Spiral conveying device

A technology of conveying device and auger, which is applied in the direction of packaging, etc., can solve the problems of inconvenient use, storage and movement, long overall length of auger pump, and increased return resistance, so as to save driving source, improve material return and reduce overall cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

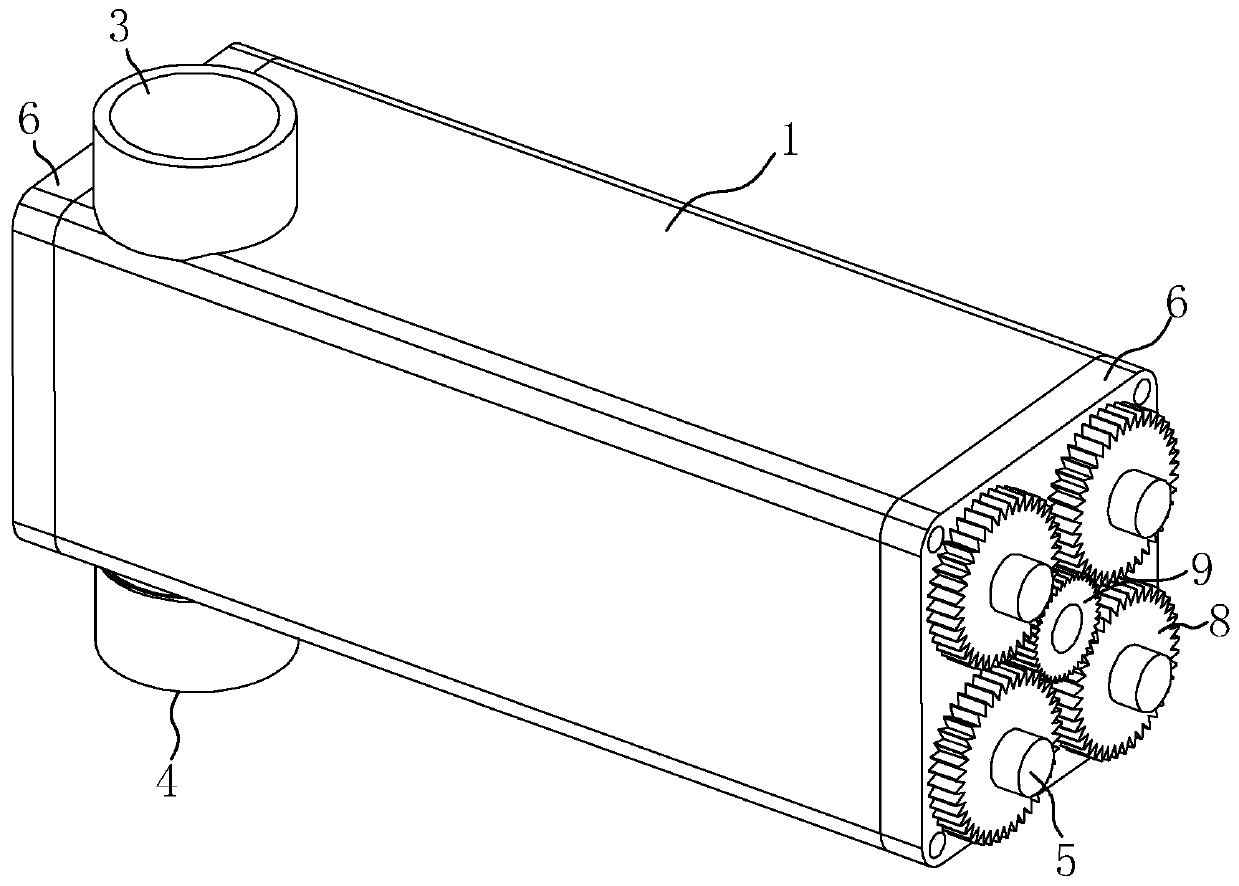

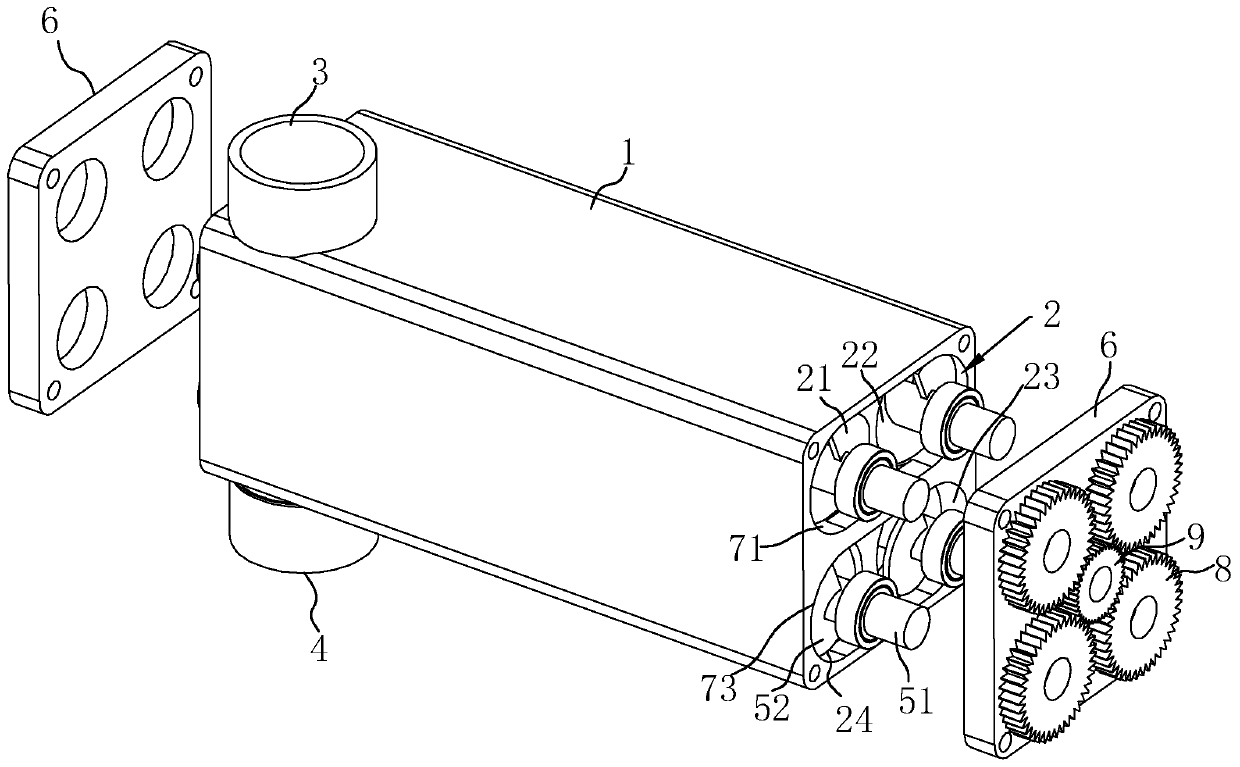

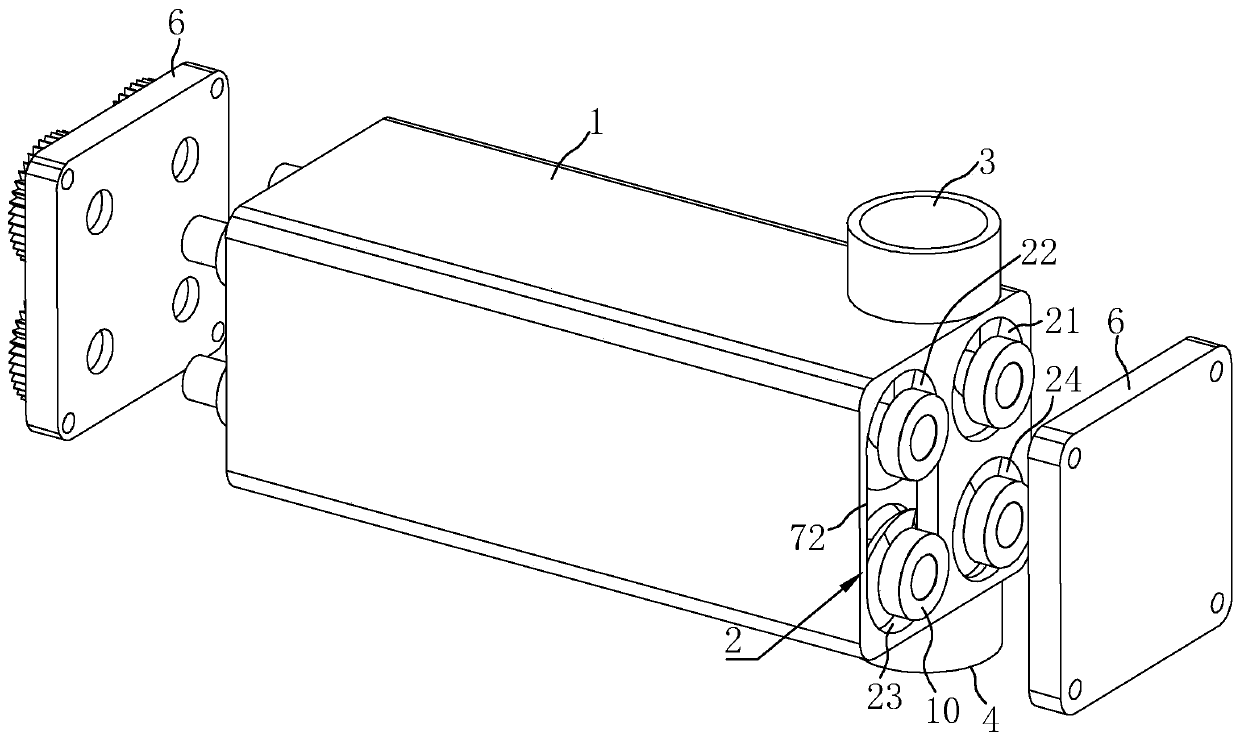

[0037] Embodiment 1: refer to figure 1 and figure 2 , is an auger conveying device disclosed in the present invention, comprising a square-shaped body 1, in which a plurality of conveying cavities 2 are arranged, and in this embodiment, four conveying cavities 2 are set and communicated in sequence, conveying Cavities 2 are arranged in parallel to form a first chamber 21, a second chamber 22, a third chamber 23 and a fourth chamber 24, the first chamber 21 and the second chamber 22 are located above, and the third chamber 23 and the fourth chamber 24 are located below, and each chamber is elongated and has a circular cross section. An inlet 3 communicating with the first chamber 21 is provided on the top side of the body 1, and at the bottom of the body 1 a The side is provided with an outlet 4 communicating with the fourth chamber 24; in the conveying chamber 2, there are screw conveying rods 5 connected in rotation, and the material enters the first chamber 21 from the inl...

Embodiment 2

[0042] Embodiment 2: refer to Figure 4 , is an auger conveying device disclosed in the present invention. The main difference between it and Embodiment 1 is that the outlet 4 includes a plurality of openings 11 arranged on the body 1, wherein there are four openings 11 and are respectively connected with each conveying Corresponding to the cavity 2, the opening 11 is opened at the end of each delivery cavity 2, and at the same time, a sealing plate 12 is horizontally slidably connected to the corresponding opening 11 of the body 1. The sealing plate 12 is used to close the opening 11, and is connected on the sealing plate 12. There is a partition 13 for separating and blocking the communication cavity. The partition 13 and the sealing plate 12 are fixed and move synchronously. The partition 13 is located at the entity between the body 1 corresponding to the adjacent delivery chamber 2, and between the sealing plate 12 and the opening 11 When it is in a staggered state, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com