Assembly equipment for air valve

A technology for assembling equipment and air valves, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of increasing the workload of production personnel, achieve the effects of improving resource utilization efficiency, saving driving sources, and improving linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Attached to the following Figure 1-10 This application will be described in further detail.

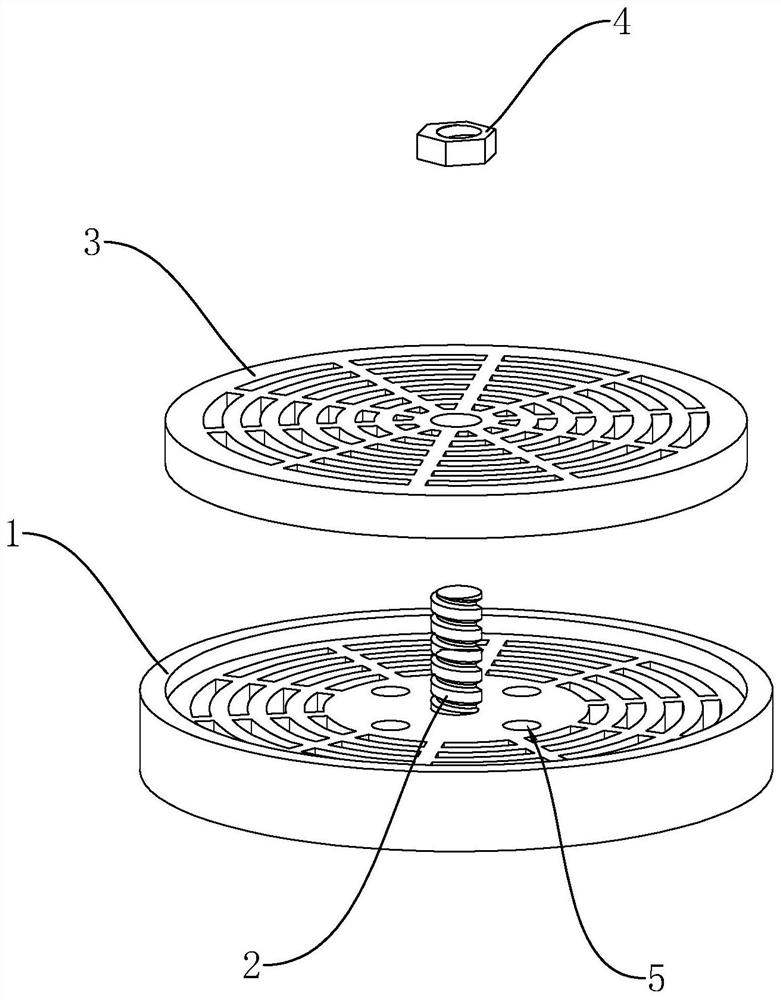

[0045] The embodiment of the present application discloses an assembly equipment for a gas valve. refer to figure 1 The air valve includes a valve body 1 , a screw 2 is vertically and fixedly connected to the center of the upper end of the valve body 1 , a valve cover 3 is sleeved on the screw 2 , and the valve cover 3 and the valve body 1 are coaxial. The screw 2 is threadedly sleeved with a nut 4 , and the nut 4 is used to press the valve cover 3 on the valve body 1 to realize the fixing of the valve body 1 and the valve cover 3 . At the same time, the valve body 1 is provided with four mounting holes 5 along its circumferential direction, so as to facilitate connection with other components.

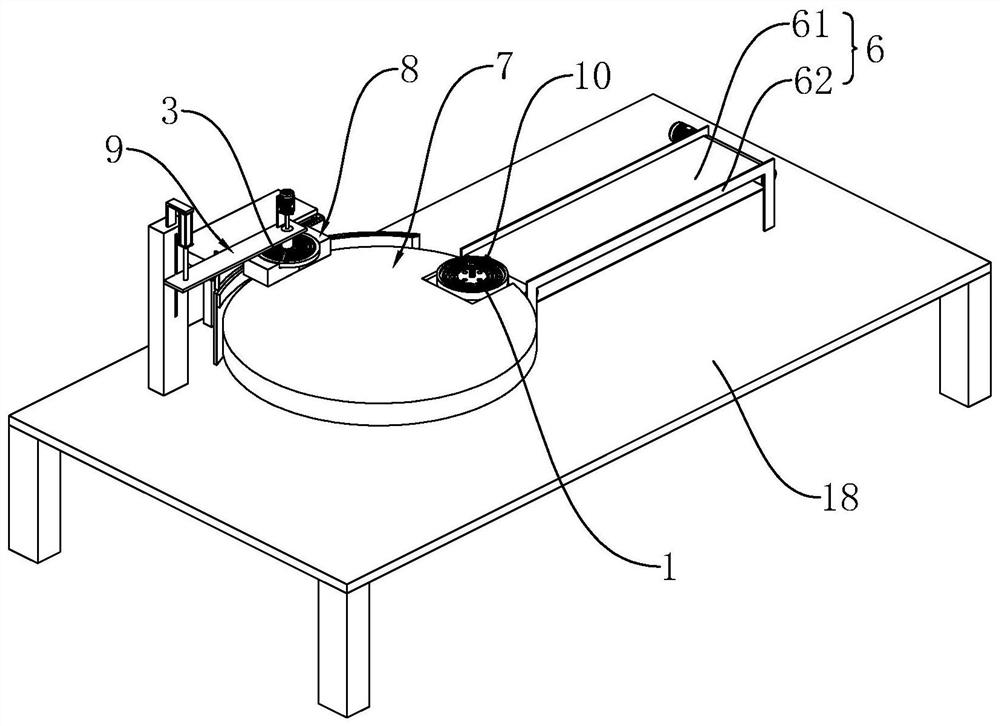

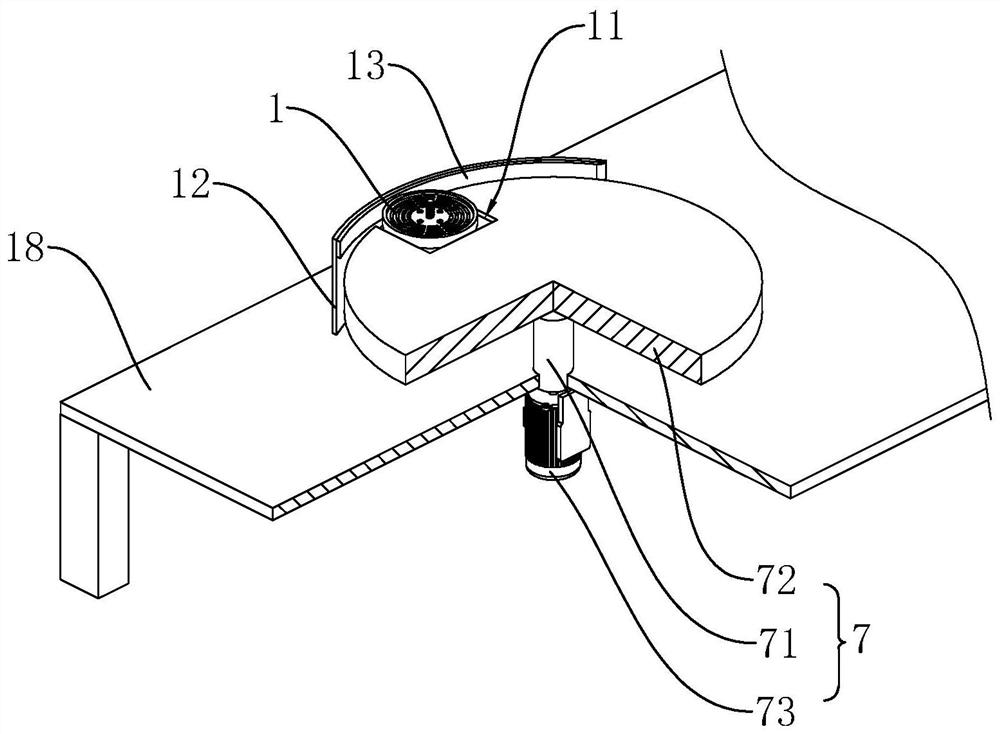

[0046] refer to figure 1 and figure 2 , The air valve assembly equipment includes a workbench 18, and the upper end of the workbench 18 is provided with a feeding mechanism 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com