Yarn clamping mechanism for spinning machine

A clamping mechanism and technology of textile machines, which are applied in textile, loom, textile and paper making, etc., can solve the problems of unadjustable yarn clamping force and unadjustable yarn tension force, and achieve the adjustment of tension degree, The effect of reducing machine downtime and increasing machine utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

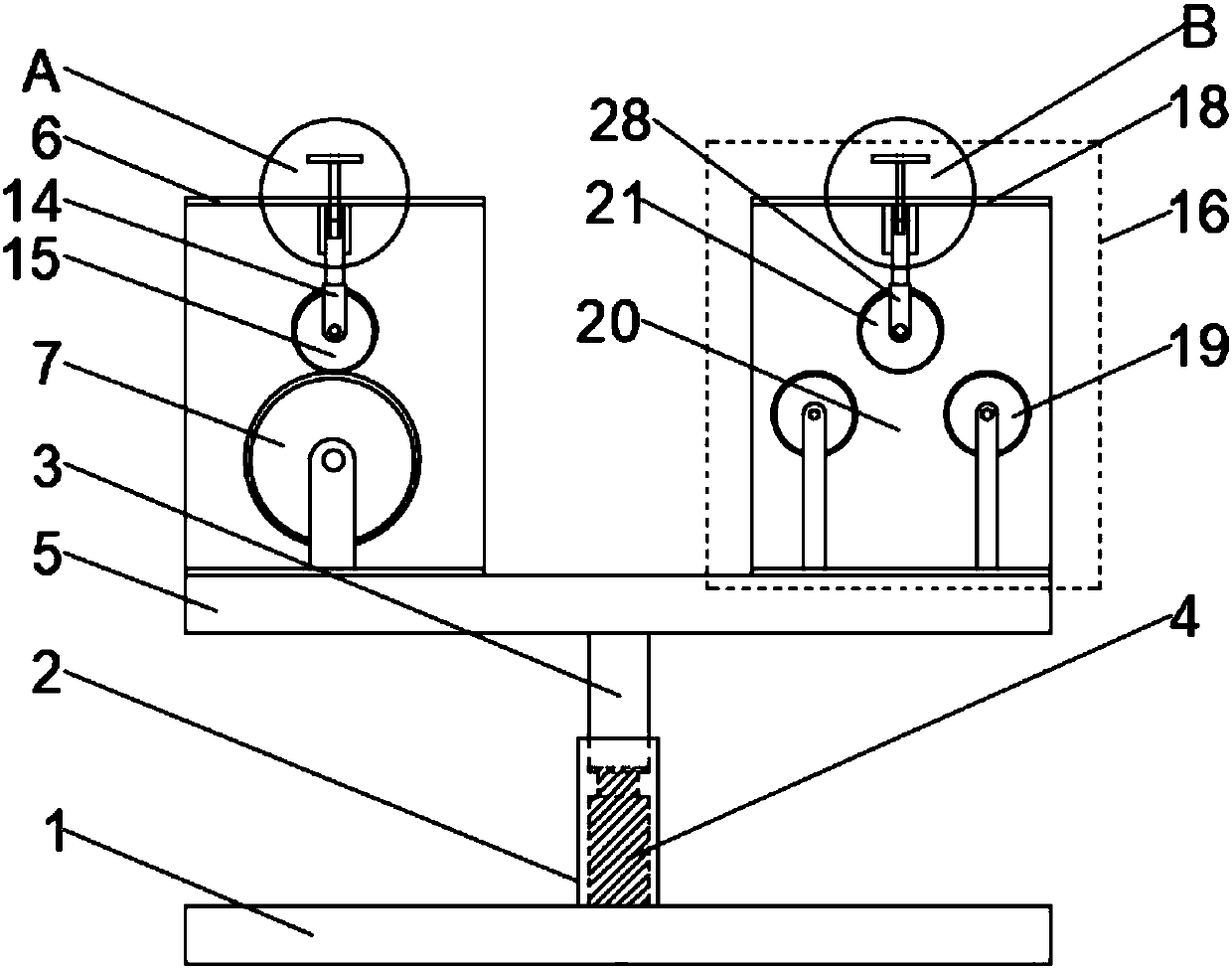

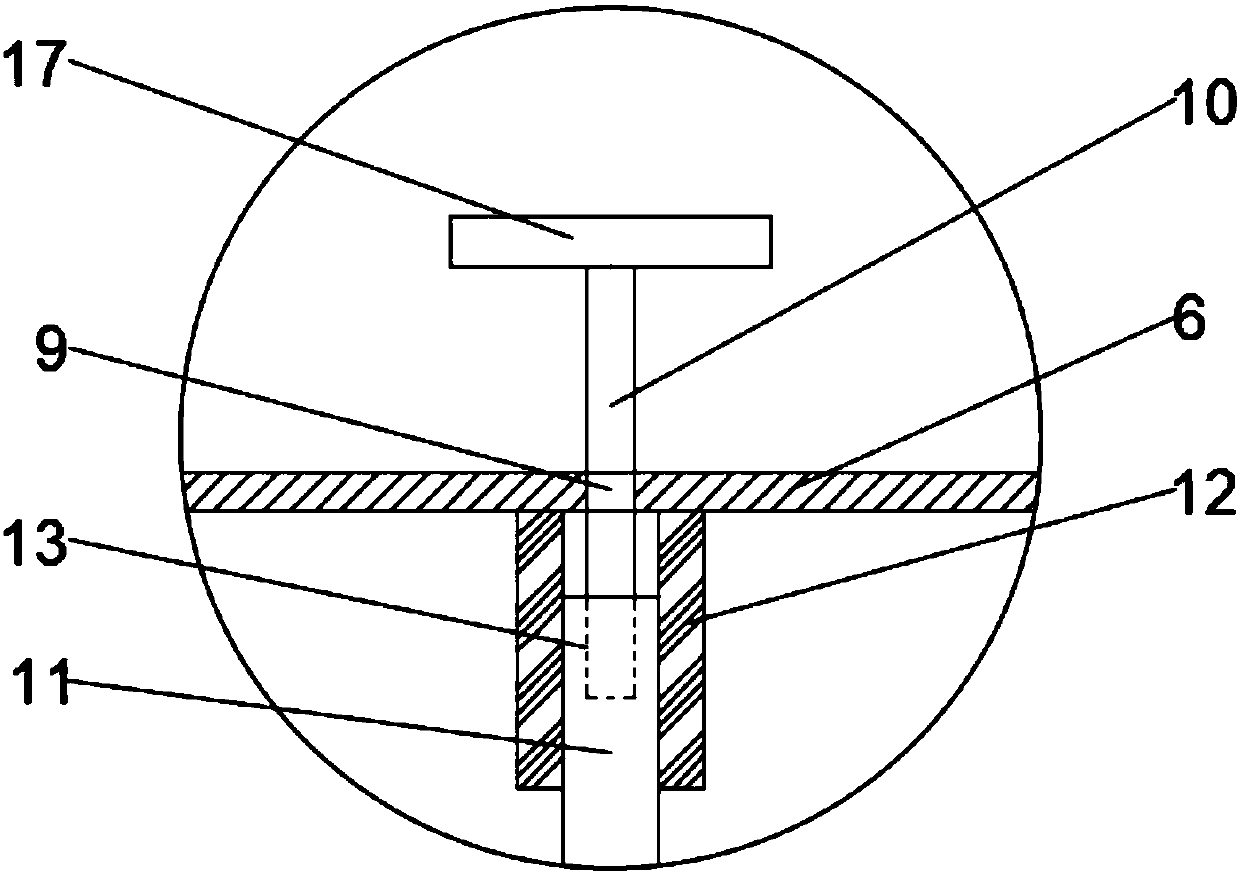

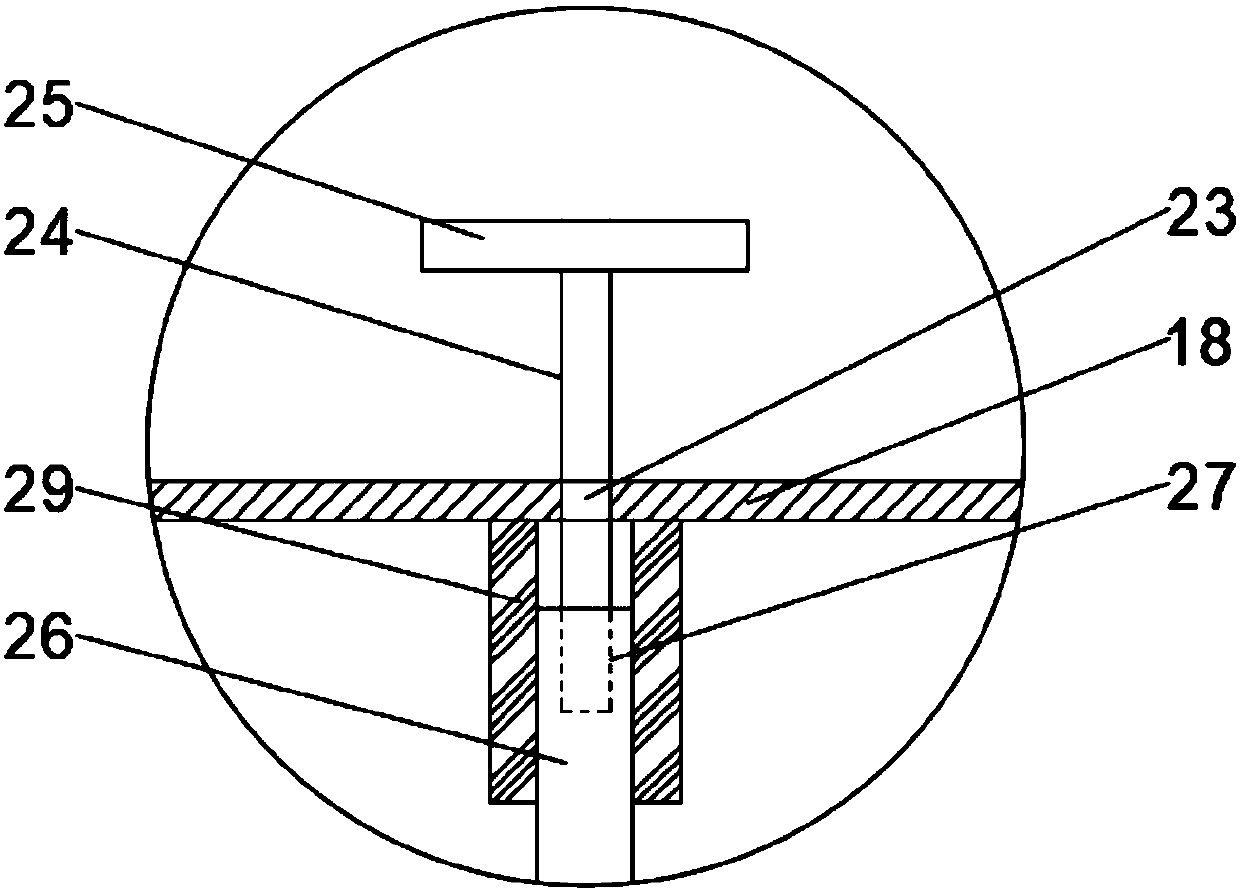

[0031] Such as figure 1 , figure 2 and Figure 4 As shown, the present invention provides a yarn clamping mechanism for a textile machine, comprising a base 1, a lifting cylinder 2 is arranged on the base 1, a lifting column 3 is arranged inside the lifting cylinder 2, and the lifting column 3 The lower end of the lifting column 3 is provided with a hydraulic cylinder 4, and the upper end of the lifting column 3 is provided with a base 5, and the base 5 is provided with an internal hollow clamping frame 6, and the clamping frame 6 is provided with a thread wheel 7 , the wheel surface of the wire passing wheel 7 is provided with a wire groove 8, and the upper end surface of the clamping frame 6 is provided with a threaded lifting hole 9, and the lifting hole 9 is internally threaded. There is an external thread clamp lifting rod 10, the lower end of the clamping lifting rod 10 is provided with a clamping slide bar 11, and the upper end of the clamping sliding bar 11 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com