Production technology of lake fresh braised sauce

A production process and stewed sauce technology, applied in application, food preparation, food science and other directions, can solve the problems of short shelf life, unauthentic taste, and quality degradation, and achieve the effect of good taste, pure taste and balanced taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

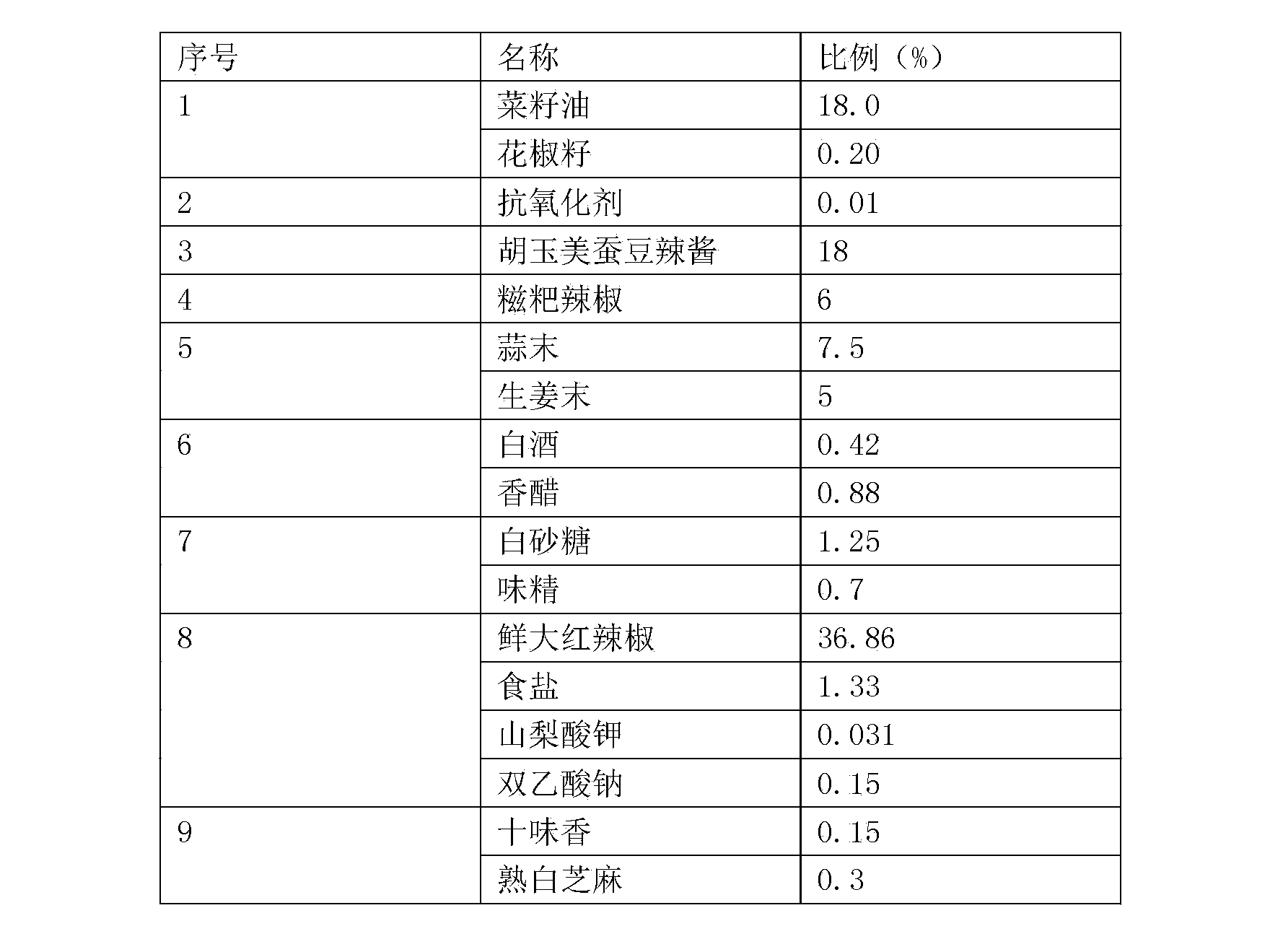

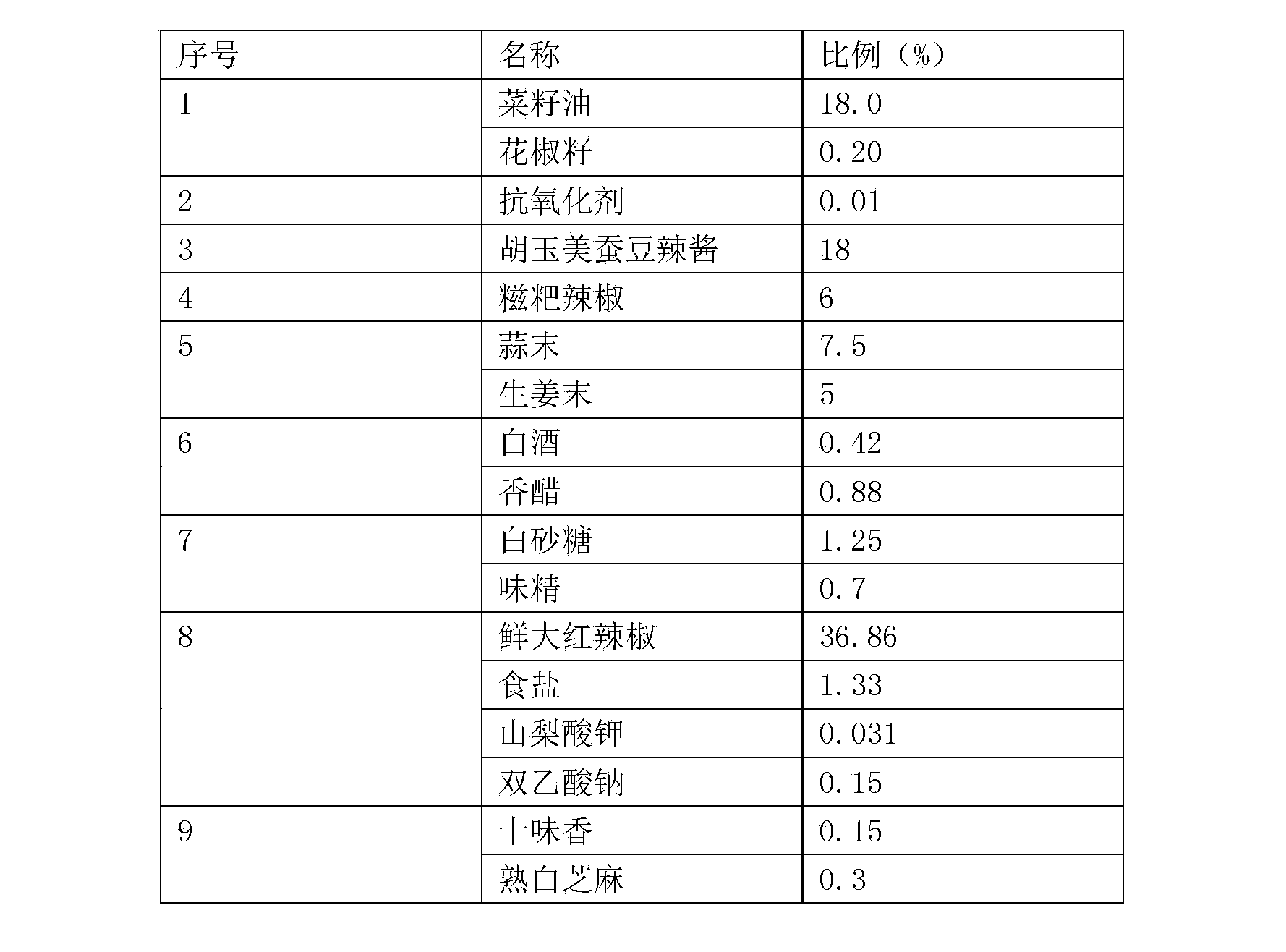

[0031] A kind of production technology of lake fresh stewed sauce is characterized in that, comprises the following steps:

[0032] Step 1. Raw material handling and weighing:

[0033] a. Onion, ginger and garlic are peeled and crushed to 1-5mm square, weighed for later use;

[0034] b. Crush fresh red peppers into 3-5mm squares, weigh them for later use;

[0035] c. Fried dried shrimps, weighed for later use;

[0036] d. Take an appropriate amount of rapeseed oil in the formula to dissolve the weighed antioxidant, and dissolve it for later use;

[0037] e. Other raw materials are weighed for standby;

[0038] Step 2, frying:

[0039] a. Soybean oil is first put into the pot and heated;

[0040] b. When the oil temperature rises to 120-150, put in the pepper seeds, fry the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com