Silage roll bale baler capable of continuous operation and baling method

A technology of round bales and balers, applied to agricultural machinery and tools, packaging, agriculture, etc., can solve problems such as the need to stop operations, and achieve the effects of improving flexibility, shortening operating hours, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail.

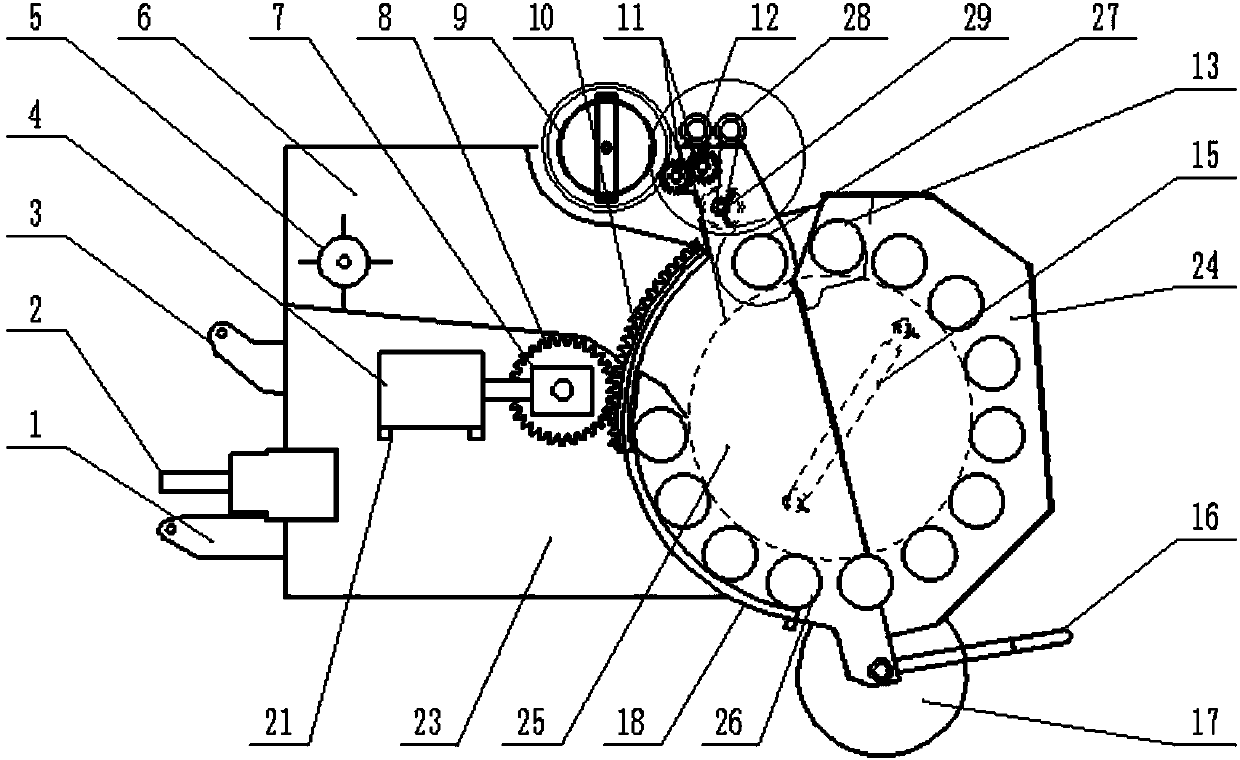

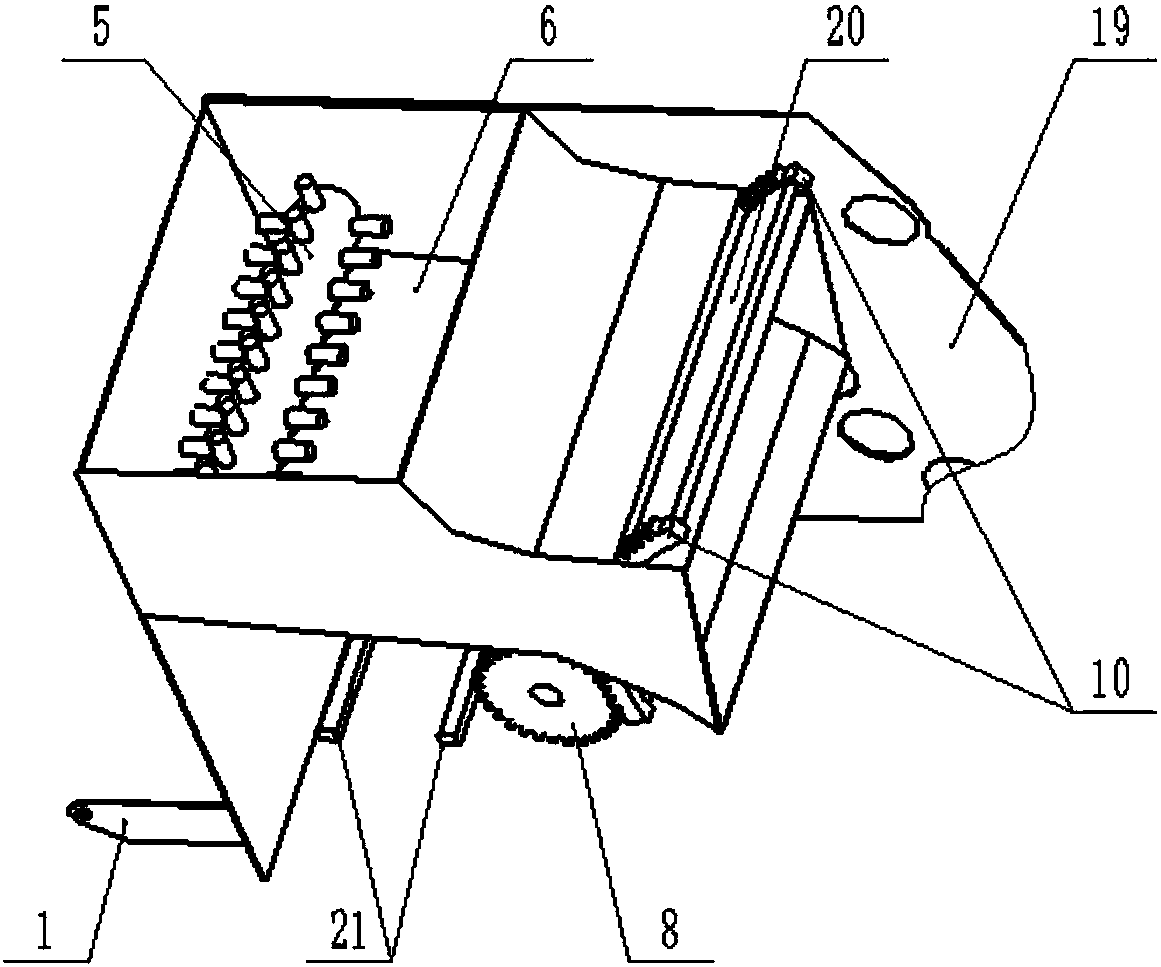

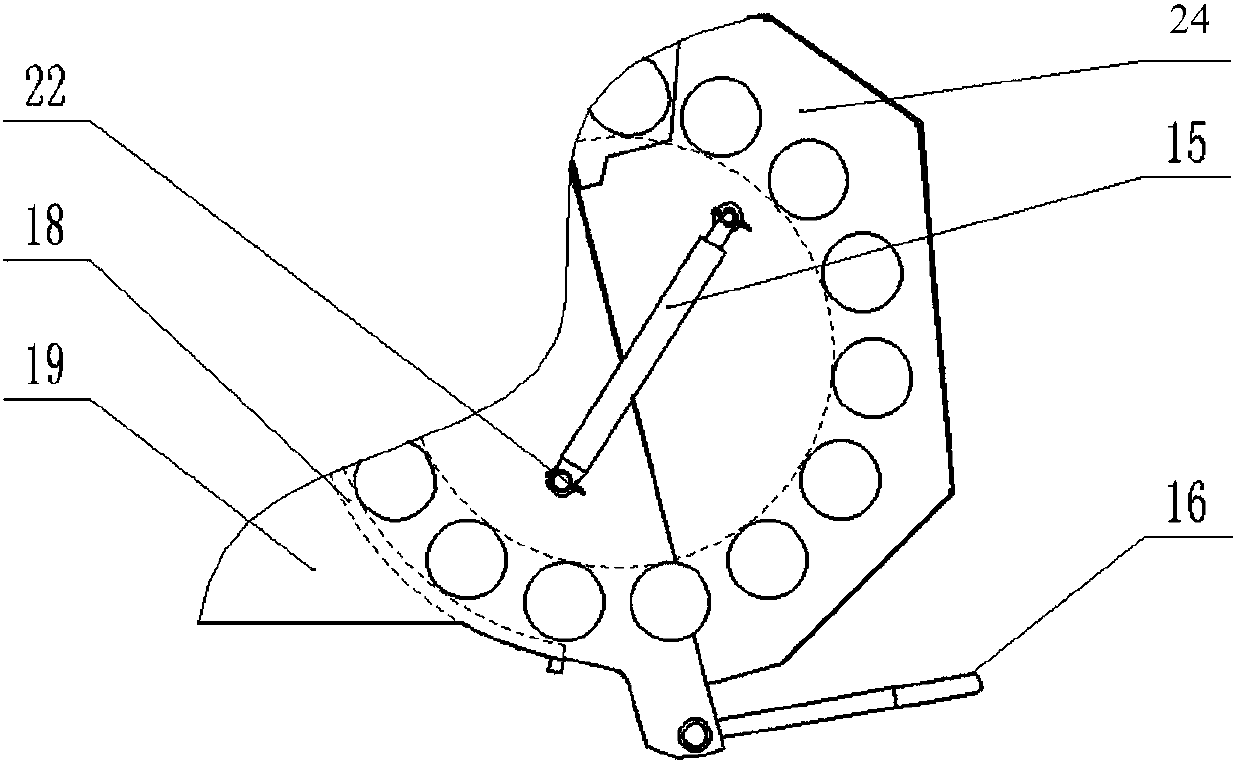

[0065] Such as Figure 1-5 As shown, a continuous operation silage round baler baler includes a main structure, a lower suspension mechanism 1, a transmission mechanism 2, an upper suspension mechanism 3, a first motor 4, a grass roller 5, a gearbox 7, and a gear 8 , Bundle unloading mechanism 16, ground wheel 17, guide rail 18, fan-shaped rack 10, warehouse door 20, net winding device, steel roller type volume bundling device and net cutting device. in:

[0066] Such as figure 1 and figure 2 As shown, the main structure includes a side wall 19 , a feed bin 6 and a front bin 23 . The two side walls 19 are respectively located on the left and right sides of the main structure. Both the feed bin 6 and the front bin 23 are installed between the two side walls 19 , and the feed bin 6 is arranged above the front bin 23 .

[0067] The inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com