Regeneration cleaning process of combined filter element

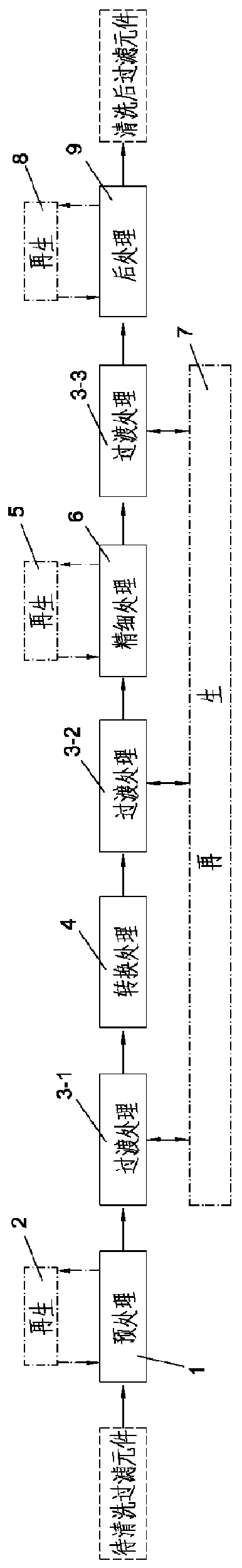

A filter element and process technology, which is applied in the field of regenerative cleaning process of combined filter elements, can solve problems such as environmental pollution, non-standard cleaning process, unfavorable large-scale production, etc., and achieve the effect of simple and clear process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1, pretreatment: the filter element to be cleaned is placed in a solution with a pH value of 6.5 consisting of 2% polyethylene glycol, 5% fatty acid monoglyceride, 0.1% Tween and water in a mass fraction. Treat for 30 minutes at 60°C and ultrasonic frequency 20KHz;

[0045] Step 2. Transition treatment: use 20KHz ultrasonic cleaning to clean the filter element treated in step 1, wherein the water used is purified water filtered through a 5-10 μm filter screen;

[0046] Step 3, conversion treatment: at room temperature, soak the filter element treated in step 2 with an aqueous solution containing 10% sodium hydroxide, that is, the conversion solution, for 5 minutes;

[0047] Step 4. Transition treatment: 40KHz ultrasonic cleaning is used to clean the filter element treated in step 1, wherein the water used is purified water filtered through a 5-10 μm filter screen;

[0048] Step 5, fine treatment: immerse the filter element treated in step 4 into 5% ethylenediamine...

Embodiment 2

[0053] Step 1, pretreatment: the filter element to be cleaned is placed in a solution with a pH value of 7.5 consisting of 3% polyethylene glycol, 1% fatty acid monoglyceride, 3.0% Tween and water in a mass fraction. Treat for 5 minutes at 80°C and ultrasonic frequency 60KHz;

[0054] Step 2. Transition treatment: 60KHz ultrasonic cleaning is used to clean the filter element treated in step 1, wherein the water used is purified water filtered through a 5-10 μm filter screen;

[0055] Step 3, conversion treatment: at room temperature, soak the filter element treated in step 2 with an aqueous solution containing 0.1% sodium hydroxide, that is, the conversion solution, for 10 minutes;

[0056] Step 4. Transition treatment: use 50KHz ultrasonic cleaning to clean the filter element treated in step 1, wherein the water used is purified water filtered through a 5-10 μm filter screen;

[0057] Step 5, fine treatment: immerse the filter element treated in step 4 into 1% ethylenediamin...

Embodiment 3

[0062] Step 1, pretreatment: the filter element to be cleaned is placed in a solution with a pH value of 7.0 consisting of 2.5% polyethylene glycol, 3.0% fatty acid monoglyceride, 1.5% Tween and water in a mass fraction. Treat for 17 minutes at 70°C and ultrasonic frequency 40KHz;

[0063] Step 2. Transition treatment: Use 3MPa high-pressure water to wash the filter element treated in step 1, wherein the water used is purified water filtered through a 5-10 μm filter screen;

[0064] Step 3, conversion treatment: at room temperature, use an aqueous solution containing 5% sodium hydroxide, that is, the conversion solution, to soak the filter element treated in step 2 for 8 minutes;

[0065] Step 4. Transition treatment: use 6MPa high-pressure water to wash the filter element treated in step 1, wherein the water used is purified water filtered through a 5-10 μm filter screen;

[0066] Step 5, fine treatment: immerse the filter element treated in step 4 into 3% ethylenediaminetet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com