A process for treating copper, mercury, selenium, lead and gold and silver in lead filter cake of copper smelting

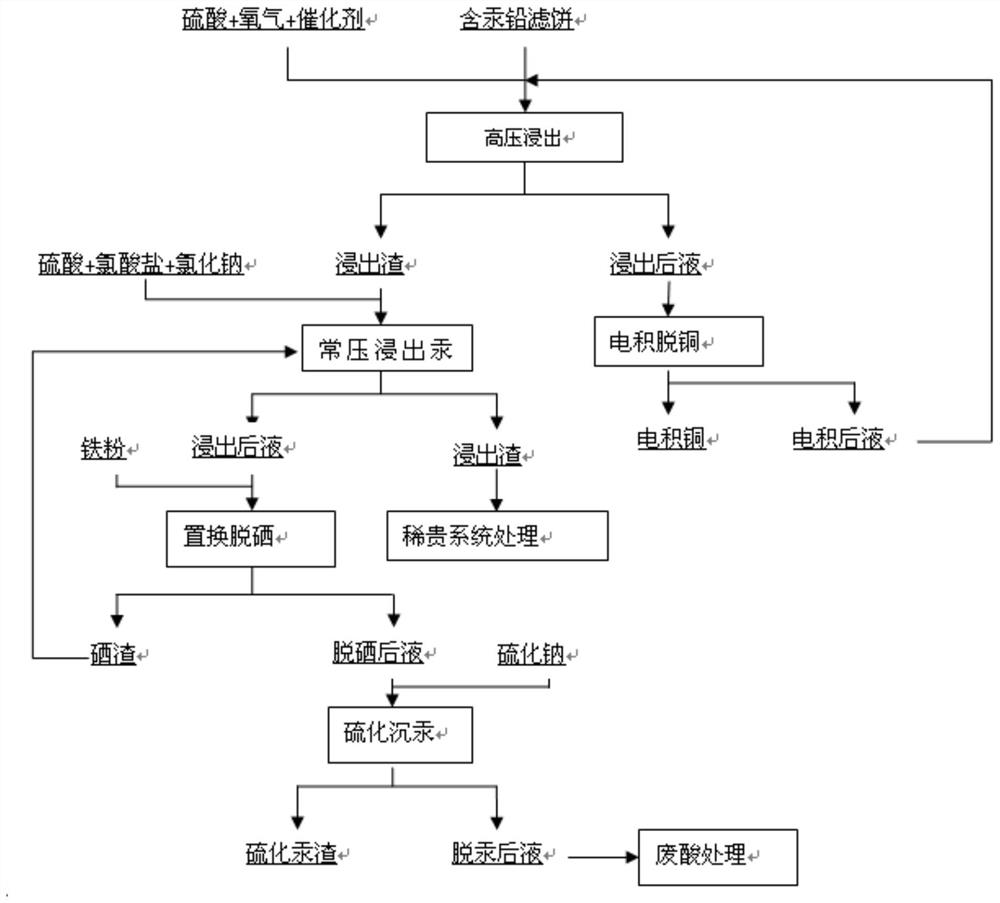

A treatment process and lead filter cake technology, which is applied in the field of raw material recovery, can solve the problem that the comprehensive treatment plan has not been publicly reported, and achieve the effects of being suitable for large-scale industrial application, strong chemical stability, and clear treatment process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Decopper removal by high pressure leaching

[0052] Take 5t of lead filter cake, main components: Cu 14%, Se 26%, Hg 11%, As 1%, Pb 9%, Au 45g / t, Ag1220g / t, moisture 20%. First configure 20m in the reaction vessel 3 Dilute sulfuric acid solution, wherein the concentration of sulfuric acid is 220g / L. After starting the stirring, add the lead filter cake and 95kg of catalyst iron powder at the same time. After stirring for half an hour, pump it to the autoclave. After the prepreg mixture enters the autoclave, heat it up to 70°C, then introduce oxygen, and the pressure in the reactor gradually increases. When the pressure reaches 0.8MPa, stop the oxygen flow, and keep the pressure for 8 hours. Filter with a filter press for solid-liquid separation, wash the filter cake with water and blow air, the solid is 2.1t of oxidized leaching residue, and the liquid is 20.5m of copper sulfate oxidized leaching solution 3 ;Working conditions of the above process: Oxygen flow rate...

Embodiment 2

[0063] 1) Decopper removal by high pressure leaching

[0064] Take 3.5t of lead filter cake, main components: Cu 30%, Se 45%, Hg 9%, As 1%, Pb 15%, Au 22g / t, Ag 1350g / t, moisture 25%; 16m 3 Dilute sulfuric acid solution, in which the concentration of sulfuric acid is 240g / L. After starting the stirring, add the lead filter cake and 82kg of catalyst iron powder at the same time. After stirring for half an hour, pump it to the autoclave to obtain the pre-soaked mixture; the pre-soaked mixture enters the autoclave Afterwards, heat up to 70°C first, and then introduce oxygen, and the pressure in the reactor gradually increases. When the pressure reaches 1MPa, stop the oxygen flow, and keep the pressure for 8 hours. After the reaction is over, release the pressure to normal pressure, and discharge to Buffer tank, pump to filter press for filtration, solid-liquid separation, filter cake washing and blowing, to obtain solid oxidation leaching residue 1.65t and liquid copper sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com