; and step three, volatilizing the outer layer fluid in the fast stretching process after the jet flow is sent out, finally forming core-sheath nano-fibers and receiving the core-sheath nano-fibers by using a fiber receiving plate. The invention also provides a core-sheath nano-fiber three-stage coaxial electrospinning preparation device which comprises the high voltage generator, the three-stage coaxial electrospinning head, the fiber receiving plate and fluid injection pumps.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

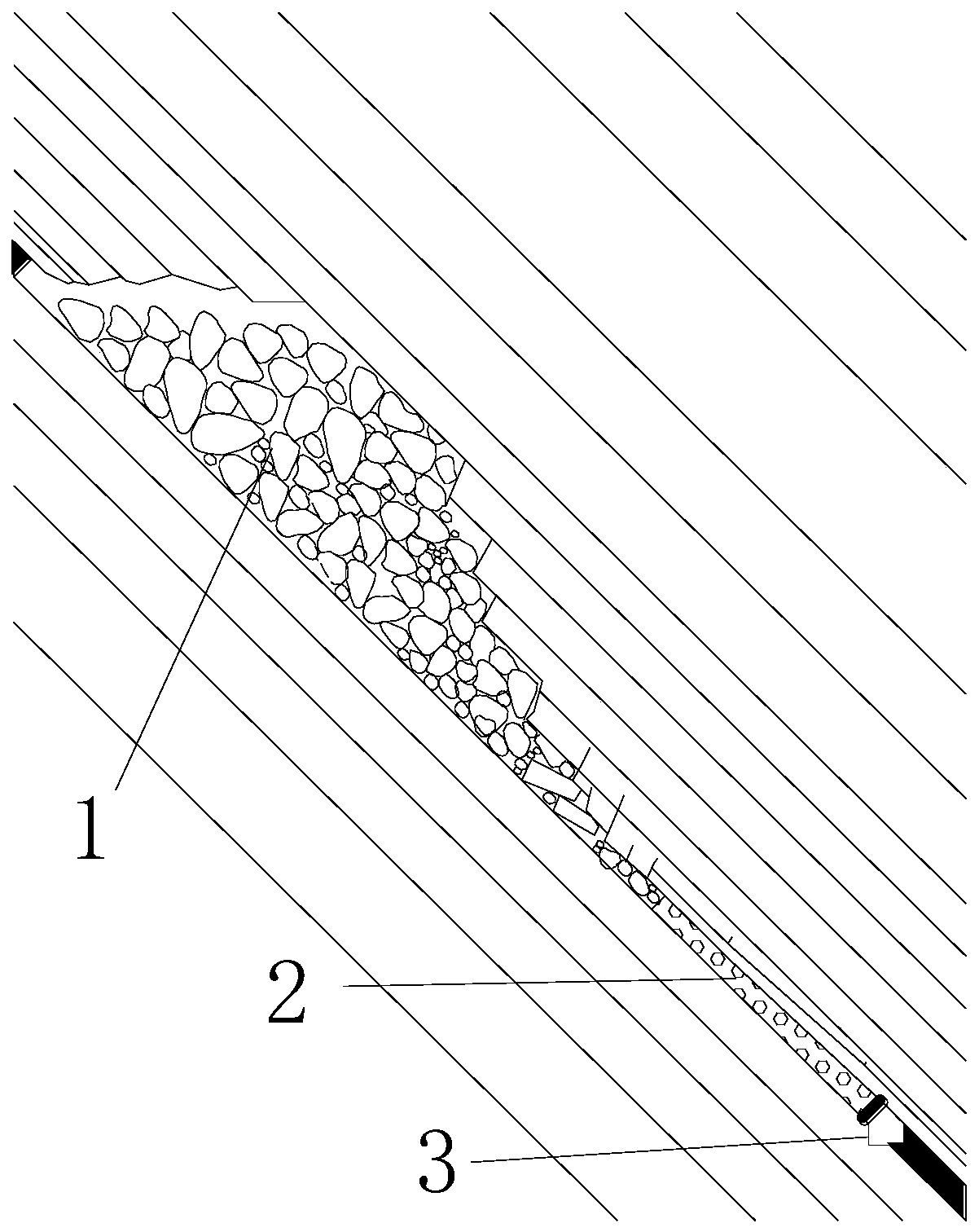

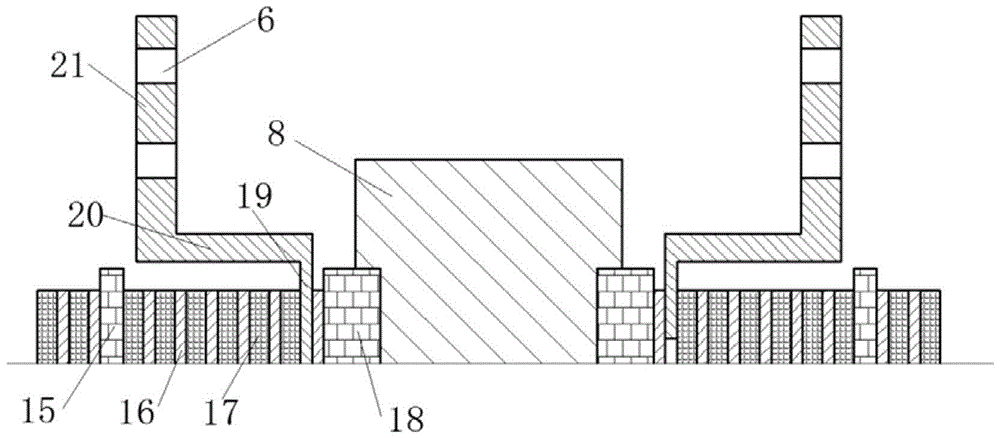

Non-coal-pillar mining method and system for partial filling of working face in large-dip-angle coal seam

ActiveCN110984987ASave resourcesIncrease mining rateUnderground miningSurface miningMining engineeringResource recovery

The invention discloses a non-coal-pillar mining method and system for partial filling of a working face in a large-dip-angle coal seam. The non-coal-pillar mining method comprises the steps that in the large-dip-angle comprehensive mining working face, hydraulic supports of the working face are arranged modularly in partitions according to a certain length, the upper part is a common support, andthe lower part is an integrated hydraulic support of mining and filling; a combined gangue retaining support is additionally arranged along a haulage way; with the recovery of the working face, artificial filling is conducted at the lower part of a goaf, grouting filling is conducted at surrounding rocks of the haulage way, and the haulage way is reserved; after the completion of mining, the reserved haulage way can be a tailgate of the working face in the lower section, and the mining system layout is achieved; and the above procedures are repeated, thus continuous mining is conducted untilthe completion of mining of the coal seam. According to the non-coal-pillar mining method, the surrounding rock state of the haulage way is improved, the stability of the remained gateway along the goaf is ensured, the non-coal-pillar mining of the large-dip-angle coal seam is achieved, the operation efficiency is improved, the resource recovery rate is increased, the mine pressure appearance intensity is reduced, the stability of the working face supports is improved, and the safe and efficient mining of the working face is ensured.

Owner:XIAN UNIV OF SCI & TECH

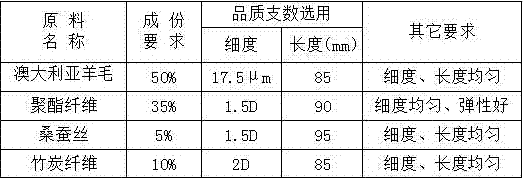

Antibacterial and healthcare plumetis capable of releasing anions and manufacturing technology of plumetis

InactiveCN107574534AFully reflect the health functionRich varietyWoven fabricsPolyesterManufacturing technology

The invention discloses antibacterial and healthcare plumetis capable of releasing anions and a manufacturing technology of the plumetis. The plumetis is prepared from 50% of Australian wool, 35% of polyester fiber, 5% of mulberry silk and 10% of bamboo charcoal fiber. The manufacturing technology of the plumetis comprises the following steps of 1, dyeing; 2, spinning; 3, weaving and 4, after-finishing. Full play is given to the excellent performance of the bamboo charcoal fiber and mulberry silk, the varieties of wool spinning fabric are enriched, the level and the addition value of the fabric are increased, the fabric is fine and smooth in appearance, smooth in hand feeling, natural and soft in luster, pure in color, good in moisture absorption and air permeability performance, clear inplumetis surface grain, and exquisite in workmanship, the healthcare function of the bamboo charcoal fiber is fully embodied, the added value of products is high, and a good market effect is obtained.

Owner:JIANGSU JIANLU WOOLEN

Coating preparation process

InactiveCN104530839AReasonable standardImprove standardsUnspecified rubber coatingsPlasticizerPolystyrene

The invention discloses a coating preparation process. The coating preparation process is characterized by comprising the first step of raw material selection, wherein raw materials comprise, by weight, 55% of polystyrene foam, phenolic foam plastic, scrap rubber and nitrocellulose, 20% of industrial alcohol, coal tar, acetone and hydrosolvents, 20% of pigments and fillers and 5% of wetting dispersing agents, defoaming agents, flatting agents and plasticizer auxiliaries; the second step of fusing refining; the third step of pre-refining; the fourth step of dispersing; the fifth step of blending and color mixing; the sixth step of filtering; the seventh step of packaging. The coating preparation process is reasonable and simple, the process flow is greatly shortened, the raw materials of the coating are wide in source and are of a waste recycling type, and production cost is reduced; meanwhile, according to the raw material ratio, coating of different functions is convenient to make and meets the needs of other production processes, material capacity and the ratio are accurate, the deviation is small, product quality is guaranteed, and the enterprise yield is effectively increased.

Owner:GUANGXI UNIV

Method for producing flavouring lotion by using saccharomycopsis fibuligera

InactiveCN105112263ASafeNo irritationAlcoholic beverage preparationMicroorganism based processesBiotechnologySaccharomycopsis fibuligera

The invention discloses a method for producing flavouring lotion by using saccharomycopsis fibuligera. The method comprises the following steps of slant culture: saccharomycopsis fibuligera FBKL 2.0094 is inoculated on a slant culture medium for culturing at 28 DEG C for 24 to 48 hours until hyphae grow fully in a test tube; strains are activated; a seed solution is prepared; solid state fermentation is performed in a triangular flask and a fermented product is obtained; preparation of the flavouring lotion: 26.47 percent of salt solution, 10 percent v / v of ethanol solution and the fermented product are mixed by a ratio of 1 ml:1 ml:1g; the mixture is evenly stirred and the stirring time is 5 to 10 minutes; the stirred mixture is put into a water bath kettle with the temperature of 50 DEG C to be subjected to water bath for 30 minutes; air distillation is performed and the temperature is controlled at 100 DEG C; the timing is started when cut fraction is distilled off; the distillation time is 20 to 40 minutes; 25 to 75 ml of cut fraction is collected into a volumetric flask, and the volumetric flask is subjected to cold storage at 4 DEG C in a refrigerator. The method for producing flavouring lotion by using saccharomycopsis fibuligera provided by the invention is short in production cycle, high in quality rate, and low in production cost.

Owner:GUIZHOU UNIV

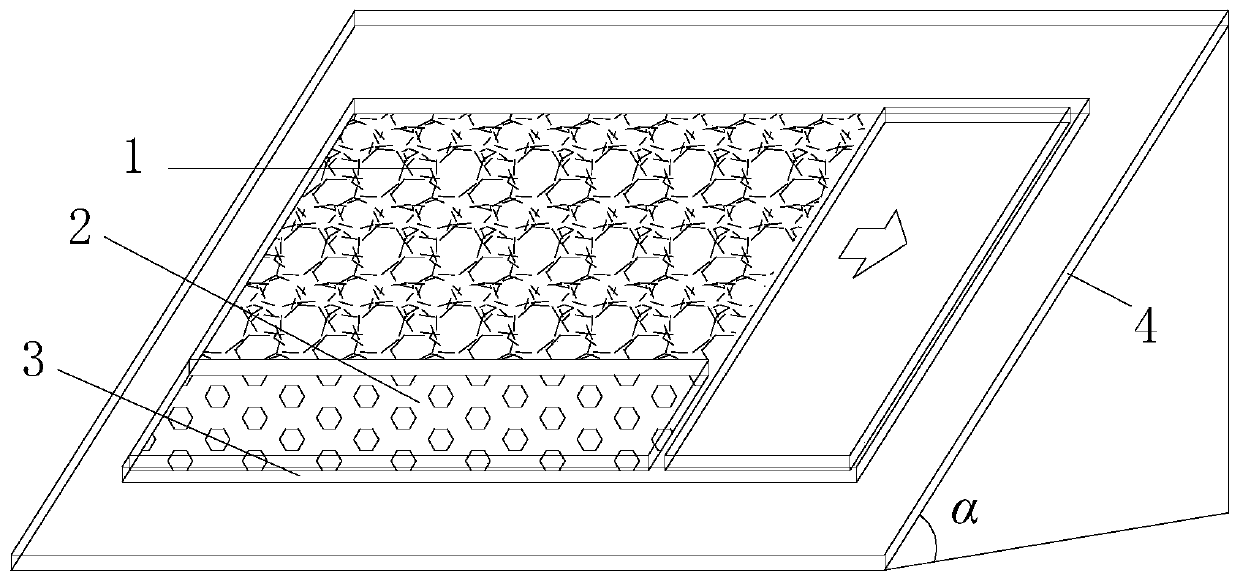

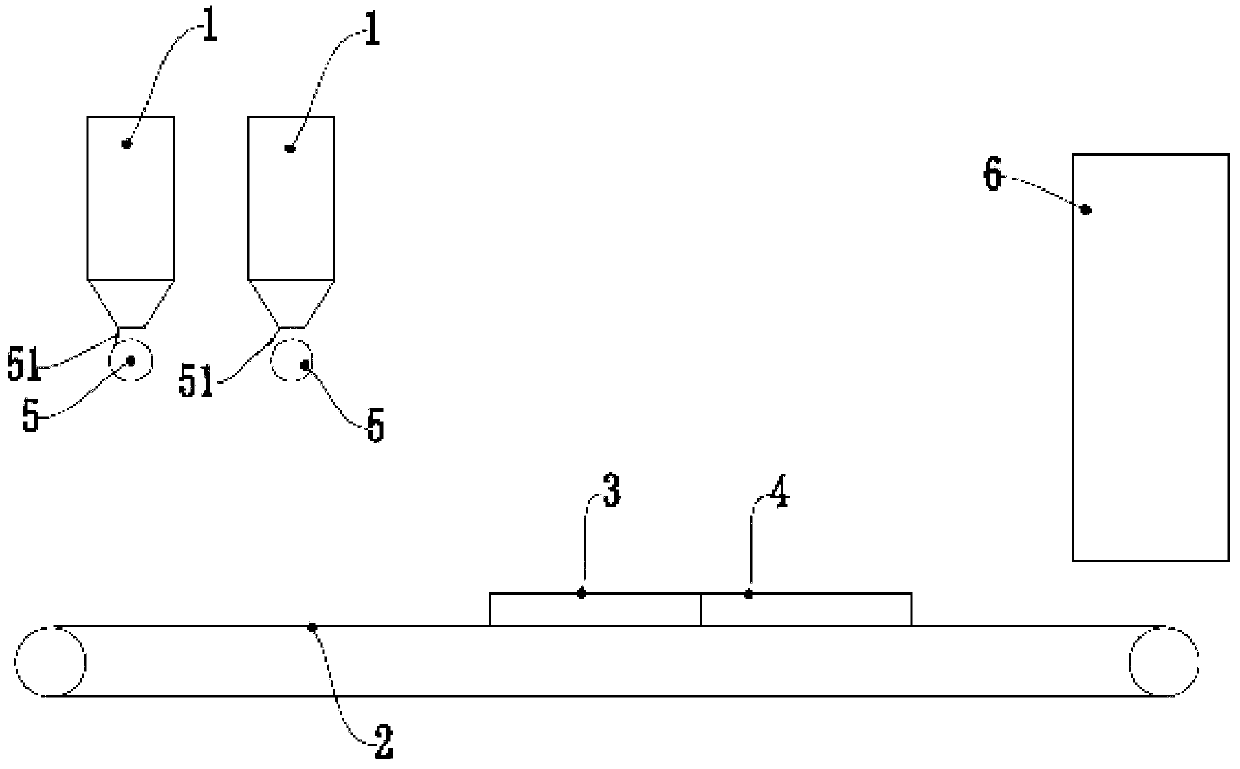

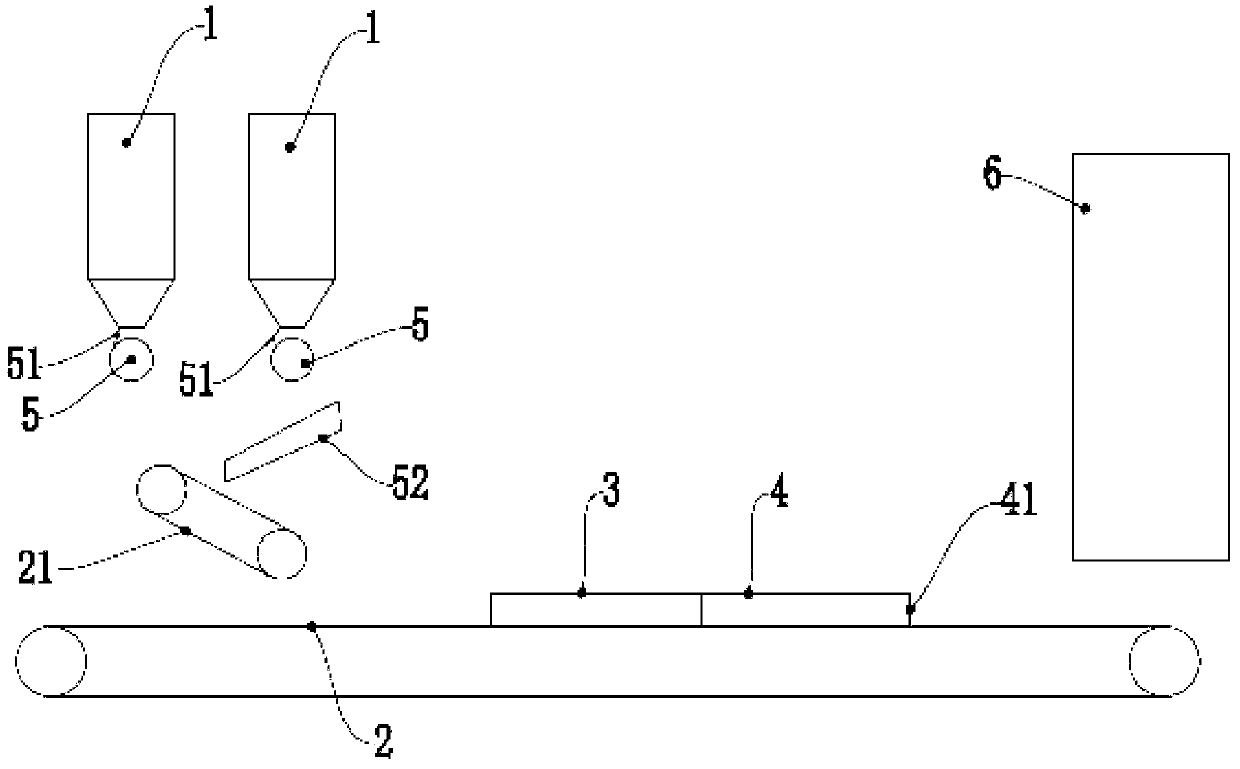

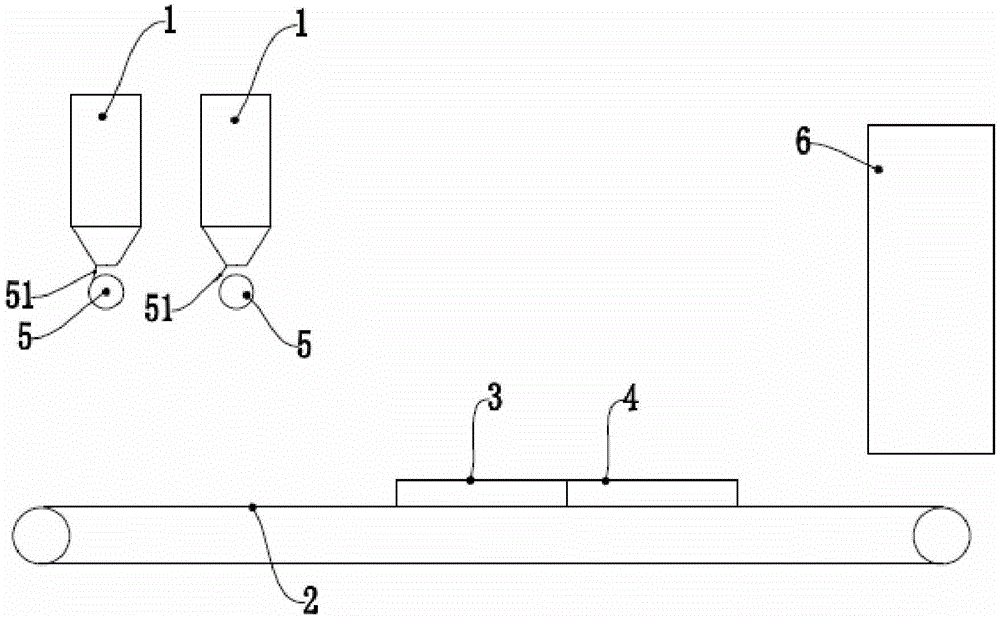

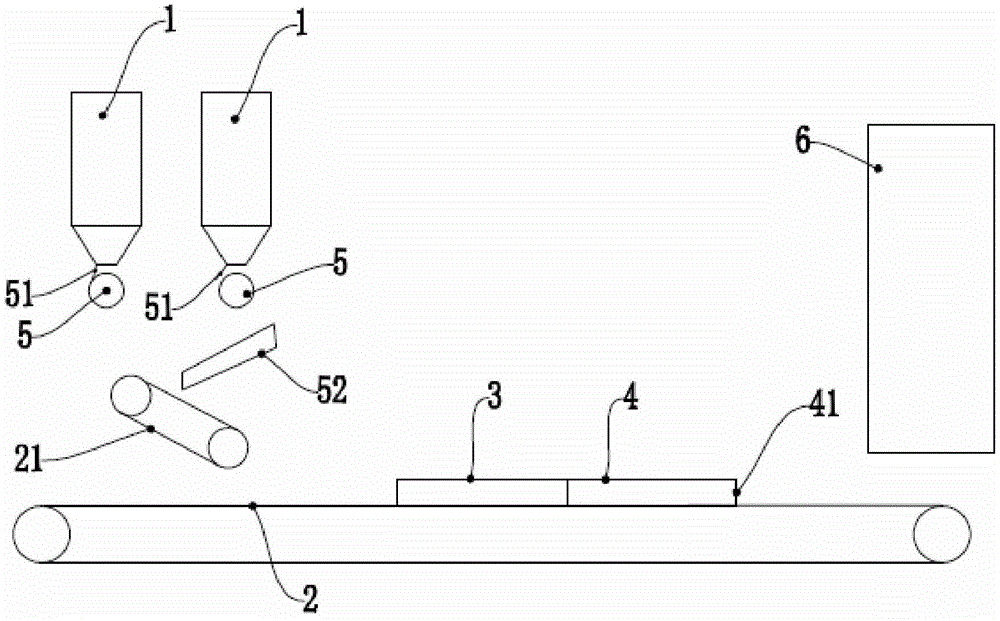

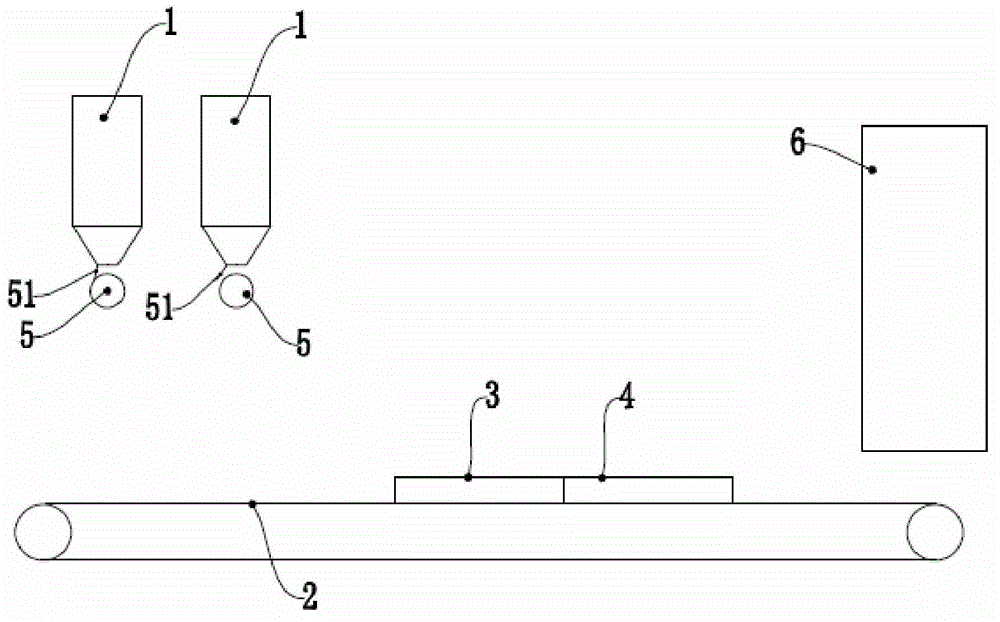

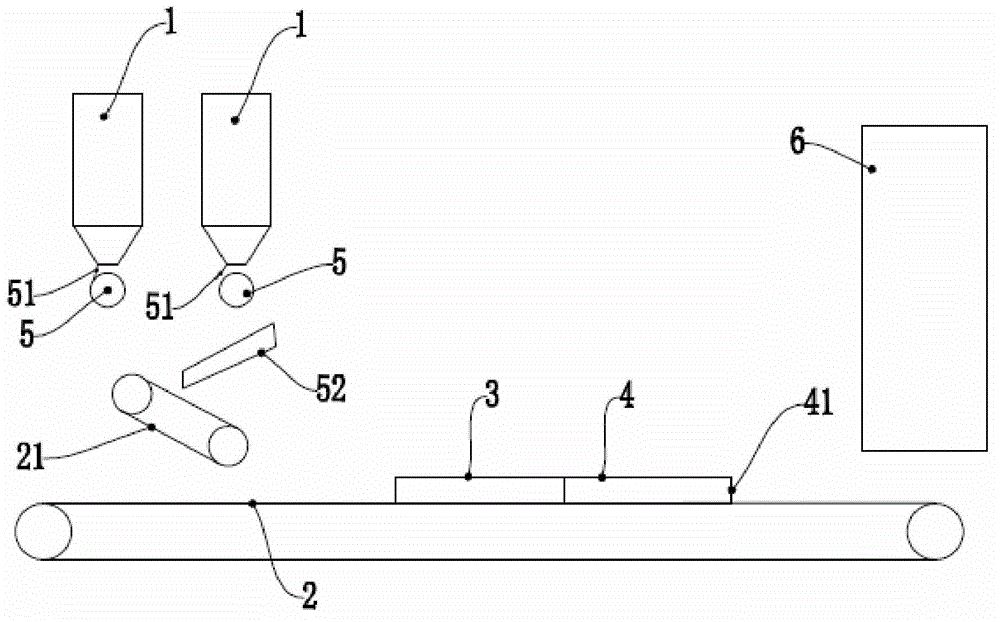

Material distribution device and method for polished tiles

ActiveCN103273557AEasy to operateRich in changeFeeding arrangmentsShaping conveyorsStructural engineeringMaterial distribution

Disclosed are a material distribution device and method for polished tiles. The material distribution device comprises a material distribution hopper, a main conveyor belt, a front material collecting box and a back material collecting box, wherein the material distribution hopper, the front material collecting box and the back material collecting box are sequentially arranged along the movement direction of the main conveyor belt, the material distribution hopper is disposed above the main conveyor belt, the front and back material collecting boxes are horizontally arranged over the main conveyor belt in a closely attaching mode, the front material collecting box is a hexahedral box which is buckled inversely on the main conveyor belt, baffles are not arranged in front and below the front and back material collecting boxes, a back baffle of the back material collecting box is a gate capable of being lifted independently, and the front and back material collecting boxes are provided with drive devices capable of lifting the front material collecting box intermittently. According to the material distribution device and method, texture patterns on surfaces of ceramic tiles are clear and stable, a material distribution process of large-turn clear lines is achieved, line textures bending in different directions are produced, the textures are rich in change, random and natural, the presentation range of the ceramic tiles is expanded, and the wide practicability is provided.

Owner:QINGYUAN NAFUNA CERAMICS +2

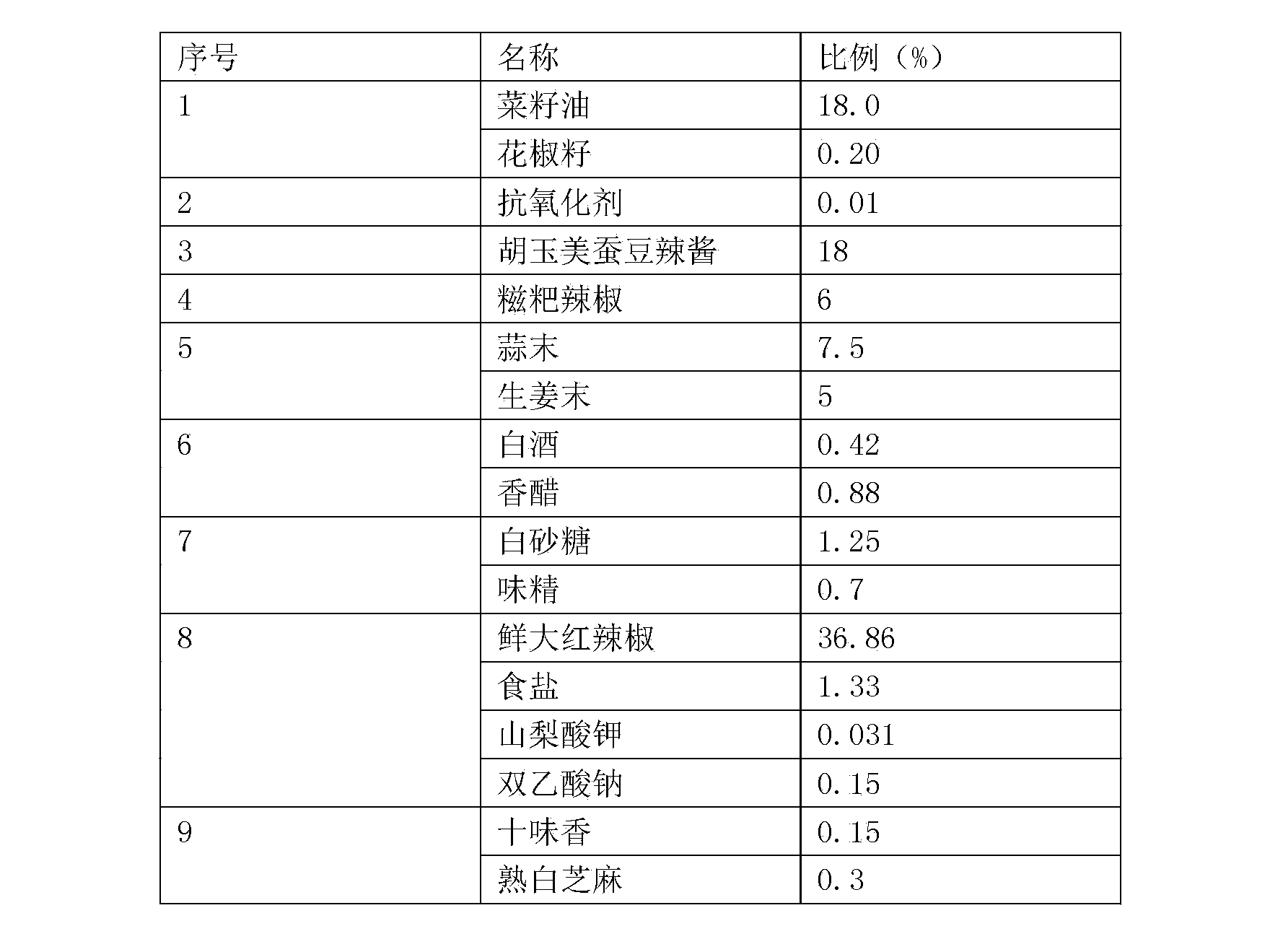

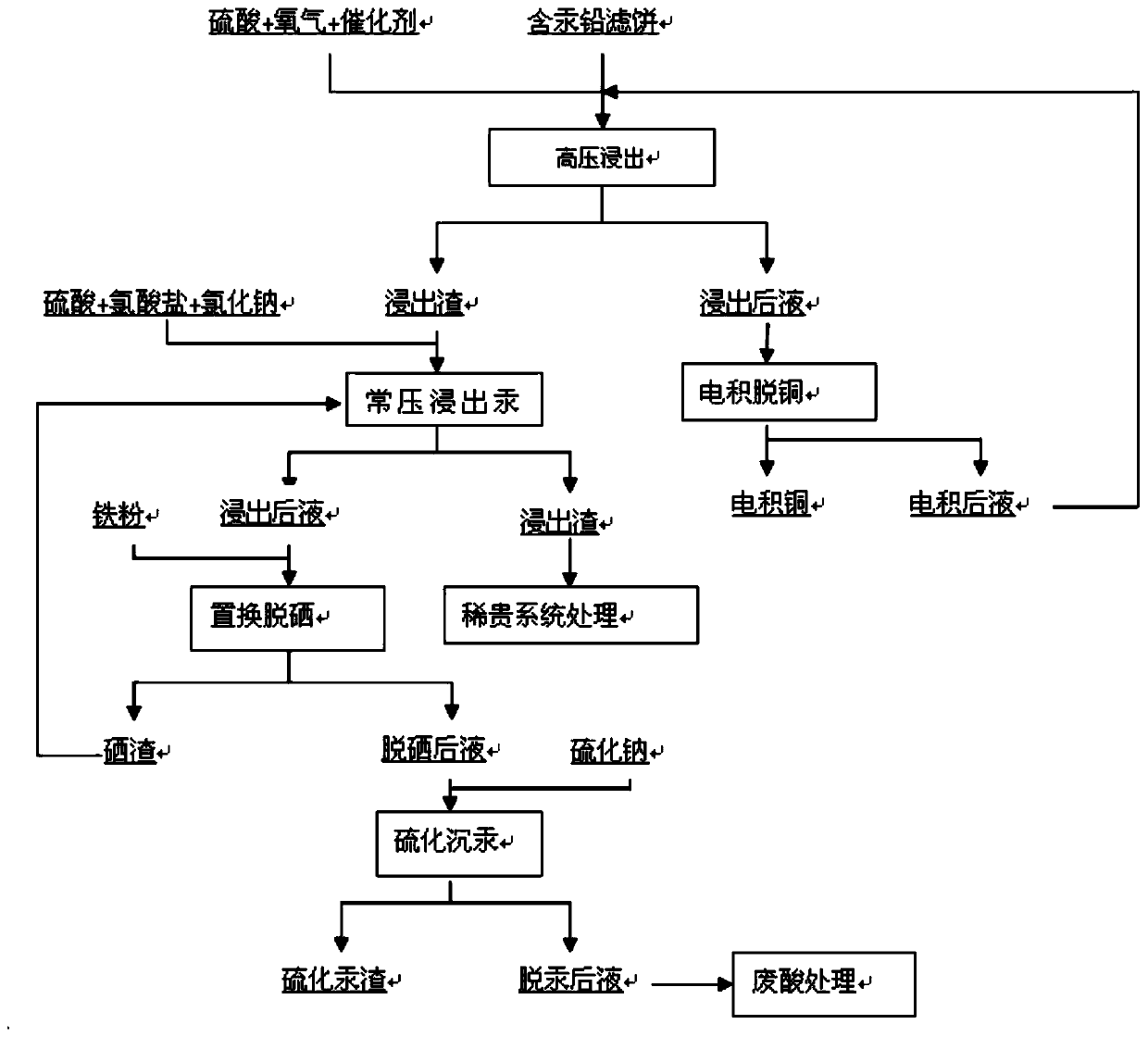

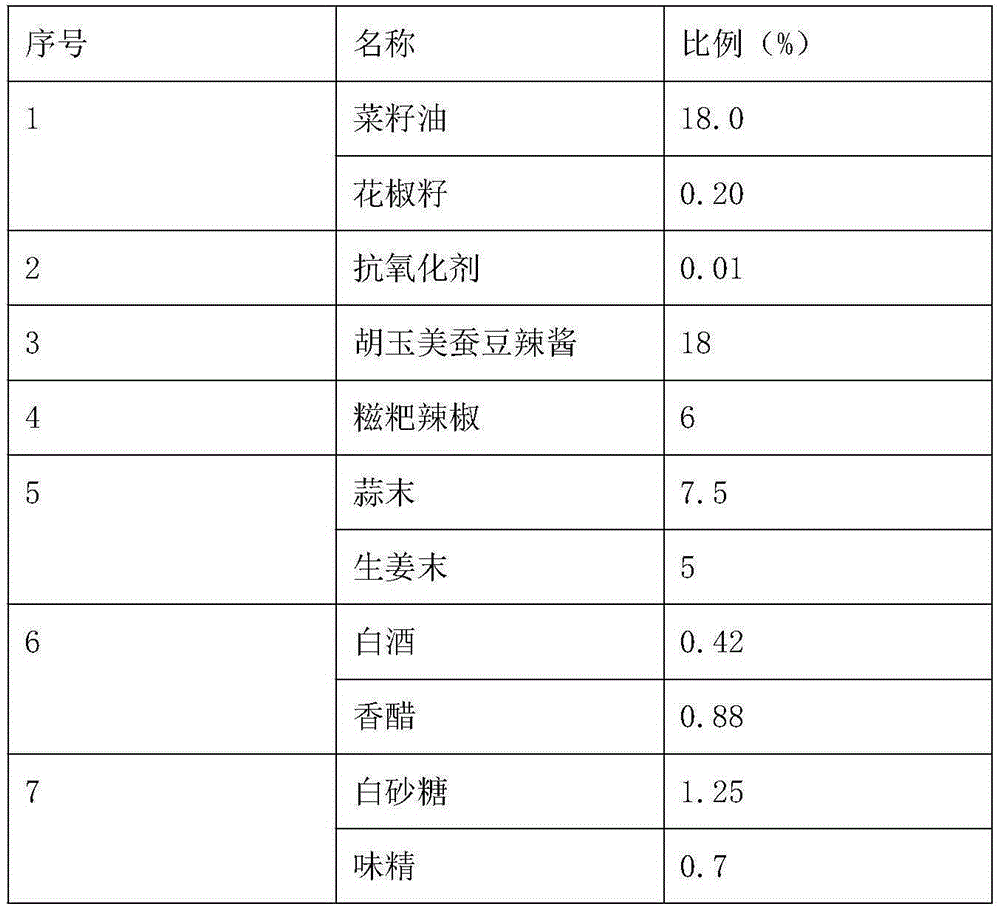

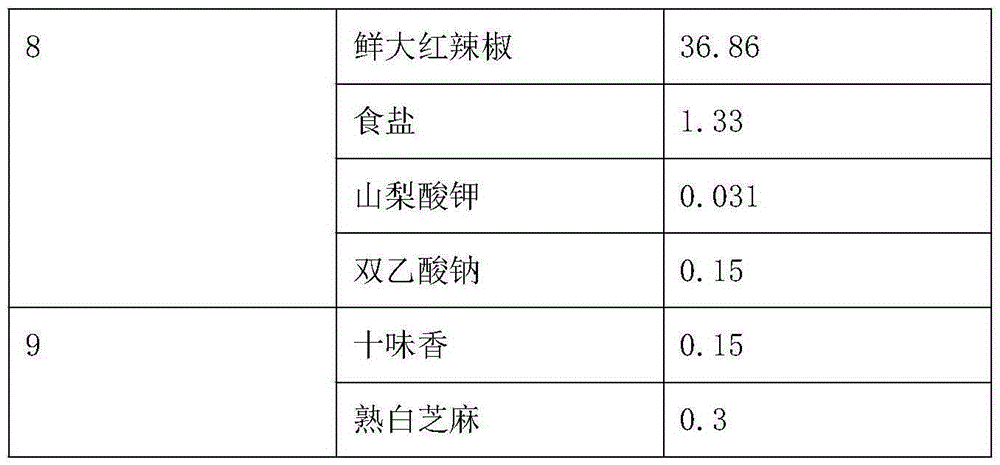

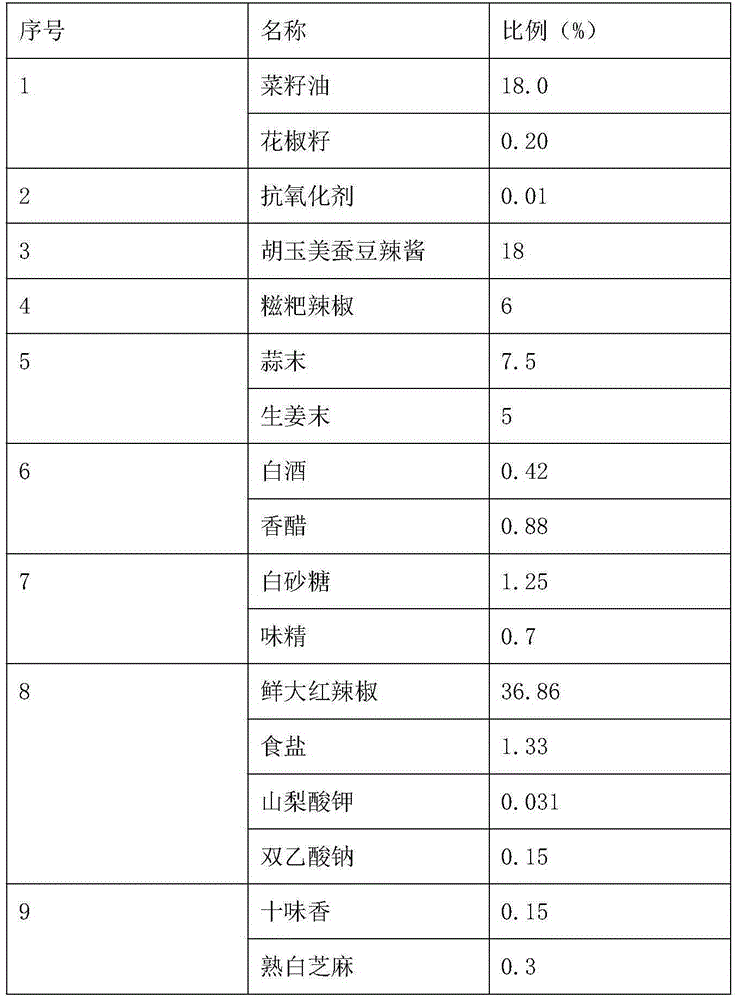

Production technology of lake fresh braised sauce

Owner:ANHUI FUHUANG SUNGEM FOODSTUFF GRP

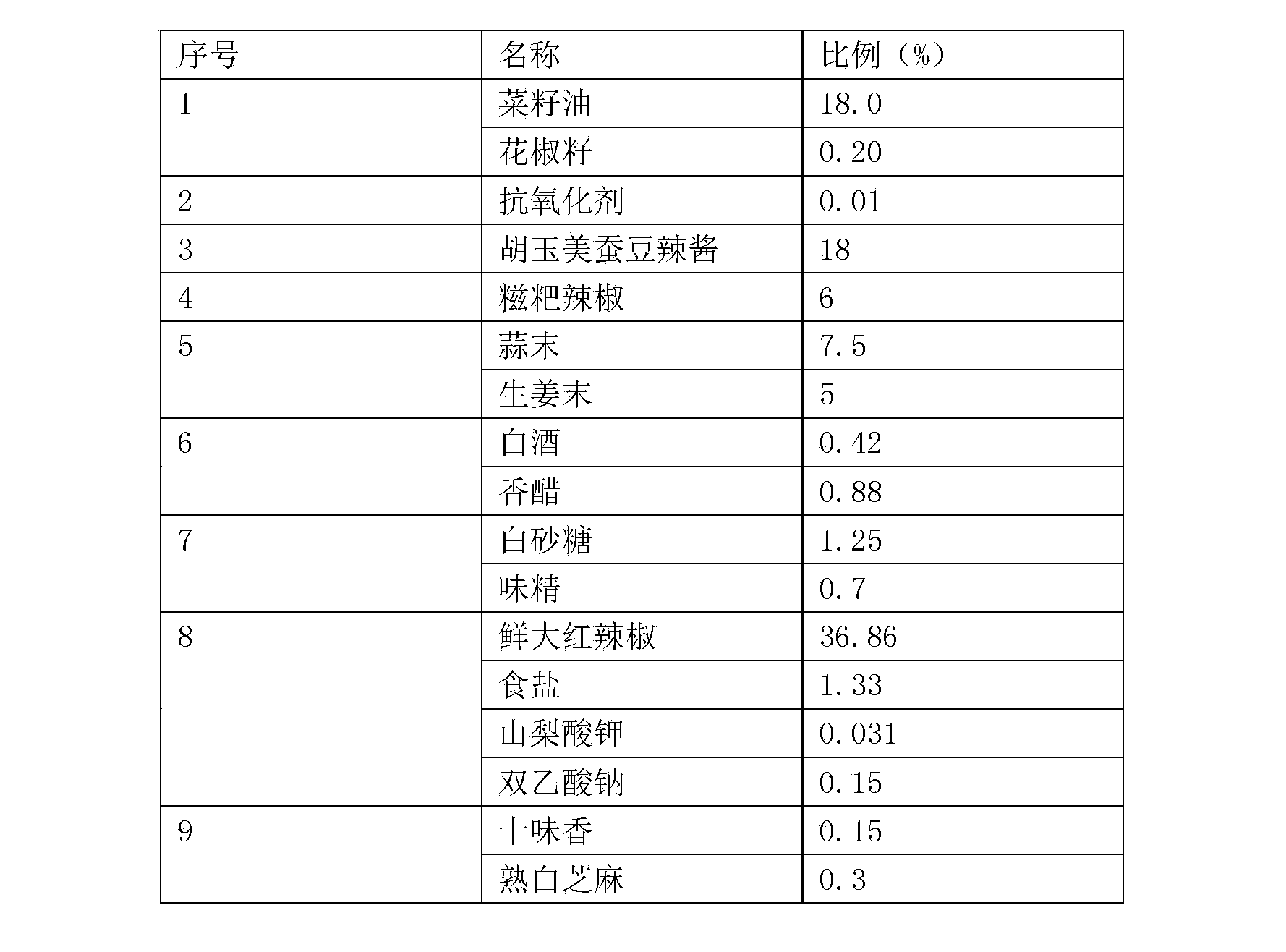

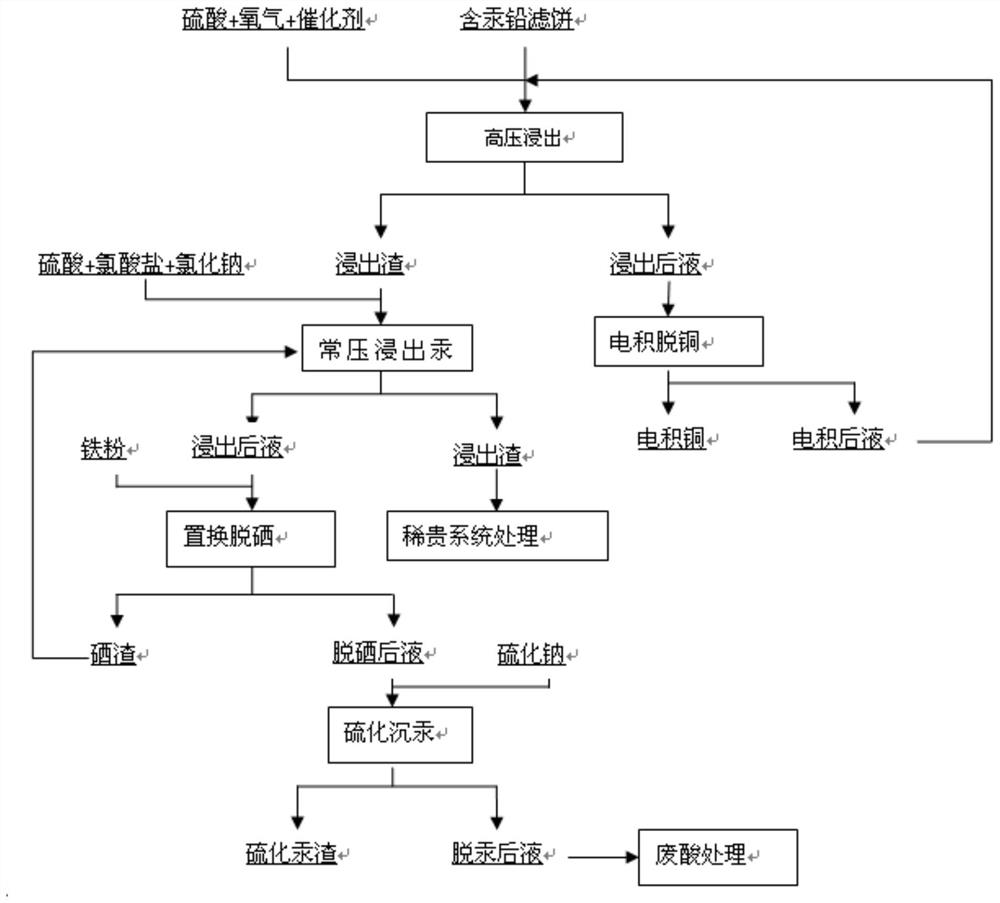

Treatment process of copper, mercury, selenium, lead, gold and silver in copper smelting lead filter cake

ActiveCN109971962AImprove leaching effectImprove overall recoveryPhotography auxillary processesProcess efficiency improvementVulcanizationSlag

The invention provides a treatment process of copper, mercury, selenium, lead, gold and silver in a copper smelting lead filter cake. The process mainly comprises following steps of low-temperature high-pressure oxidizing leaching of copper, normal-pressure oxidizing leaching and removal of mercury, replacement of selenium and vulcanization mercury sediment and further comprises rare precious system treatment and electrodeposition copper removal treatment. The treatment process is thorough in copper, mercury, selenium, lead, gold and silver separating effect, the gold, silver and selenium arebasically and completely enriched in the slag phase, the copper recycling rate is about 96%, the leaching rate of mercury is above 90%, and the aim of comprehensively treating valuable elements is achieved.

Owner:YANGGU XIANGGUANG COPPER

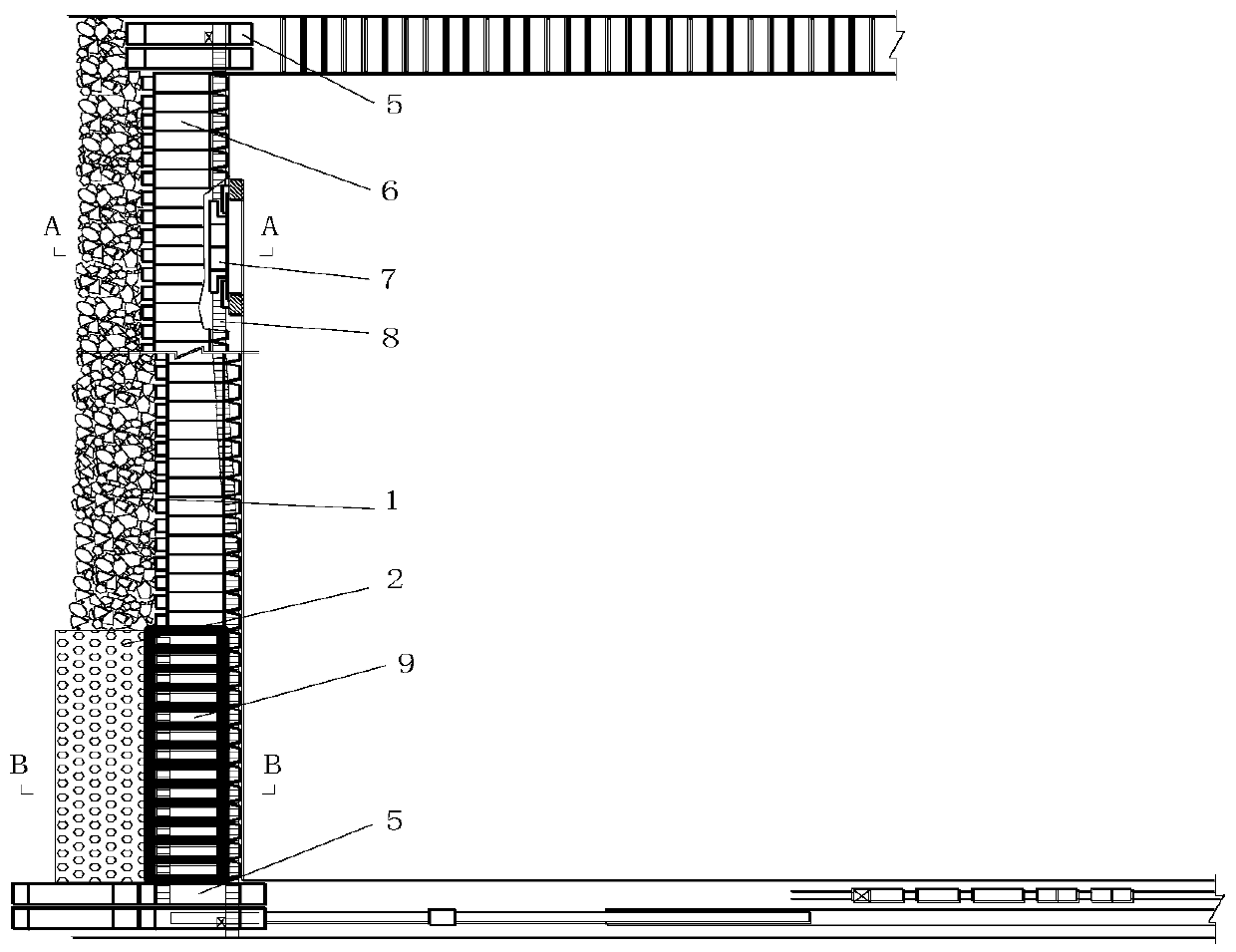

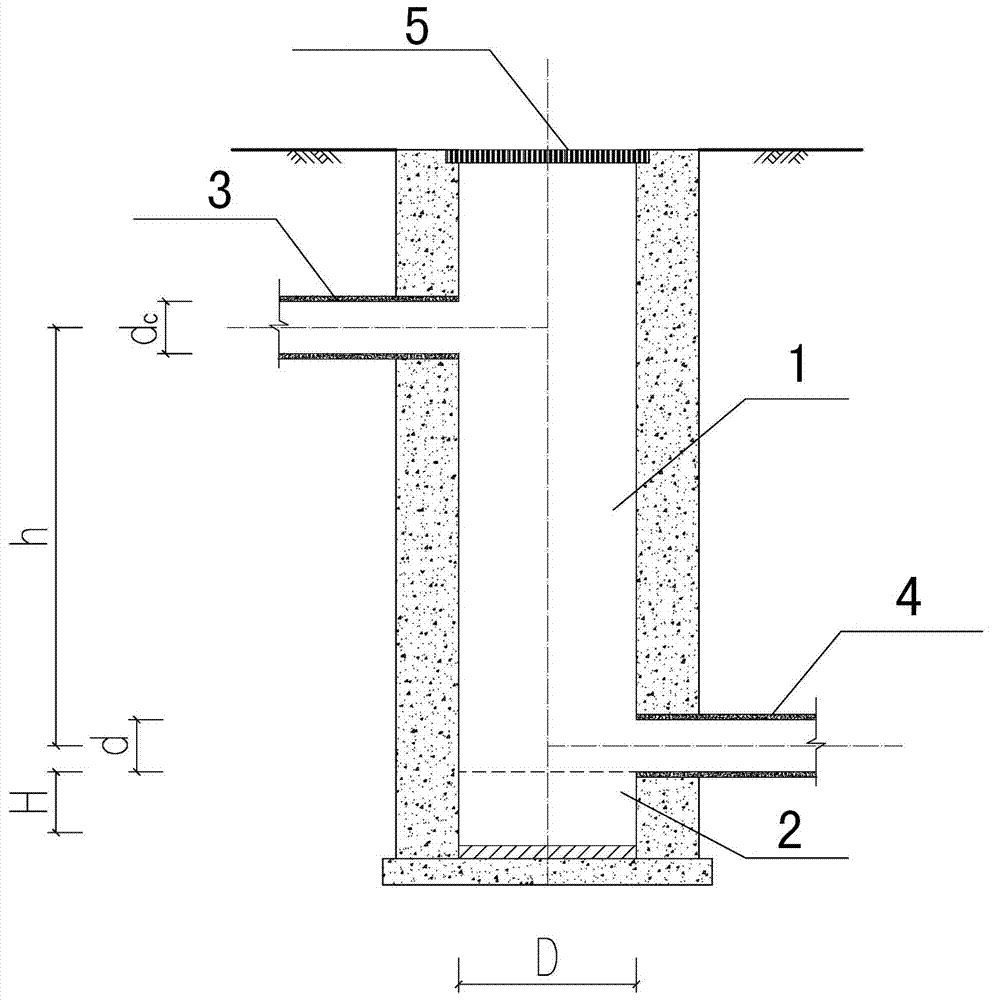

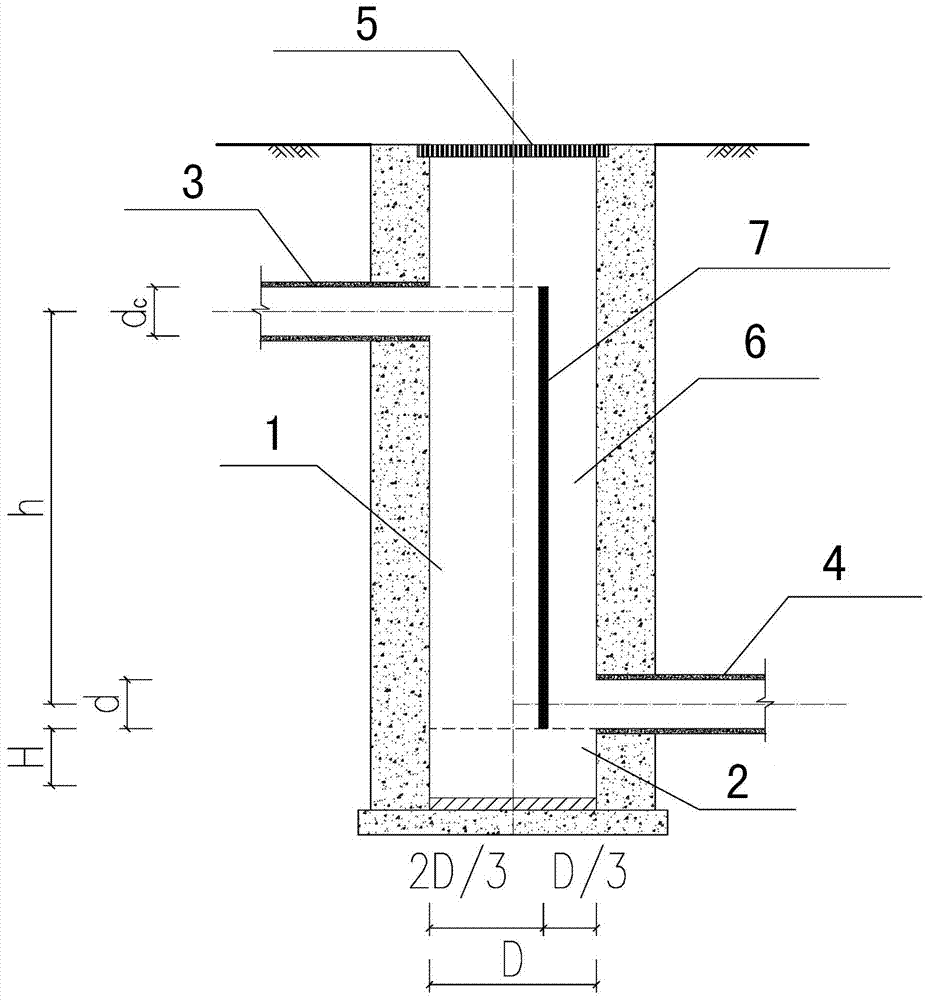

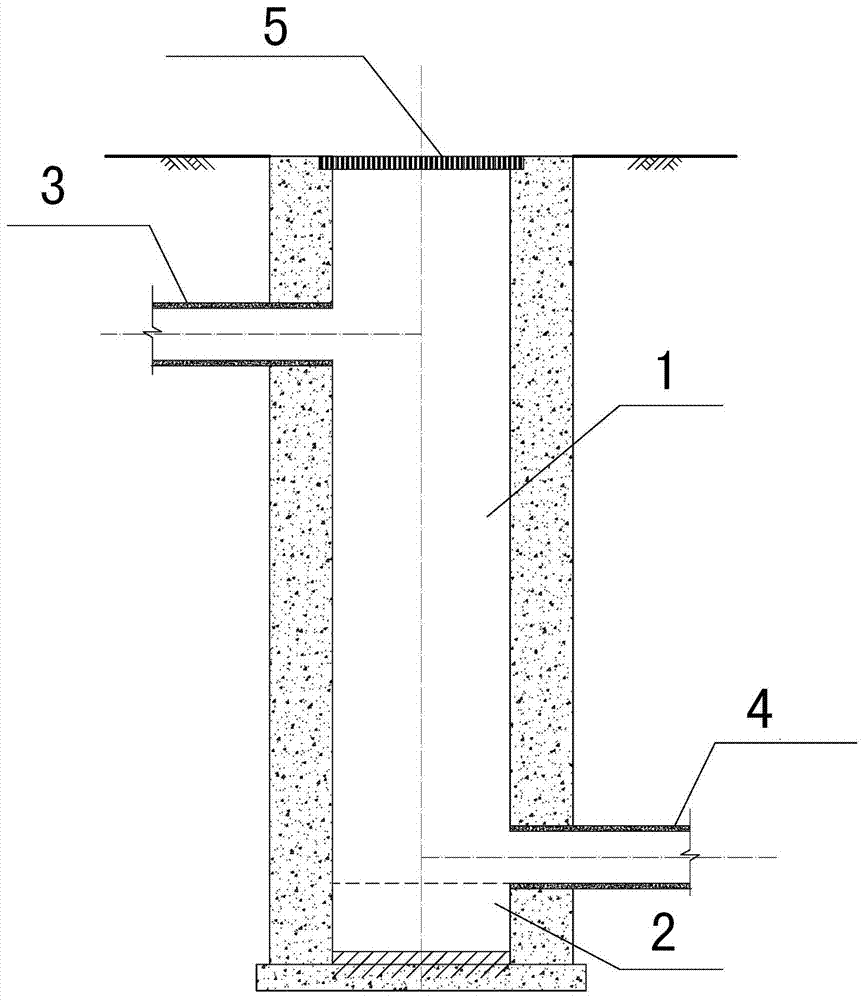

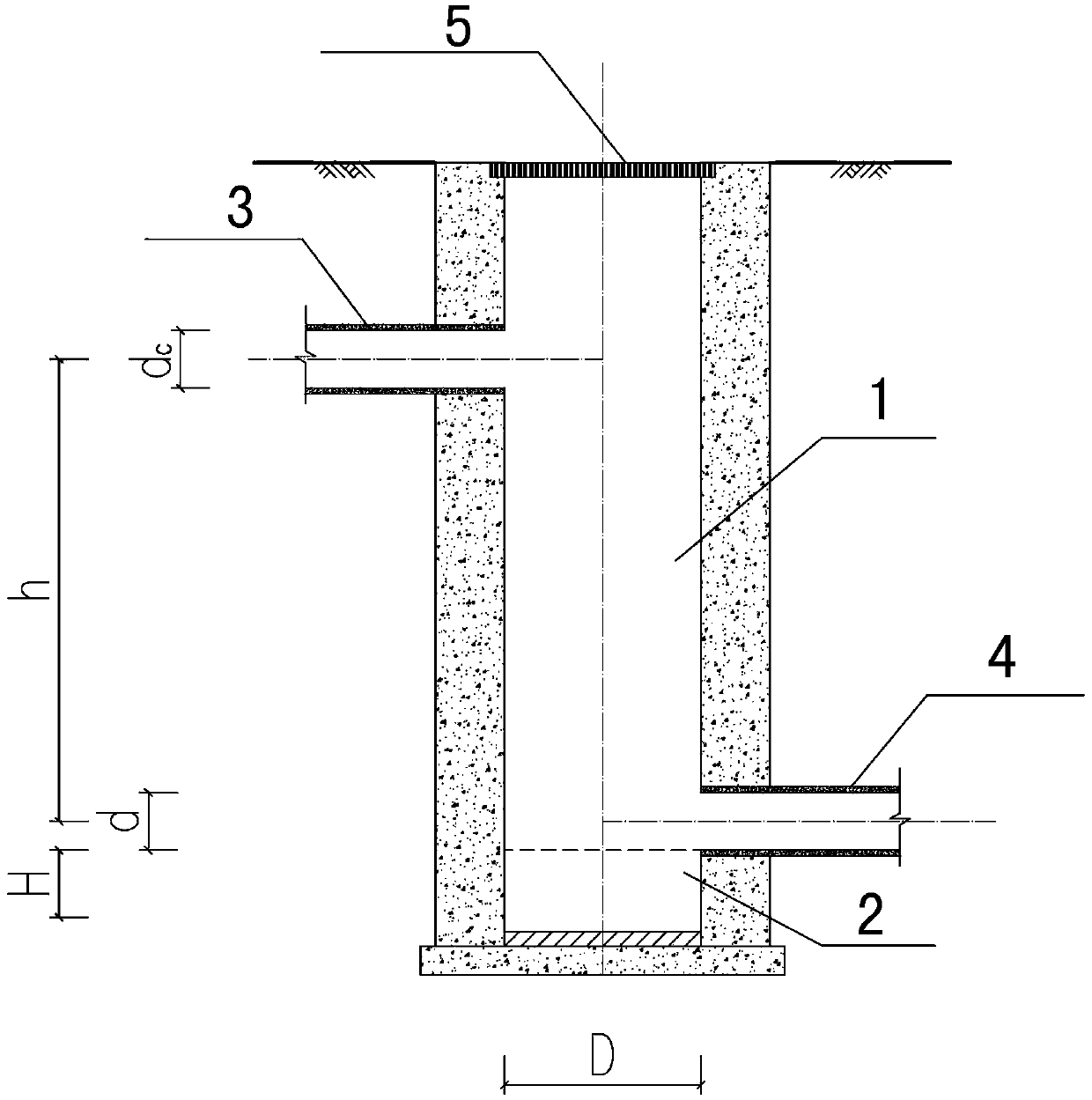

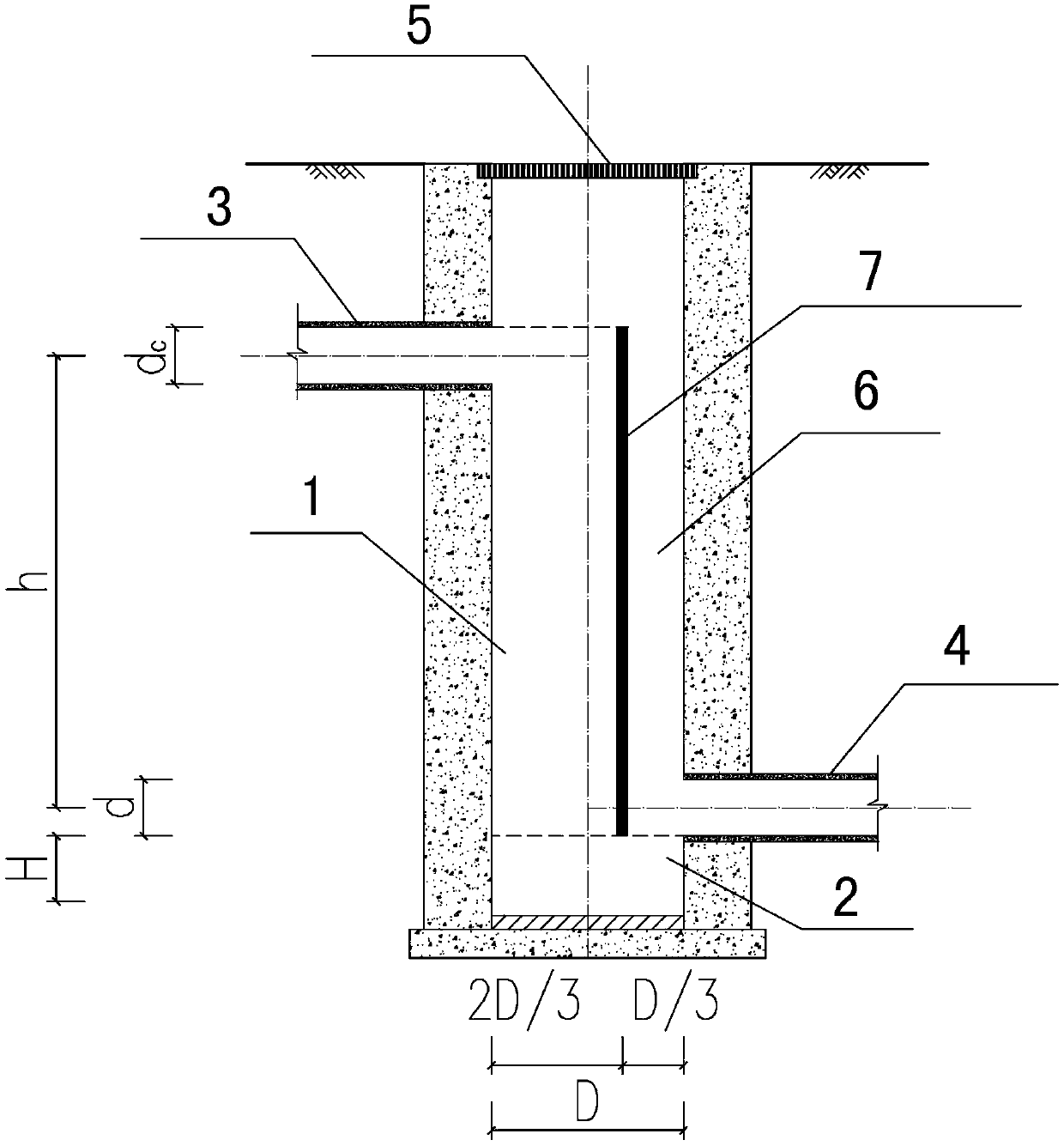

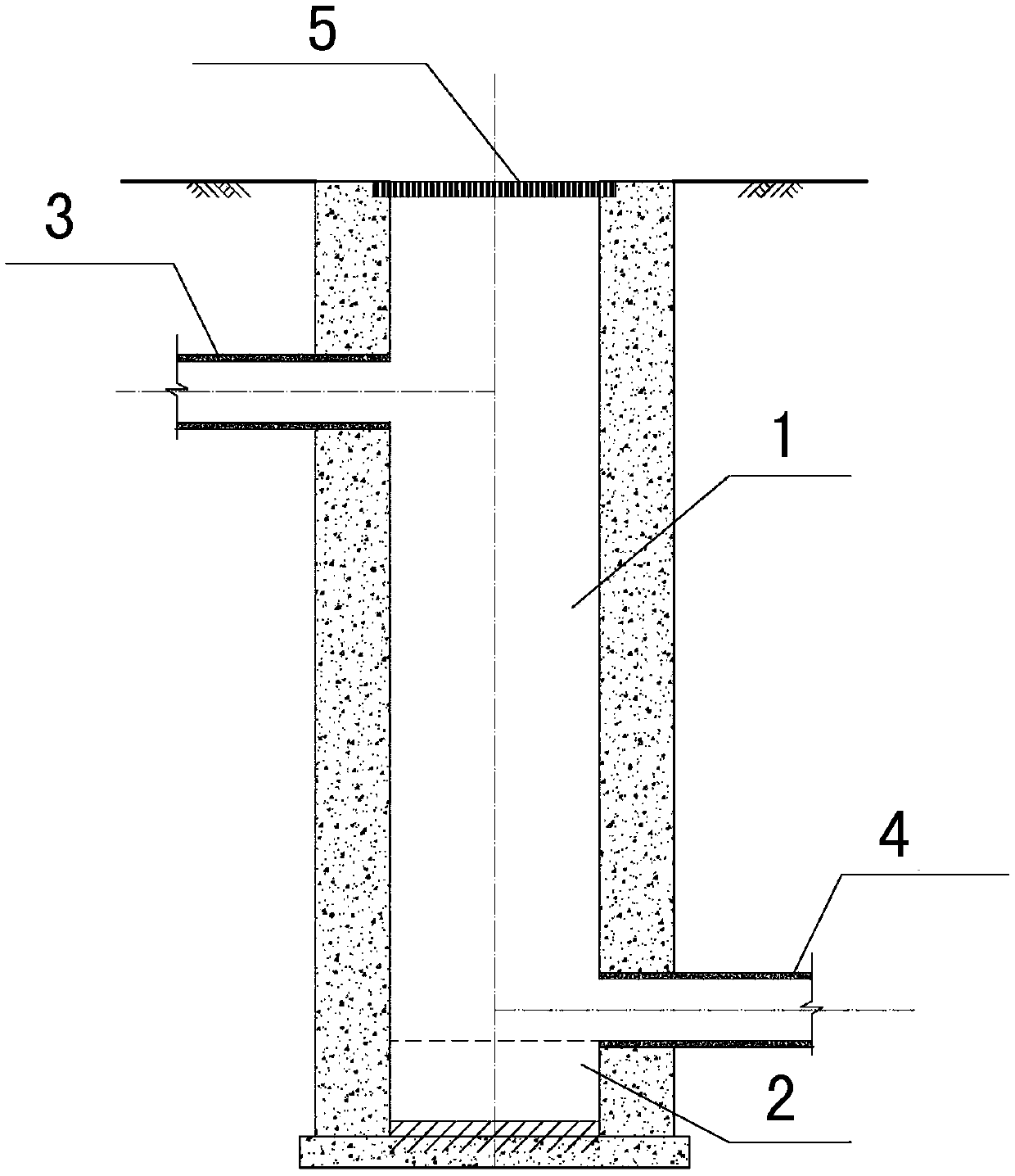

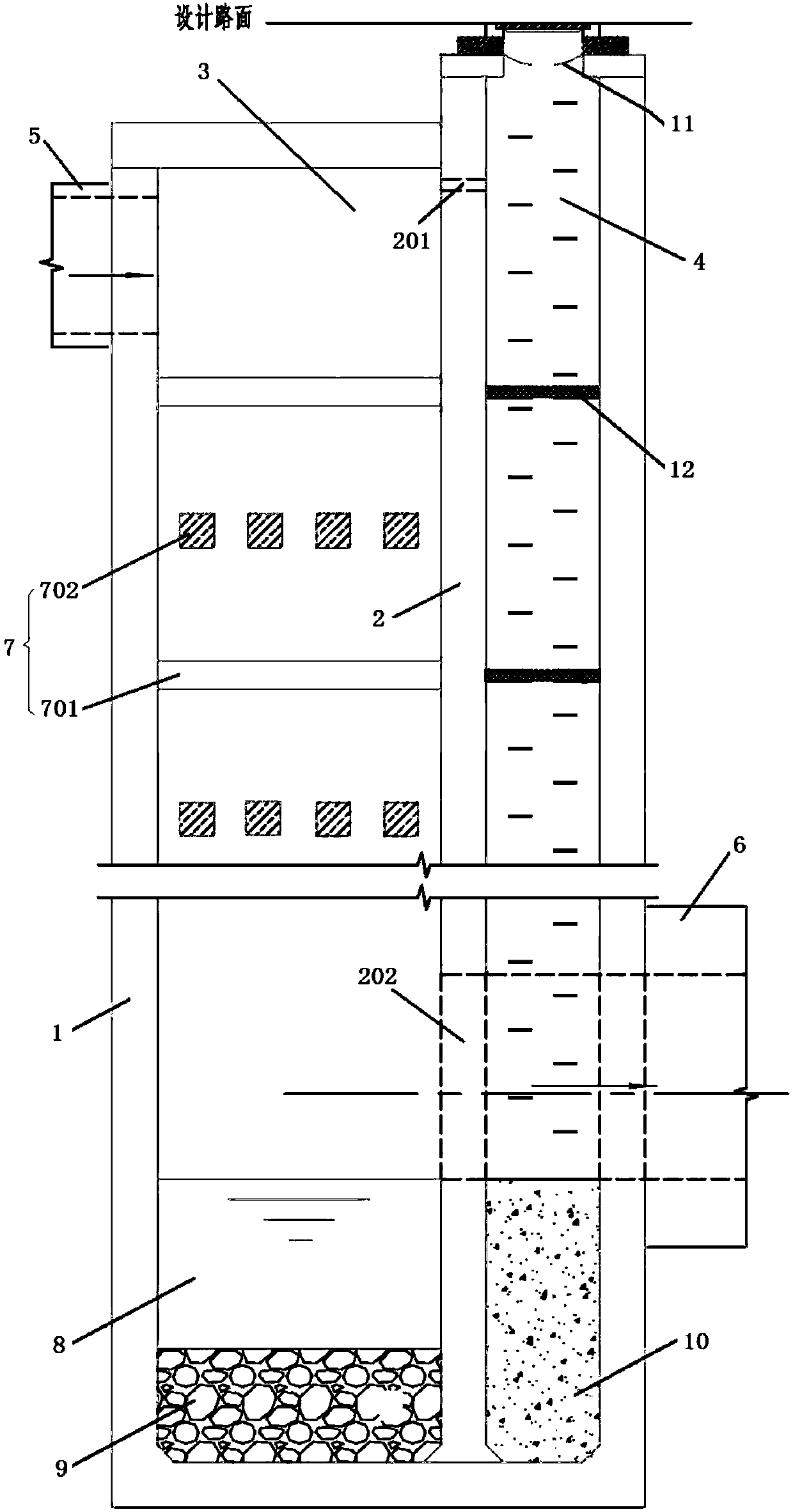

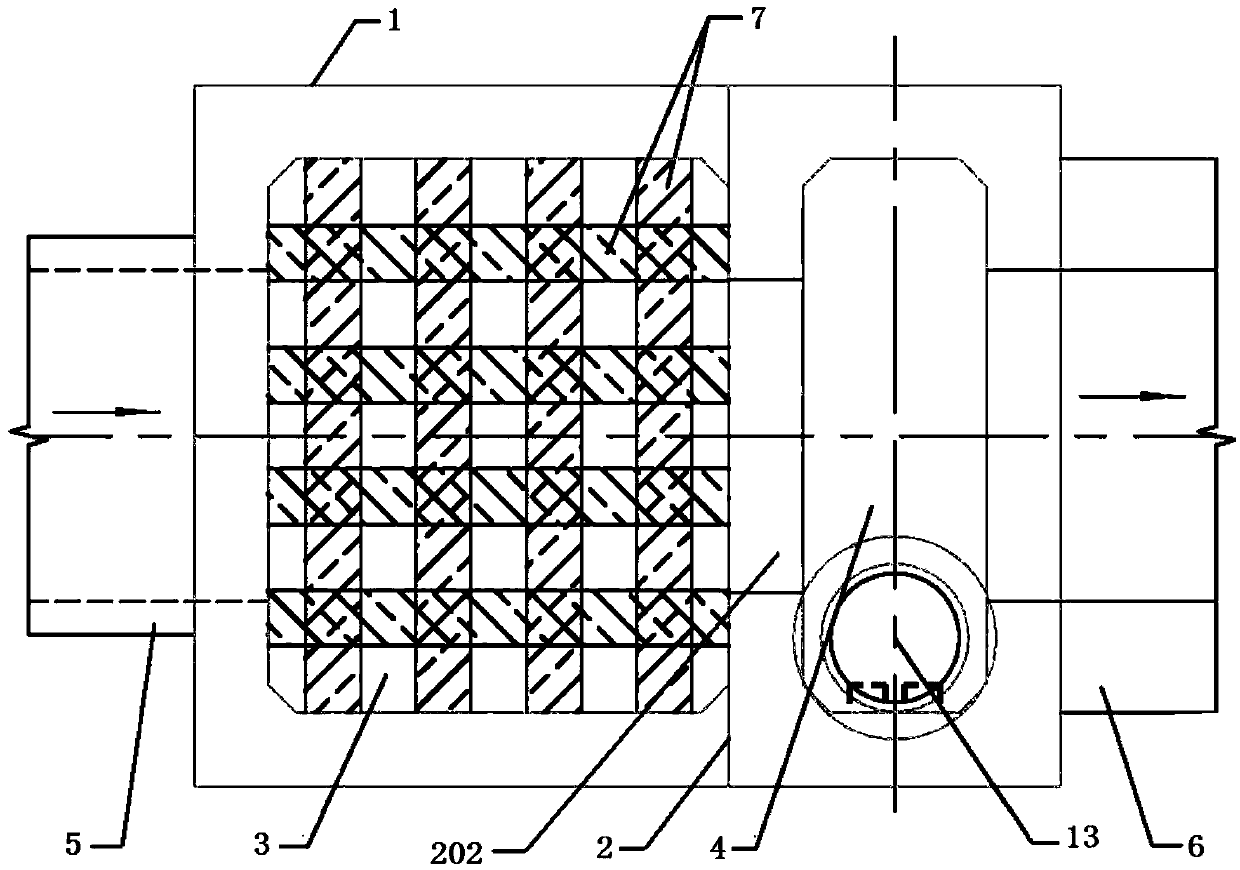

A straight-fall drainage drop well

ActiveCN105369880BSolve the problem of energy dissipationTo achieve the purpose of energy dissipationSewerage structuresNetwork densityEconomic shortage

The invention relates to a direct drop type draining drop well which mainly comprises a drop well body. The draining drop well is characterized in that the drop well body comprises a well chamber arranged on the upper portion of the drop well body and a pool arranged on the lower portion of the drop well body, the well chamber is directly vertically communicated with the pool, and the well chamber is provided with a water inlet pipe, a water outlet pipe and a ventilation well lid. The direct drop type draining drop well has the advantages that the draining drop well conforms to the development trend of land saving of draining projects and is efficient in function, clear in process and simple in structure, the well chamber is directly hydraulically communicated with the pool, the buffer effect of water stored in the pool is fully utilized, the energy dissipation problem of the drop well is solved, and the drop well can be conveniently applied to building areas with land shortage and high pipe network density.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

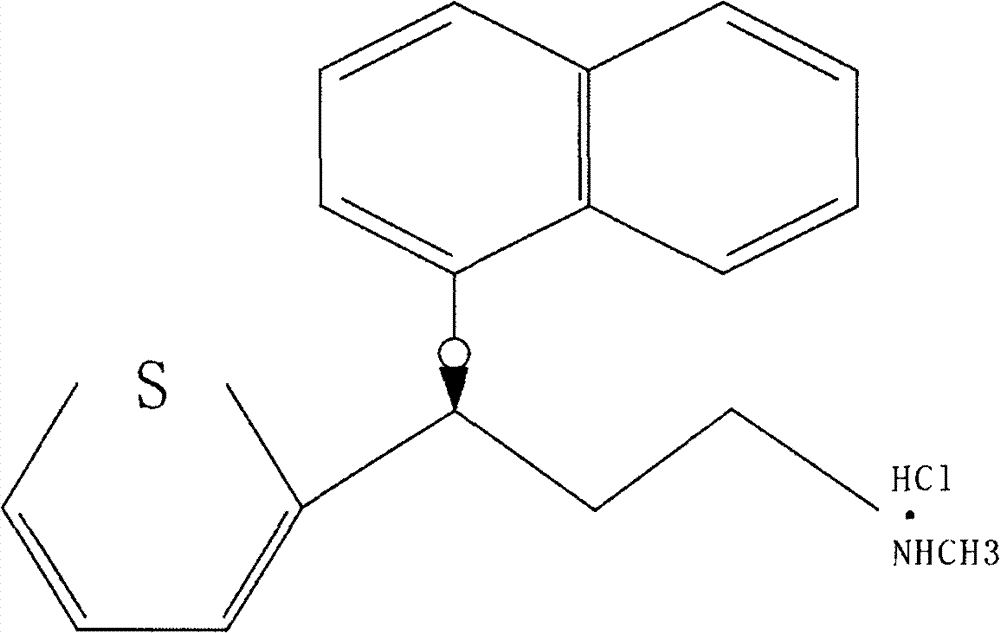

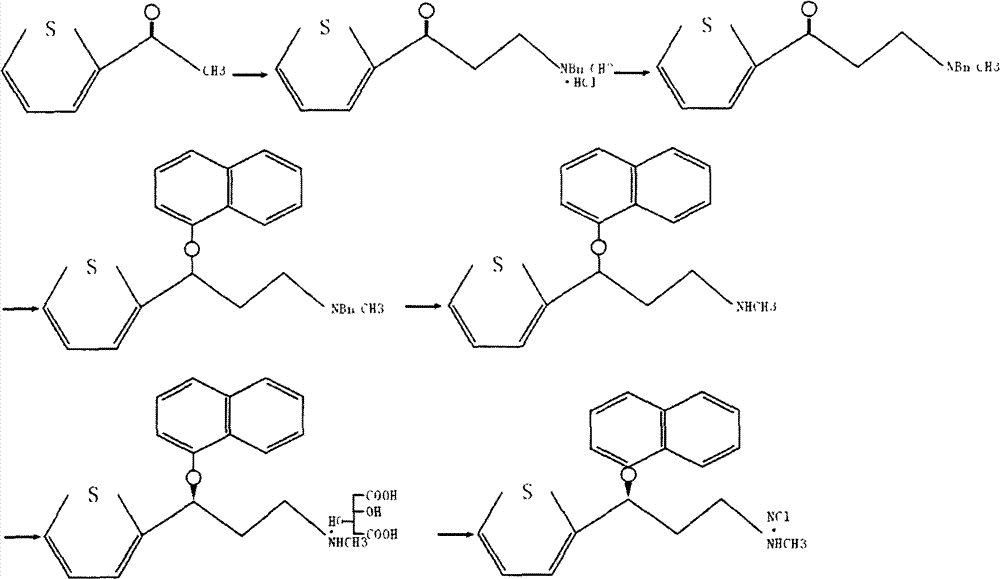

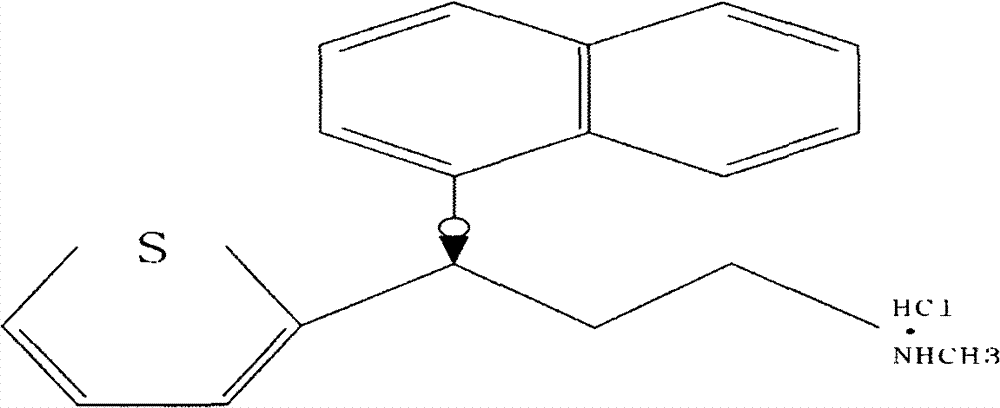

New preparation process of medicinal raw material duloxetine hydrochloride of antidepressant drug

InactiveCN103360365AMild reaction conditionsClear workmanshipOrganic chemistryTreatment effectMannich reaction

The invention relates to a new preparation process of the medicinal raw material duloxetine hydrochloride of an antidepressant drug and belongs to the technical field of drug synthesis. The new preparation process is characterized in that N-methyl benzylamine hydrochloride but not dimethylamine hydrochloride is used in Mannich reaction; because benzyl is easier to remove as compared with methyl, dealkylation in a subsequent step has better effect and higher yield; an expensive chiral catalyst or a phase-transfer catalyst is not used; a better solvent crystallizing and removing method is adopted, so that the harm of a residual crystallizing solvent to a human body is prevented; the splitting of a chiral compound is carried out after dealkylation, and a mixture obtained after splitting is separated by adopting a unique recrystallization technology to prepare (S)-N-methyl-3-(1-naphthoxy)-3-(2-thienyl) propylamine / tartrate with high purity and high optical activity, so that a finally obtained duloxetine hydrochloride product can achieve better treatment effect. The new preparation process disclosed by the invention has the advantages of mildness in reaction condition, clear process, good easiness and convenience in operation and low production cost and is extremely favorable for industrial production.

Owner:李晓红

Single-layer double-sided heat transfer printing process for polyester blankets

InactiveCN110117915ABroaden the field of printing and dyeingPlay a protective effectTransfer printing processDyeing processWater usePolyester

The invention discloses a single-layer double-sided heat transfer printing process for polyester blankets. The printing process includes the steps of 1), pretreatment; 2), double-sided printing; 3), over-hydrolyzed untwisting ; 4), drying; 5), brushing; 6), aftertreatment; 7), production of finished products. In the printing process, the single-layer double-sided magnetic rod printing technology of traditional polyester blankets is innovated, good permeability of blanket fiber in the printing process with a heat transfer printing machine is achieved, and the printing process is simple, clear and time saving and labor saving; continuous washing and fixing of high-temperature evaporated flowers using over-hydrolyzed untwisting instead of traditional magnetic bar printing machines greatly reduces the amount of water used and can guarantee the untwisting degree of the blanket fiber, functions in energy saving and no sewage treatment are imperceptibly achieved, and the concept of green environmental protection production is met; most importantly, the effect of printing is quite realistic and can be matched with digital printing heat transfer printing paper, traditional heat transfer printing paper can be used as well, and a wide market prospect is achieved.

Owner:江苏康尼纺织品有限公司

Direct drop type draining drop well

ActiveCN105369880ASolve the problem of energy dissipationTo achieve the purpose of energy dissipationSewerage structuresNetwork densityEngineering

The invention relates to a direct drop type draining drop well which mainly comprises a drop well body. The draining drop well is characterized in that the drop well body comprises a well chamber arranged on the upper portion of the drop well body and a pool arranged on the lower portion of the drop well body, the well chamber is directly vertically communicated with the pool, and the well chamber is provided with a water inlet pipe, a water outlet pipe and a ventilation well lid. The direct drop type draining drop well has the advantages that the draining drop well conforms to the development trend of land saving of draining projects and is efficient in function, clear in process and simple in structure, the well chamber is directly hydraulically communicated with the pool, the buffer effect of water stored in the pool is fully utilized, the energy dissipation problem of the drop well is solved, and the drop well can be conveniently applied to building areas with land shortage and high pipe network density.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Large-flow, high-drop drainage drop well and its multi-layer energy dissipation construction method

Owner:CMCU ENG

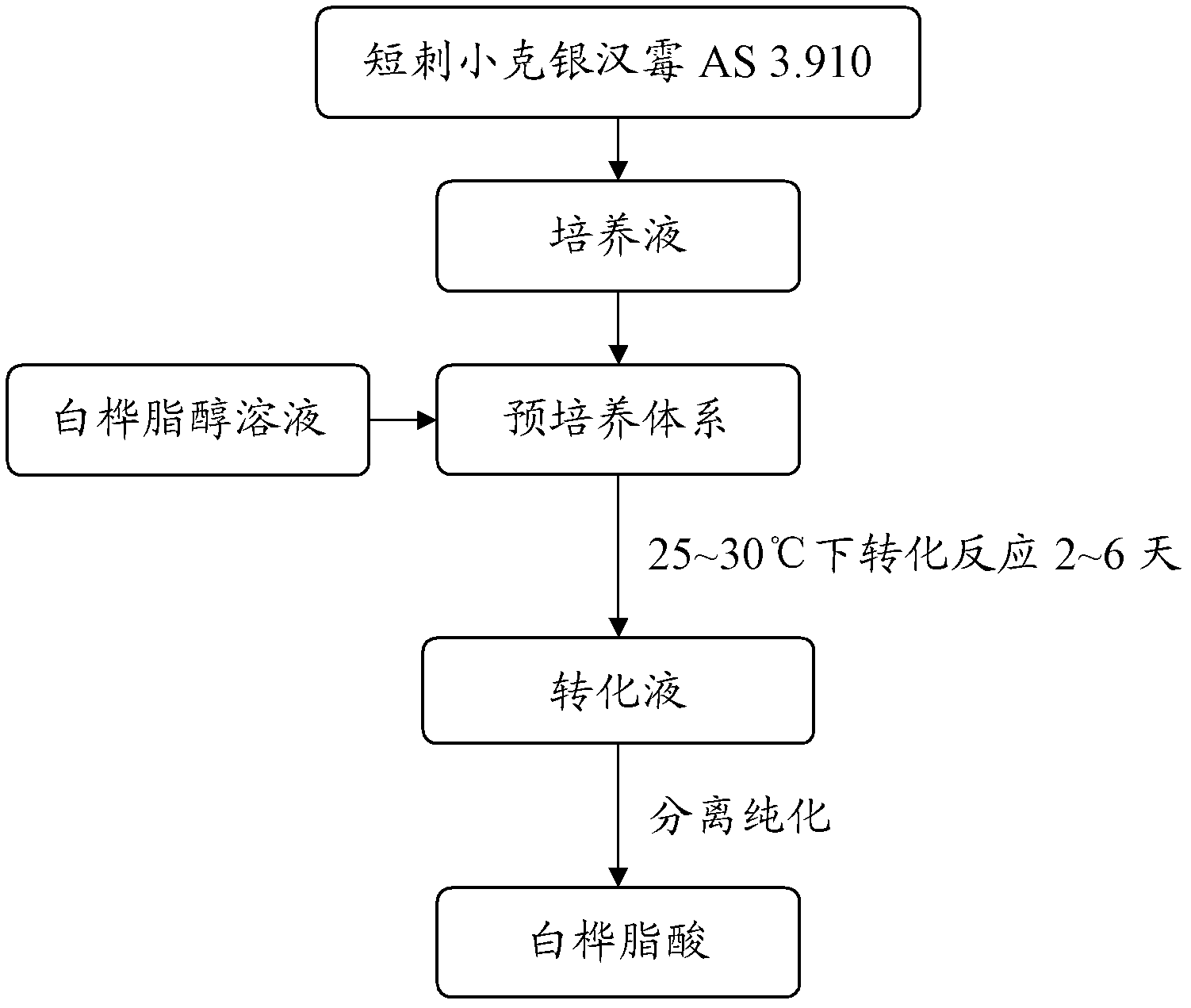

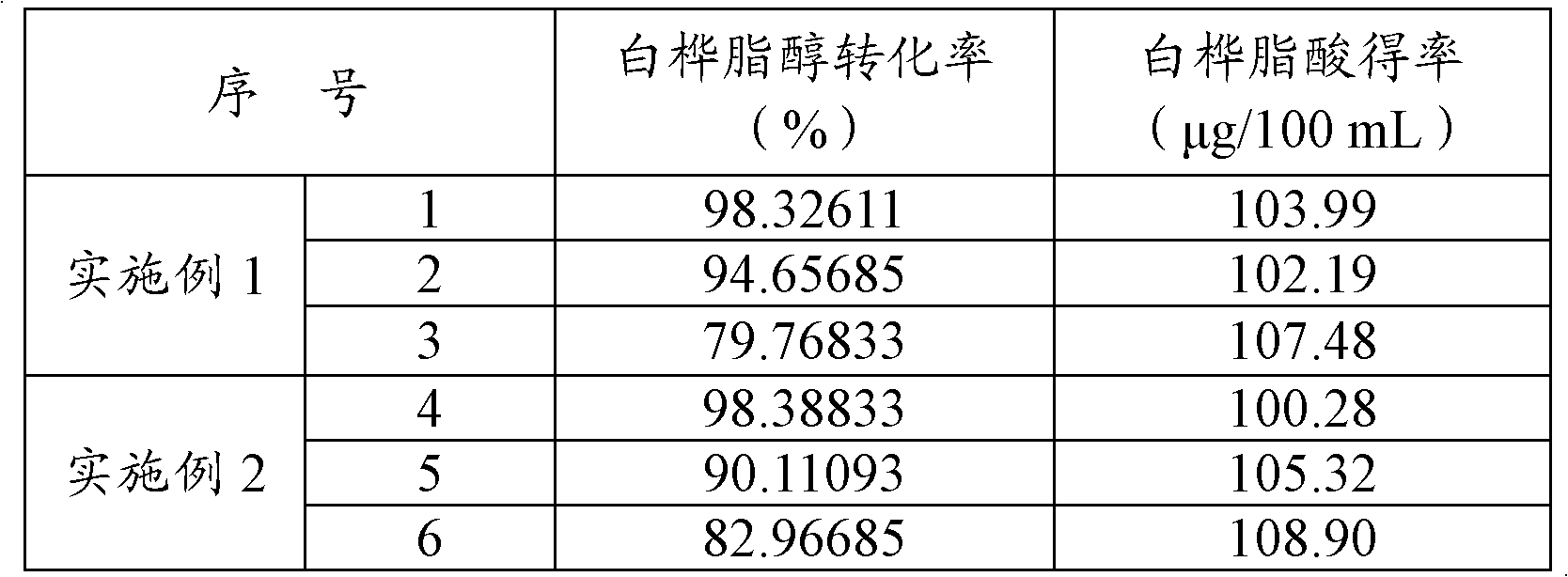

Method for synthesizing betulinic acid by transforming betulin into betulin from silvery mildew

InactiveCN102286595ASimple processMild transformation conditionsMicroorganism based processesFermentationCunninghamella blakesleeanaDrug biotransformation

The invention discloses a method for synthesizing betulinic acid through converting cunninghamella blakesleeana into betulin, which comprises the following steps of introducing cunninghamella blakesleeana AS 3.910 into sterilized culture solution to obtain a pre-culture system; then, adding betulin solution and surfactants so that the concentration of the betulin reaches 0.01 to 0.1g / L; carrying out conversion reaction for 2 to 6 days at 25 to 30 DEG C to obtain conversion liquid; and obtaining the betulinic acid through separation and purification. The method provided by the invention uses the cunninghamella blakesleeana as a carrier and uses the betulin as substrates for synthesizing the betulinic acid through biotransformation, the process is simple, the condition is mild, the transformation period is short, the product yield is high, the environmental-friendly effect is realized, and the betulinic acid with a higher yield can be obtained.

Owner:ZHEJIANG UNIV

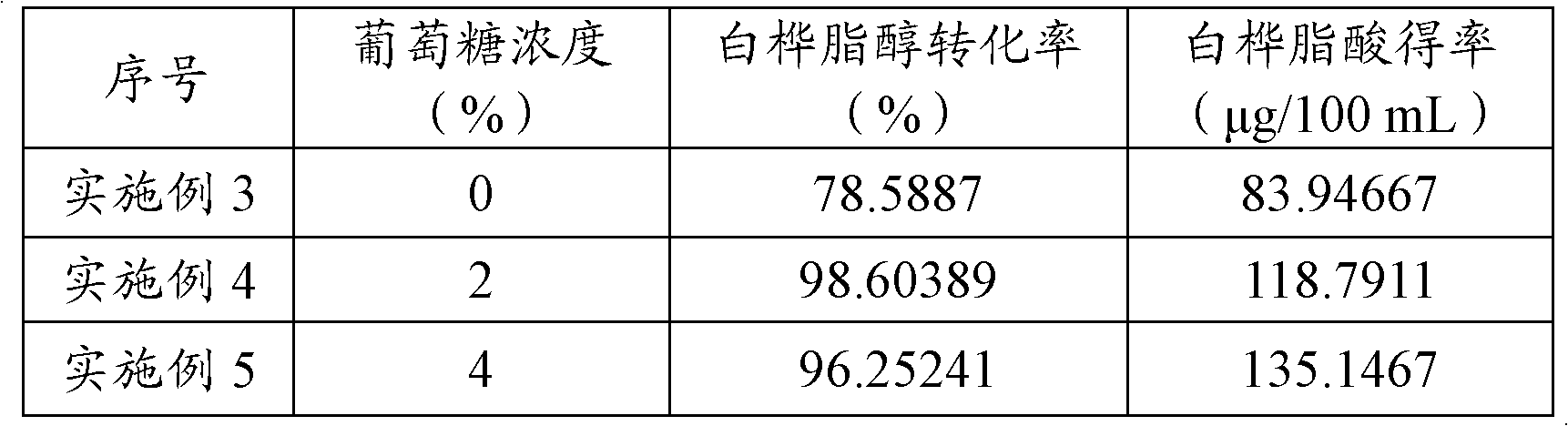

Regeneration cleaning process of combined filter element

ActiveCN110478983ANo pollution in the processFilter recoveryFilter regenerationHigh pressure waterSolvent

The invention discloses a regeneration cleaning process of a combined filter element. The regeneration cleaning process comprises the following steps: performing pretreatment in a solution consistingof a dispersing agent, an emulsifying agent, a cosolvent and water; performing ultrasonic treatment or high-pressure water washing as transition treatment; performing conversion treatment in a conversion solution prepared from strongly basic sodium salt; performing ultrasonic treatment or high-pressure water washing as transition treatment; carrying out fine treatment in a solution consisting of achelating agent, a corrosion inhibitor, a surfactant and water; performing ultrasonic treatment or high-pressure water washing as transition treatment; performing post-treatment in an aqueous solution containing a passivator and a brightener; then, performing ultrasonic treatment or high-pressure water washing; and finally drying the filter element. Through the process, the filtering element is cleaned more thoroughly, the filtering performance of the cleaned element is close to that of a new product, the cleaning agent is free of pollution to the environment and can be recycled, the cleaningoperation process is safe, the process is simple and clear, and the process is suitable for large-scale production.

Owner:WESTERN BAODE TECH CO LTD

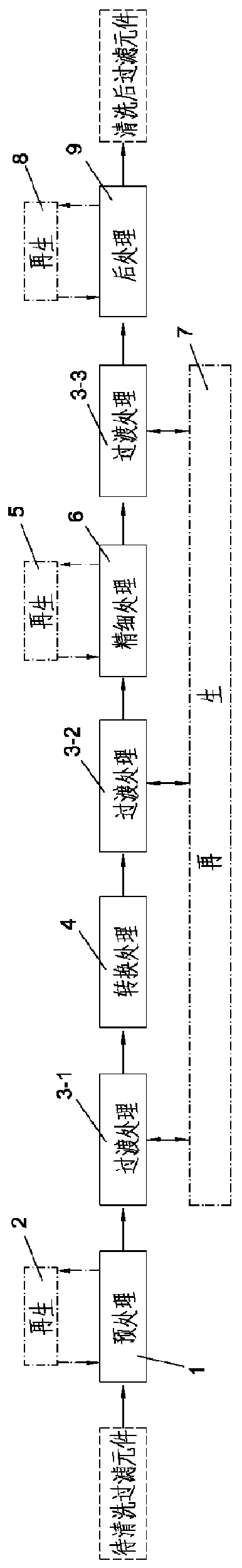

Cast aluminum composite metal heat exchange device and manufacturing method thereof

InactiveCN106500525AReduce volumeNot easy to scaleStationary conduit assembliesHeat exchanger casingsHeat conductingAluminum composites

The invention discloses a cast aluminum composite metal heat exchange device and relates to the field of heat exchange devices. The cast aluminum composite metal heat exchange device comprises heat conducting pipes and a frame connected with the heat conducting pipes. The frame comprises an outer frame body and cooling fins fixedly connected with the outer frame body. The two sides of each cooling fin are connected with the walls of the corresponding adjacent heat conducting pipes. The cooling fins are arranged on the outer frame body and directly make contact with the outer frame body. The outer frame body can transmit and conduct heat for the cooling fins, so that the heat conducting area is enlarged, and the heat exchange effect is more excellent. The two sides of each cooling fin are connected with the walls of the corresponding adjacent heat conducting pipes, the same cooling fin can enlarge the heat exchange areas of the corresponding two adjacent heat conducting pipes at the same time, and thus the overall size of a heat exchanger is reduced. In use, multiple cast aluminum composite metal heat exchange devices are assembled side by side to form the heat exchanger, a continuous wavy surface is formed by the cooling fins and heat exchange pipes so that turbulent flow or eddies can be formed repeatedly when heat exchange media flow through the heat exchange pipes, and accordingly the surfaces of the heat exchange pipes and the surfaces of the cooling fins are not prone to scaling.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

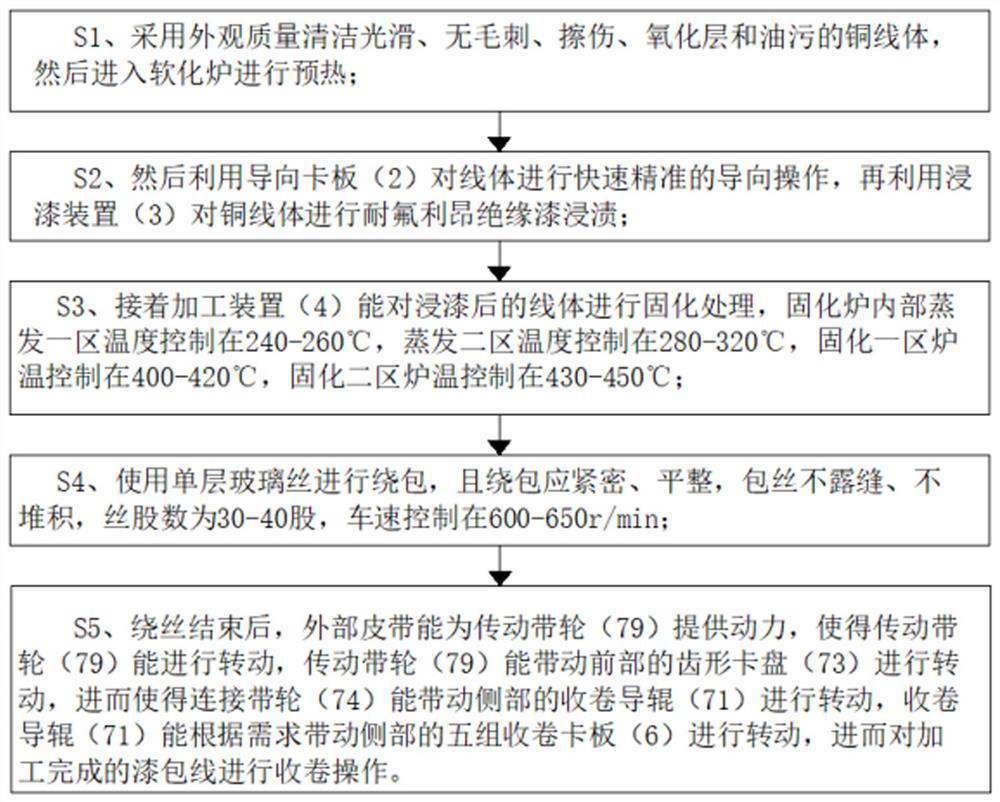

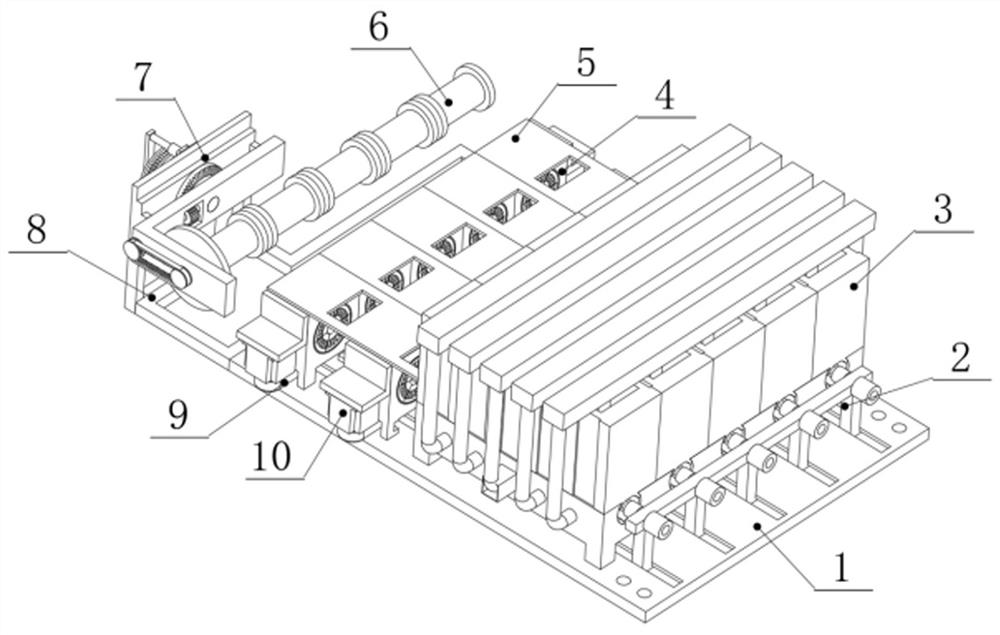

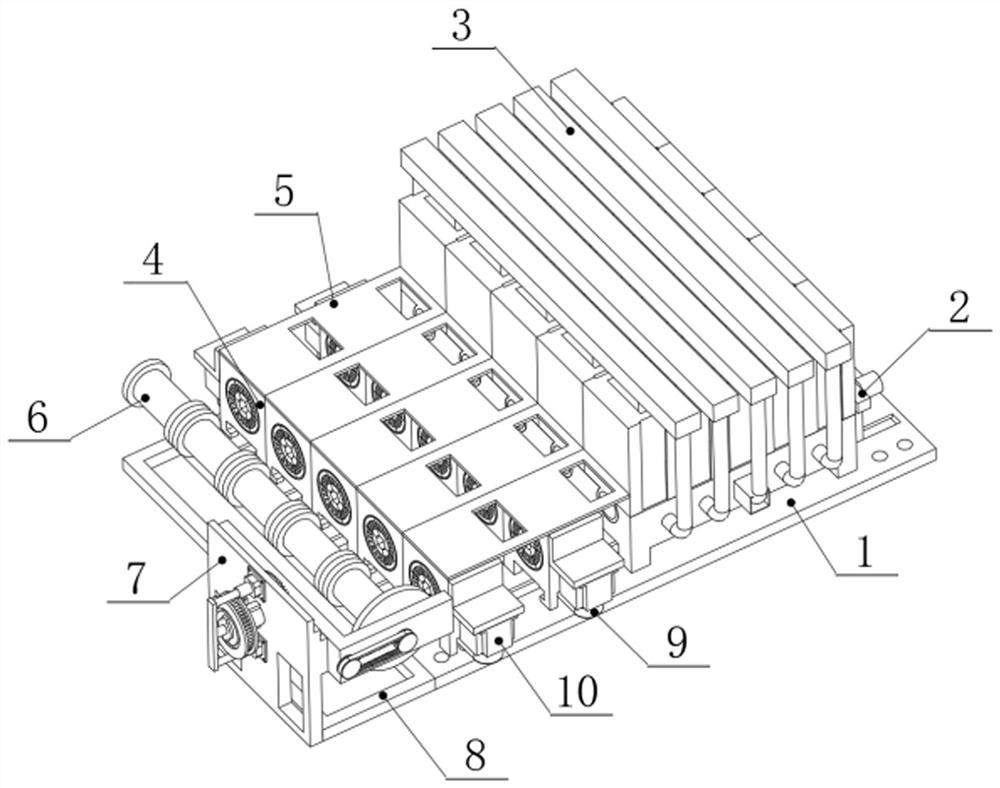

Production process and equipment of Freon-resistant composite enameled wire with glass fiber wrapping

ActiveCN114520083AImprove winding efficiencyImprove processing efficiencyFilament handlingInsulating conductors/cablesGlass fiberFiber

The invention relates to the technical field of composite enameled wire production, in particular to a production process and equipment of a Freon-resistant composite enameled wire wrapped with glass fiber, and the process comprises the following steps: a copper wire body which is clean and smooth in appearance quality and free of burrs, scratches, oxidation layers and oil stains is adopted and then enters a softening furnace to be preheated; then, the wire body is quickly and accurately guided, and the copper wire body is subjected to Freon-resistant insulating paint dipping by using a paint dipping device; then the processing device can carry out curing treatment on the wire body subjected to paint dipping; single-layer glass fibers are used for wrapping, wrapping needs to be tight and flat, and the wrapping fibers are free of seam exposure and accumulation; winding operation is carried out after wire winding is finished; the equipment comprises a supporting bottom plate, a guiding clamping plate, a paint dipping device, a machining device, a connecting clamping plate, a winding clamping plate, a winding device, a connecting bottom frame, a tooth-shaped belt and a servo motor. The preparation method is reasonable in design, simple in process and clear in process route, and the prepared finished product has excellent performance of high temperature resistance, high pressure resistance and corrosion resistance.

Owner:湘潭市霞城电工有限公司

A coating preparation process

The present invention disclosed a coating preparation technology, which is characterized by the process steps: (1) Select the raw material: according to the weight percentage, 65%of the polystyrene foam, phenolic foam plastic, waste rubber and nitro fiber, industrial alcohol, Coal Coroline, acetone and water solvent accounted for 15%, pigments and fillers accounted for 15%, and 5%of moisture dispersant, elimination agent, lighting agent, plasticizer auxiliary agent; (2) melting refining;; (4) Disclosure; (5) harmonization; (6) filtering; (7) packaging; the invention is reasonable and concise, which greatly shortens the process of process.At the same time, according to the raw material ratio, coatings that are convenient for the functions of each medium, suitable for the needs of its production process, the amount and ratio of the proportion are accurate, the deviation is small, the product quality is guaranteed, and the company's output is effectively improved.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

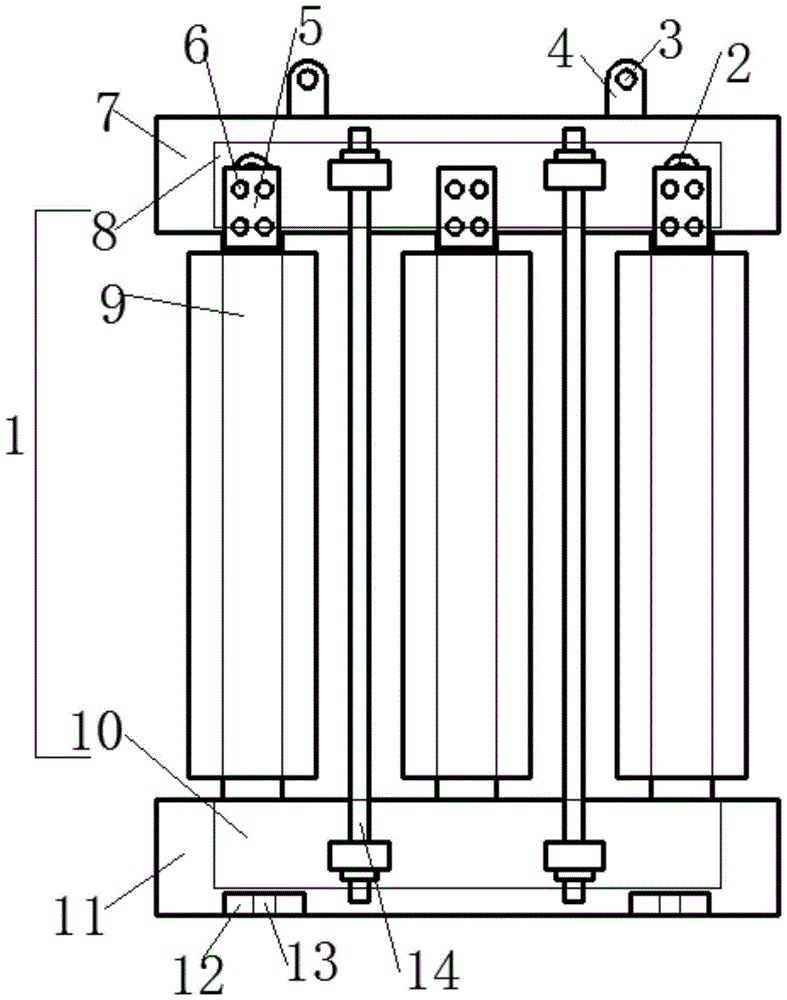

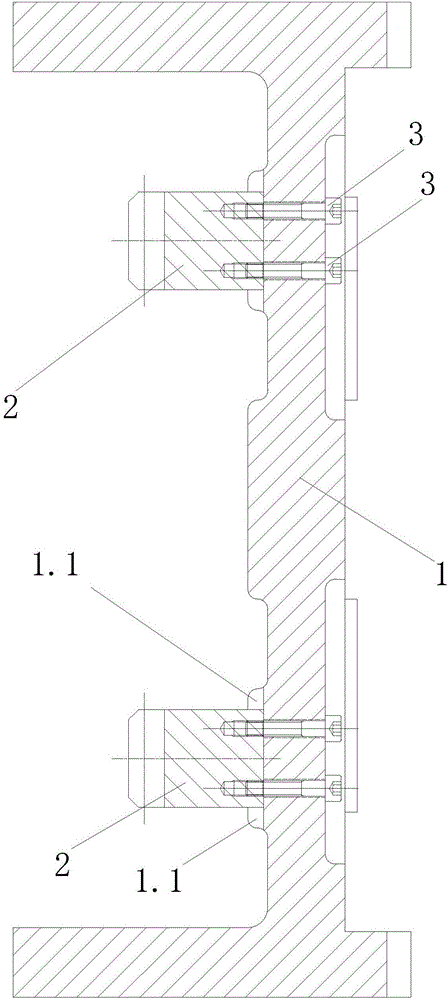

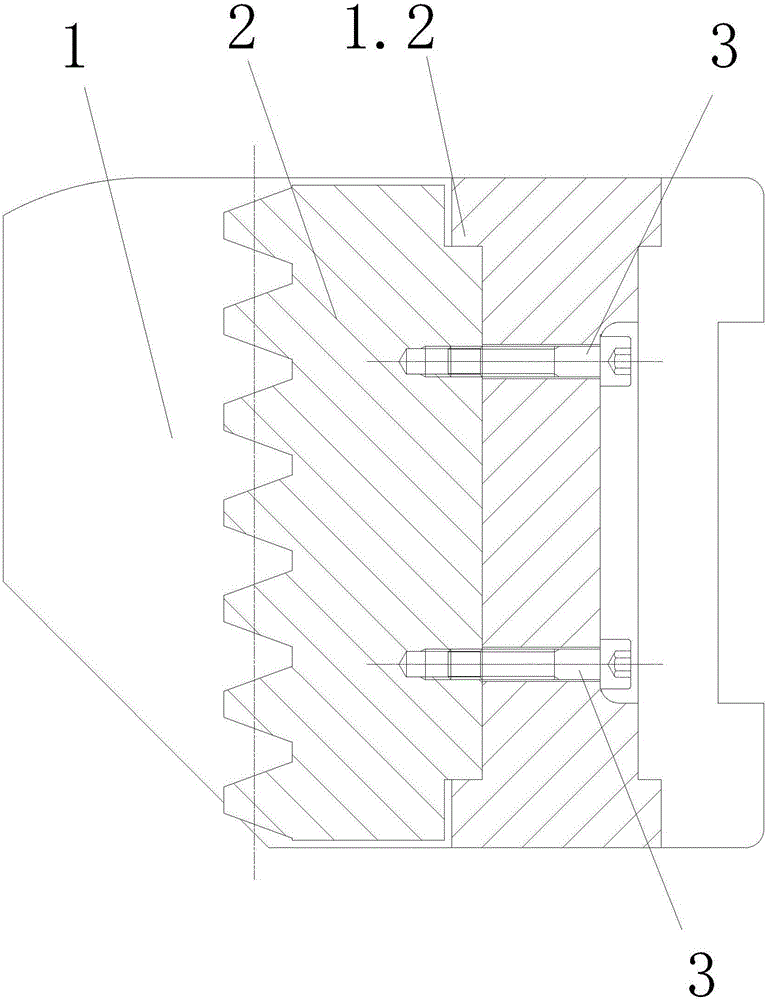

Electric reactor iron core structure

InactiveCN104992818APlay a protective effectSimple structureTransformers/inductances magnetic coresEngineeringAluminum foil

The invention discloses an electric reactor iron core structure comprising a framework. The framework is formed by an upper jaw, a lower jaw and three base columns between the upper jaw and the lower jaw, wherein two sides of the upper jaw are respectively provided with a line discharging bench; each line discharging bench is in a step shape and consists of a connection plate, a line tidying plate and a line discharging plate; aluminum foils and insulation films are arranged outside the base columns; the aluminum foils and the insulation films are overlapped outside the base columns and spirally wind; the connection plate is arranged the innermost layer aluminum foil and the innermost layer insulation film; a right-angle separation block is arranged between the innermost layer aluminum foil and the base columns; a square separation block is arranged between each five aluminum foils and the insulation films; the separation block is clamped on two ends of the aluminum foils and separates the insulation film; the bottom end of the lower jaw is provided with a supporting plate; and a positioning hole is formed in the supporting plate. The iron core structure is a simply structure and convenient to operate compared with the traditional technology; the circuit can be cleaned with high efficiency and at large scale by the three base columns; main structure is formed by the base columns, the aluminum foils and insulation films winding the base columns; and harmonic waves of the circuit can be filtered.

Owner:ANHUI GUANGZHENG ELECTRICAL TECH

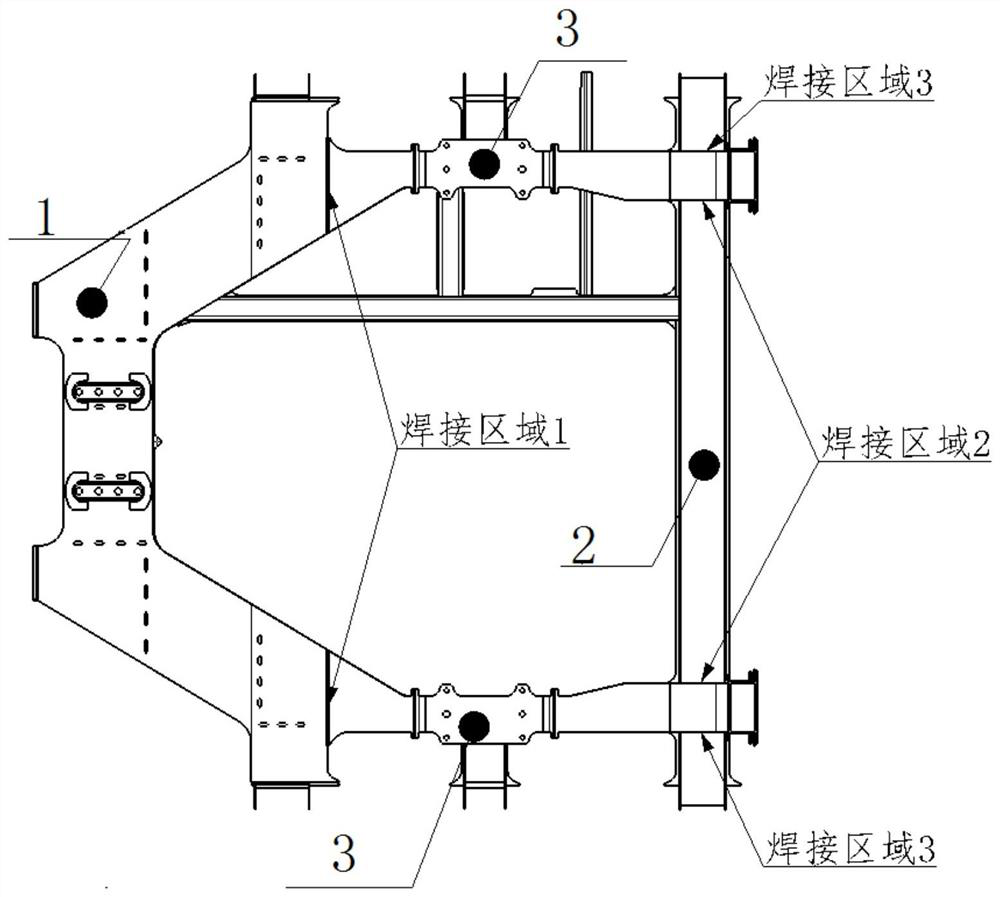

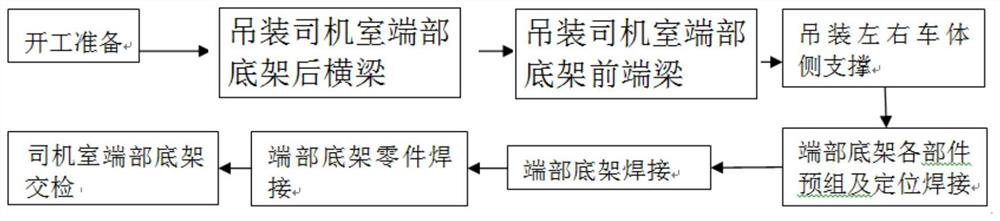

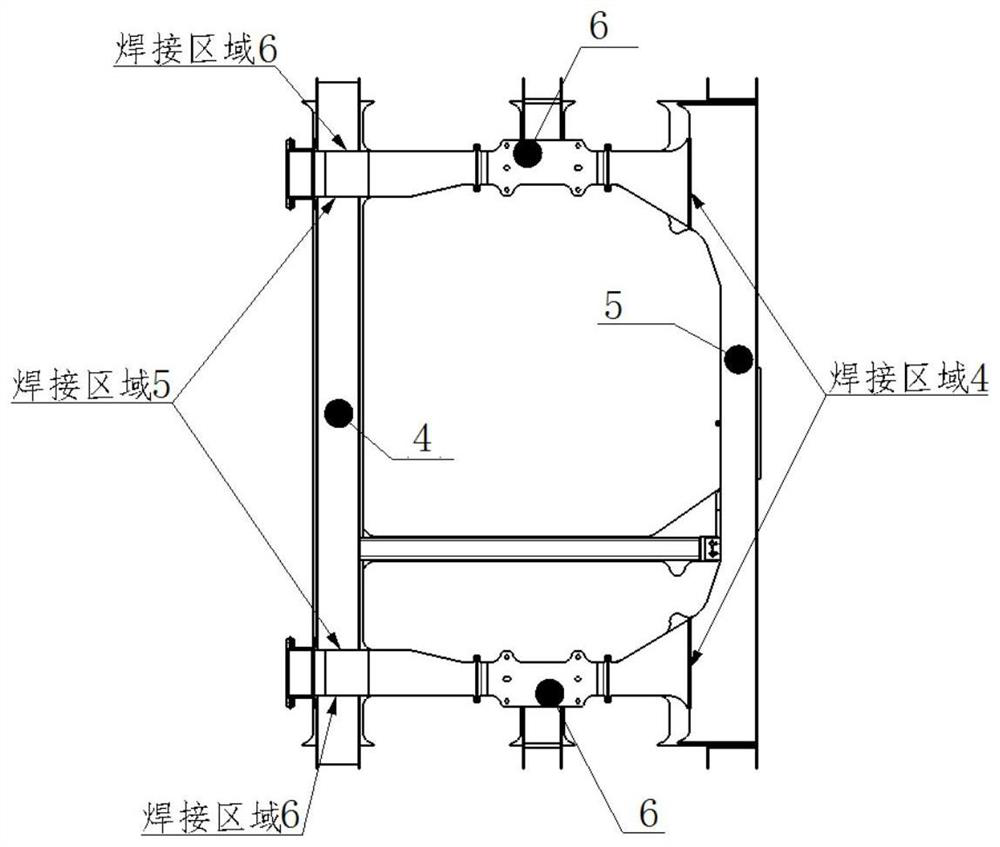

Car body underframe assembly and its welding process

ActiveCN110860770BStructural strength has no effectStructural Strength EffectArc welding apparatusUnderframesWelding processAutomotive engineering

The invention discloses a car body underframe assembly and its welding process. The process adopts a modularized production method to complete the assembly and welding of the driver's cab end underframe and the two-position end underframe respectively, and then hoist the above two The end chassis and the side beams of the chassis on both sides are attached to the base plate to complete the pre-assembly and positioning of the chassis frame; finally, parts are added on the basis of the chassis frame, and the front welding and reverse welding are completed successively to form the vehicle. Body underframe assembly; the welding is all using CMT pulse cold transition process. The present invention adopts a modular process, divides the bottom frame into three large modules, and each large module has different small modules, and carries out blanking, processing and distribution of materials according to the modules. The site is clean and the process is clear, effectively avoiding The phenomenon of wrong installation and missing installation. The invention also discloses a vehicle body underframe assembly.

Owner:安徽雷尔伟交通装备有限公司

A process for treating copper, mercury, selenium, lead and gold and silver in lead filter cake of copper smelting

ActiveCN109971962BImprove leaching effectImprove overall recoveryPhotography auxillary processesProcess efficiency improvementSlagMercury (element)

The invention provides a treatment process of copper, mercury, selenium, lead, gold and silver in a copper smelting lead filter cake. The process mainly comprises following steps of low-temperature high-pressure oxidizing leaching of copper, normal-pressure oxidizing leaching and removal of mercury, replacement of selenium and vulcanization mercury sediment and further comprises rare precious system treatment and electrodeposition copper removal treatment. The treatment process is thorough in copper, mercury, selenium, lead, gold and silver separating effect, the gold, silver and selenium arebasically and completely enriched in the slag phase, the copper recycling rate is about 96%, the leaching rate of mercury is above 90%, and the aim of comprehensively treating valuable elements is achieved.

Owner:YANGGU XIANGGUANG COPPER

Sliding seat of plastic corrugated-pipe forming machine and machining process of sliding seat

InactiveCN106476310AReduce the difficulty of processing and manufacturingReduce use and maintenance costsCorrugation articlesMetal working apparatusMolding machineEngineering

A sliding seat of a plastic corrugated-pipe forming machine comprises a sliding seat body and a rack which is detachably fixed on the sliding seat body. The machining process of the plastic corrugated-pipe sliding seat includes: 1), machining a rack mounting surface on the sliding seat body and machining a rack positioning structure on the rack mounting surface, and correspondingly, machining a binding surface of the sliding seat body on the rack; 2), machining a plain hole used for being connected with a rack screw in the sliding seat body and machining a corresponding screw hole in the rack; 3), fixing the rack in the sliding seat body through the screw. The plastic corrugated-pipe sliding seat has the advantages of simple structure, easiness in machining and manufacturing and convenience in maintenance; the machining process of the plastic corrugated-pipe sliding seat is clear in process, machining speed is favorably increased, and machining and manufacturing cost is lowered.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

Production process of freon resistant, double glass fiber covered enamelled wire

ActiveCN101615451BHigh temperature resistantEasy to withstand high temperatureFurnace typesHeat treatment furnacesGlass fiberOperational costs

The invention relates to a production process of a freon resistant, double glass fiber covered enamelled wire, which solves problems of lag in an existing production process of glass fiber covered enamelled wires, large waste of raw materials, high energy consumption, environmental pollution and quality instability. The production process ensures quality of finished products and work efficiency by the following steps: strictly selecting the raw materials, taking the raw materials into a softening furnace for solidifying treatment by freon resistant insulating impregnating varnish; covering with conductor glass fiber, wherein, two layers of the glass fiber are covered in reverse directions to prevent single cladding; and controlling temperature of a baking furnace and the like. The production process has rational design, simple process, low manufacturing cost, low operating cost, reliable work, high efficiency, stable quality and strong workability, can help manufacture a plurality of different single and double glass fiber, paper covered and enamelled flat copper wires, round copper wires and irregular copper wires, and various electromagnetic wires for different uses, and the production process has wide market prospect.

Owner:湘潭市霞城电工有限公司

A kind of method that utilizes waste to prepare nano flame retardant coating

The invention discloses a method of preparing a nano fire retardant coating by using wastes. The method is characterized by comprising the following technical steps: (1) selecting the following raw materials in percentage by weight: 65% of polystyrene foam, phenolic foam plastic, waste rubber and nitryl fibers, 15% of industrial alcohol, coal tar, acetone and a hydrosolvent, 15% of pigments and fillers, and 5% of a wetting dispersing agent, a defoamer, a delustering agent and a plasticizer assistant; (2) melting and extracting; (3) pre-extracting; (4) dispersing; (5) reconciling and modulating colors; (6) filtering; and (7) packaging. The method provided by the invention is reasonable and concise in process, the process flow is greatly shortened, the raw material of the coating is wide in source, and the method belongs to waste recycle, so that the production cost is lowered. Meanwhile, coatings with various functions are conveniently prepared according to raw material ratio, so that the method is applicable to demand of production process. The inventory rating and proportioning are accurate with less inventory rating, the product quality is ensured, and the yield of enterprises is effectively improved.

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

A kind of production technology of lake fresh braised sauce

Owner:ANHUI FUHUANG SUNGEM FOODSTUFF GRP

Material distribution device and method for polished tiles

Disclosed are a material distribution device and method for polished tiles. The material distribution device comprises a material distribution hopper, a main conveyor belt, a front material collecting box and a back material collecting box, wherein the material distribution hopper, the front material collecting box and the back material collecting box are sequentially arranged along the movement direction of the main conveyor belt, the material distribution hopper is disposed above the main conveyor belt, the front and back material collecting boxes are horizontally arranged over the main conveyor belt in a closely attaching mode, the front material collecting box is a hexahedral box which is buckled inversely on the main conveyor belt, baffles are not arranged in front and below the front and back material collecting boxes, a back baffle of the back material collecting box is a gate capable of being lifted independently, and the front and back material collecting boxes are provided with drive devices capable of lifting the front material collecting box intermittently. According to the material distribution device and method, texture patterns on surfaces of ceramic tiles are clear and stable, a material distribution process of large-turn clear lines is achieved, line textures bending in different directions are produced, the textures are rich in change, random and natural, the presentation range of the ceramic tiles is expanded, and the wide practicability is provided.

Owner:QINGYUAN NAFUNA CERAMICS +2

Dry-rotten fresh-keeping preparation process of cooked pork

InactiveCN111493130AExtend freshnessAchieve long-term quality and freshnessMeat/fish preservation using chemicalsFood ingredient as mouthfeel improving agentBiotechnologyPork meat

Owner:山西省平遥亲圪垯餐饮文化传播有限公司

System and method for distributing ceramic tiles

The invention relates to a material distribution system and a material distribution method of a ceramic tile. The material distribution system comprises material distribution hoppers, a main conveying belt, material distribution rollers and a material collecting box; after passing through the material distribution hoppers and the material distribution rollers, powder is fed into the material collecting box by the main conveying belt for accumulation to form a grain on the surface of the ceramic tile; a plurality of gates of which the opening and closing can be independently controlled are arranged above the material distribution rollers along the axis directions of the material distribution rollers; when closed, the gates cling to the engraving rollers; and when the gates are opened, the powder falls onto the conveying belt from the engraving rollers. The material distribution system and the material distribution method have the benefits that a grain pattern on the surface of the ceramic tile is more clear and stable, the material distribution process of a large-turning clear line is realized, and the performance range of the ceramic tile is expanded, therefore, the practicability is wide.

Owner:FOSHAN DONGPENG CERAMIC +2

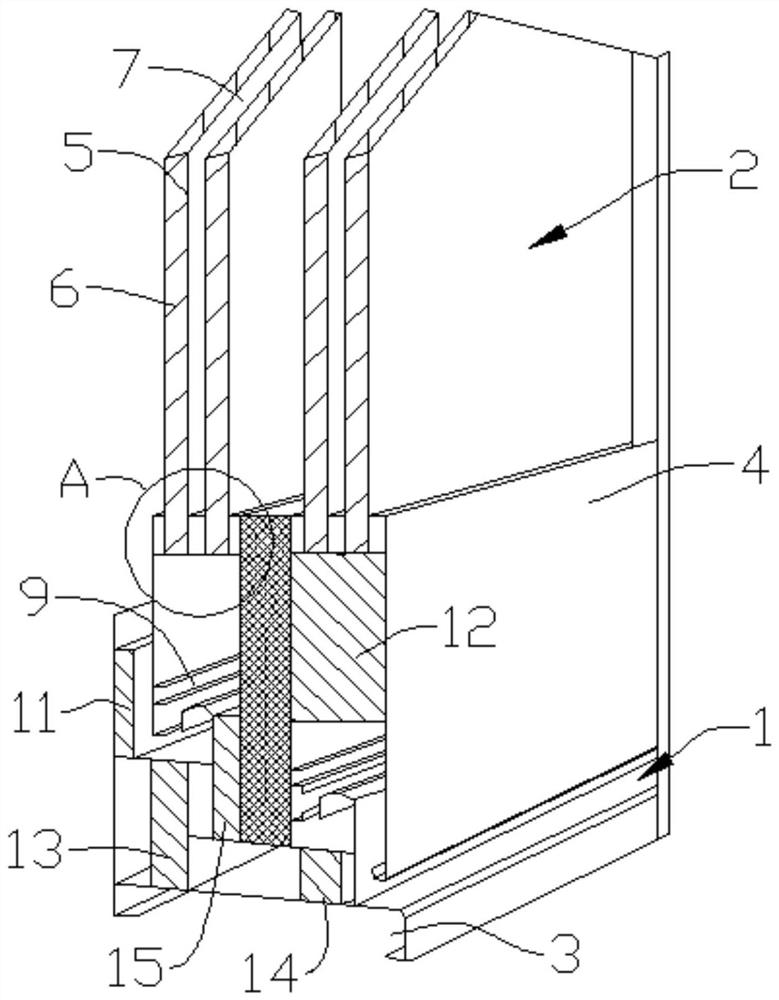

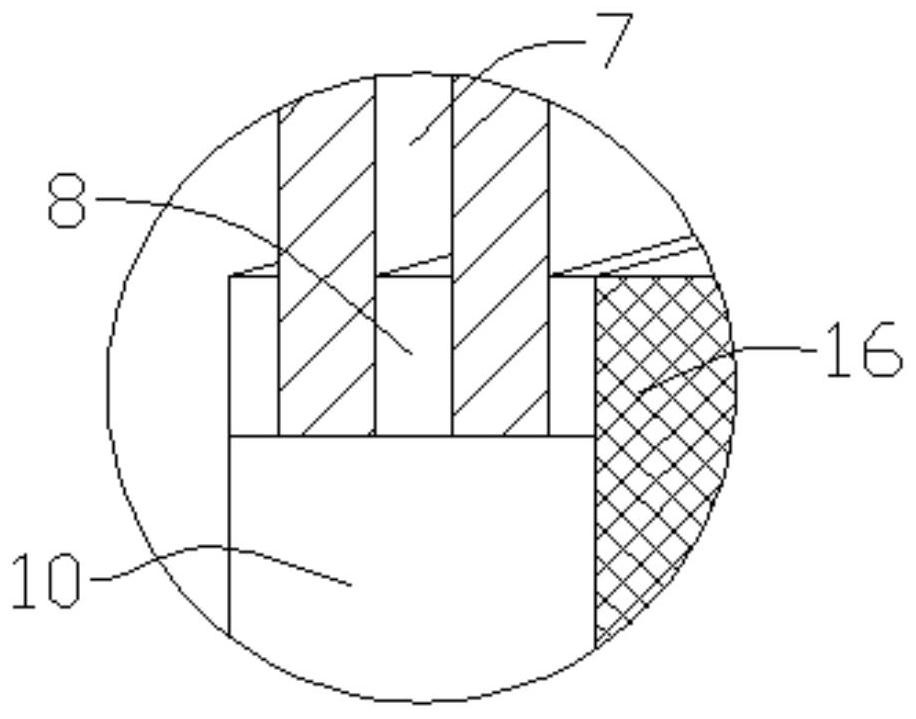

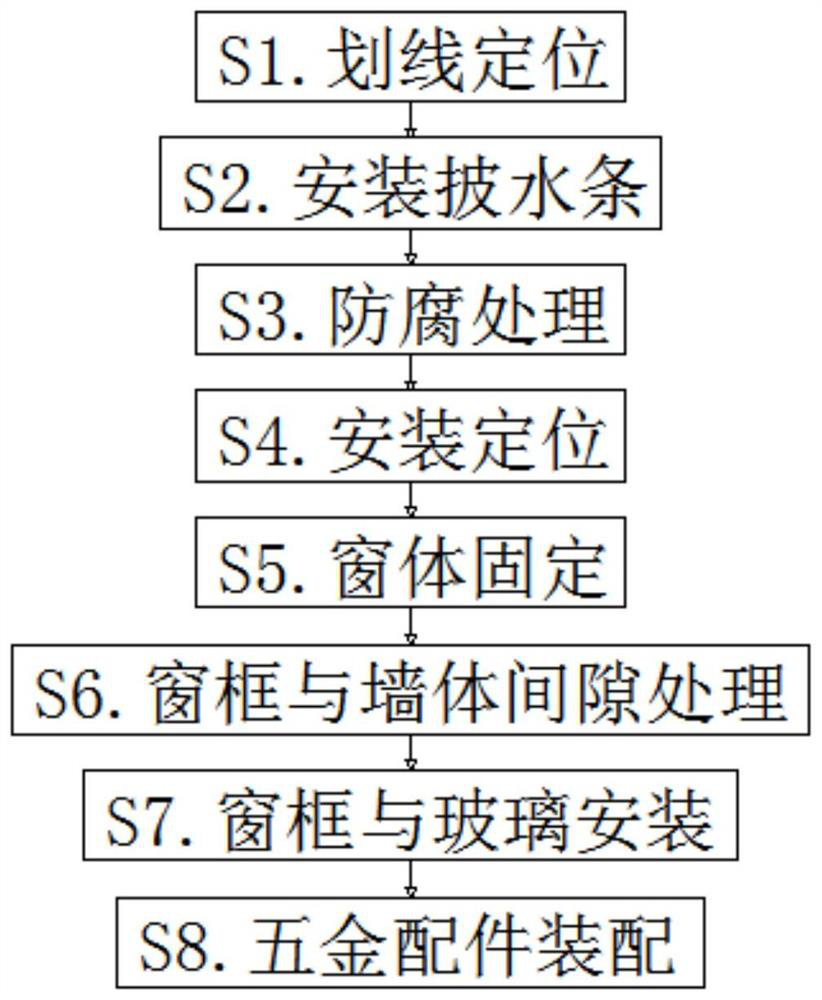

Bridge-cut-off aluminum heat insulation window and mounting method thereof

InactiveCN112681951AEffective isolationAvoid interferenceFireproof doorsClimate change adaptationEngineeringToughened glass

The invention discloses a bridge-cut-off aluminum heat insulation window and a mounting method thereof. According to the technical scheme, the bridge-cut-off aluminum heat insulation window is characterized by comprising a window frame and a window body, wherein the window frame comprises a sliding cavity and two mounting side plates; the window body comprises two sets of glass units; each set of glass units comprises two pieces of single tempered glass; a vacuum cavity is formed between every two pieces of single tempered glass; the vacuum cavities are filled with protective argon; the single tempered glass and the mounting side plates are fixedly connected through elastic materials; the mounting side plates and the sliding cavity are connected into a whole through a heat insulation bridge-cut-off; a cavity is formed between the heat insulation bridge-cut-off and the mounting side plates; and a first insulation material filling layer, a second insulation material filling layer, a third insulation material filling layer, a fourth insulation material filling layer and a fifth insulation material filling layer which are used for heat insulation and sound insulation are arranged between the two mounting side plates. The effects of excellent heat insulation and preservation performance and good sound insulation and noise reduction performance are achieved.

Owner:JIANGSU IN LEADER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com