Plate loading machine

A feeder and plate technology, applied in the field of plate feeder, can solve the problems of low feeding efficiency, complex feeder structure, high cost, etc., and achieve the effect of improving feeding efficiency, fast feeding speed and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

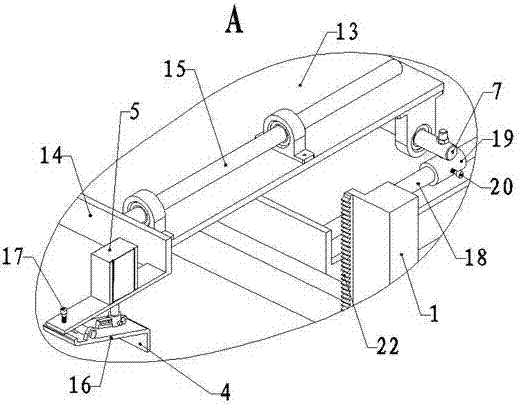

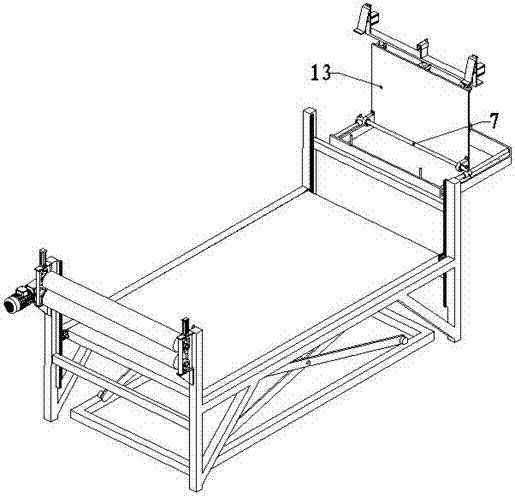

[0021] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

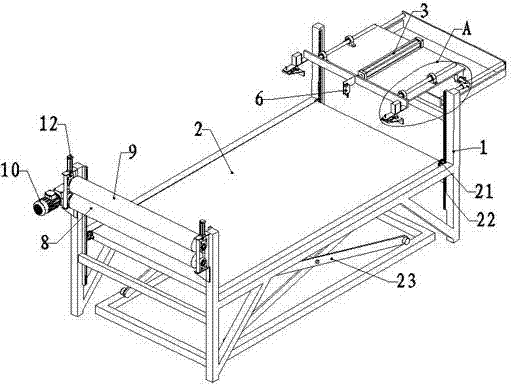

[0022] like Figure 1~Figure 5 As shown, a plate loading machine includes a frame body 1, a pallet 2, a scissor lift 23, a pushing mechanism and a pulling mechanism.

[0023] The supporting plate 2 is located inside the frame body 1 and is connected with the scissor lift 23. The four corners of the supporting plate 2 are provided with synchronous gears 21, and the frame body 1 is provided with a synchronous rack 22 meshing with the synchronous gear 21. Through the synchronous gear 21 and The synchronous rack 22 can improve the stability of the lifting of the scissor lift 23 and prevent the supporting plate 2 from being uneven and affecting the operation of the equipment.

[0024] The pushing mechanism is located at the head end of the frame body 1, and the pushing mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com