A kind of pickering emulsion emulsifier and its preparation method and application

An emulsifier and emulsion technology, which is used in the preparation and application of nanomaterials, can solve problems such as low emulsion concentration, and achieve the effects of improving lipophilicity, reducing coalescence and good density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Emulsifiers for Pickering emulsions were prepared using the following steps:

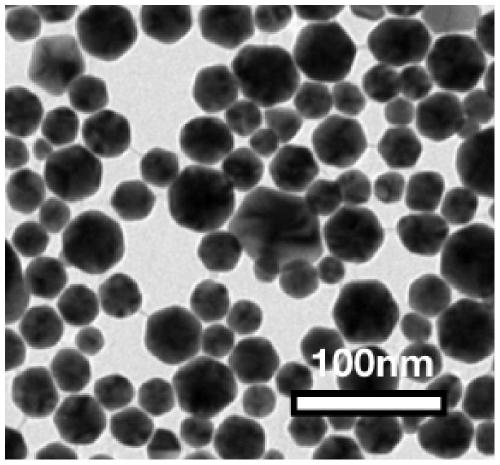

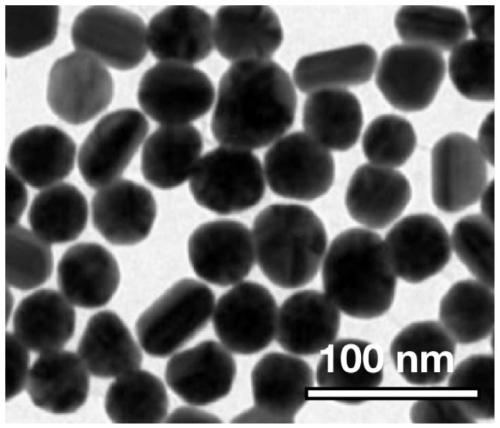

[0042] (1) 60 parts by weight of HAuCl 4 and 1 part by weight of M w 55kg / mol of PVP-DADMAN were dissolved in water to obtain a concentration of 1 × 10 -2 MHAuCl 4 solution and concentration of 1 x 10 -7 The solution of PVP-DADMAN of M, mixed and boiled for 1h, then added 20 parts by weight of ascorbic acid, stirred and reacted in the dark at 98°C for 1h, centrifuged at 5000rpm for 5min to obtain the supernatant, the TEM picture of the supernatant is as follows figure 2 Shown; The supernatant was vacuum-dried to obtain modified gold nanoparticles with an average particle size of 45nm.

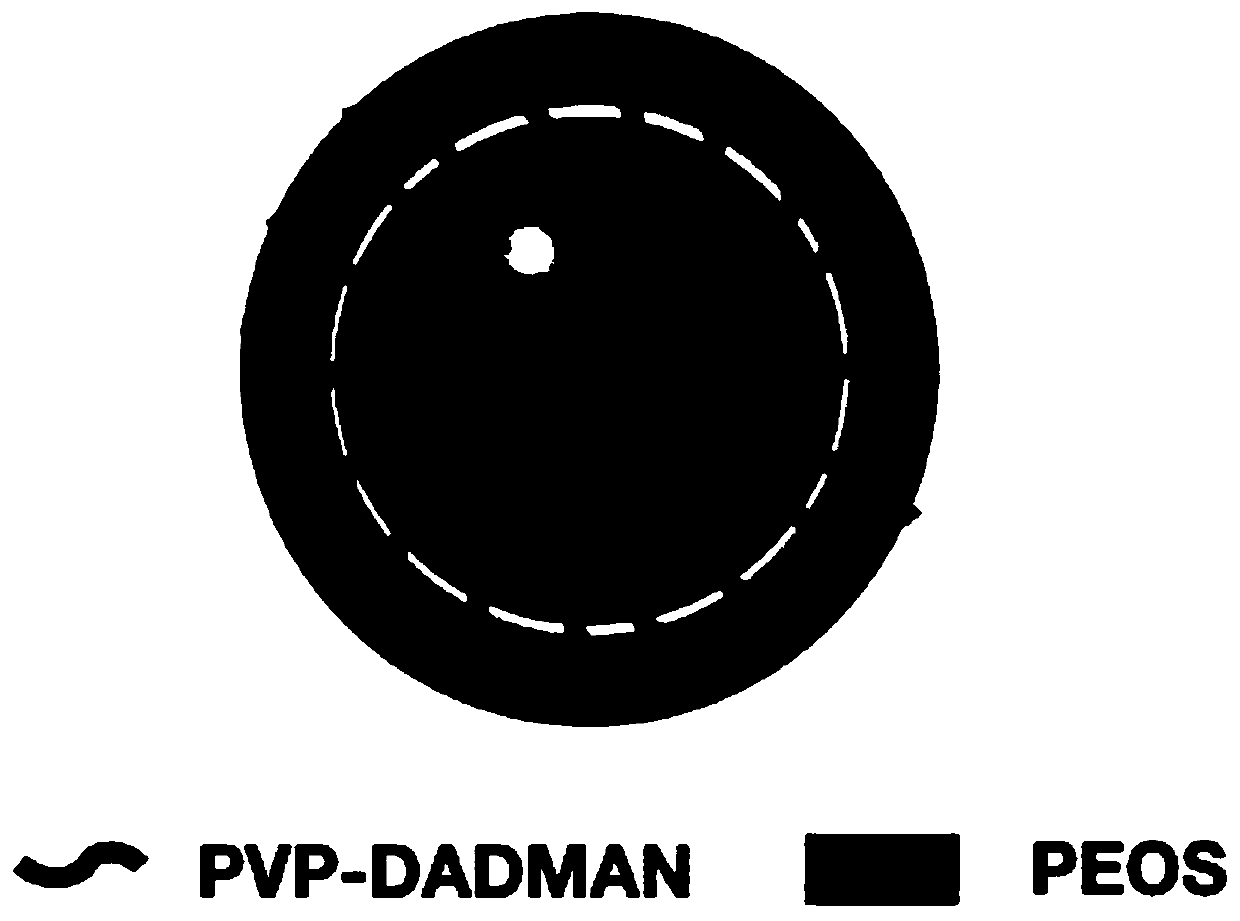

[0043] (2) 1 weight part of M w 1 kg / mol of PEOS is dissolved in 2 parts by weight of toluene as an oil phase; 2 parts by weight of the modified nano-gold prepared in step (1) is dissolved in water to make a solution with a concentration of 0.1% by mass; Add 0.4 parts by weight of n-butanol, drop dilute...

Embodiment 2

[0047] (1) 35 parts by weight of HAuCl 4 and 1 part by weight of M w 60kg / mol of PVP-DADMAN were dissolved in water to obtain a concentration of 3 × 10 -3 MHAuCl 4 solution and concentration of 6 x 10 -6 The solution of PVP-DADMAN of M, mixed and boiled for 1h, then added 70 parts by weight of thiourea, stirred and reacted in the dark at 98°C for 1h, centrifuged at 10000rpm for 15min to obtain the supernatant, the TEM picture of the supernatant is as follows figure 2 Shown; The supernatant was vacuum-dried to obtain modified gold nanoparticles, with an average particle size of 43nm.

[0048] (2) 1 weight part of M w The PEOS that is 1.3kg / mol is dissolved in the xylene of 5 weight parts, as oily phase; The modified nano-gold prepared in step (1) is got 2.5 weight parts and is dissolved in water, and the concentration that makes mass percentage is 1% solution; add 1 weight part of propanol, drop dilute hydrochloric acid to adjust the pH to 2, as the water phase; add the w...

Embodiment 3

[0052] (1) 20 parts by weight of HAuCl 4 and 1 part by weight of M w 68kg / mol of PVP-DADMAN were dissolved in water to obtain a concentration of 1 × 10 -4 MHAuCl 4 solution and concentration of 1 x 10 -5 The solution of PVP-DADMAN of M, mixed and boiled for 1h, then added 100 parts by weight of ascorbic acid, stirred and reacted in the dark at 98°C for 1h, centrifuged at 20000rpm for 30min to obtain the supernatant, the TEM picture of the supernatant is as follows figure 2 Shown; The supernatant was vacuum-dried to obtain modified gold nanoparticles with an average particle size of 40nm.

[0053] (2) 1 weight part of M w 3 kg / mol of PEOS is dissolved in 8 parts by weight of ethylbenzene as the oil phase; 0.2 parts by weight of the modified nano-gold prepared in step (1) is dissolved in water to make a solution with a concentration of 0.1% by mass Add 0.1 parts by weight of ethanol, add dropwise citric acid aqueous solution to adjust the pH to 4, as the water phase; add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com