Twisting method of natural yarn blending, twisting weaving method and twisting device

A twisting device and yarn blending technology, which is applied in the direction of braided fabrics, yarns, textiles, and papermaking, can solve the problems of delayed product production cycle, high twisting cost, and insufficient randomness, etc., to reduce large-scale color difference and avoid cross-fertilization. The effect of delaying the deadline and reducing the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

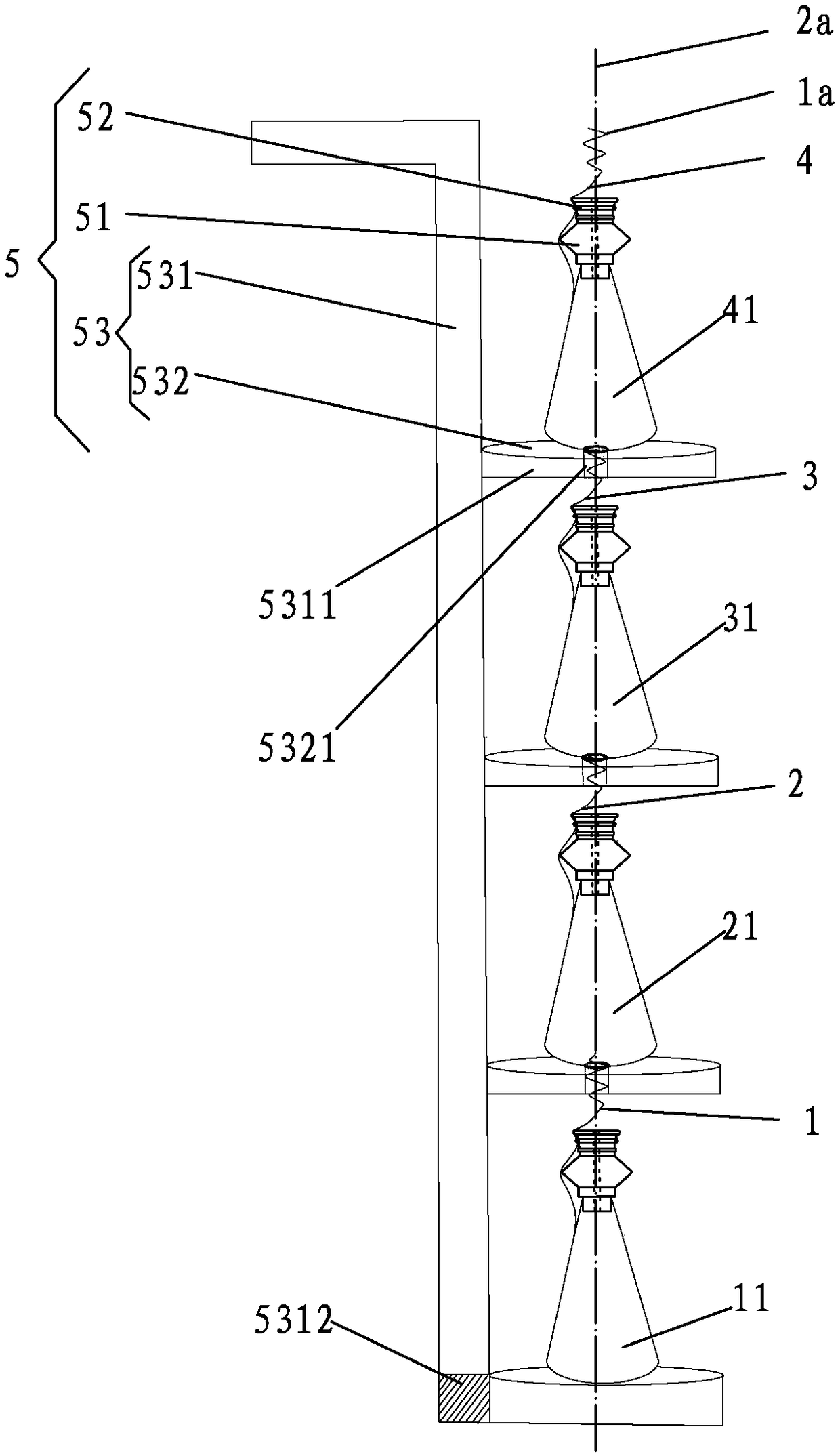

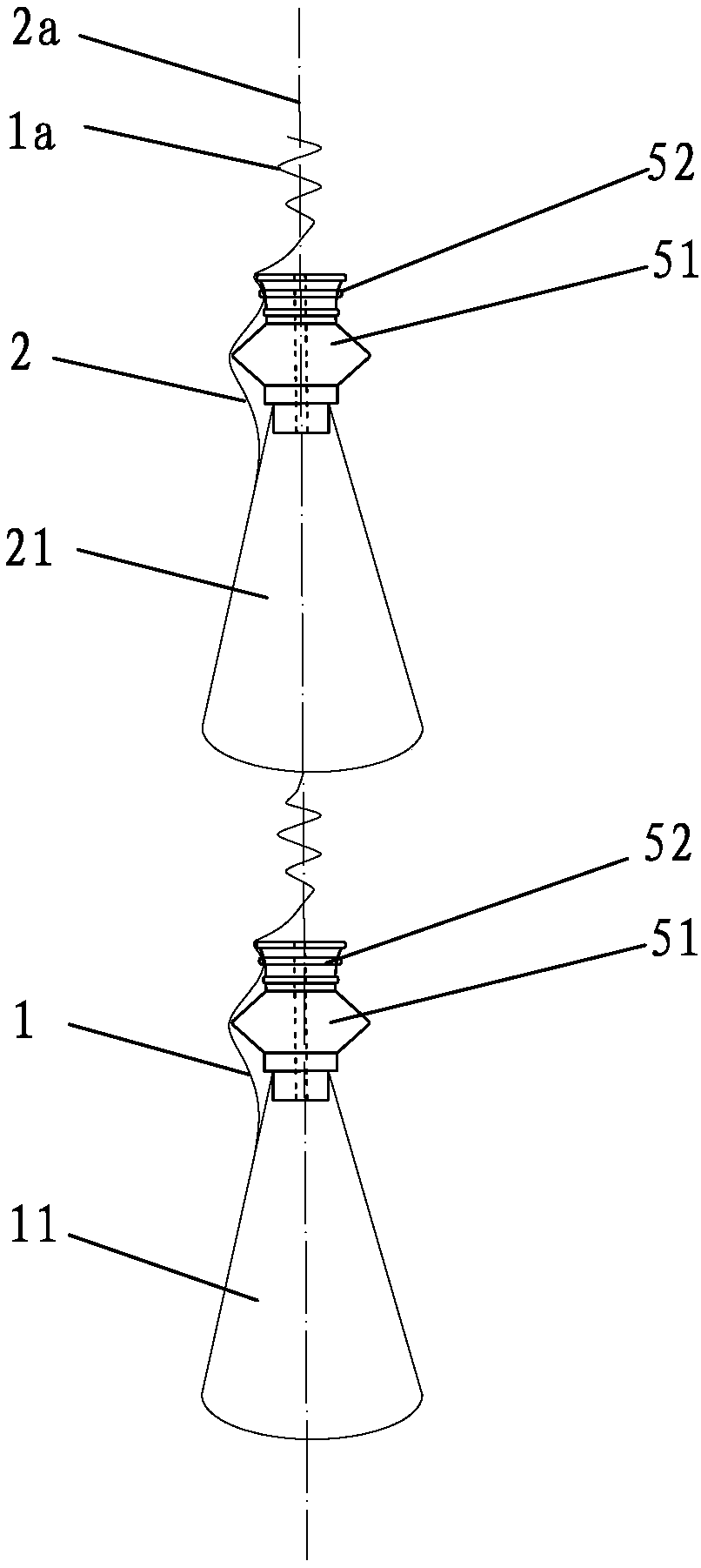

[0048] In this case, the twisting method of natural blended yarn is mainly as follows, the loop-wound second yarn 2 wraps around at least one first yarn 1 to achieve twisting, and twists to form a twisted yarn 1a. The first yarn 1 and / or the second yarn 2 are coiled and wound into a bobbin shape, a ball shape or a ball shape.

[0049] In the following, the first yarn 1 is wound into a hollow frustum-shaped first bobbin 11, and the second yarn 2 is wound into a hollow frustum-shaped second bobbin 21 for example, wherein the first bobbin 11 , A barrel hole is formed in the second bobbin 21 . Of course, if multiple yarns such as the third yarn 3 and the fourth yarn 4 are used, the third yarn 3, the fourth yarn 4 and other multiple yarns are also correspondingly wound into the third bobbin 31 and the fourth bobbin. 41 etc. The twist guiding bodies 51 placed on the first bobbin 11, the second bobbin 21, the third bobbin 31, the fourth bobbin 41, etc. correspond to the first twist...

Embodiment 2

[0056] In this case, adopting the twisting method of natural blending mentioned above can realize the twisting knitting method of natural blending as follows.

[0057] The pulling mechanism of the knitting machine pulls the first yarn 1 and the second yarn 2 to be twisted and advances correspondingly, and the second yarn 2 completes the looping around the first yarn 1. During the stripping process, The first yarn 1 and the second yarn 2 drawn forward realize twisting, and the twisted yarn 1a formed by twisting is drawn by the pulling mechanism and enters the knitting machine for knitting, thus realizing knitting while twisting. The above-mentioned knitting machine and the thread-drawing mechanism can all adopt the existing structures, and will not repeat them here.

Embodiment 3

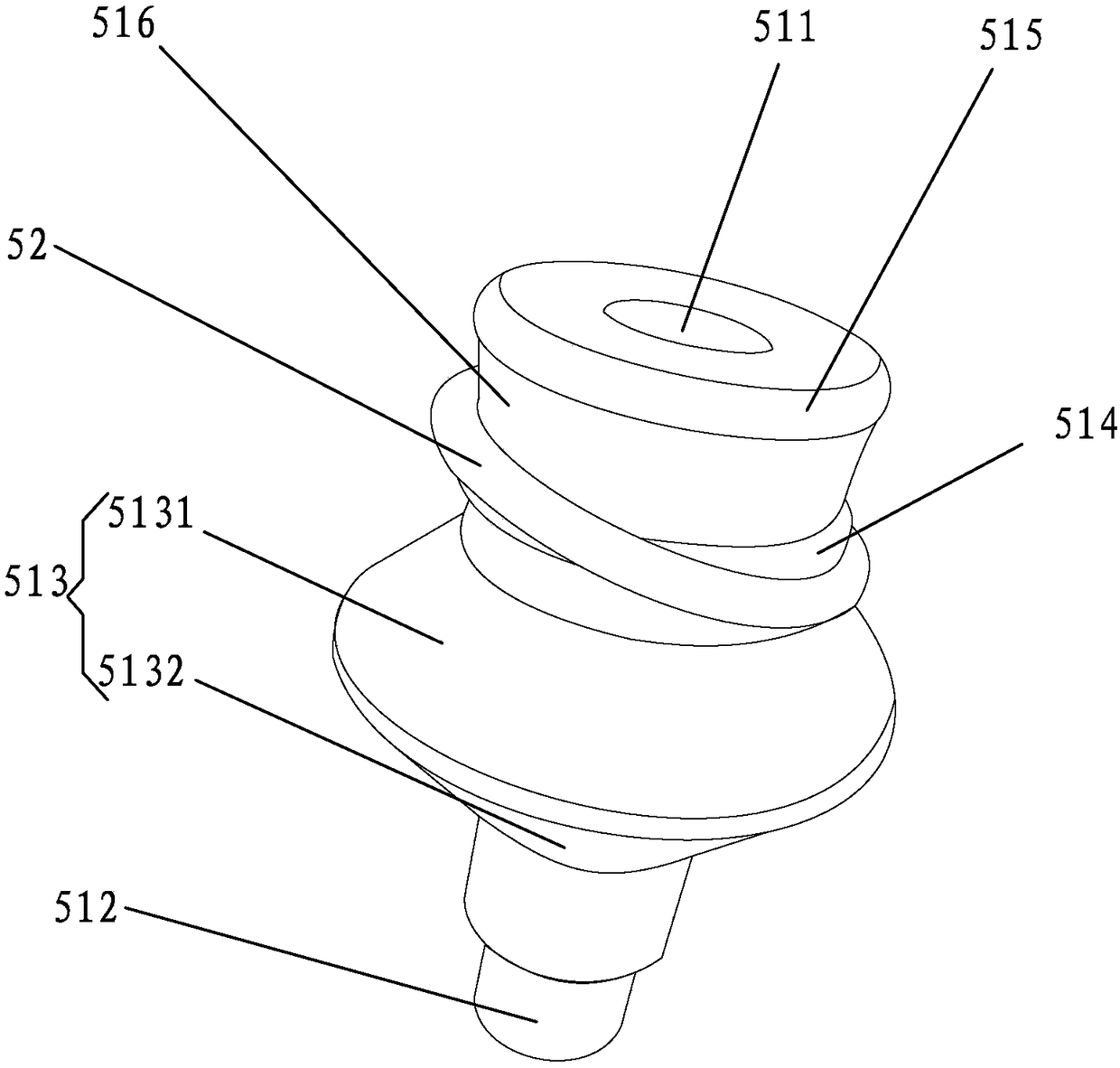

[0059] In this case, the twisting device 5 of natural yarn blending can be used in the above methods, hereinafter referred to as the twisting device 5. The twisting device 5 mainly includes a twist guiding body 51 and a movable ring 52. The twist guiding body 51 and the movable ring 52 can make a plurality of yarns fall off naturally and start winding and twisting, finally realizing twisting. In addition, a shelf 53 for placing bobbins may also be included. The twist guiding here refers to pulling and guiding the yarn to be twisted during the twisting process, so as to derive the yarn to be twisted.

[0060] The twist-guiding body 51 can support the twisted yarn after the loop is removed. The twist-guiding body 51 is a rotating body provided with a twist-guiding through hole 511 inside. The end of the twist-guiding body 51 corresponding to the twist-guiding through hole 511 is the leading end. The other end is the export end. Taking the leading end as the lower end of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com