Non-coal-pillar mining method and system for partial filling of working face in large-dip-angle coal seam

A mining method and technology for working face, which are applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of broken roadway surrounding rock, large span of the roof of transport level road, poor application effect, etc. The effect of high mining rate and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Here, the schematic embodiments of the present invention and descriptions are used to explain the present invention (where the filling of gobs is exemplified by solid slurry filling), but not as Limitations on the Invention.

[0045] The process step of mining method of the present invention is:

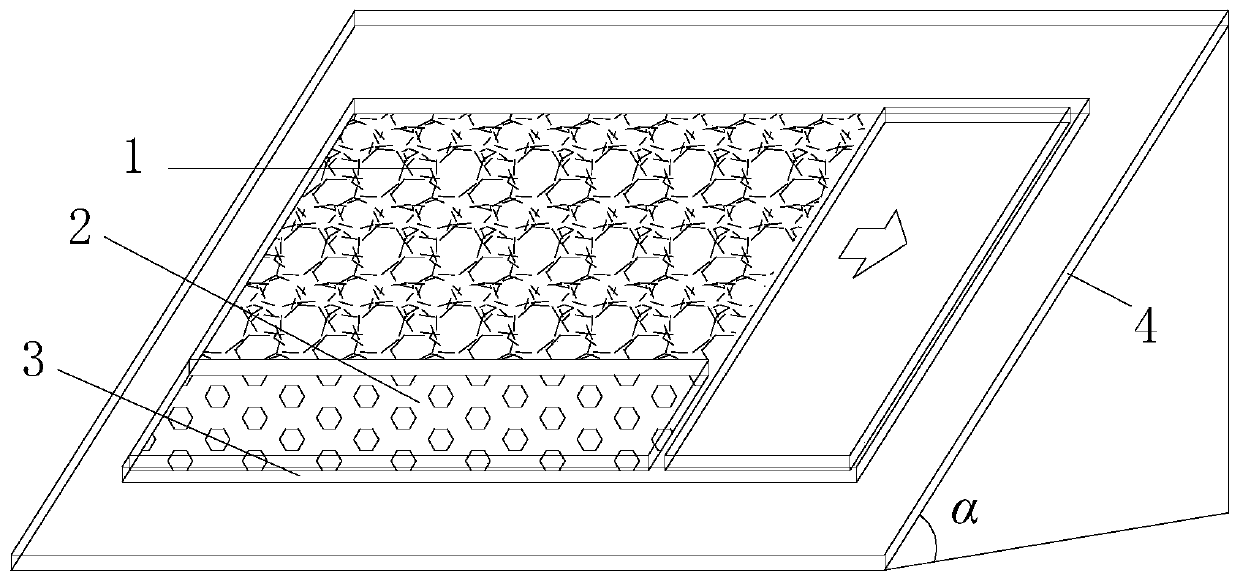

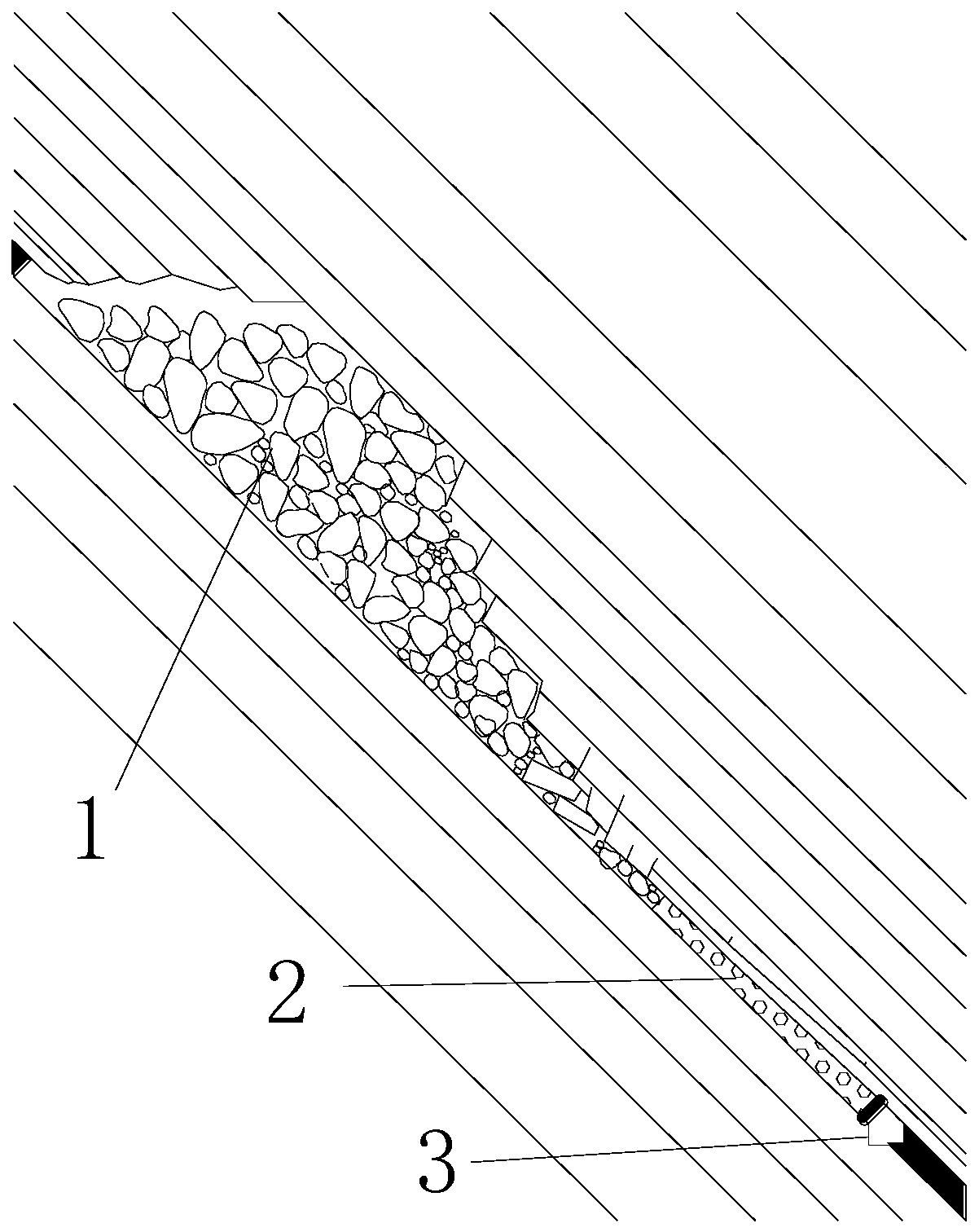

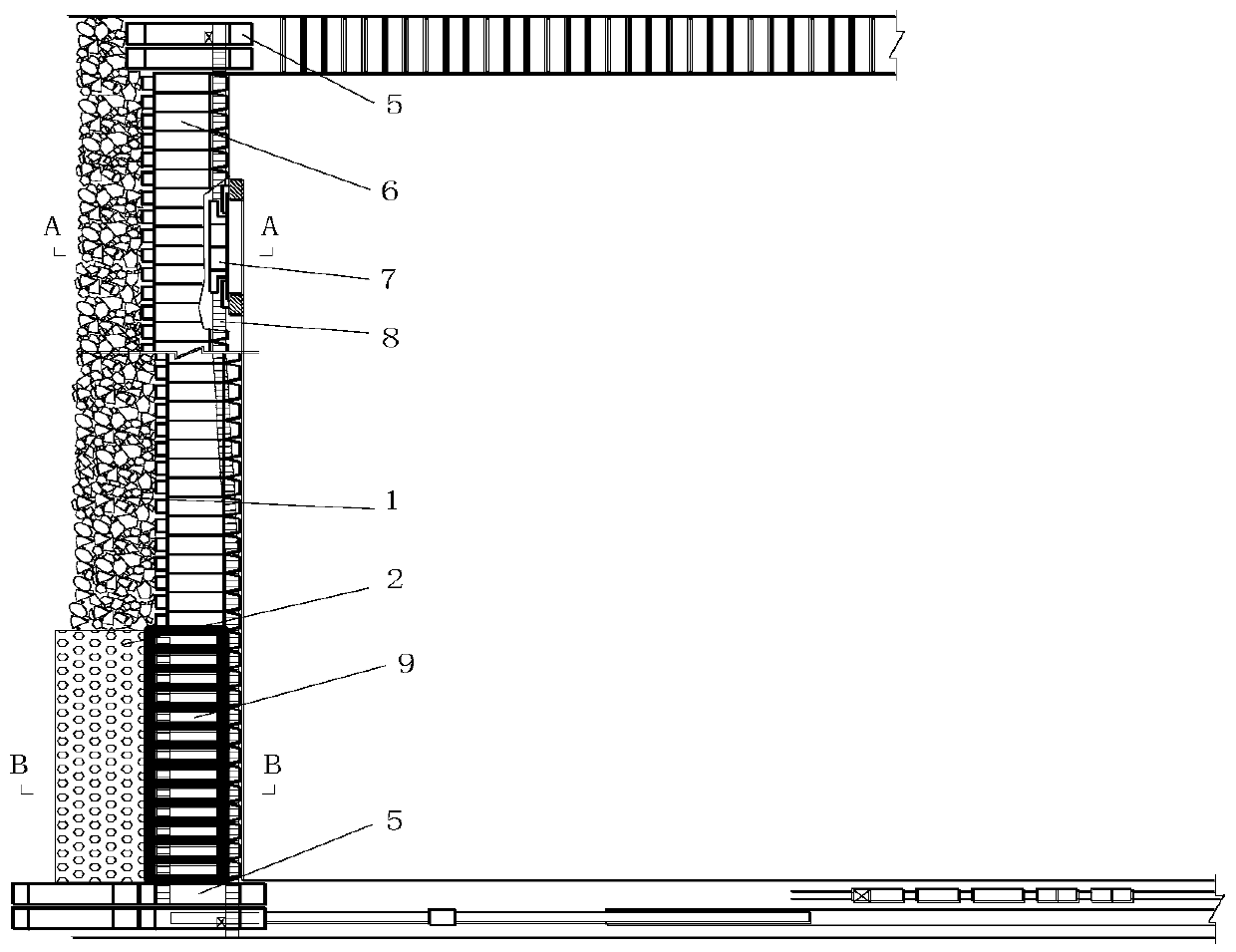

[0046] Step 1: Layout of working face mining system. combine figure 1 , 2 As shown, a mineable coal seam 4 with an inclination α of 5°-5° is selected, wherein the gangue 1 in the goaf is above the filling body 2 in the lower part of the goaf; The lower part of the slope is arranged along the roof of the coal seam with the transportation level roadway 3, and the cutout is arranged along the coal seam 4, such as Figure 3aAs shown, the hydraulic support 5 at the end of the working face with a large inclination angle is installed along the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com