Steamed stuffed bun forming machine

A molding machine and steamed stuffed bun technology, applied in dough molding machinery or equipment, food molding, baking, etc., can solve the problems of low production efficiency, a large number of manpower implementation, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

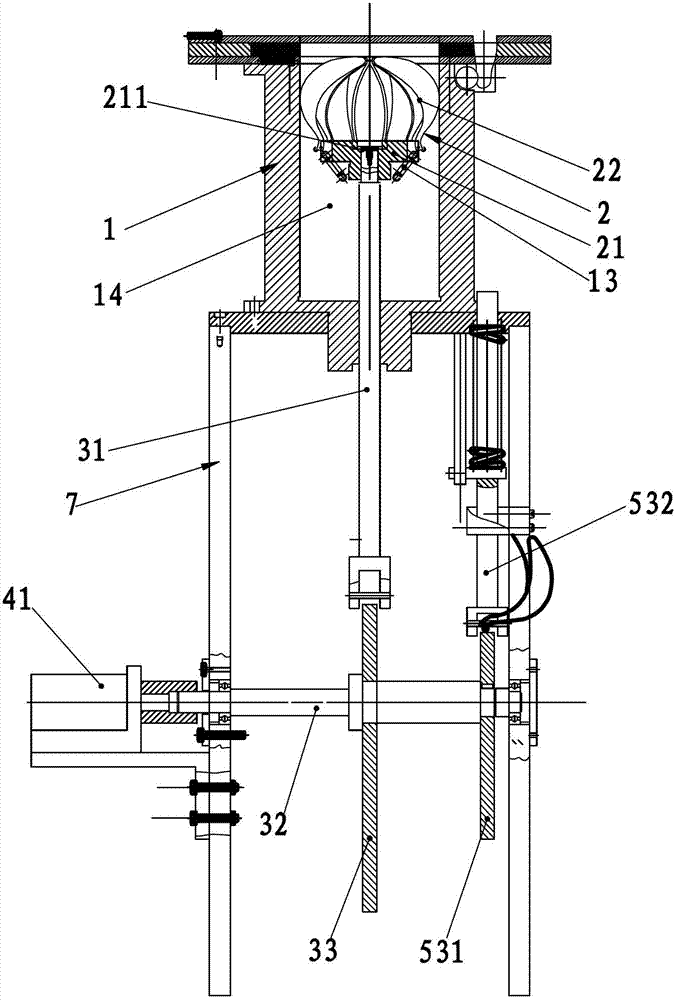

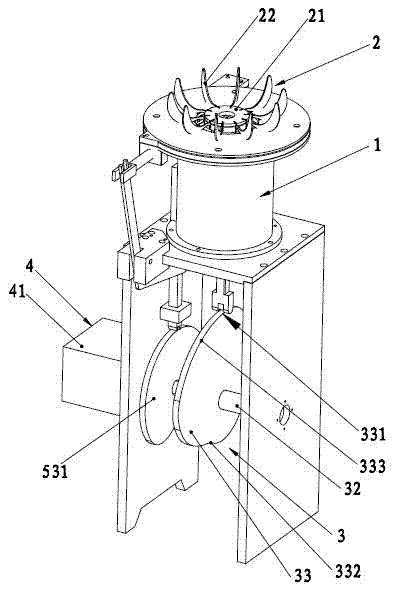

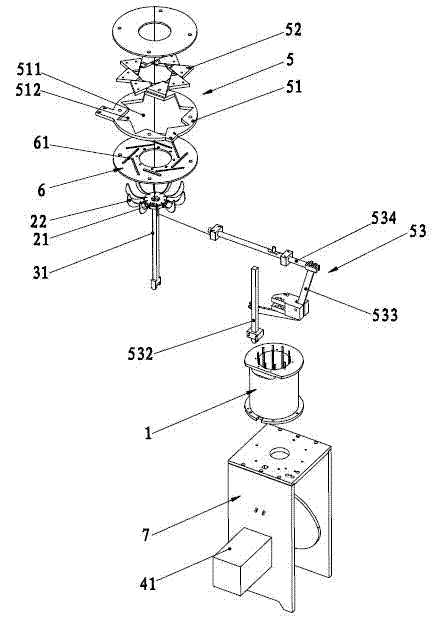

[0027] Such as figure 1 — Figure 6 A steamed stuffed bun forming machine shown includes a mounting base 1, a forming coating mechanism 2, a transmission mechanism 3 and a driving mechanism 4 for driving the transmission mechanism 3, the driving mechanism 4 is a motor 41, the transmission mechanism 3 and the forming coating mechanism 2 Cooperate to form the reciprocating movement of the forming and covering mechanism 2 along the axial direction of the mounting seat 1 and the expansion and closing of the forming and covering mechanism 2; The transmission mechanism 3 includes a push rod 31 connected with the sliding plate 21, a transmission shaft 32 linked with the drive mechanism 4, and a transmission unit 33 that constitutes a linkage between the push rod 31 and the transmission shaft 32. The cam that is linked and located at the lower end of the push rod 31 includes a pressing point 331 and a contraction point 332 that cooperate with the push rod 31. The pressing point 331 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com