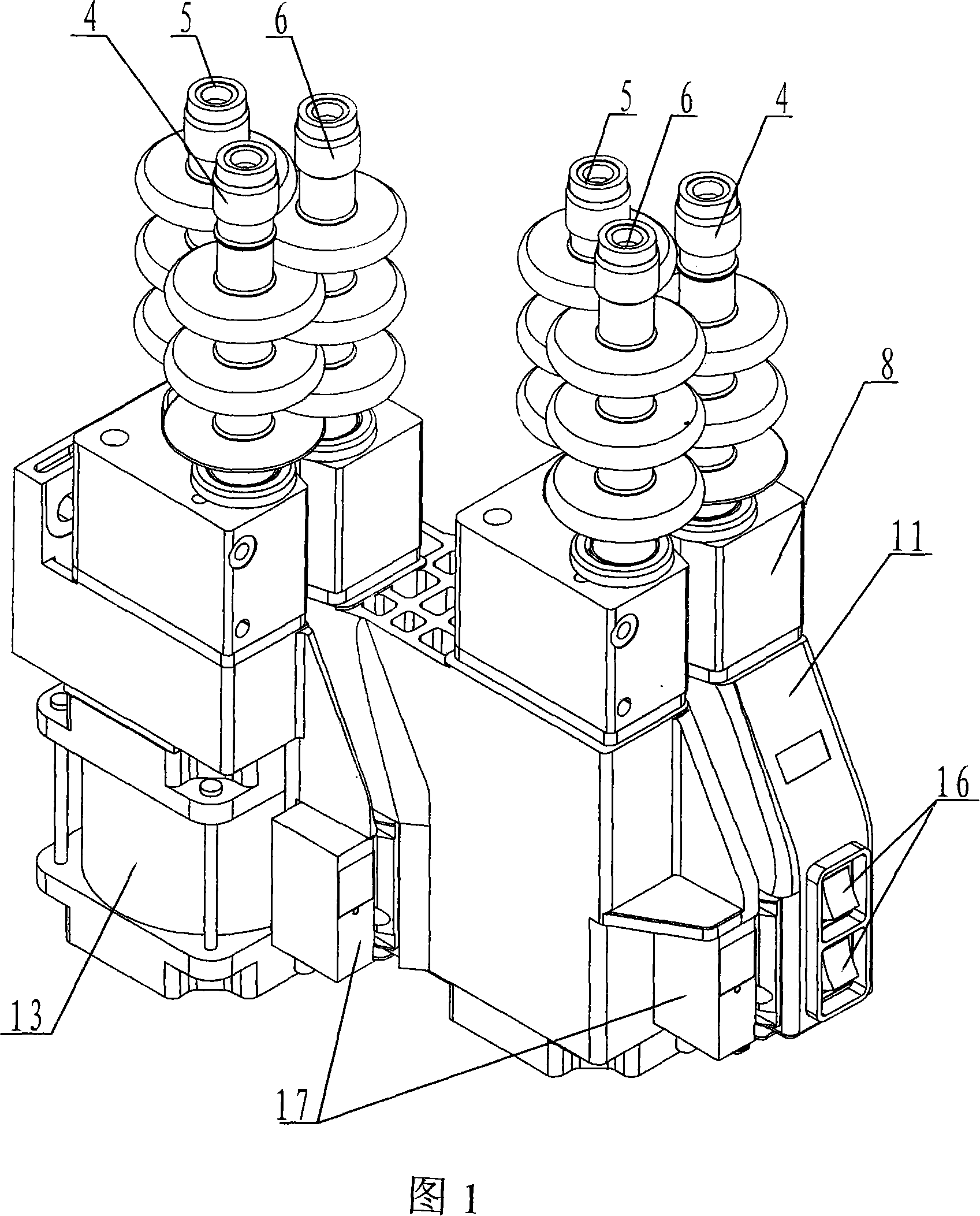

Composite double ingot set false twisting device of false-twist texturing machine

A technology of composite double-spindle group and false-twist texturing machine, which is applied in textile and papermaking directions, can solve the problems of inconsistent twist loss, inconsistent transmission speed, reduced machine utilization rate, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

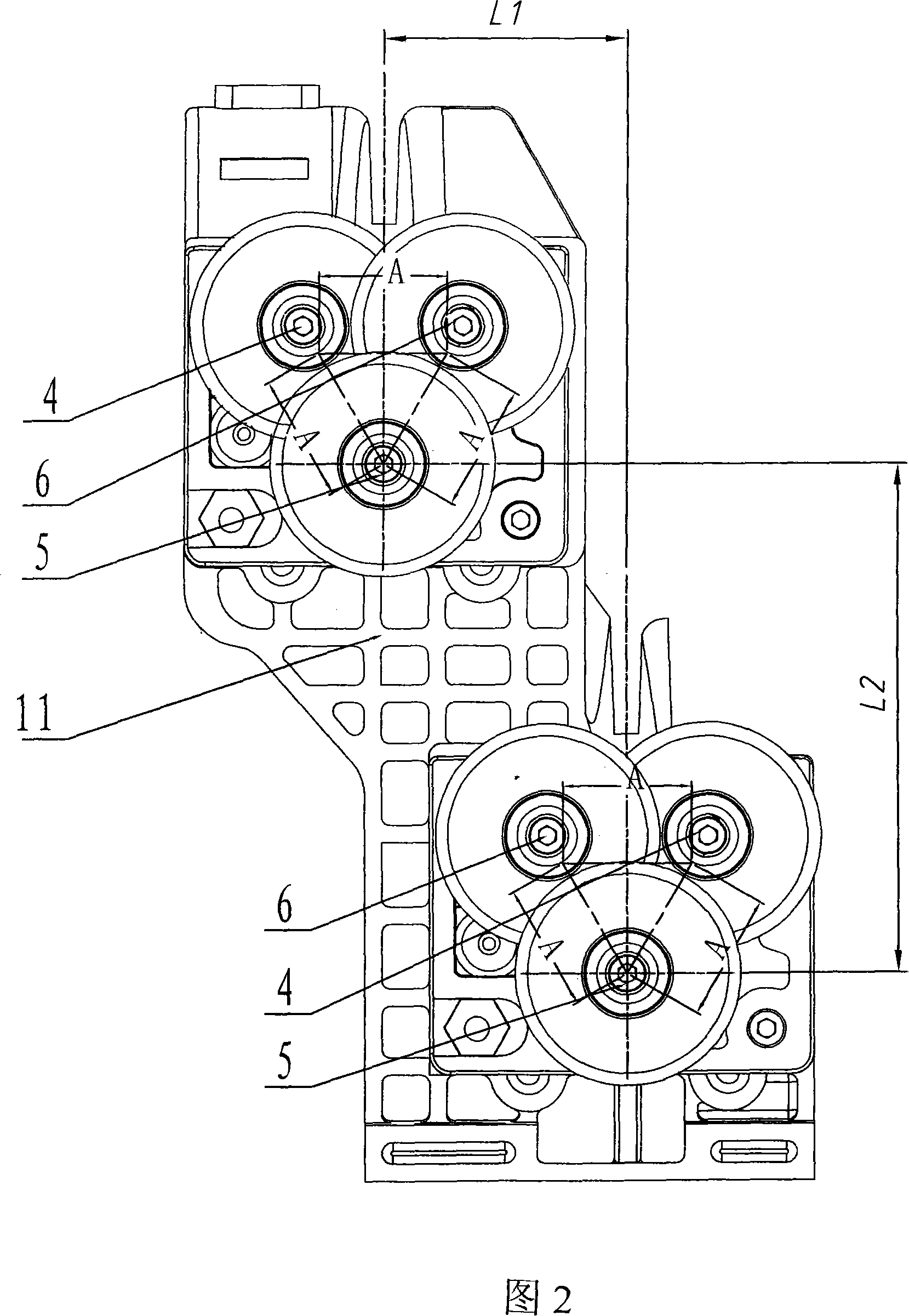

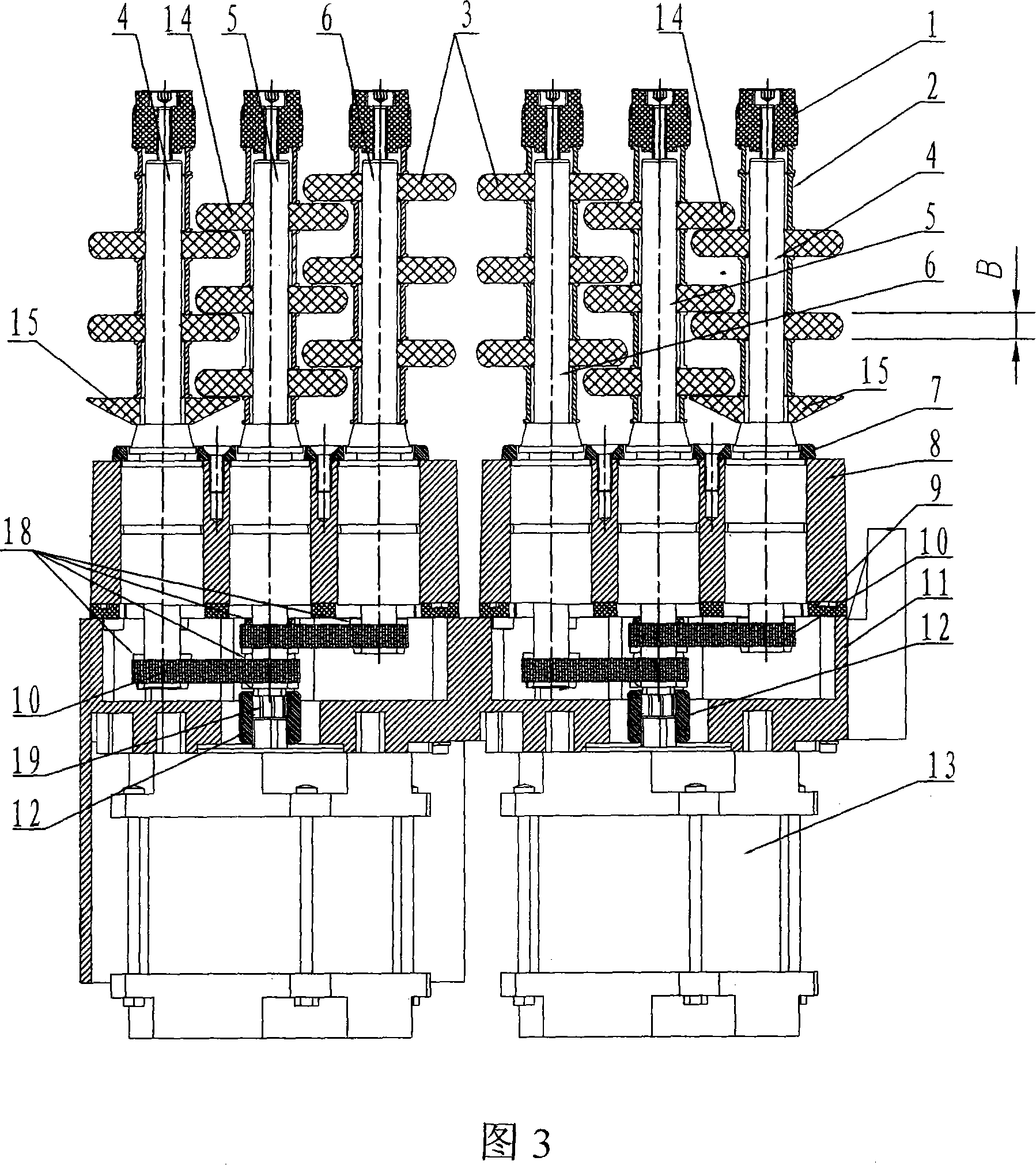

[0025] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0026] The present invention contains two groups of spindle shafts, each group of spindle shafts is composed of a driving spindle shaft 5 and two driven spindle shafts 4, 6, the center distances A of the three spindle shafts 4, 5, 6 are equal and form an equal side triangle. Each group of spindle shafts is provided with friction discs 3, 14, 15 and are superimposed on each other at the center of the axis triangle in a certain order, and the friction discs 3, 14, 15 of the two groups of spindle shafts are stacked in the same way but in opposite directions , one clockwise and one counterclockwise. The false-twisted yarns of the friction discs 3, 14, and 15 superimposed clockwise are Z-twisted, and the false-twisted yarns of the counter-clockwise superimposed friction discs are S-twisted, so that the above two sets of spindle shafts are S+Z twisted, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com