Double-exchange workbench

A double-exchange workbench and workbench technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems that it is difficult for one person to take care of multiple equipment, long waiting time for equipment shutdown, and high manufacturing cost. To achieve the effects of compact structure, low manufacturing cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments, so as to facilitate a clear understanding of the present invention, but they do not limit the present invention.

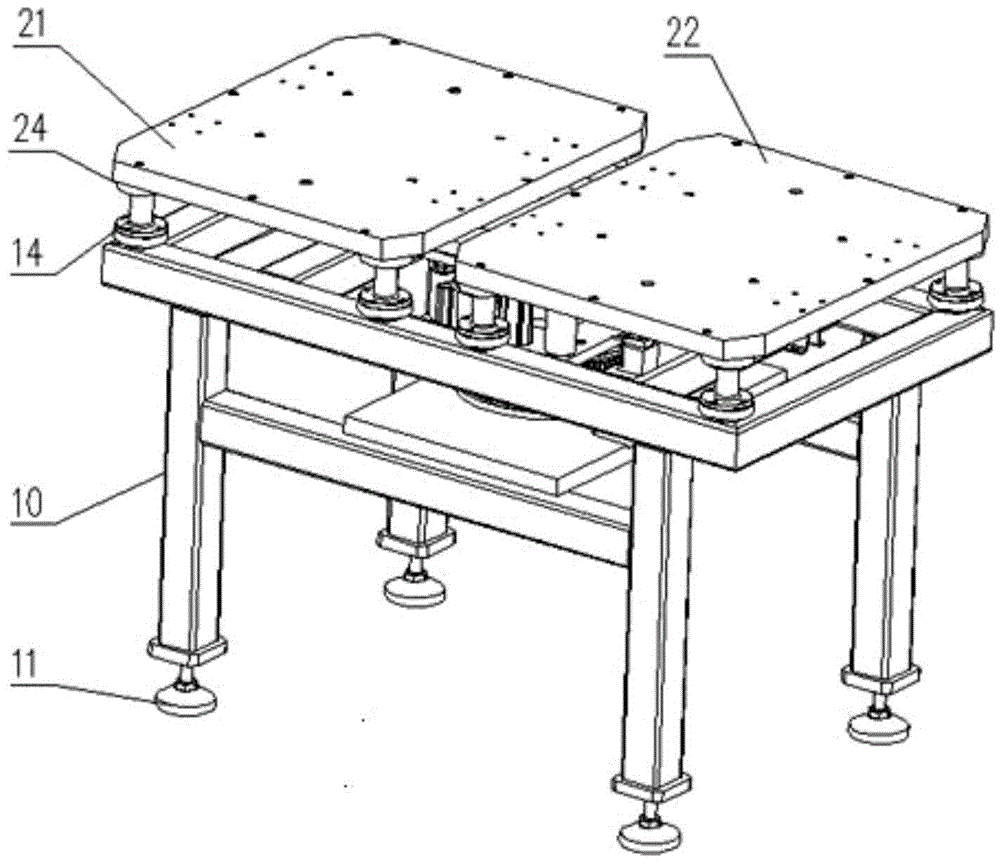

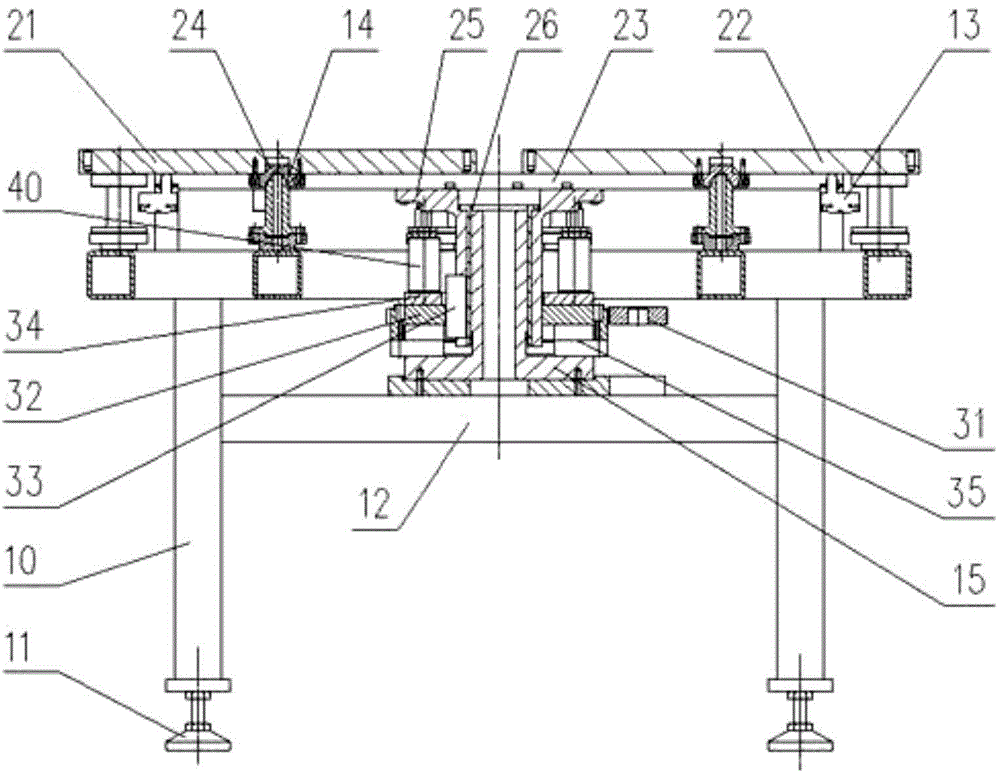

[0018] like figure 1 , figure 2 As shown, the present invention includes a bracket 10, a worktable, a transmission mechanism, a support mechanism and a positioning device, wherein the worktable includes a first worktable 21, a second worktable 22, a cantilever beam 23 and a rotating disk 25, and the transmission mechanism includes a driving gear 31. The driven gear 32 and the guide flat key 33, the supporting mechanism is the lifting cylinder 40.

[0019] The bottom of the bracket 10 is provided with an adjustment foot 11 that can adjust the height of the bracket, and the height of the exchange table can be adjusted according to the actual processing needs; There is also an induction switch 13 that can detect the rotationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com