Unidirectionally-driven three-dimensional three-linkage-period stepping mechanism

A technology of stepping mechanism and driving mechanism, which is applied in planting methods, transplanting machinery, applications, etc., and can solve the problems of slow speed of the driving mechanism of the jacking needle, leakage of the top of the grid seedling tray, and large driving force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

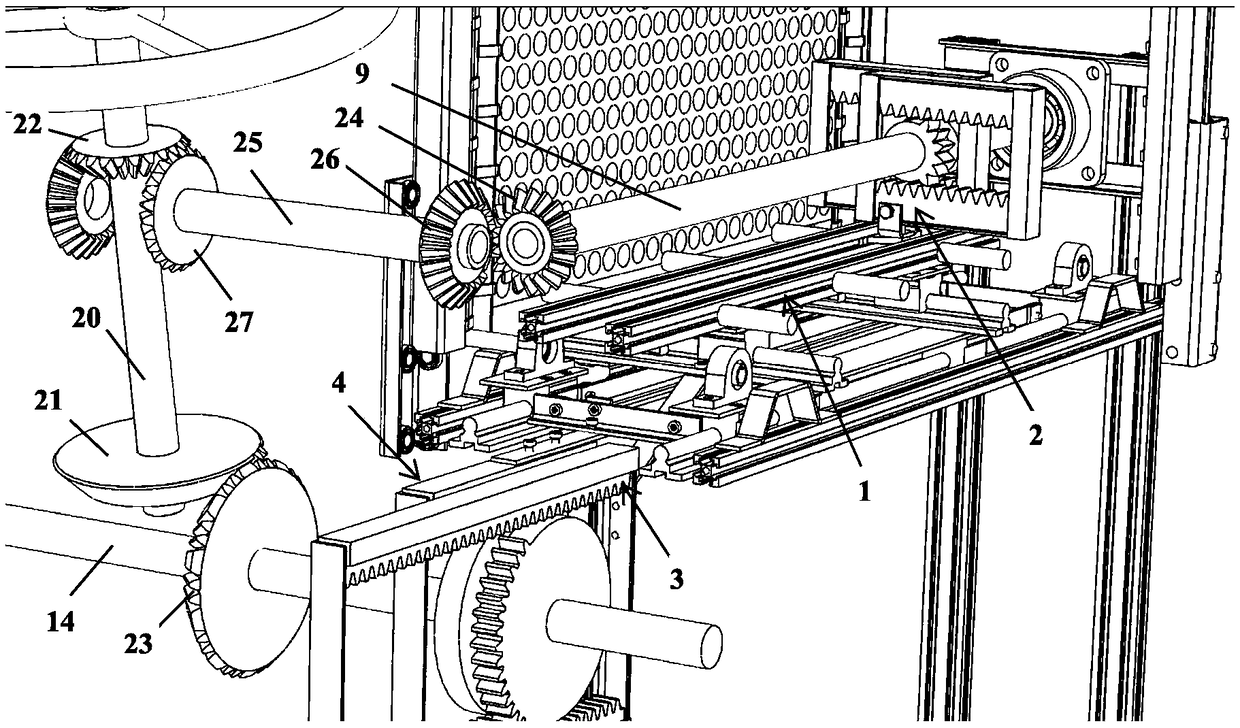

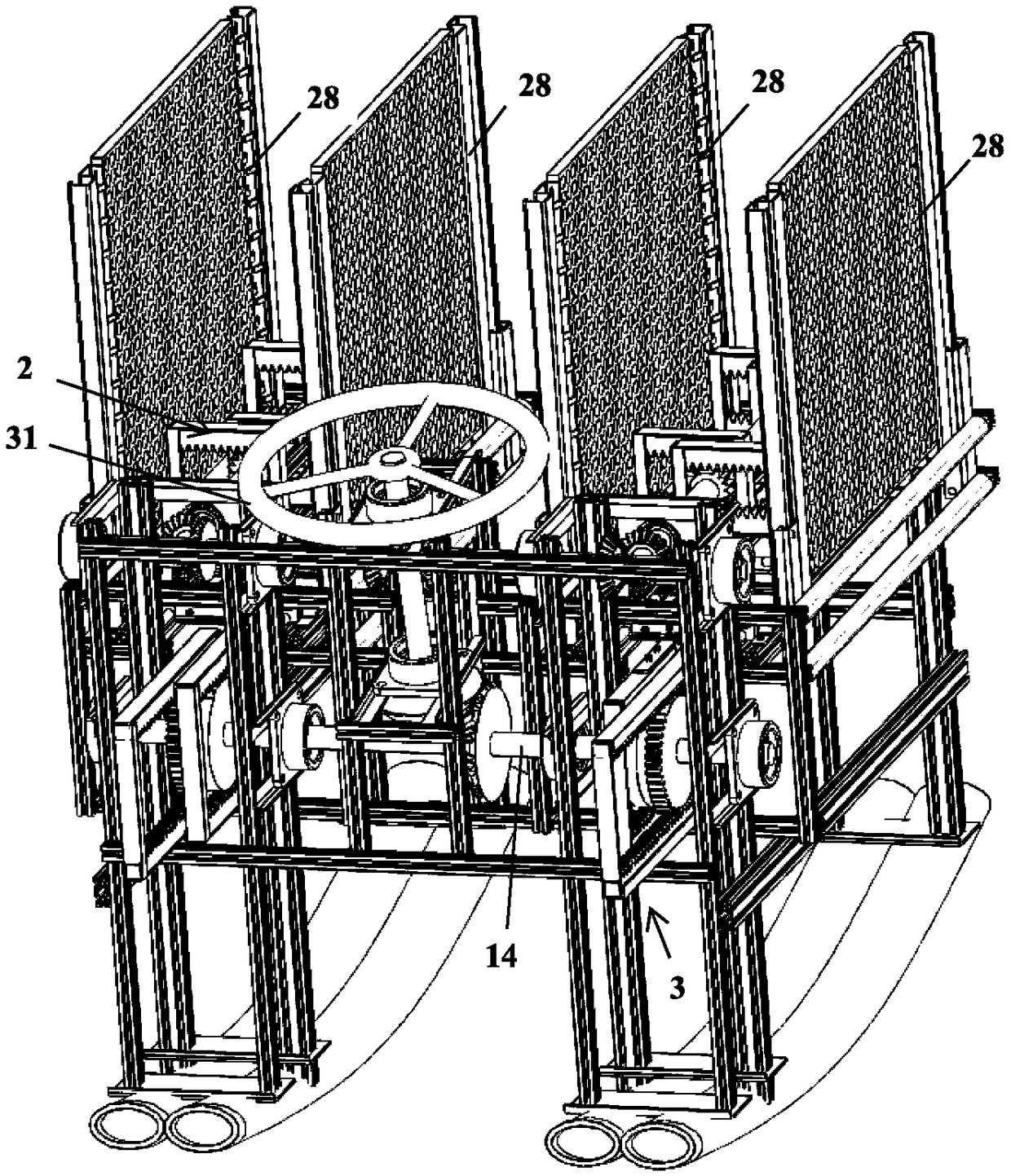

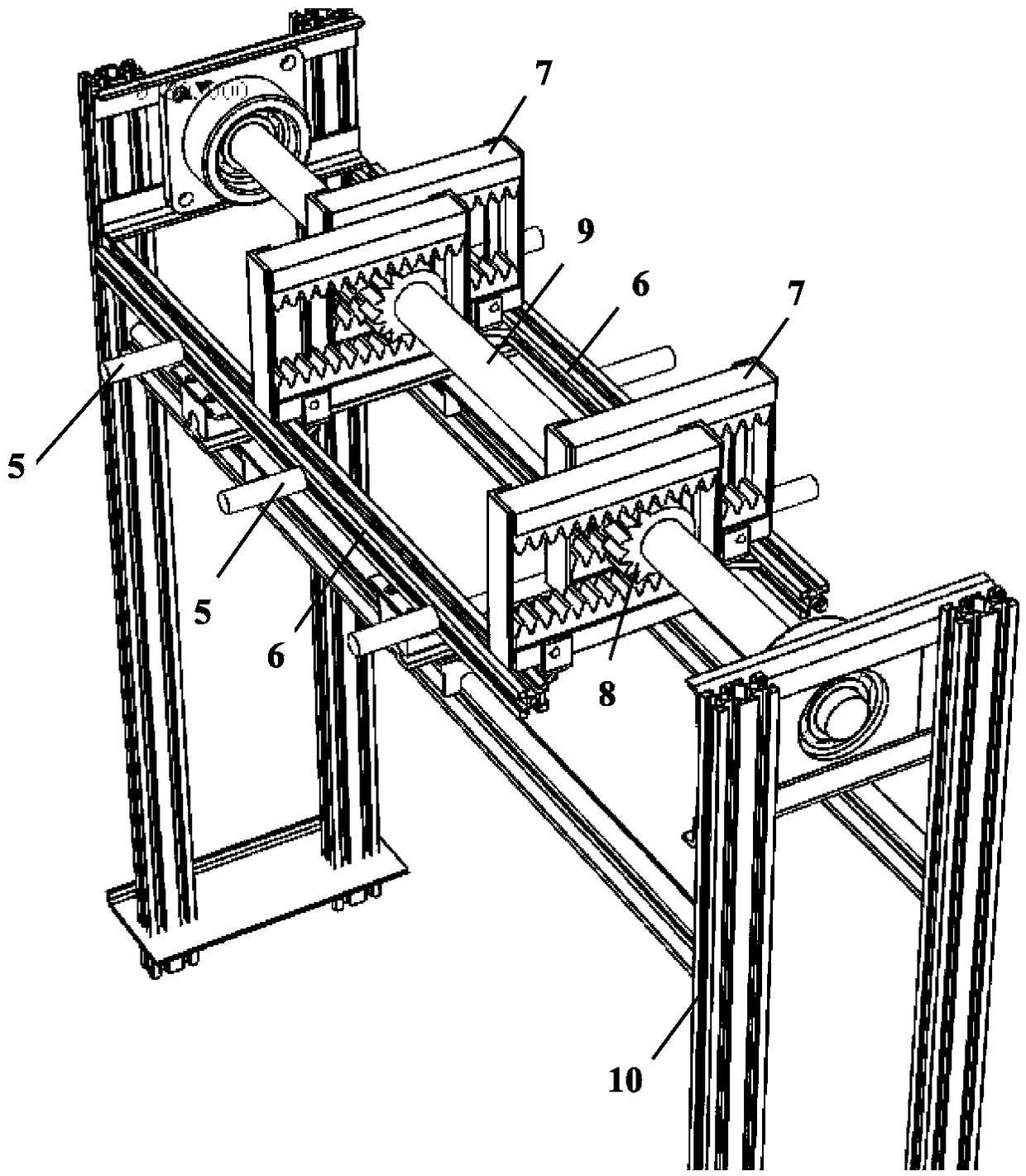

[0042] see figure 1 and figure 2 A unidirectionally driven three-dimensional three-linkage periodic stepping mechanism of the present invention includes a seedling ejecting needle assembly 1 arranged on a frame 10, a telescopic driving mechanism 2 for driving the ejecting needle assembly 1 to perform telescopic ejecting tasks, The mobile driving mechanism 3 used to drive the ejector needle assembly 1 to perform horizontal switching between different seedling grids, the step-down driving mechanism 4 used to drive the grid seedling tray 28 for overall downward movement, and the total power mechanism, wherein, The jacking needle assemblies 1 are two groups, and the two groups of jacking needle assemblies 1 are arranged back to back on the jacking needle support, and each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com