Preparation method of liquid crystal gel super-stable foam system

A technology for stabilizing foam and system, applied in the field of foam system, can solve the problems of easy rupture and stratification, difficult application, stop, etc., and achieves the effect of delaying the process of bubble dissolution and coalescence, improving stability and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation process of the present invention is:

[0026] a. Preparation of polyglycerol:

[0027] Add 0.75g of glycerol into a three-necked flask equipped with a stirring bar, nitrogen gas tube, thermometer, and condenser tube, weigh 5g of NaOH and dissolve it in 50mL of water, add it, heat it to 80°C to make it react, and pass nitrogen gas to protect the reaction. Connect a measuring cylinder under the condenser tube, observe the water output, stop heating when it reaches 25mL, and continue to pass nitrogen, but when the temperature drops below 160°C, polyglycerol is obtained.

[0028] b. Synthesis of carbon chain fatty acid polyglycerol esters in surfactants:

[0029] Add 10mL of polyglycerin to a three-necked flask equipped with a stirring bar, nitrogen gas tube, thermometer, and condenser tube, weigh 5mL of lauric acid and 5mL of capric acid, heat to 70°C to melt, add to the flask, and then add 1g of NaOH solution is used as a catalyst, stir and heat up to 22...

Embodiment 1

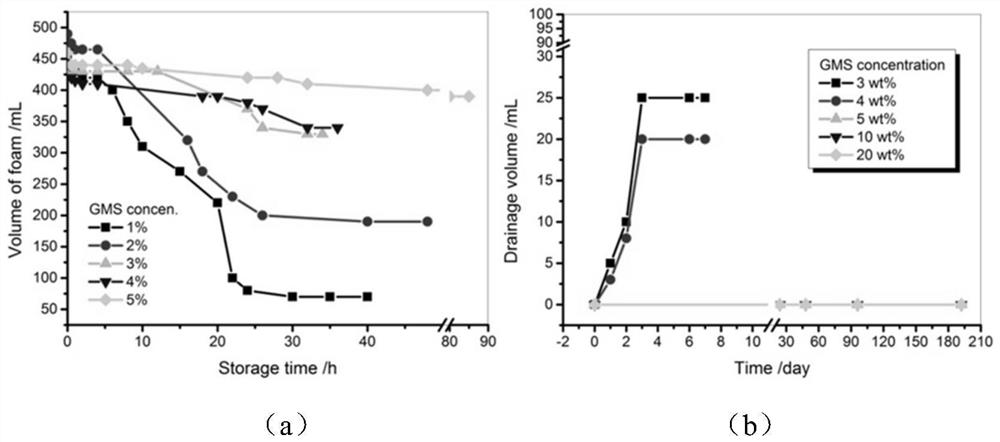

[0045] A preparation method of a liquid crystal gel ultra-stable foam system prepared by a single nonionic surfactant is as follows:

[0046] Step 1: First, slowly raise the temperature of the fatty acid polyglyceride aqueous solution with a mass fraction of 1% to a constant temperature of 60°C; secondly, use a stirrer to stir so that the stirring speed is controlled at 3000rpm for 5min, when the solution is translucent and uniform After dispersing the system, cool it down to room temperature (25°C) naturally, and set it aside.

[0047] Step 2: First take 100mL of the surfactant fatty acid polyglycerol ester-water mixture after the above pretreatment, and then use high-speed stirring to foam, so that the stirring speed is controlled at 8000rpm for 10min, and the volume of the liquid can be observed to expand, forming a white A foam whose shape is similar to that of an emulsion. Record the foaming amount of the sample after stirring.

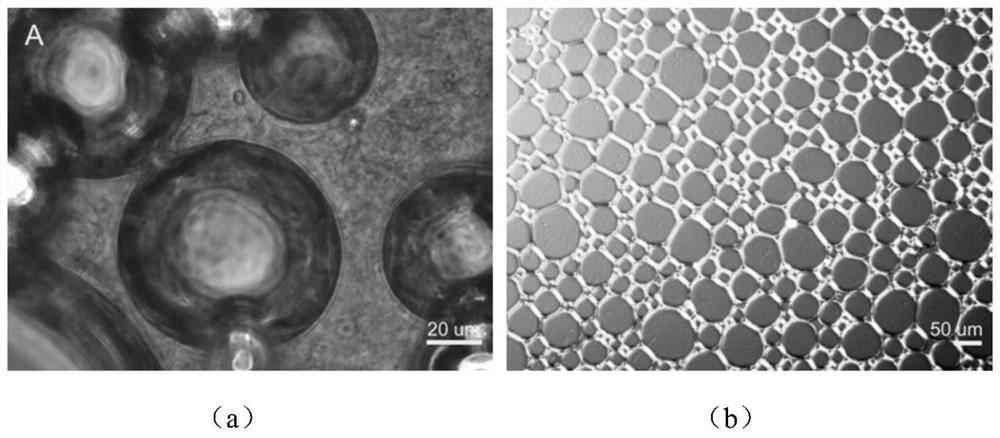

[0048] The particle size of foam bubbles...

Embodiment 2

[0051] A preparation method of a liquid crystal gel ultra-stable foam system prepared by a single nonionic surfactant is as follows:

[0052] Step 1: First, slowly raise the temperature of the fatty acid polyglyceride aqueous solution with a mass fraction of 2% to a constant temperature of 60°C; secondly, use a stirrer to stir so that the stirring speed is controlled at 4000rpm for 5min, when the solution is translucent and uniform After dispersing the system, cool it down to room temperature (25°C) naturally, and set it aside.

[0053] Step 2: First take 100mL of the surfactant fatty acid polyglycerol ester-water mixture after the above pretreatment, and then use high-speed stirring to foam, so that the stirring speed is controlled at 9000rpm for 10min, and the volume of the liquid can be observed to expand, forming a white A foam whose shape is similar to that of an emulsion. Record the foaming amount of the sample after stirring.

[0054] The particle size of foam bubbles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com