System and method for distributing ceramic tiles

A cloth system and ceramic tile technology, which is applied in the field of ceramic tile cloth system, can solve the problem of inability to accurately control the change of line texture, the number and thickness of line texture, etc., and achieve rich line texture cloth, stable equipment operation, simple and clear process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

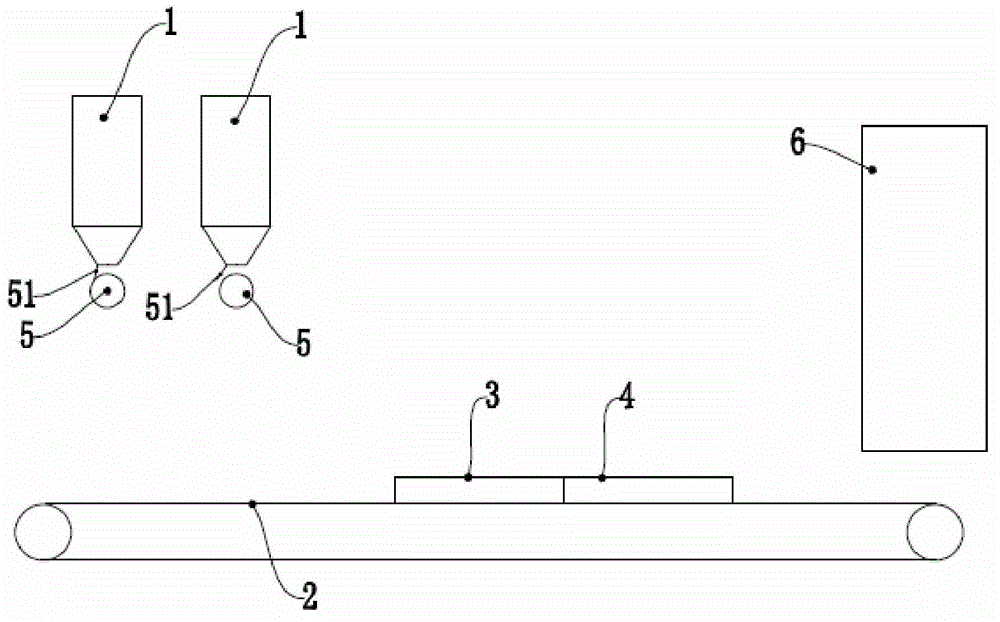

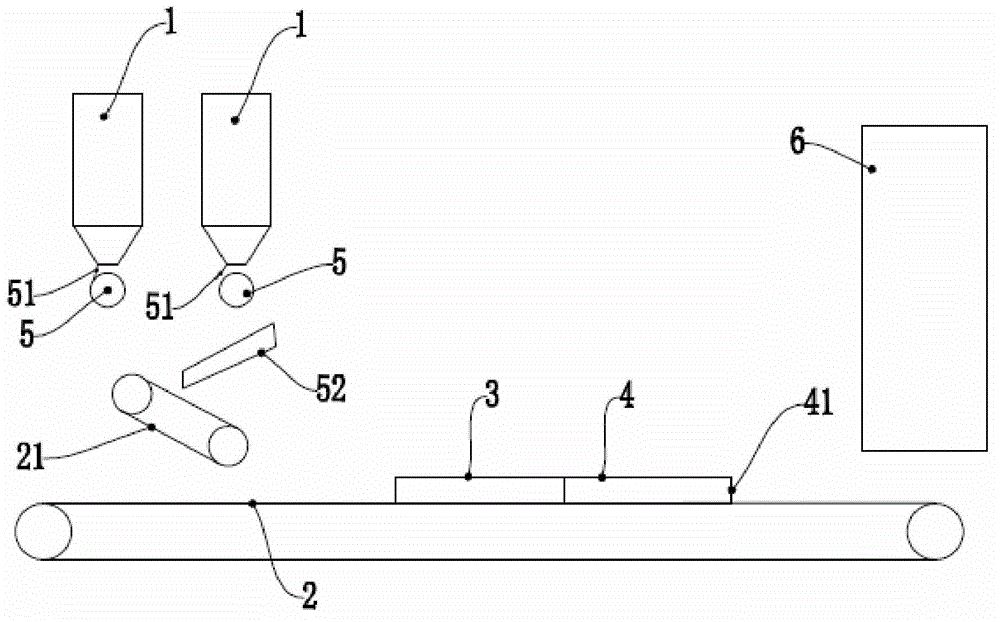

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0026] A distributing system for ceramic tiles, including a distributing hopper 1, a main conveyor belt 2, a distributing roller 5 and a collecting box, after powder passes through the distributing hopper 1 and the distributing roller 5, it is sent into the collecting box by the main conveyor belt 2 for accumulation Form the texture of the ceramic surface; the top of the distribution drum 5 is provided with a plurality of individually controlled opening and closing gates 51 along the axial direction of the distribution drum 5, and the gates 51 are close to the distribution drum 5 when closed , when the gate 51 is opened, the powder falls from the distribution drum 5 to the main conveyor belt 2 . The distribution roller 5 makes the order and quantity of the powder entering the front collecting box 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com