Three-dimensional ultrasonic inspection device

Through three-dimensional ultrasonic inspection equipment, matrix or array piezoelectric vibrators and signal processing technology are used to solve the problem of difficulty in accurately inspecting welding parts with two-dimensional equipment, achieving fast and accurate three-dimensional welding defect detection, simplifying operations, and improving Detection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0130] Embodiments of the three-dimensional ultrasonic inspection apparatus in the present invention will be described below with reference to the drawings.

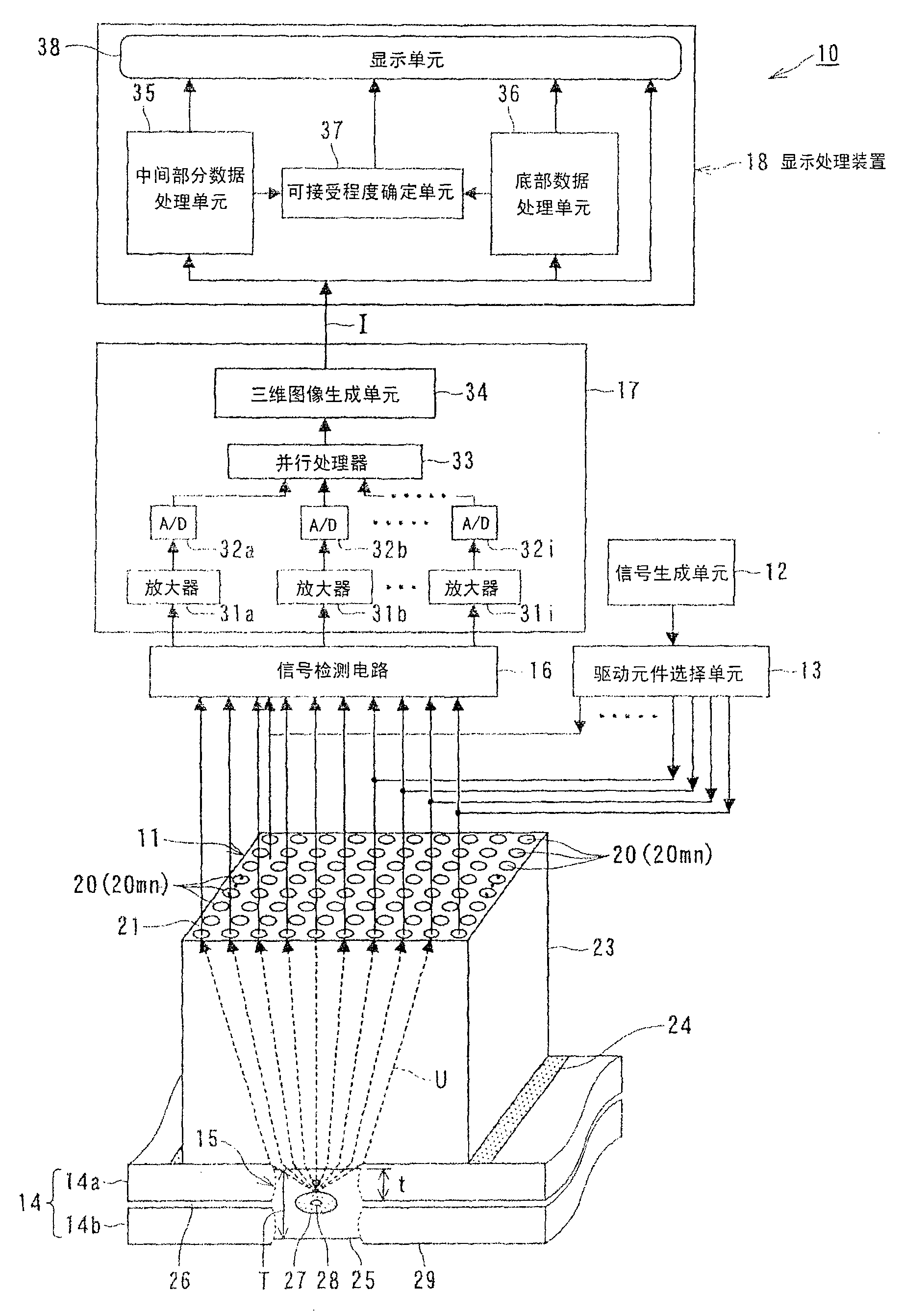

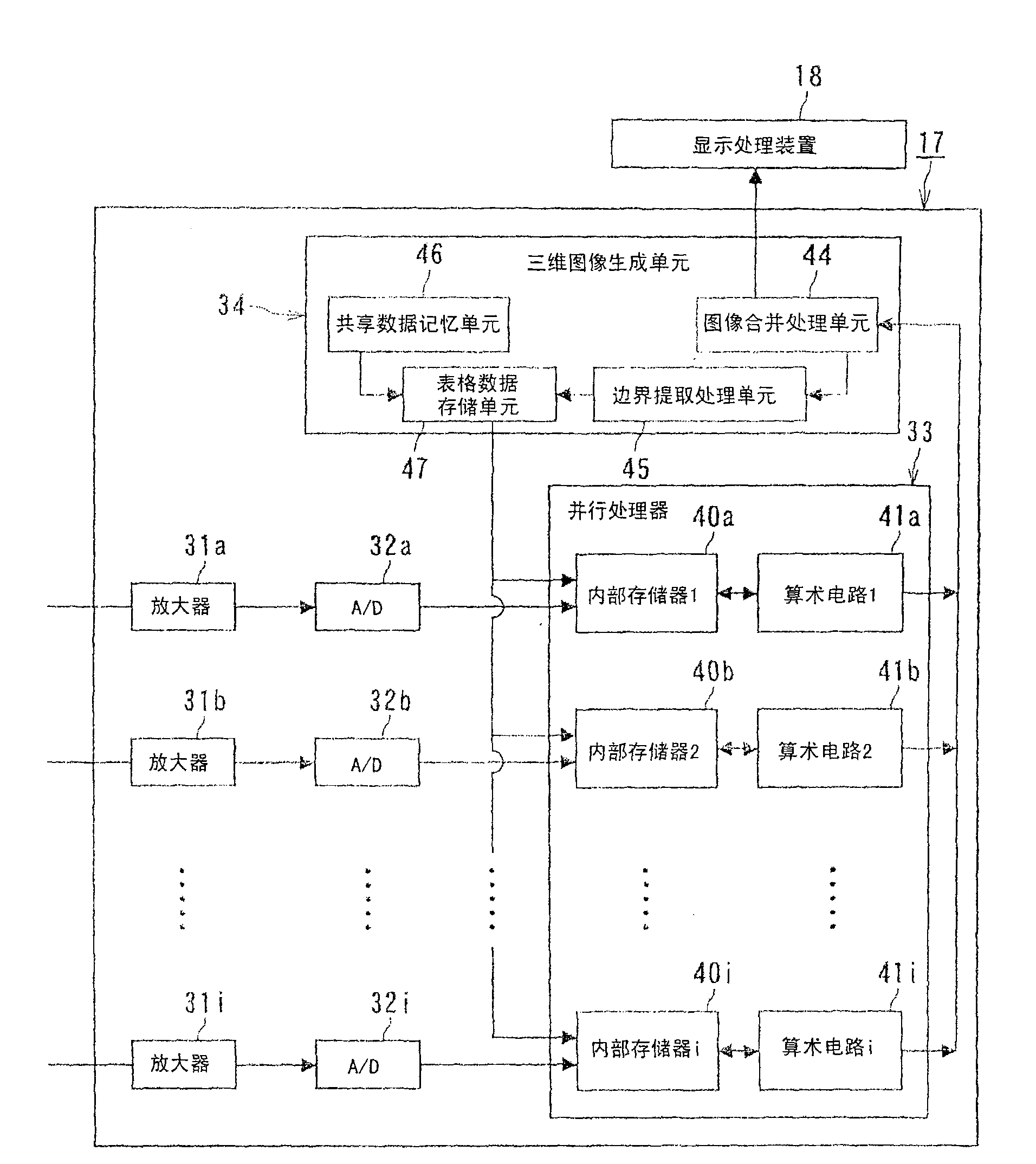

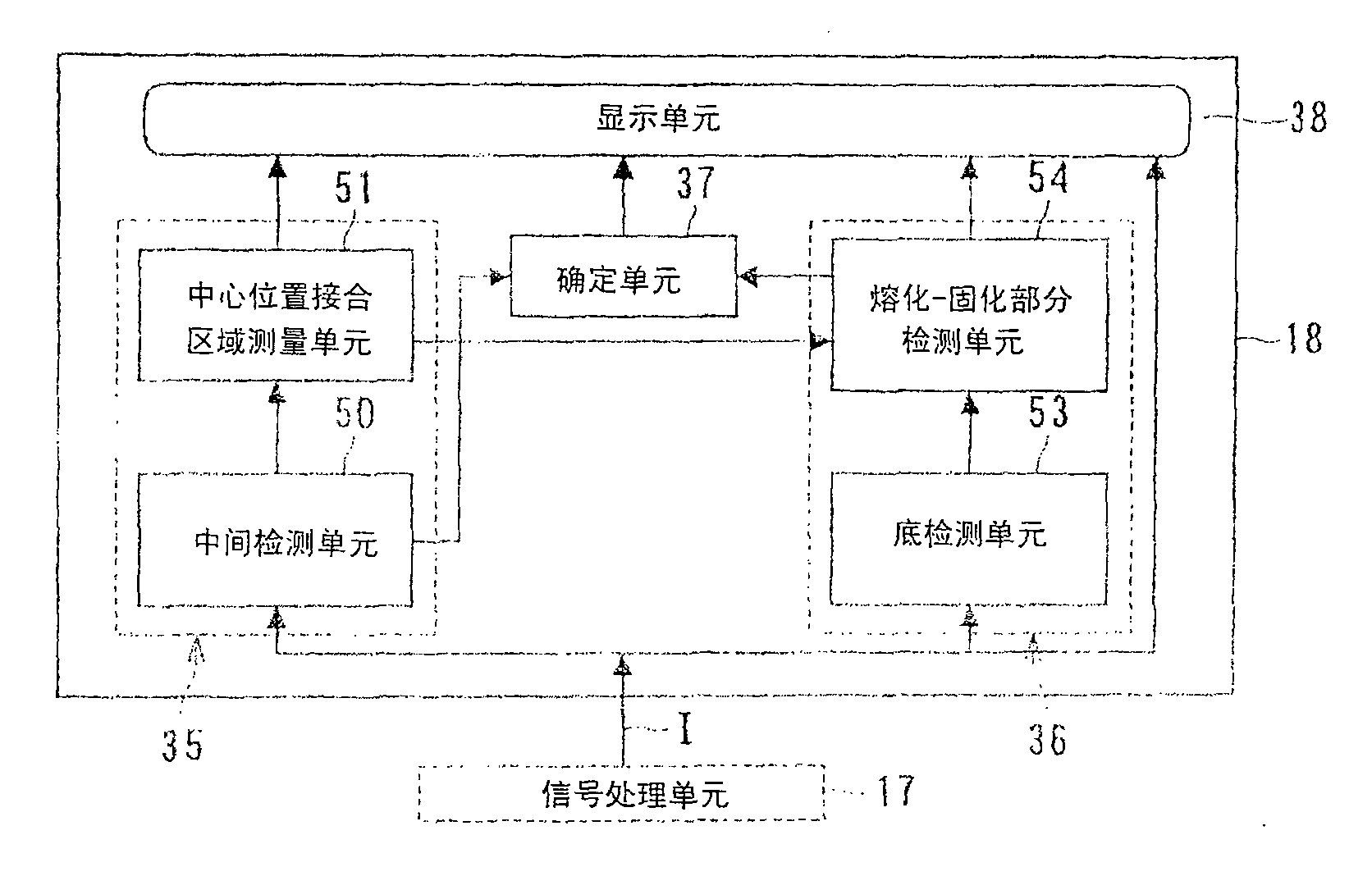

[0131] figure 1 is a structural diagram illustrating an embodiment of the three-dimensional ultrasonic inspection apparatus in the present invention.

[0132] The three-dimensional ultrasonic inspection apparatus 10 includes: a sensing device 100 for ultrasonic inspection (details thereof will be described below), including a transducer 11 as an ultrasonic sensor that converts ultrasonic vibration into an electrical signal, and an electrical signal The signal is converted into ultrasonic vibrations, and transmits and receives ultrasonic waves with a desired frequency; the signal generation unit 12 is used to generate a drive signal to drive the ultrasonic transducer 11; the drive element selection unit 13 is used to select the signal generation unit 12 The drive signal selectively drives the piezoelectric vibrator of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com