Upflow type reactor gas-liquid distribution disc and applications thereof

A gas-liquid distribution and reactor technology, which is used in chemical instruments and methods, hydrocarbon oil cracking, petroleum industry, etc. Deterioration of the effect and other problems, to achieve the effect of simple structure, high space utilization, reducing collision and coalescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

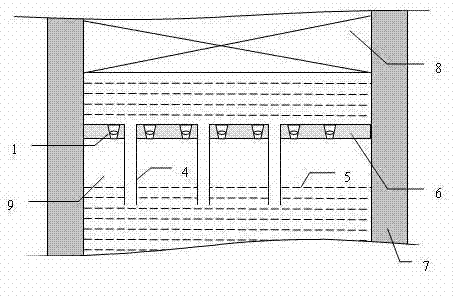

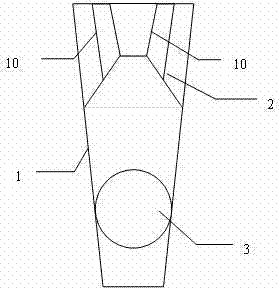

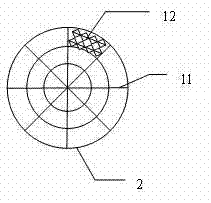

[0028] Such as figure 1 , 2 As shown, the gas-liquid distribution plate of the upflow reactor is composed of an upflow gas-liquid distribution plate tray 6 , a one-way valve 1 and a riser pipe 4 . The one-way valve 1 of this embodiment adopts a spherical one-way valve operating mechanism, that is, when the spherical one-way valve operating mechanism rises upwards, the logistics flow through in one direction. The one-way valve 1 is composed of a spherical one-way valve operating mechanism 3 and a grille crushing net 2 with a diversion function. The grid crushing net 2 is composed of two layers of conical cylindrical annular walls 10 with a small bottom and a large upper top, a grid 11 evenly distributed between the conical cylindrical annular walls 10, and a screen-like crushing net 12 above. After the gas-liquid mixture material passes through the catalyst bed in the lower part of the reactor, the liquid phase passes through the gas-liquid distribution tray 6 upwards from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com