Jet aeration reactor used in active sludge method and its jet aeration process

A technology of jet aeration and reactor, applied in fluid mixer, water/sludge/sewage treatment, chemical instruments and methods, etc. Cutting and serving area are small and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

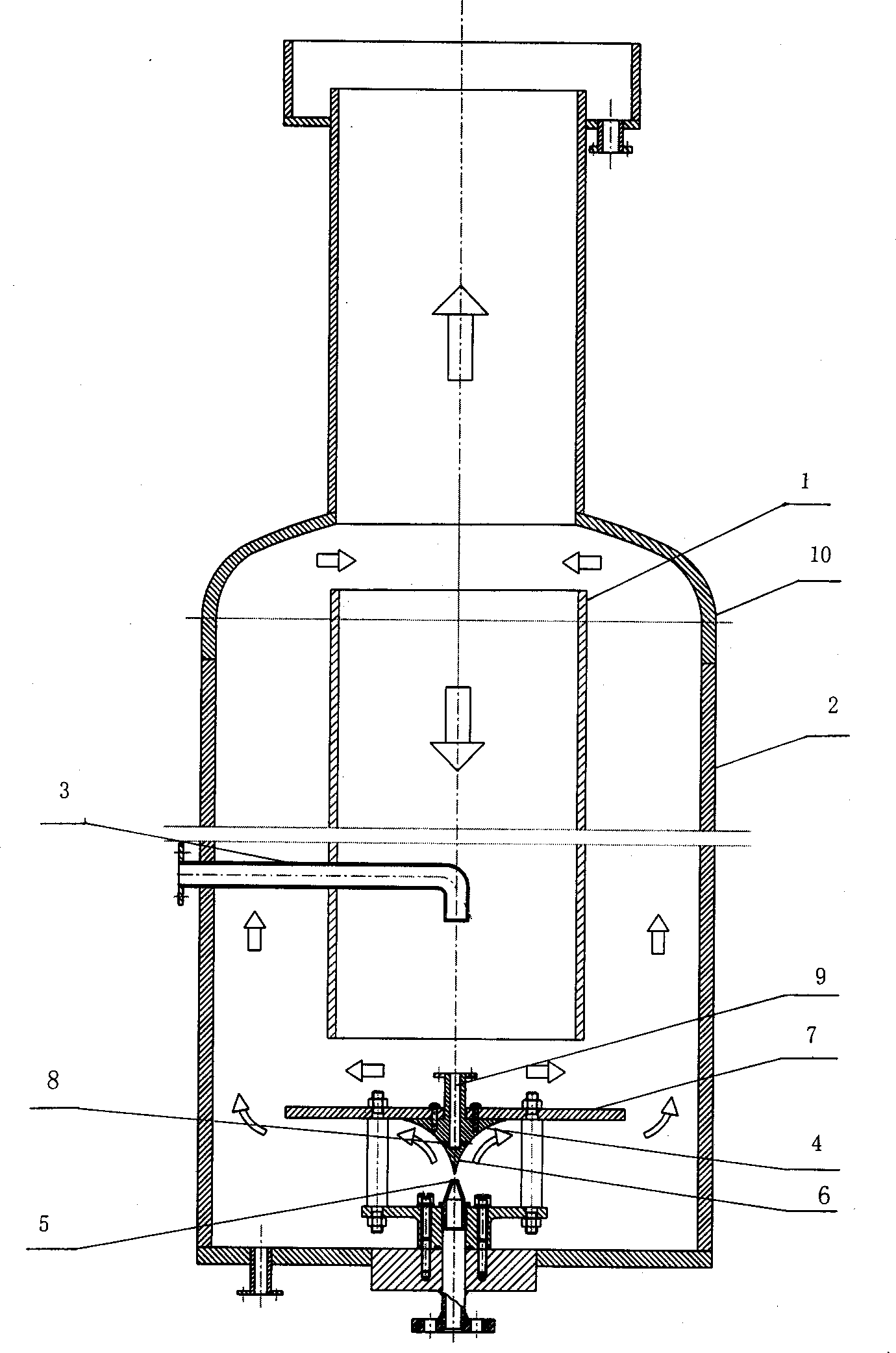

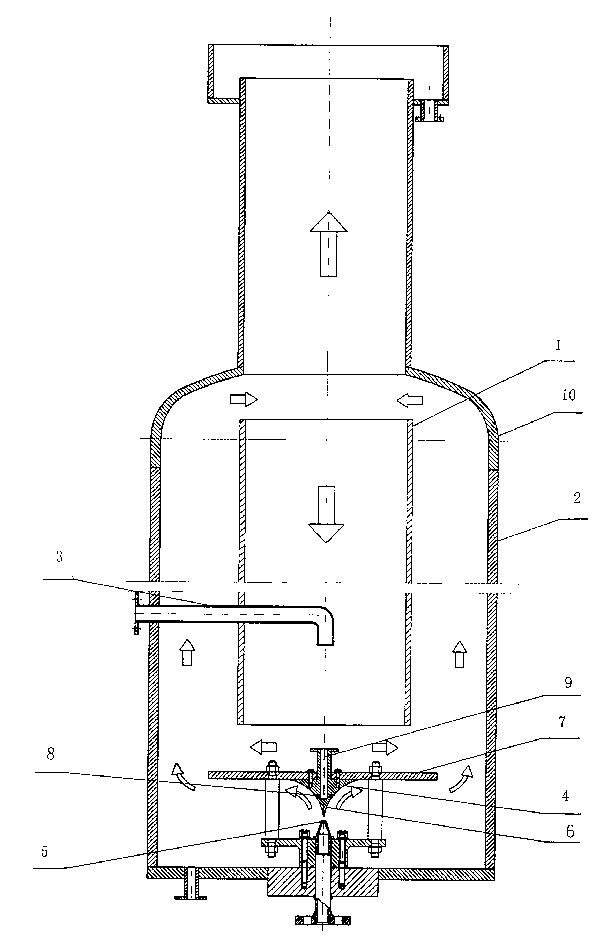

[0016] Concrete structure and process method of the present invention are specified below in conjunction with accompanying drawing:

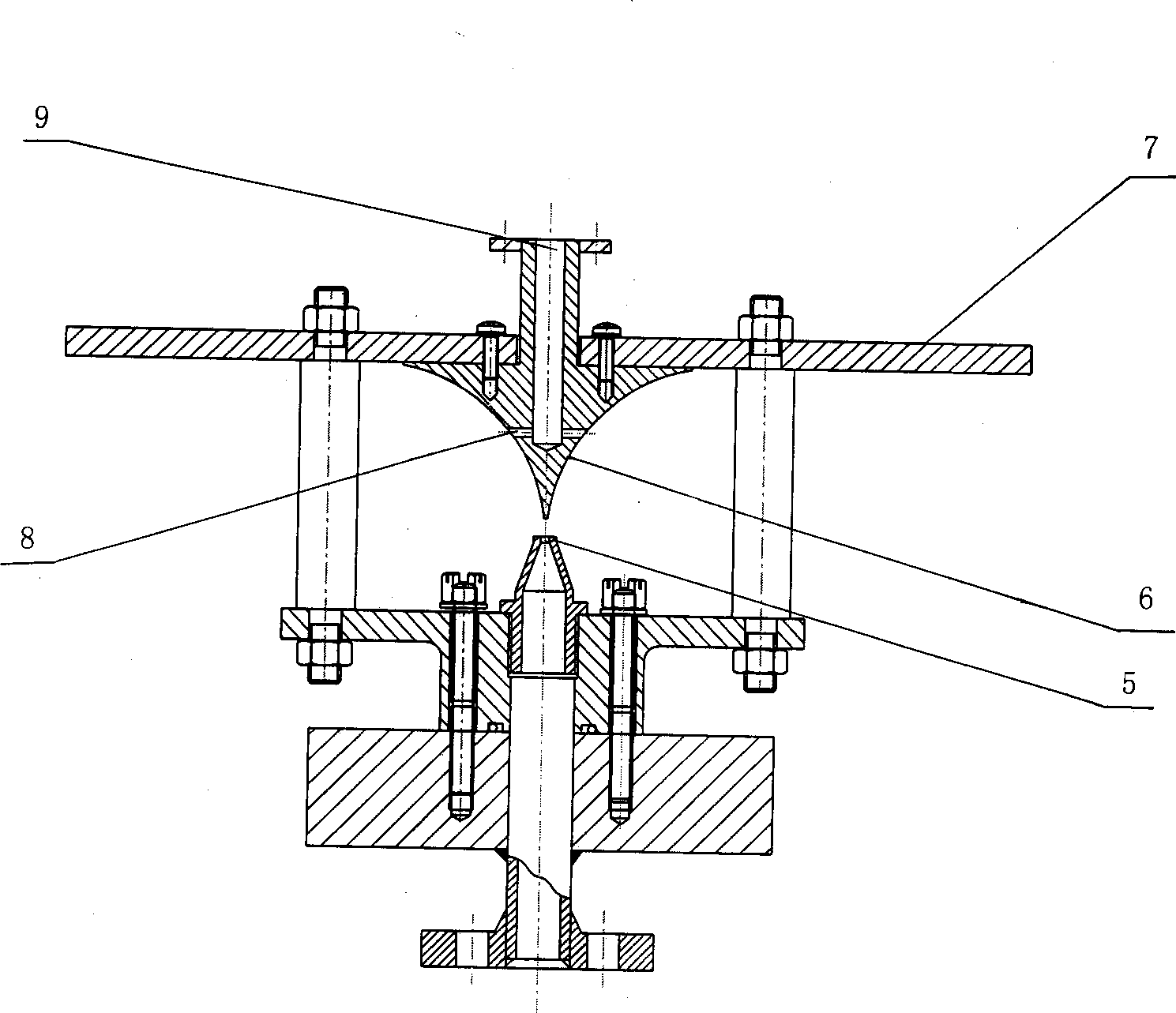

[0017] figure 1 It is a sectional view of jet aeration reactor used in activated sludge process. The jet aeration reactor mainly includes a guide tube 1, a jet circulation reactor 2, a sludge return distributor 3, a jet aerator 4 arranged at the bottom of the reactor and concentric with it, and an impinger arranged at the middle and upper part of the reactor. Surface 10. The jet aeration reactor is divided into two parts, the upper and lower reactors. Jet aerators (such as figure 2 (shown) mainly includes a liquid-driven nozzle 5, a fixed cone 6, a distribution plate 7, an annular gap 8, and a gas channel 9.

[0018] The liquid-driven nozzle 5 selects a conical convergent nozzle, keeps the flow velocity of the nozzle at 20-25m / s, and determines its geometric size according to the flow rate and the flow velocity of the nozzle.

[0019] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com