A kind of low-viscosity high-speed cigarette glue and its preparation method

A low-viscosity, cigarette-adhesive technology, used in adhesives, adhesive types, grafted polymer adhesives, etc. The connection speed cannot meet the corresponding requirements and other problems, so as to ensure the storage stability, reduce the generation probability, and increase the particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

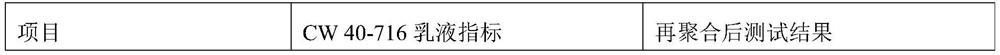

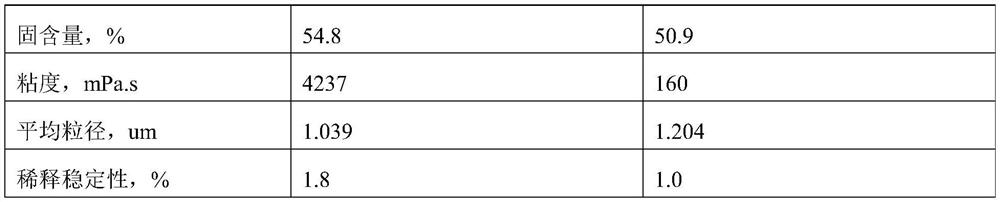

[0027] The VAE emulsion CW JZ-Ⅱ emulsion (SVW Chongqing China Petrochemical Corporation Chemical Co.) was added 800g reactor, the stirrer started, and then added 92.0g of water, 3.0 g of sodium bicarbonate and 27.5% hydrogen peroxide at a concentration of 5.0g, complete after the start of heating; mass when the kettle temperature was raised to 80 ± 2 ℃, maintaining the temperature at 80 ± 2 ℃ 30min; then / min. rate evenly added 0.75g 80.0g vinyl acetate monomer mixture and 10.0g of ethylene glycol, addition time is 120min. Vinyl acetate monomer and ethylene glycol feed mixture started simultaneously at a rate of 0.1g / min for the total amount of potassium persulfate was added a solution of 13.0g (10% concentration), time 130min addition, the reaction temperature was maintained during the addition 80 ± 2 ℃; potassium persulfate solution after the addition had finished, the reaction temperature was raised to 85-90 deg.] C, followed quickly by addition of a total of 16.0g of sodium...

Embodiment 2

[0031] 800.0g of VAE emulsion CW JZ-II lotion (Sinopec Group Chongqingchuan Wei Chemical Co., Ltd.) was added to the reactor, the stirrer was activated, then 100.0 g of water, 3.0 g sodium bicarbonate and concentration of 27.5% hydrogen-oxide 1.0g, After completion, the temperature is started; when the material temperature in the reactor rises to 80 ± 2 ° C, the temperature is 80 ± 2 ° C for 30 min; then the mixture of 80.0 g of acetate monomer and 10.0 g of ethylene glycol is added at a rate of 0.75 g / min. The feed time is 120 min. While the acetate monomer is added to the ethylene glycol mixture, the total amount of 13.0 g of potassium sulfate (concentration is 10%) is added at a rate of 0.1 g / min, and the feed time is 130 min, and the feed process remains the reaction temperature. After 80 ± 2 ° C; after the potassium sulfate solution is added, the reaction temperature rises to 85-90 ° C, and the total amount of a total amount of azulid sulfite (concentration is 6%) after t...

Embodiment 3

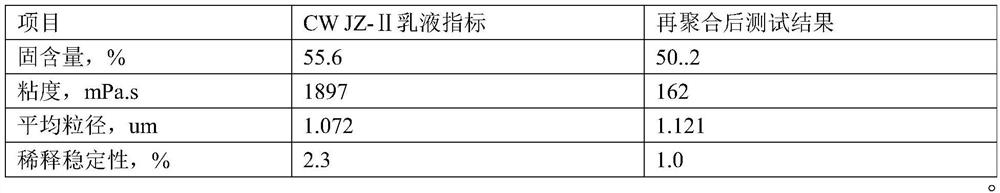

[0036] Add a VAE lotion CW 40-707 lotion 700.0g (Sinopec Group Chongqingchuan Wei Chemical Co., Ltd.) to the reactor, start the stirrer, then add 120.0 g of water, 3.0 g sodium bicarbonate and concentration of 27.5% hydrogen peroxide 6.0g, After completion, the temperature is started; when the material temperature is raised to 80 ± 2 ° C in the reaction kettle, the temperature is 80 ± 2 ° C for 30 min; then the mixture of 120.0 g of acetate monomer with 10.0 g of acetate and 10.0 g of glycerol is then added at 1.1 g / min. The feed time is 120 min. While the acetate monomer is added to the glycerol mixture, the total amount of 16.0 g of potassium sulfate solution (10%) is added at a rate of 0.12 g / min, and the feed time is 130 min and the feed temperature is maintained. 80 ± 2 ° C; After the potassium sulfate solution is added, the reaction temperature rises to 85-90 ° C, and then the total amount of 18.0 g of a sodium-crociate solution (concentration is 6%); after 30min, reduci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com