Preparation method and product of stress-sensitive paper anti-fake coating

A paper and stress technology, which is applied in the field of preparation of alkenyl succinic anhydride (ASA) paper anti-counterfeiting emulsion, can solve the problems such as the large influence of anti-counterfeiting coatings, and achieve the effects of good humidity stability, reduced agglomeration, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) 60 parts by weight of HAuCl 4 and 1 part by weight of M w 68kg / mol of PVP-DADMAN were dissolved in water to obtain a concentration of 1 × 10 -2 MHAuCl 4 solution and concentration of 5 x 10 -6 M solution of PVP-DADMAN, mixed and boiled for 1 hour, then added 50 parts by weight of ascorbic acid, stirred and reacted in the dark at 98°C for 1 hour, centrifuged at 8000 rpm for 15 minutes to obtain a supernatant; vacuum-dried the supernatant to obtain a modified nano Gold particles, the average particle size is 65nm;

[0030] (2) 1 weight part of M w 1 kg / mol of PEOS is dissolved in 3 parts by weight of ASA as the oil phase; 2 parts by weight of the modified nano-gold prepared in step (1) is dispersed in water to make a solution with a concentration of 0.4% by mass, Add dilute hydrochloric acid dropwise to adjust the pH to 1, as the water phase; add the water phase to the oil phase, the volume ratio of the oil phase and the water phase is 1:5, stir ultrasonically at...

Embodiment 2

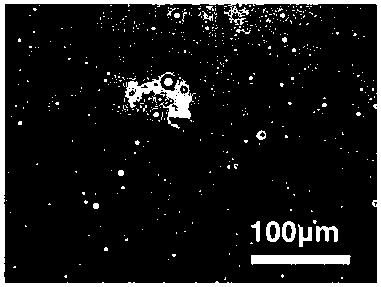

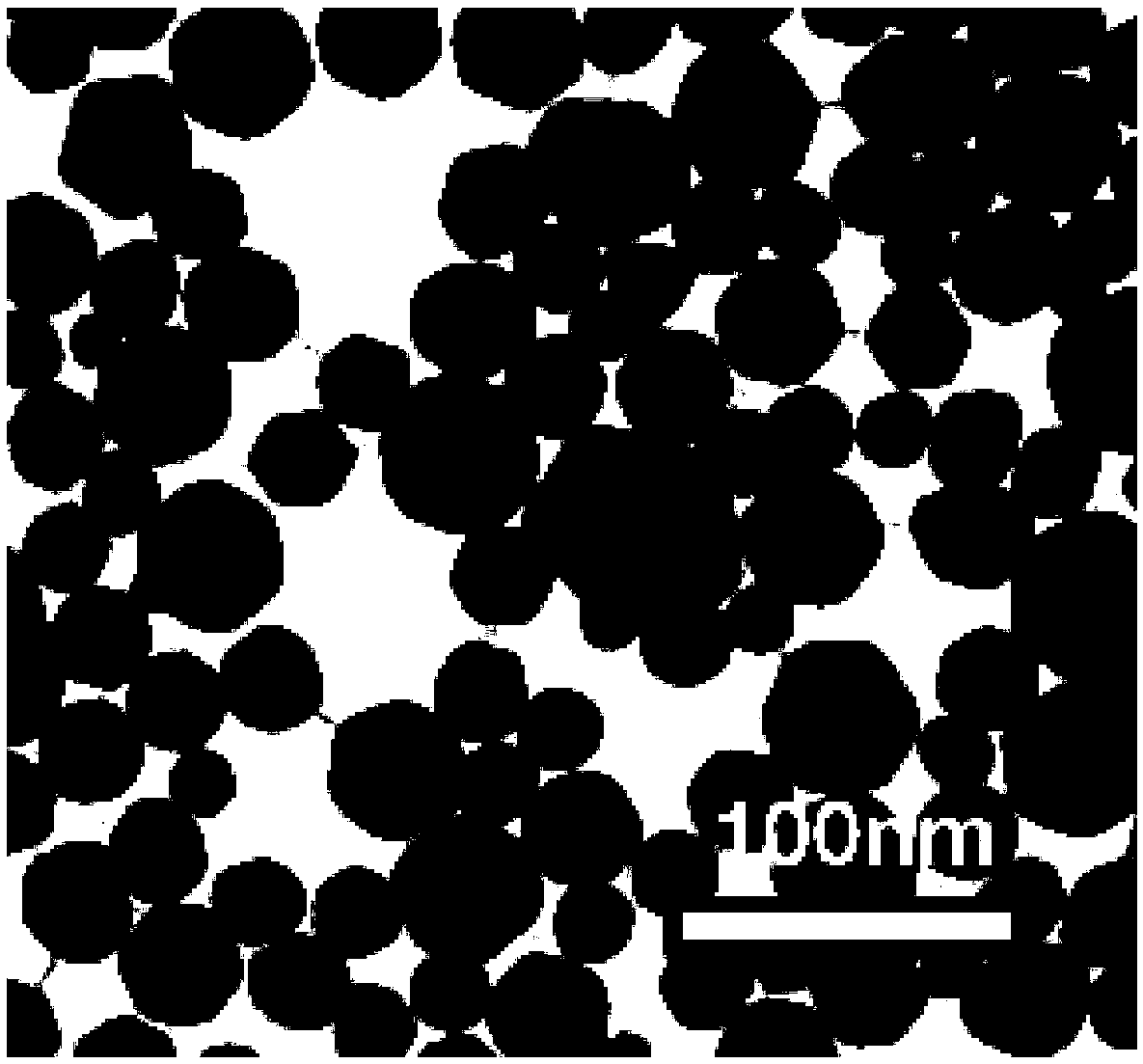

[0036] (1) 55 parts by weight of HAuCl 4 and 1 part by weight of M w 68kg / mol of PVP-DADMAN were dissolved in water to obtain a concentration of 1 × 10 -2 MHAuCl 4 solution and concentration of 5 x 10 -6 The solution of PVP-DADMAN of M, mixed and boiled for 1h, then added 70 parts by weight of ascorbic acid, stirred and reacted in the dark at 98°C for 1h, centrifuged at 10000rpm for 15min to obtain the supernatant, the TEM picture of the supernatant is as follows figure 1 Shown; Obtain modified nano-gold particles after the supernatant is vacuum-dried, and the average particle diameter is 40nm;

[0037] (2) 2 parts by weight of M w1 kg / mol of PEOS is dissolved in 12 parts by weight of ASA as the oil phase; 2 parts by weight of the modified nano-gold prepared in step (1) is dispersed in water to make a solution with a concentration of 0.8% by mass, Add dilute hydrochloric acid dropwise to adjust the pH to 2, as the water phase; add the water phase to the oil phase, the vol...

Embodiment 3

[0043] (1) 20 parts by weight of HAuCl 4 and 1 part by weight of M w 68kg / mol of PVP-DADMAN were dissolved in water to obtain a concentration of 1 × 10 -2 MHAuCl 4 solution and concentration of 5 x 10 -6 M solution of PVP-DADMAN, mixed and boiled for 1 hour, then added 100 parts by weight of ascorbic acid, stirred and reacted in the dark at 98°C for 1 hour, centrifuged at 20,000 rpm for 25 minutes to obtain a supernatant; vacuum-dried the supernatant to obtain a modified nano Gold particles, the average particle size is 18nm;

[0044] (2) 5 parts by weight of M w 1 kg / mol of PEOS is dissolved in 100 parts by weight of ASA as the oil phase; 1 part by weight of the modified nano-gold prepared in step (1) is dispersed in water to make a solution with a concentration of 1.2% by mass. Add dilute hydrochloric acid dropwise to adjust the pH to 4, as the water phase; add the water phase to the oil phase, the volume ratio of the oil phase and the water phase is 1:1, stir ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com