A method for manufacture a perovskite solar cell which enhances humidity resistance stability and photoelectric performance

A photoelectric performance, solar cell technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of stability hindering the commercialization of perovskite solar cells, easy to decompose, devices are not resistant to humidity, etc., to achieve novel technology, raw materials Ease of availability, improved humidity resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

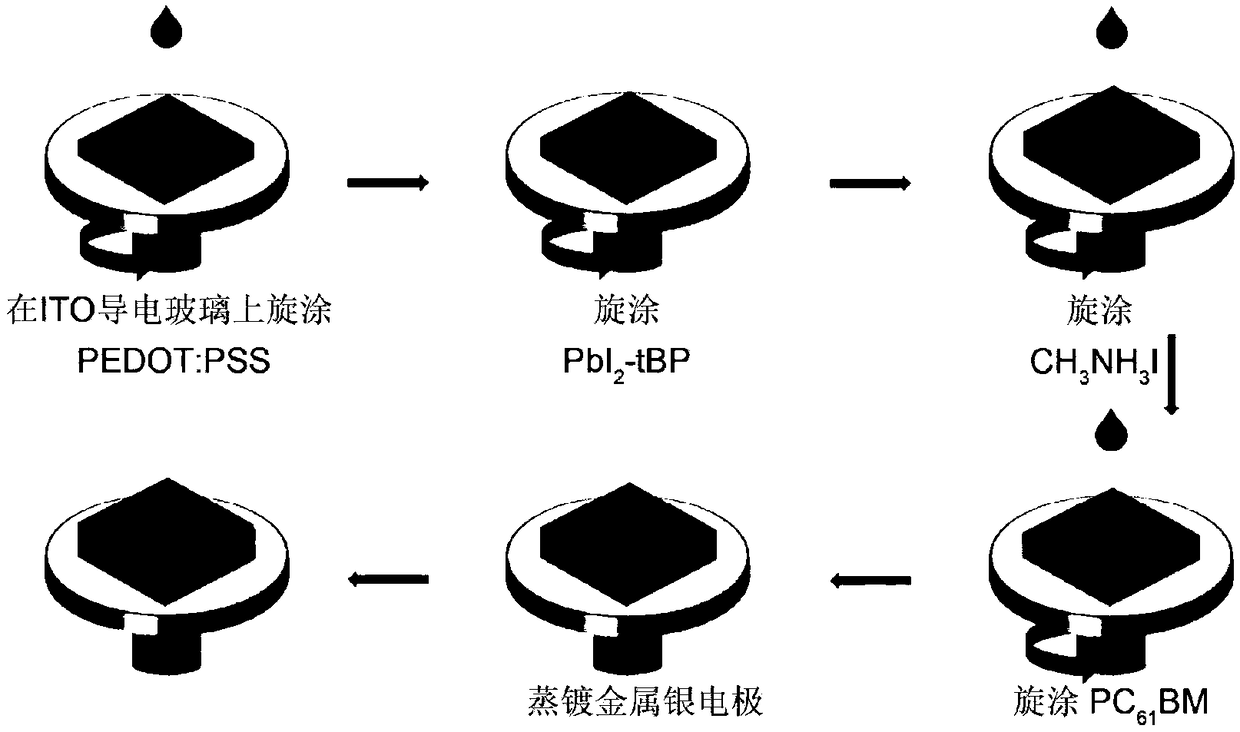

[0043] The etched ITO conductive glass was cleaned with acetone, deionized water and absolute ethanol for 15 minutes respectively, blown dry with nitrogen, and then treated in an ultraviolet ozone atmosphere for 15 minutes; dynamic spin-coating PEODT:PSS solution. The PEODT:PSS solutions of all embodiments of the present invention are all from Xi'an Baolaite Optoelectronics Technology Co., Ltd.

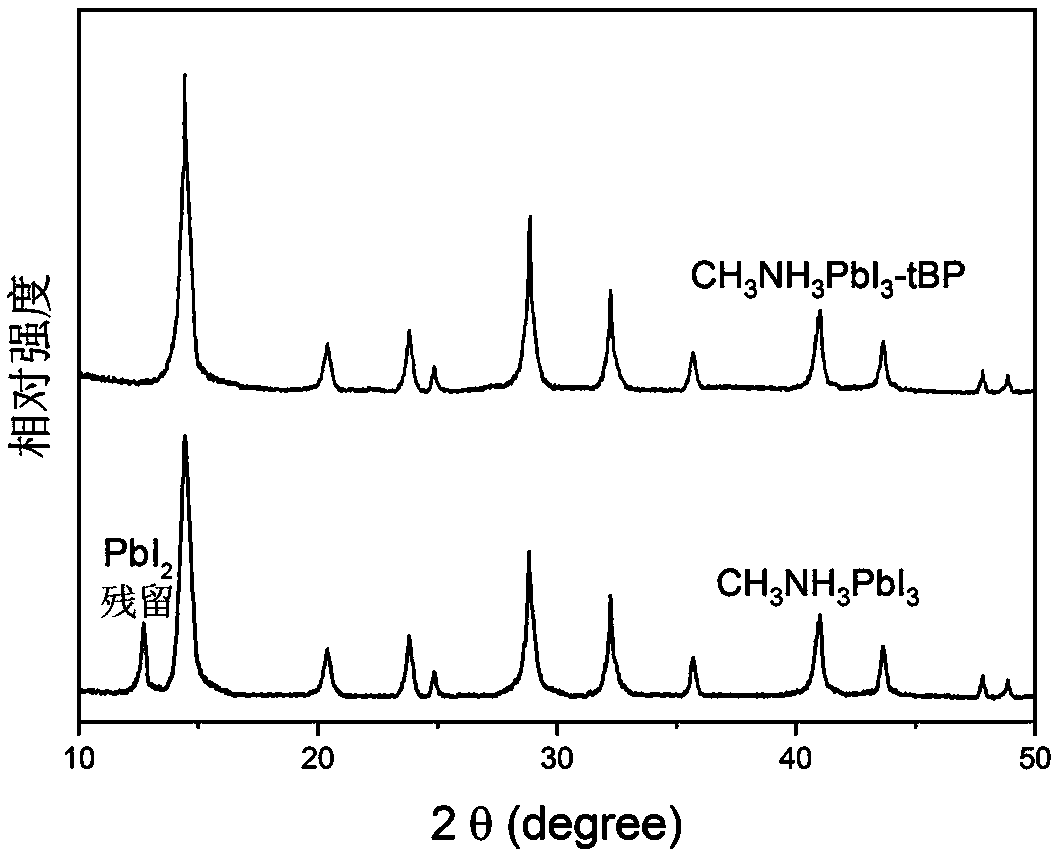

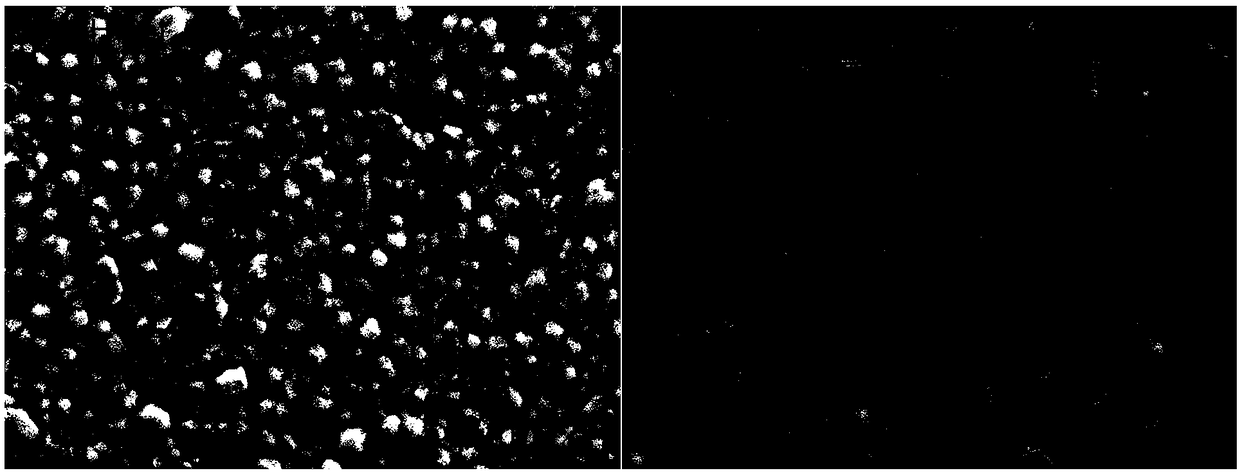

[0044] The dynamic spin coating process is as follows: the speed of the spin coater is adjusted to 2000 rpm for 10 seconds, and the PEODT:PSS solution is added dropwise during this process, then changed to 5000 rpm for 30 seconds, and taken out at a temperature of 120 degrees Celsius. Heated on the heating plate for 40 minutes; then spin-coated PbI 2 - tBP precursor solution, PbI 2 The solution concentration is 1.2 mol / ml, tBP:PbI 2 The solution volume ratio is 1:25, the spin coating speed is 4500 rpm, and the spin coating time is 30 seconds. Take it out and heat it on a heating pla...

Embodiment 2

[0050] The etched ITO conductive glass was cleaned with acetone, deionized water and absolute ethanol for 15 minutes respectively, blown dry with nitrogen, and then treated in an ultraviolet ozone atmosphere for 15 minutes; dynamic spin-coating PEODT:PSS solution. The dynamic spin coating process is as follows: the speed of the spin coater is adjusted to 1800 rpm for 8 seconds, and the PEODT:PSS solution is added dropwise during this process, then changed to 4800 rpm for 20 seconds, and taken out at a temperature of 115 degrees Celsius. Heated on the heating plate for 20 minutes; then spin-coated PbI 2 - tBP precursor solution, PbI 2 The solution concentration is 1 mol / ml, tBP:PbI 2 The solution volume ratio is 1:50, the spin coating speed is 4300 rpm, and the spin coating time is 20 seconds. Take it out and heat it on a heating plate at a temperature of 65 degrees Celsius for 10 minutes; then spin coat CH with a concentration of 12 mg / ml. 3 NH 3 1 isopropanol solution, rot...

Embodiment 3

[0053] The etched ITO conductive glass was cleaned with acetone, deionized water and absolute ethanol for 15 minutes respectively, blown dry with nitrogen, and then treated in an ultraviolet ozone atmosphere for 15 minutes; dynamic spin-coating PEODT:PSS solution. The dynamic spin coating process is as follows: the speed of the spin coater is adjusted to 2200 rpm for 12 seconds, and the PEODT:PSS solution is added dropwise during this process, and then changed to 5200 rpm for 40 seconds, and taken out at a temperature of 125 degrees Celsius. Heated on the heating plate for 60 minutes; then spin-coated PbI 2 - tBP precursor solution, PbI 2 The solution concentration is 1.4 mol / ml, tBP:PbI 2 The solution volume ratio is 1:10, the spin coating speed is 4700 rpm, and the spin coating time is 40 seconds. Take it out and heat it on a heating plate at a temperature of 75 degrees Celsius for 20 minutes; then spin coat CH with a concentration of 12 mg / ml. 3 NH 3 1 isopropanol soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com