Milling machine floating material receiving device

A material receiving device and milling machine technology, which is applied in roads, road repairs, roads, etc., can solve the problems of floating plate jamming, material leakage, and poor sliding of floating plates, and achieve smooth twisting and smooth sliding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing.

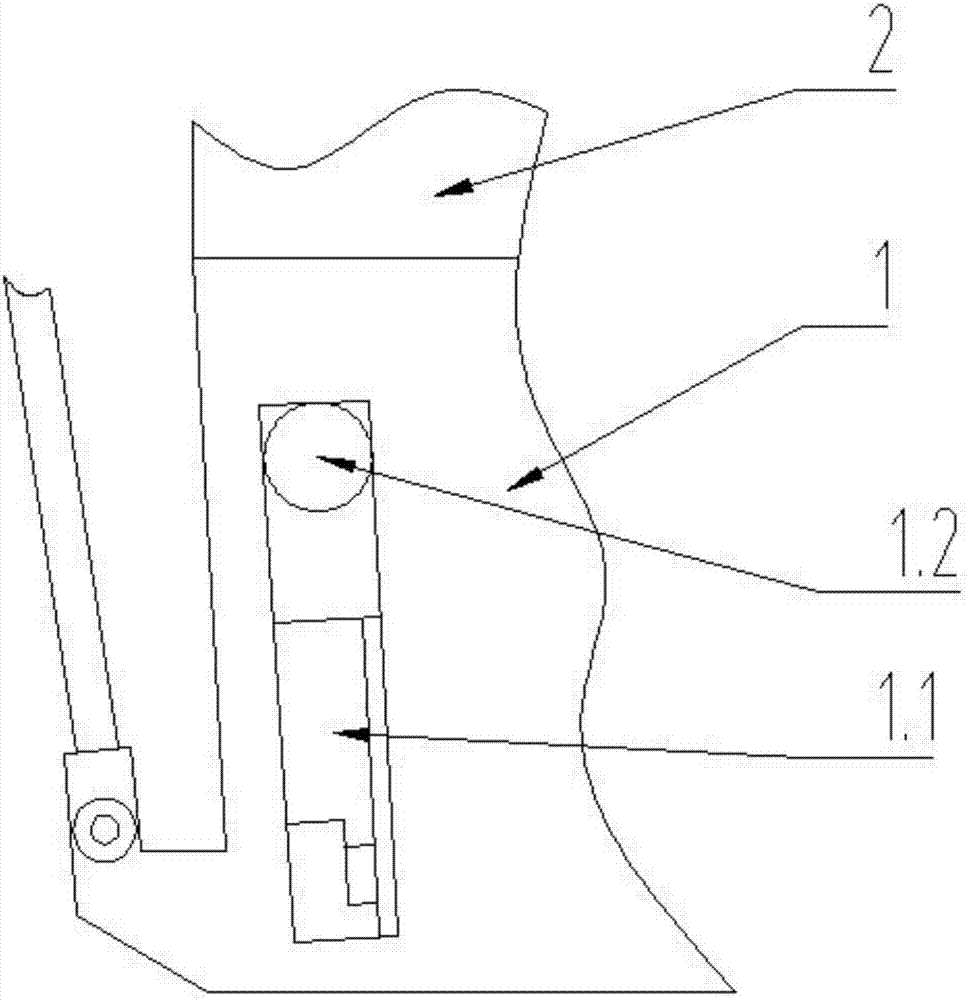

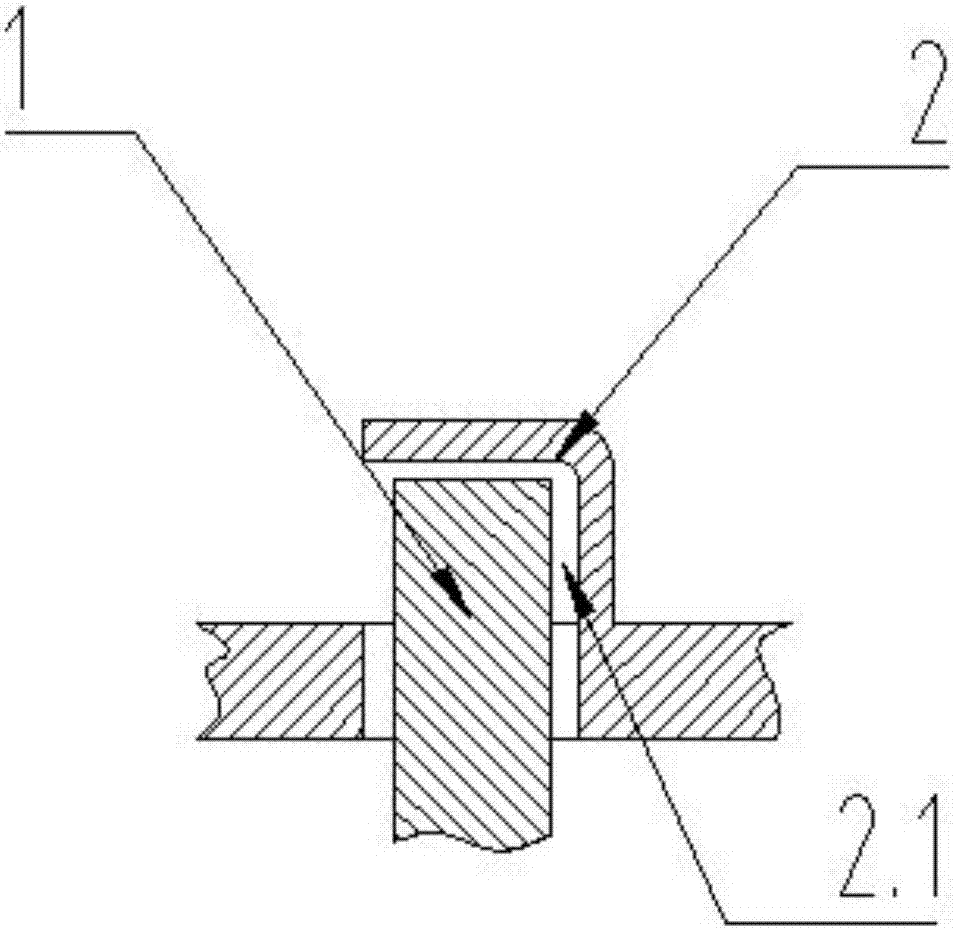

[0011] Such as figure 1 and figure 2 As shown, a milling machine floating receiving device includes a floating plate 1 and a hood side plate 2, the two sides of the floating plate 1 are connected with the hood side plate 2 through a hydraulic cylinder, and the upper end of the hood side plate 2 has Card slot 2.1, the upper end of the floating plate 1 is limited in the card slot 2.1. It is characterized in that the card slot 2.1 is semi-closed, and the width of the card slot is wider than the thickness of the floating plate 1; The slot through hole 1.1, the connecting part of the hood side plate 2 and the chute through hole 1.1 has a guide block 1.2, and the floating plate 1 floats up and down along the guide block 1.2; the vertical guide surface of the chute through hole 1.1 is along the milling The angle of inclination in the direction of travel of the planer is 7° to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com