Automatic assembling equipment for USB interfaces

A USB interface, automatic assembly technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as increasing the workload of production personnel, and achieve the effect of improving resource utilization efficiency, reducing workload, and improving linkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

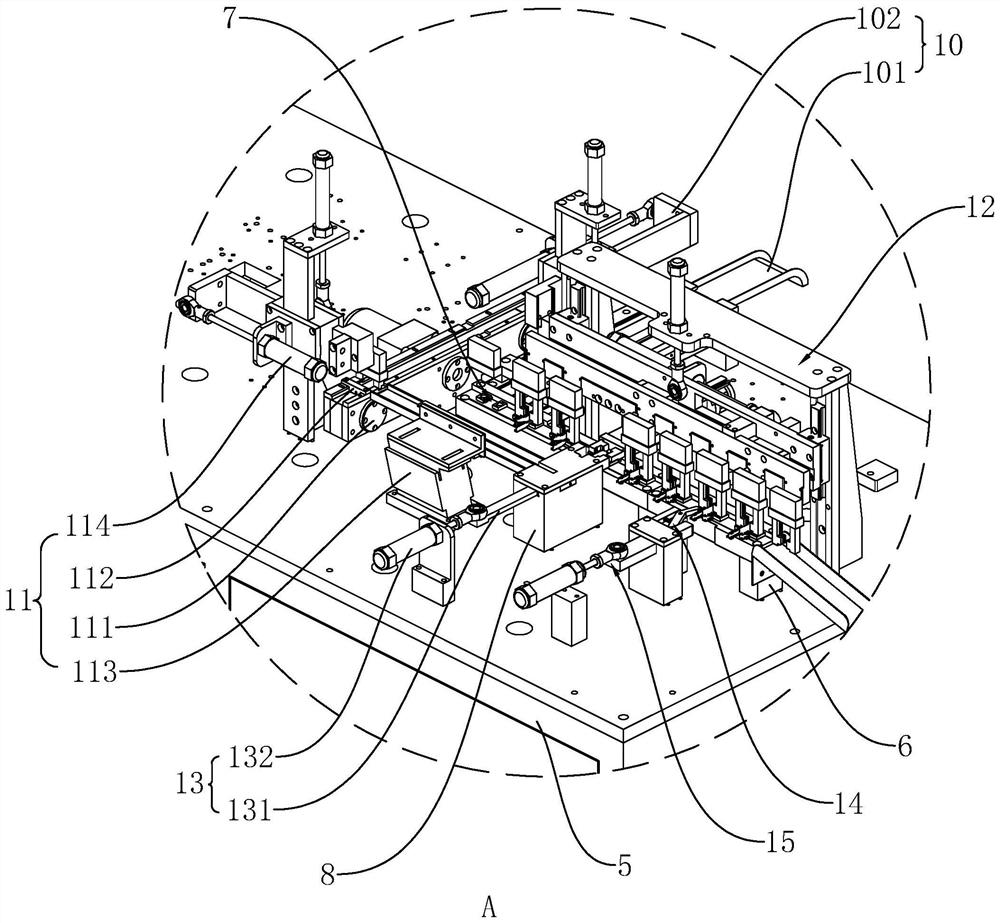

[0042] The following is attached Figure 1-10 The application is described in further detail.

[0043] The embodiment of the present application discloses a USB interface automatic assembly device.

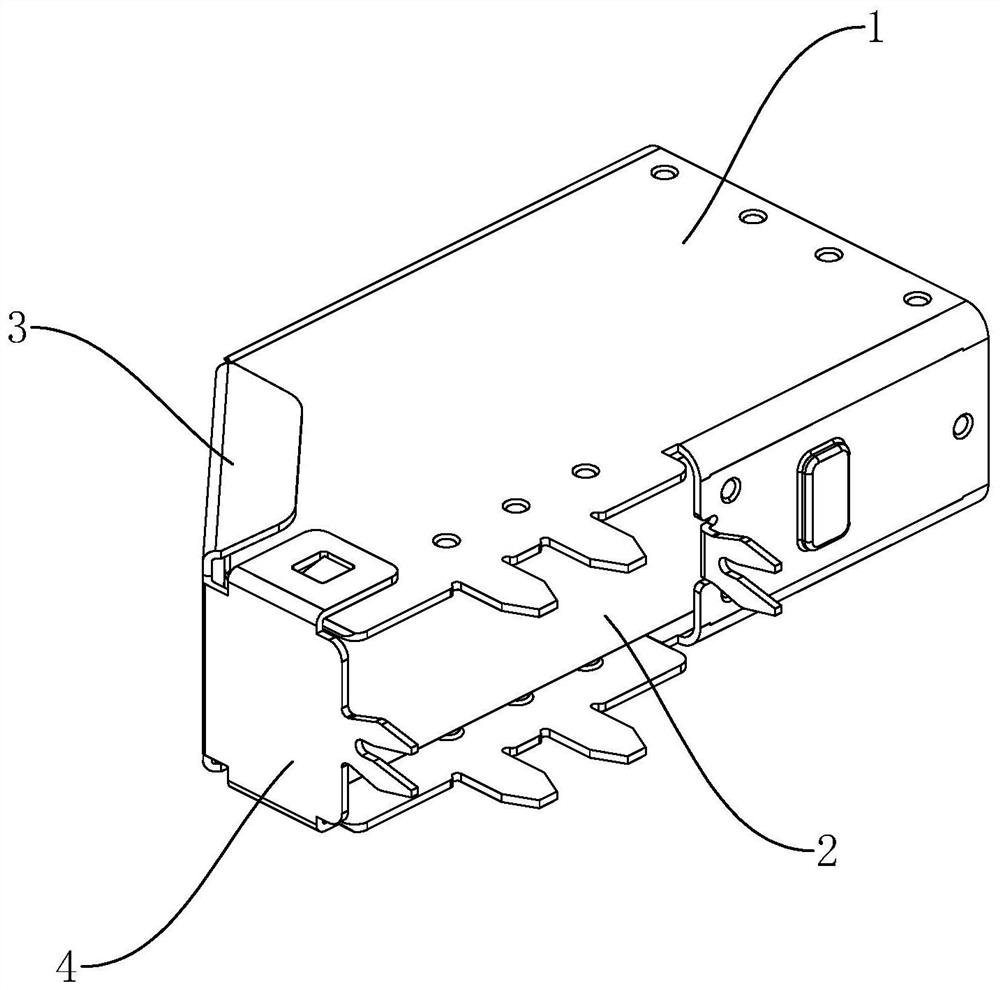

[0044] refer to figure 1 , the USB interface includes a housing 1 and a terminal body 2 snapped into the housing, a cover 3 is integrally formed at the port of the housing 1 , and a pressure plate 4 is integrally formed at the end of the cover 3 away from the housing 1 . At the same time, the cover plate 3 and the pressing plate 4 abut against the terminal body 2 respectively, and the cover plate 3 and the pressing plate 4 jointly close the port of the housing 1 to prevent the terminal body 2 from sliding out of the housing 1 .

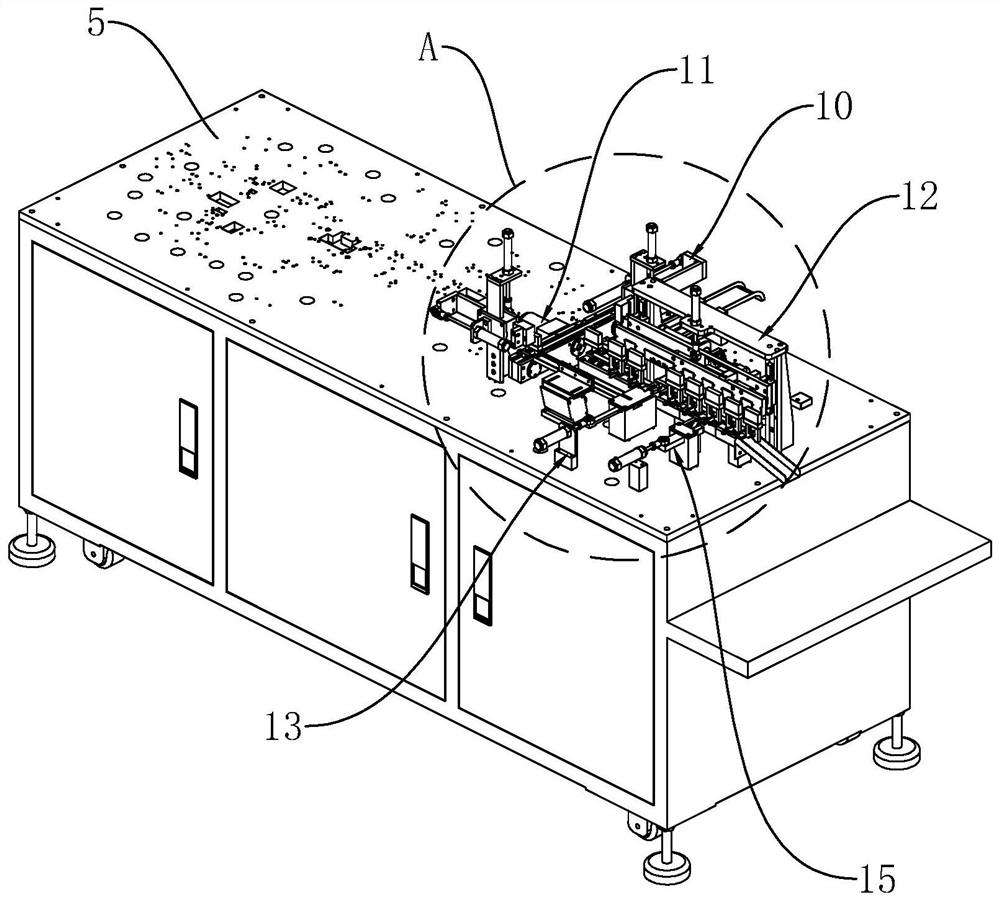

[0045] refer to figure 2 and image 3 , the USB interface automatic assembly equipment includes a workbench 5, a receiving frame 6 is fixedly connected to the working table 5, one end of the receiving frame 6 is a starting end, and the other end is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com