Electromagnetic relay

A technology of electromagnetic relays and relays, applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve problems such as large working hours, increased component size, and shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

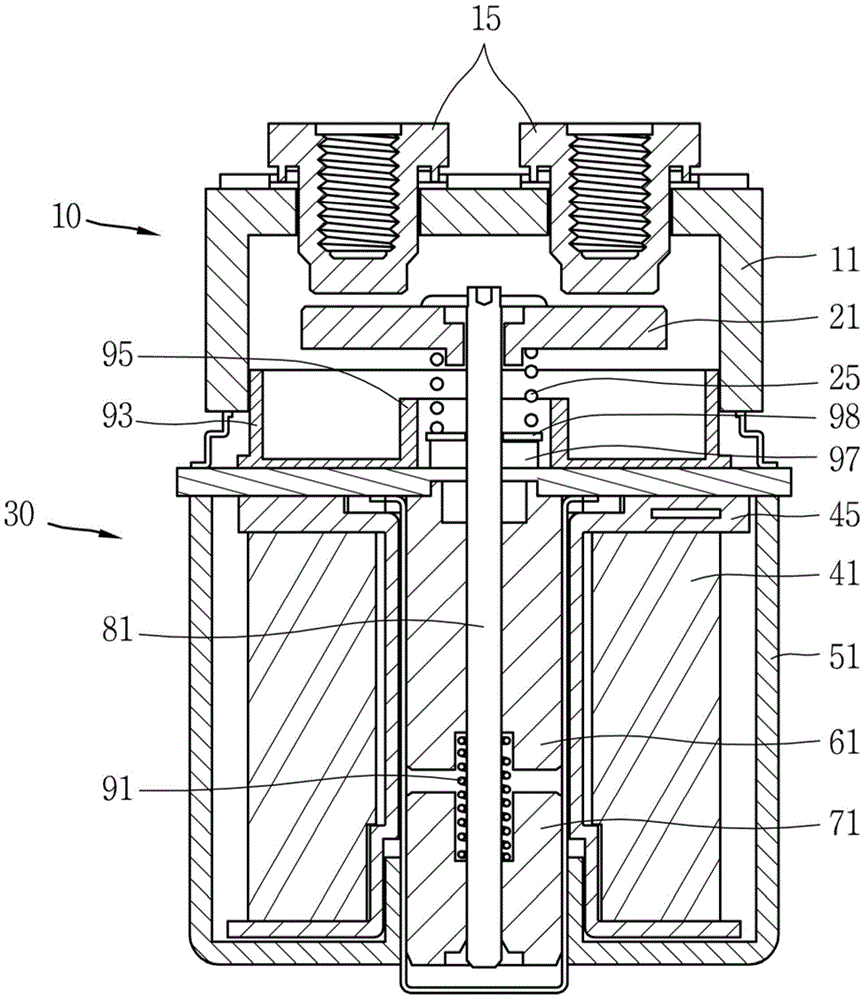

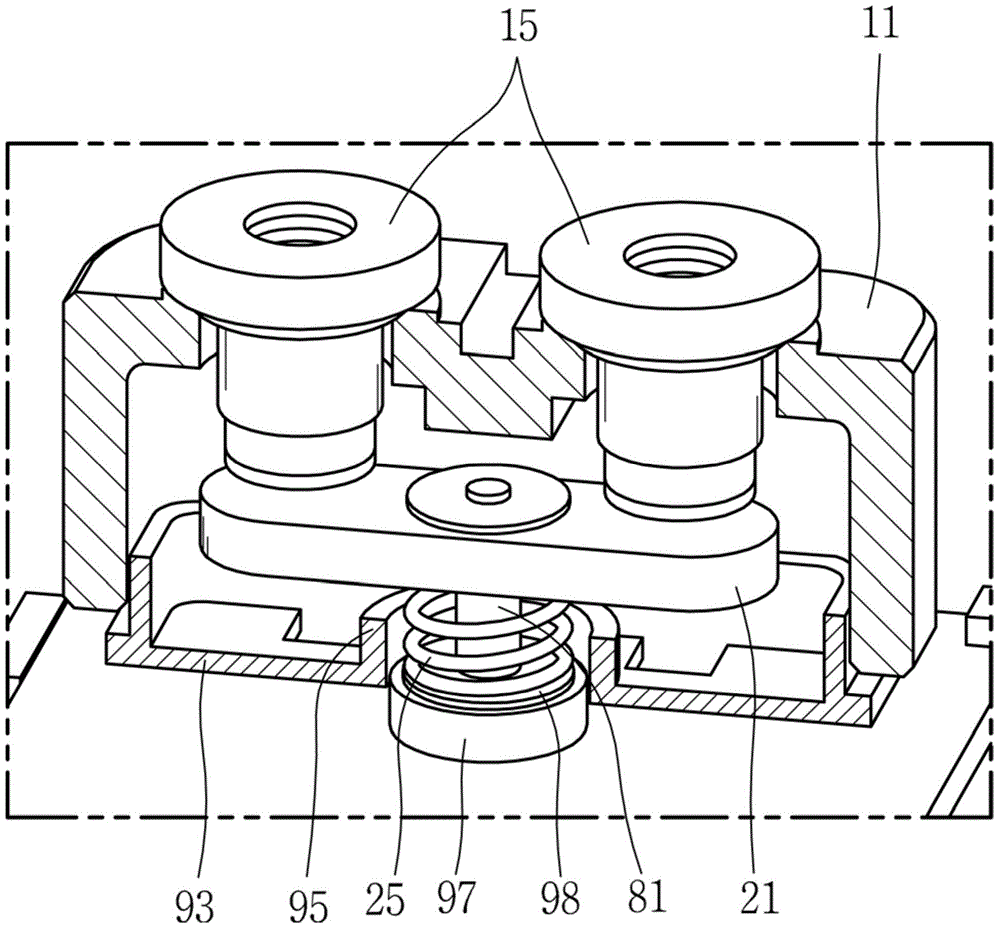

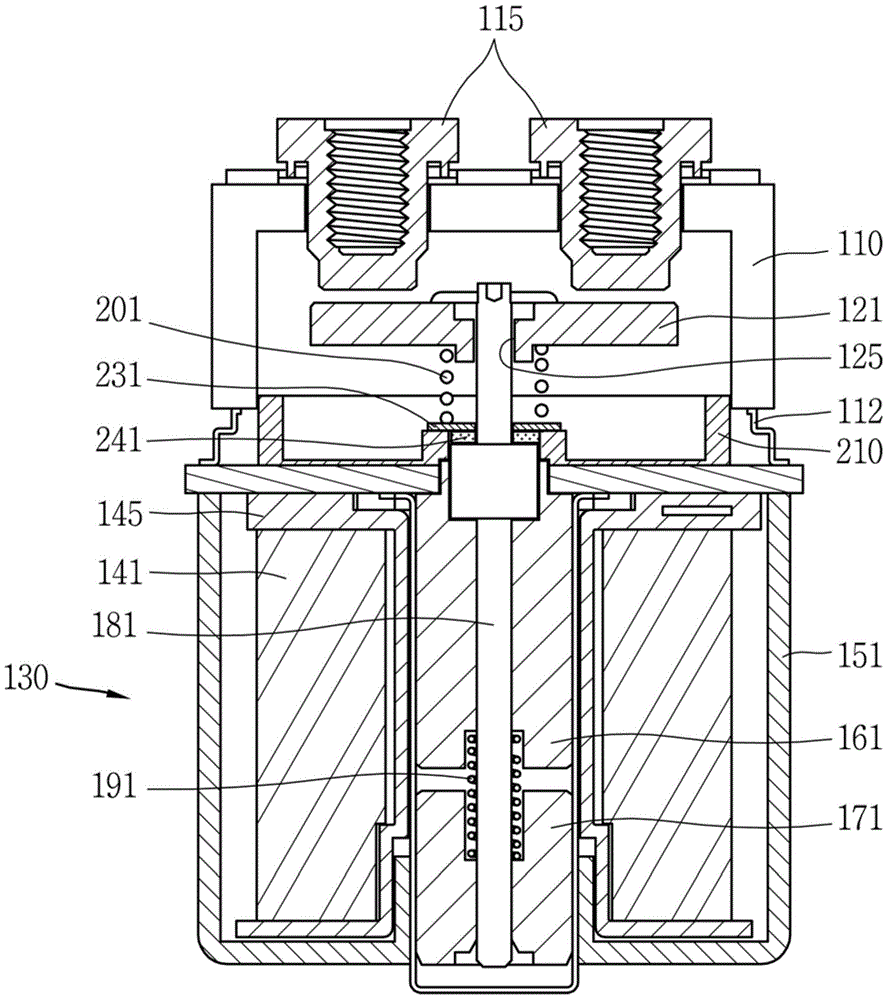

[0054] Hereinafter, preferred embodiments of the electromagnetic relay according to the present invention will be described in detail with reference to the accompanying drawings.

[0055] Such as image 3 and Figure 4 As shown, the electromagnetic relay according to the embodiment of the present invention may include: a casing 110; a fixed contact 115 disposed in the casing 110; a movable contact arranged in the casing 110 so as to be in contact with and separated from the fixed contact 115 Point 121; drive unit 130, which is configured to drive the movable contact 121, and includes a compression spring 201, and a shaft connected to the movable contact 121 at one end, the compression spring 201 is used to apply an elastic force to the movable contact 121 and an arc protector 210 including an arc shield portion 211 for shielding an arc and a compression spring support portion 221 formed to protrude from the arc shield portion 211 to support the compression spring 201 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com