General-purpose fastener automatic control screwing device of process for assembling drive axle assembly

A drive axle assembly and fastener technology, which is applied in the field of automatic control and tightening devices for general fasteners in the assembly process of the drive axle assembly, can solve the problem that the assembly quality of core components and high production efficiency cannot be guaranteed, and the operation accuracy of operators can be increased. Difficulty of control, different nut tightening procedures, etc., to achieve standardized operation, improve operation efficiency, and eliminate human factors.

Active Publication Date: 2010-12-01

LIAONING SG AUTOMOTIVE GRP CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the assembly line of the drive axle assembly adopts a multi-variety collinear production mode in turn, and the installation spacing of the bolts and nuts of the differential sub-assembly and the main reducer assembly of different structural types is also diverse, resulting in bolts and nuts tightening operations The process is not the same, so if the assembly of the two core components meets the product technical requirements, it will bring considerable difficulty

At present, in the automobile axle industry, there are still more technical operation methods in which the production line operators hold pneumatic wrench to tighten the bolts and nuts, and then check the tightening torque value with the indicator wrench. This method is mainly based on the operator's work experience. It often happens that the tightening torque of the bolts and nuts is too large or too small and must be reworked. However, tightening the bolts and nuts for many times will easily destroy the precision of the thread fit and cause technical problems of potential failure modes, and the production efficiency is also very low. Especially in the assembly of the drive axle assembly of medium and heavy vehicles, due to the high tightening torque value of the bolts and nuts, the torque that acts on the hands of the operator is very large, which increases the difficulty of the operator's operation precision control, and its work intensity is also high. very big

To sum up, the existing automobile drive axle assembly process operation method cannot guarantee the assembly quality of its core components and the technical requirements of high production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

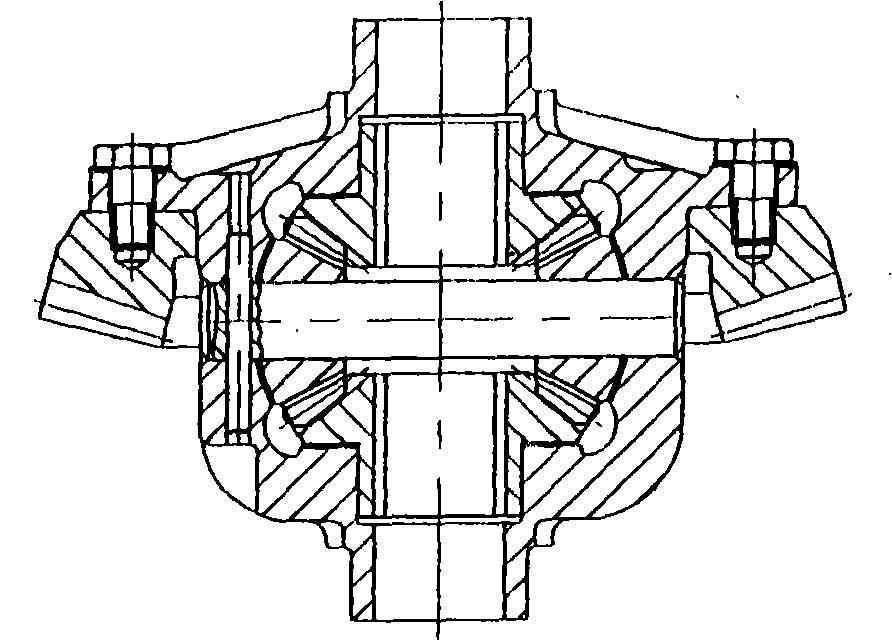

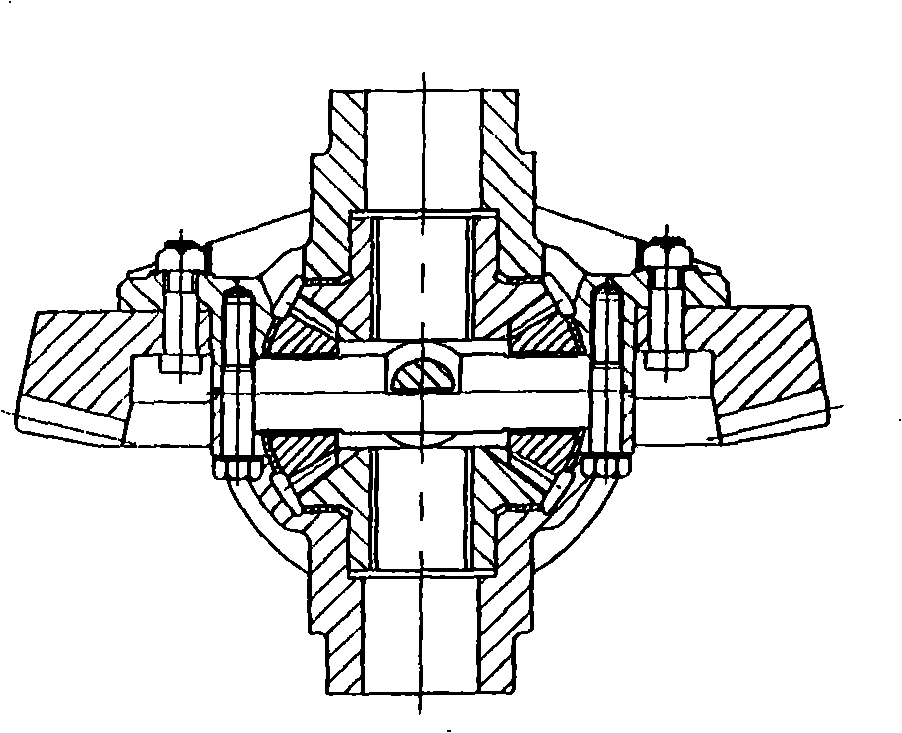

The invention relates to a differential mechanism sub-assembly for a vehicle driving axle assembly, bolts in a main reducing gear assembly, and a fastening device of a nut type fastener. In order to finish the automatic tightening operations on the differential mechanism sub-assembly, the bolts in the main reducing gear assembly and a nut, the invention provides a universal fastener automatic control tightening device used in the assembling process of the driving axle assembly. The tightening device comprises a horizontal rotary operating board which is driven to ascend and descend by a lifting mechanism and is provided with a servo tightening mechanism, a tightening operating head, and a counter torque balance positioning head which keeps certain adjustable center distance with the servotightening mechanism; and a driver of the servo tightening mechanism is connected with a communication interface of an electronic control unit. The technical proposal eliminates personal factors and the disturbing influence under the action of the counter torque in the assembly process to the utmost extent so as to ensure that the product technical requirement is used as a standard to improve theoperation quality for the assembling production of the driving axle assembly and improve the operational efficiency.

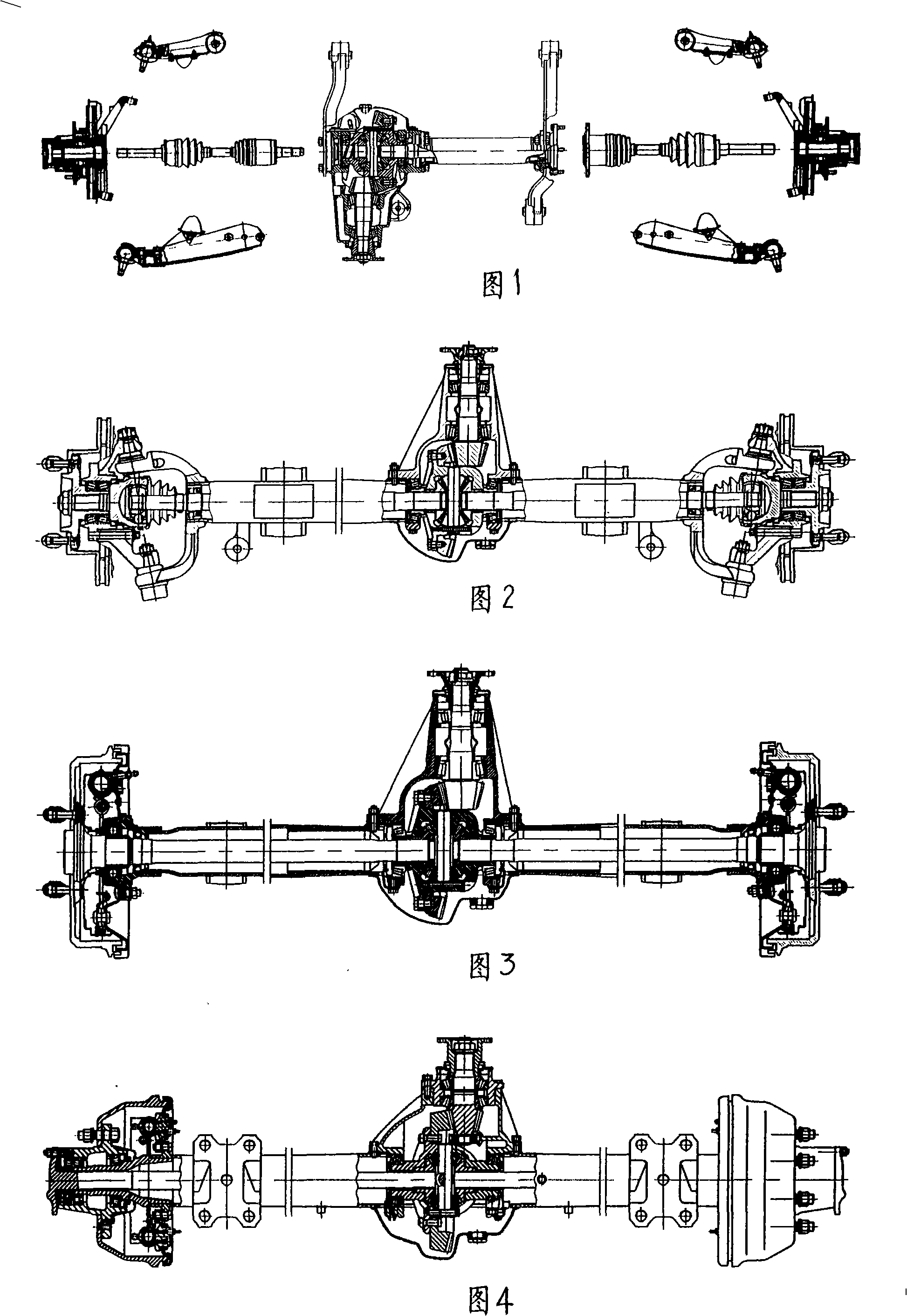

Description

Automatic control tightening device for universal fasteners in drive axle assembly process technical field The patent application of the present invention relates to an operating device for tightening bolts and nuts in the differential sub-assembly and the final drive assembly in the assembly process of the automobile drive axle assembly. Background technique One of the key quality characteristics of the finished product of the automobile drive axle assembly is to effectively control the tightening torque value of the bolts and nut fasteners in the assembly of the differential sub-assembly and the final drive assembly and make it reach the product level. skills requirement. The differential sub-assembly and the main reducer assembly are the core components of the automobile drive axle. The differential sub-assembly is divided into two types of assembly structures: integral type and split type according to the number of inner planetary gears and the installation method. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P19/06

Inventor 于刚高飞

Owner LIAONING SG AUTOMOTIVE GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com