Electromagnetic relay and assembling method of electromagnetic unit thereof

An electromagnetic relay and electromagnetic unit technology, applied in relays, polarized relays, electrical components, etc., can solve the problems of easy shaking, waste of processing time and manpower, inability to increase production capacity, etc., and achieve automatic assembly operations and realize assembly operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

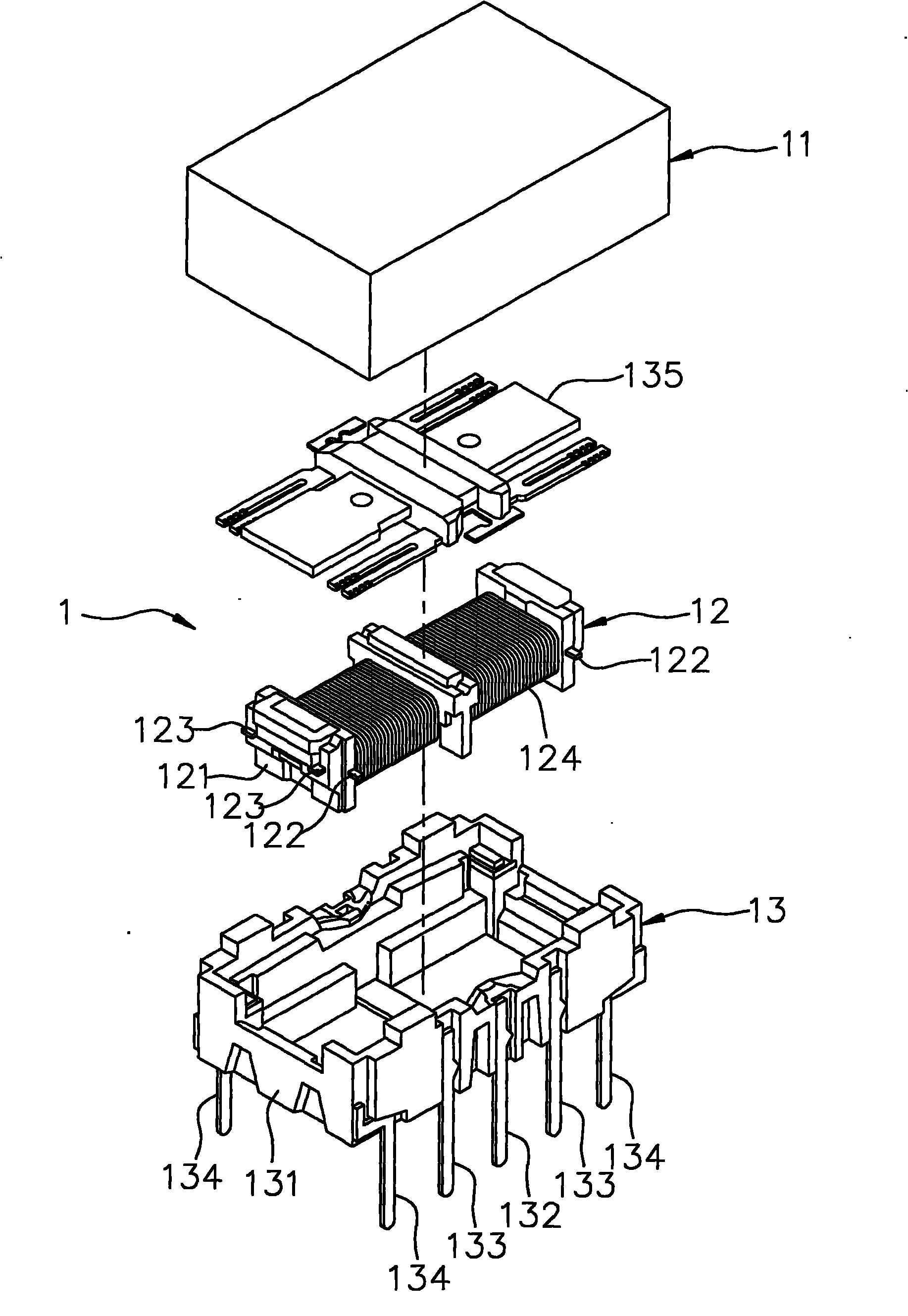

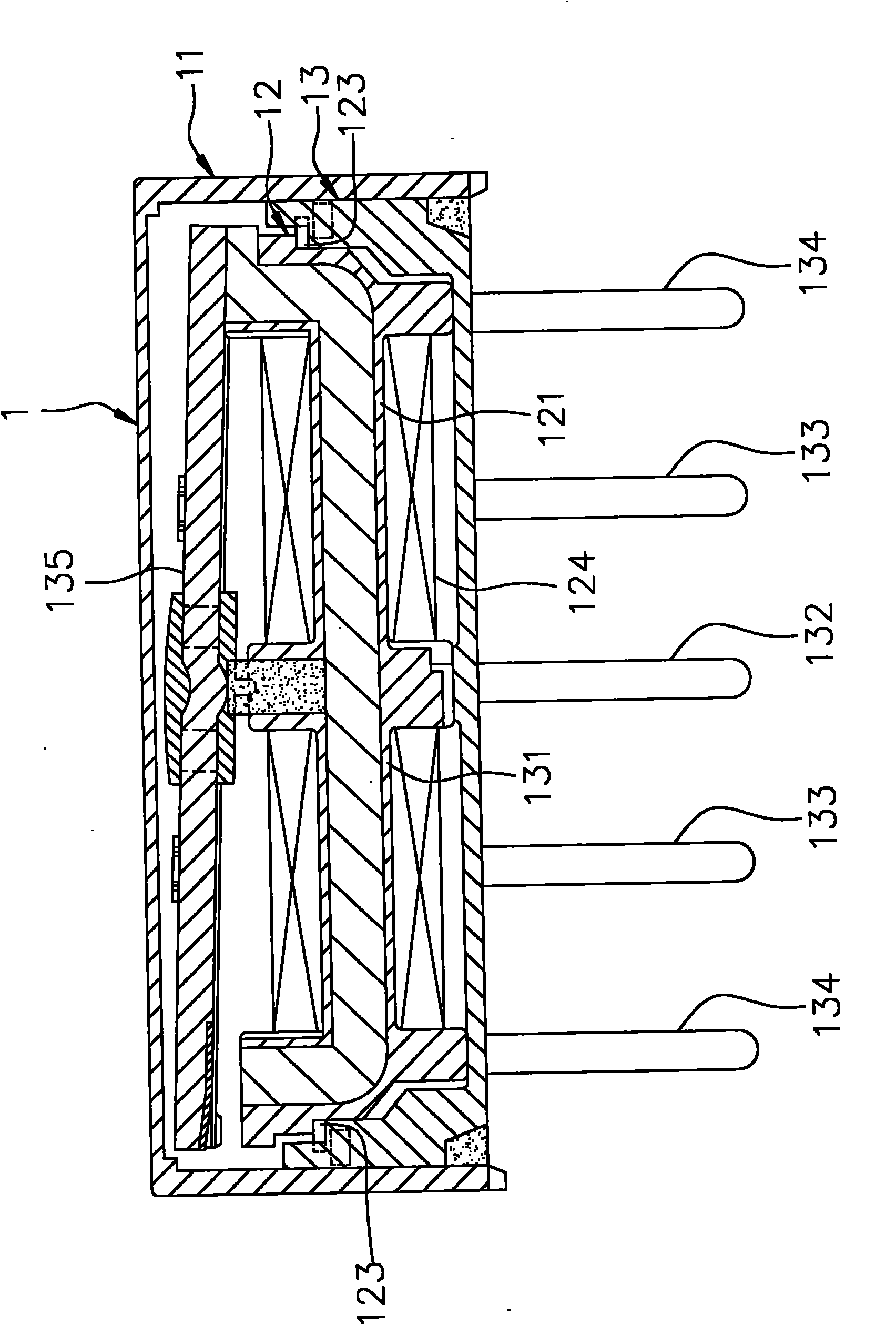

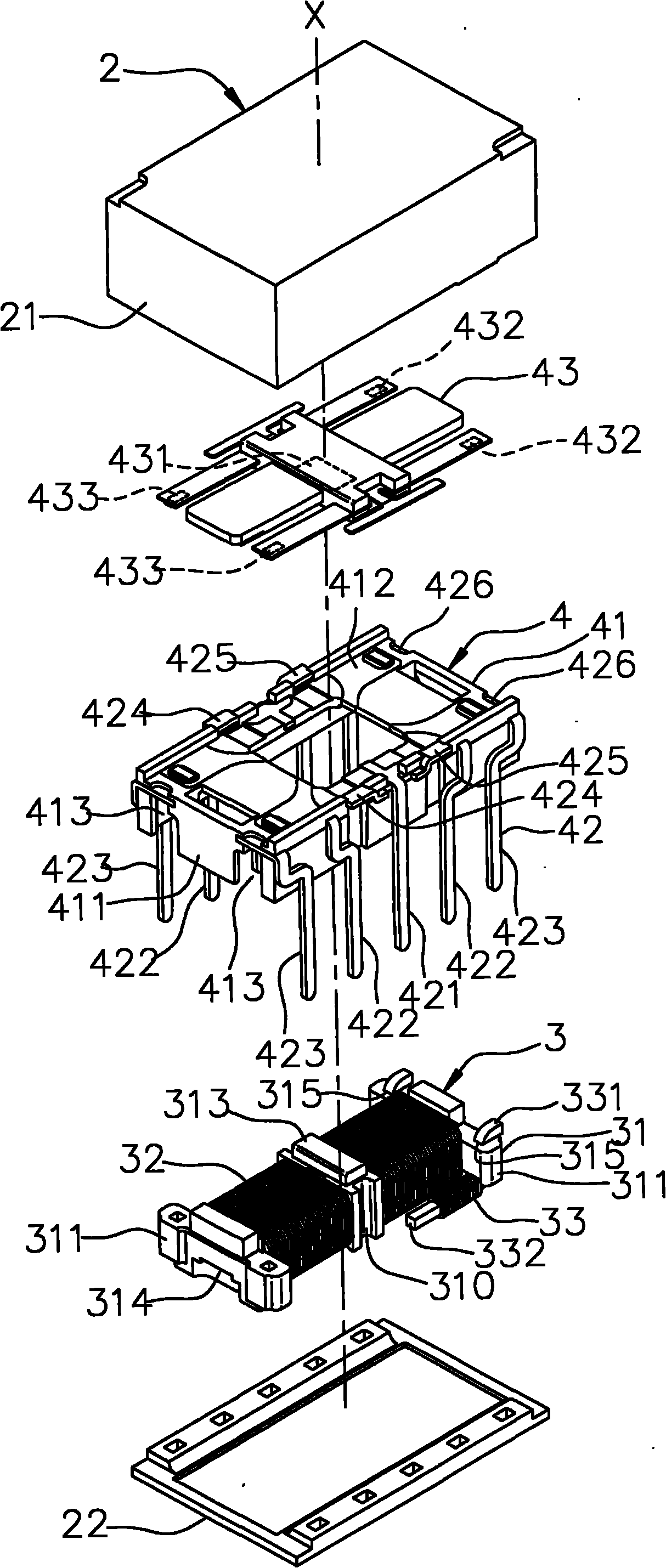

[0021] refer to image 3 and Figure 4 , A preferred embodiment of the electromagnetic relay of the present invention includes a housing 2 , an electromagnetic unit 3 , and a switch unit 4 .

[0022] The case base 2 has a first shell 21 and a second shell 22 that are aligned with each other along an axis X and used to encapsulate the electromagnetic unit 3 and the switch unit 4 .

[0023] The electromagnetic unit 3 has a magnetic wire frame set 31 , a coil set 32 , and a pair of winding terminals 33 . The wire frame set 31 has a wire frame 310 for winding the coil group 32 , a pair of frame rods 311 and the wire frame 310 formed on both ends of the wire frame 310 along a long axis direction and extending along a short axis direction. An integral injection molded core 312, a permanent magnet 313 embedded in the wire frame 310, two grooves 314 formed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com