Vertical lifting corrugation flange conveyor

A corrugated sidewall and conveyor technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of shortened life, large force on the tape, and more material scattering, so as to improve the life of the tape and prevent the The effect of material scattering and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with embodiment.

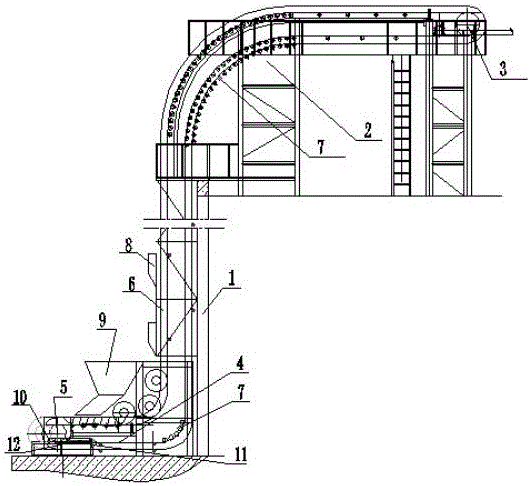

[0015] Such as figure 1 , 2 As shown, the vertical lifting corrugated sidewall conveyor of the present invention comprises a vertically arranged truss 1, a head support 2 arranged on the upper end of the truss 1 and an upper end reversing roller 3 arranged at the end of the head support, arranged on The tail support 4 under the truss 1 and the lower end reversing roller 5 arranged at the end of the tail support 4, the idlers provided on the tail support 4, truss 1, and head support 2 to provide support for the corrugated sidewall 6, Set in the tail support 4, the truss 1, the head support 2 and the corrugated edge band 6 that is wound around the upper end reversing drum 2 and the lower end reversing drum 5 and rotates up and down on the idler roller, the tail support 4, the head The upper support 2 is arranged horizontally and is perpendicular to the truss 1 respectively. Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com