Electric reactor iron core structure

A technology of iron core structure and reactor, applied in the direction of transformer/inductor magnetic core, etc., can solve the problems of messy related lines, complicated process, inconvenient use, etc., and achieve the effect of reduced processing cost, simple process and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

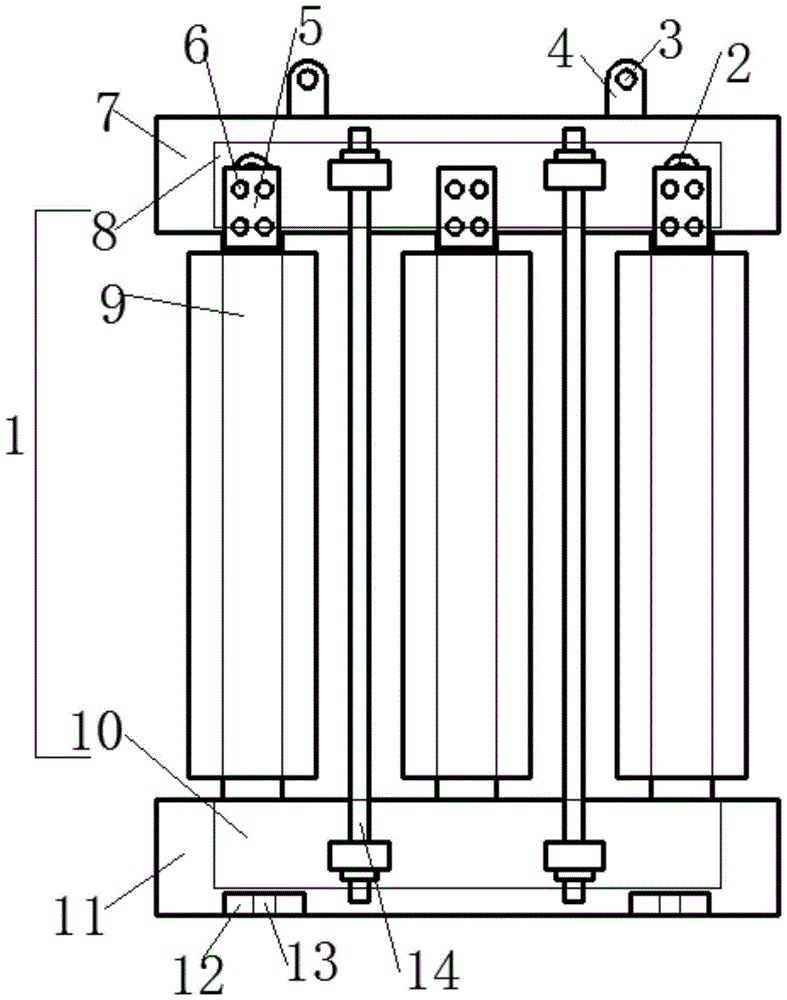

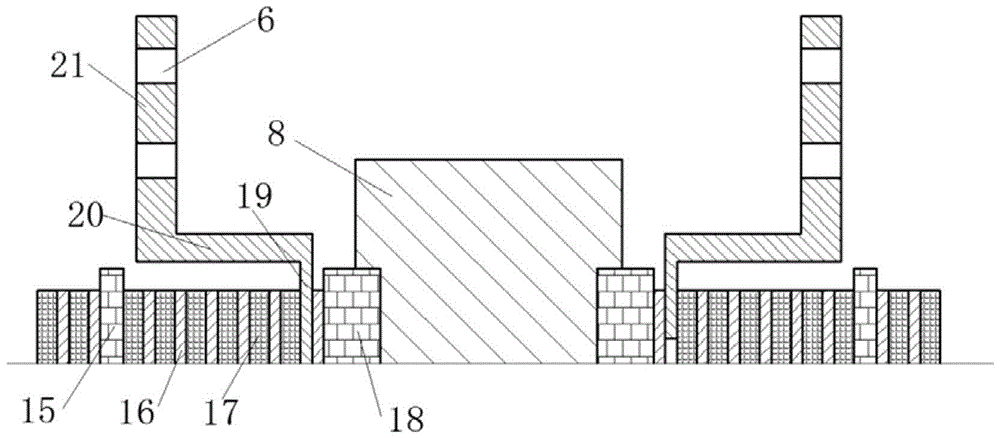

[0015] figure 1 A specific embodiment of a reactor core structure of the present invention is shown: a reactor core structure including a frame 1, wherein the frame 1 includes an upper jaw 8, a lower jaw 10, and three bases between the upper jaw 8 and the lower jaw 10. Column 9, upper jaw 8 and lower jaw 10 are provided with an upper baffle and a lower baffle respectively. A fixing bolt 2 is provided between the upper baffle 7 and the fixing bolt 2 passes through the upper jaw 8. Both sides of the upper baffle are provided Outlet stand, the outlet stand is in a stepped shape, including connecting board 19, cable management board 20 and outlet board 215, base column 9 is provided with aluminum foil 16 and insulating film 17, aluminum foil 16 and insulating film 17 overlapped on the outer spiral of base column 9 Surrounding, there is a connecting plate 19 between the innermost aluminum foil 16 and the innermost insulating film 17; a right-angle partition 18 is provided between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com