Seaweed cake making equipment

A seaweed and equipment technology, applied in the field of seaweed cake making equipment, can solve the problems of poor cake quality and low production efficiency, and achieve the effects of reducing overall cost, cost reduction and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

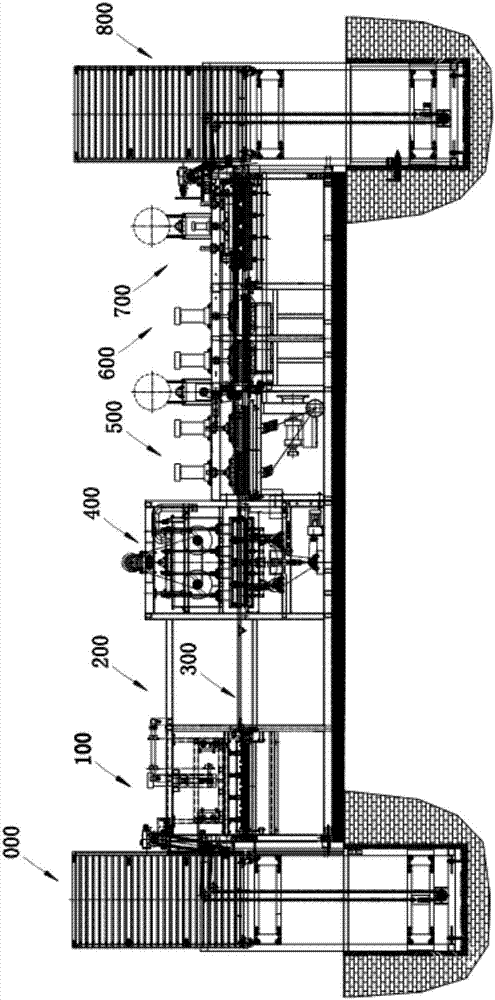

[0047] Such as figure 1 with figure 2 As shown, the present invention provides a seaweed cake making equipment, including a feeding trolley 000, a vegetable peeling device 100, a cake pouring device 400, an initial dehydration shaping device 500, a dehydration device 600, a loosening device 700 and a reclaiming platform arranged in sequence Cart 800, between the vegetable peeling device 100 and the cake pouring device 400 is provided with a manual vegetable picking space 200. After the vegetable peeling link, when the seaweed is seriously stuck to the material tray due to cleaning or other reasons, the seaweed will be peeled. The vegetable device 100 cannot be completely taken out. In this case, it is necessary to use manpower to peel the vegetables again. At this time, if the unit stops, the production efficiency will decrease, and the power consumption will increase significantly. Therefore, only The vegetable peeling is realized online, and the manual vegetable picking sp...

Embodiment 2

[0063] The present invention provides a kind of seaweed cake making equipment, its structure is basically the same as that of Embodiment 1, the difference is that:

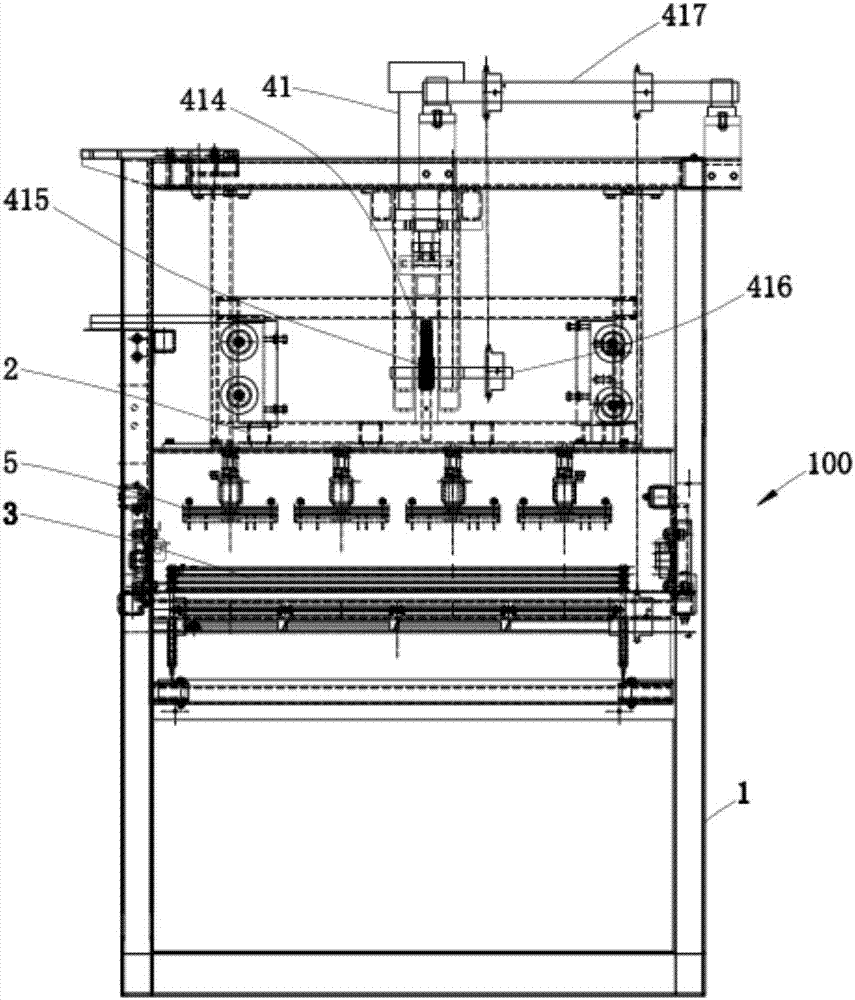

[0064] Such as Figure 5 with Image 6 As shown, the vegetable peeling drive device includes a drive source 41, a first drive assembly and a second drive assembly, the drive source 41 is linked with the first drive assembly, the second drive assembly is linked with the first drive assembly, and the first drive assembly is linked with the lifting mechanism 2, the first drive assembly is used to drive the lifting mechanism 2 to move up and down, the second drive assembly is connected to the transfer device 3, and the second drive assembly is used to drive the transfer device 3 to rotate.

[0065] That is to say, the drive source 41 can drive the first drive assembly to work, and then the first drive assembly drives the lifting mechanism 2 to move up and down. At the same time, the first drive assembly can drive the...

Embodiment 3

[0096] The present invention provides a seaweed cake making equipment, the structure of which is basically the same as that of Embodiment 1 or Embodiment 2, the difference is that a further improvement is made on the basis of Embodiment 1 or Embodiment 2, and its performance is increased. Specifically:

[0097] like Figure 8 As shown, the cake pouring device 400 includes a cake pouring frame 401, on which the cake pouring frame 401 is provided with a material pool 402, the bottom of the material pool 402 is provided with a number of leakage holes corresponding to the positions of the material trays, and the top of the material pool 402 moves up and down. The cake pouring lifting beam 403 is driven by the first cake pouring driving device. The first cake pouring driving device can use an air cylinder or a hydraulic cylinder, or a cam mechanism driven by a motor. Those skilled in the art can choose according to needs, and there is no limitation here There is a blockage 404 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com