Centrifugal casting air discharging method for squirrel cage rotor and centrifugal casting die for implementing method

A squirrel-cage rotor and centrifugal casting technology, which is applied in the field of squirrel-cage rotors, can solve the problems of reduced motor energy conversion efficiency, broken ribs, entrained air bubbles, complex equipment structure, etc., to achieve improved efficiency, good compactness, and countercurrent effect small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

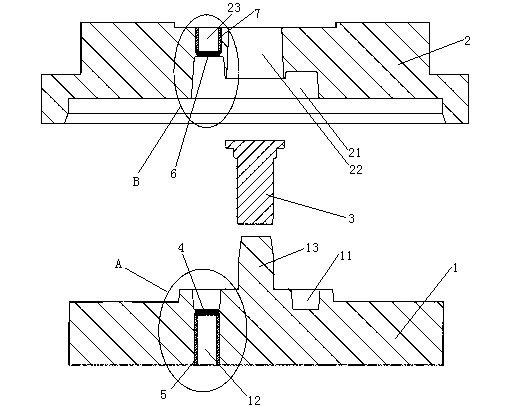

[0030] Embodiment one, see figure 1 , a squirrel-cage rotor centrifugal casting mold, comprising a lower mold 1, an upper mold 2 and a core 3.

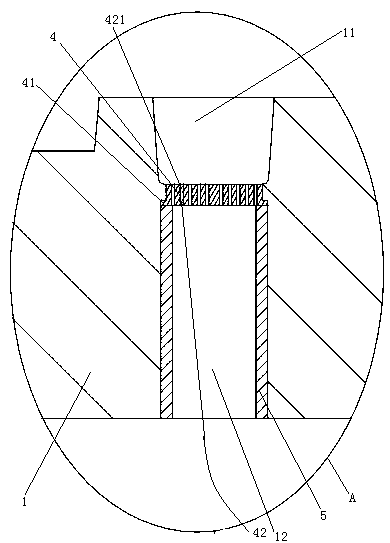

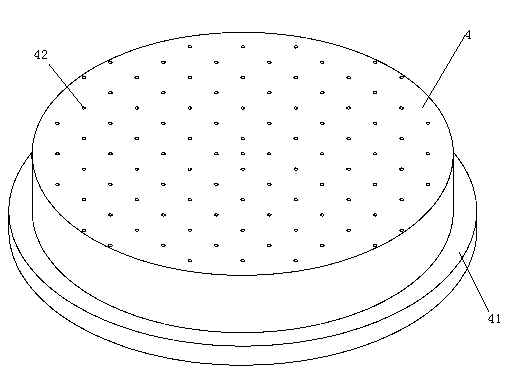

[0031] The lower mold 1 is provided with a ring cavity 11 at the lower end of the rotor. Seven lower installation through holes 12 are provided on the bottom wall of the rotor lower end ring cavity 11 . The lower mounting through holes 12 are evenly distributed along the circumferential direction of the rotor lower end ring cavity 11 . A lower exhaust mesh 4 and a lower exhaust mesh pressing rod 5 are arranged in the lower installation through hole 12 . The lower exhaust mesh pressing rod 5 is a tubular structure. The lower mold 1 is provided with a positioning mandrel 13 .

[0032] The upper mold 2 is provided with a rotor upper end ring cavity 21 and a casting hole 22 . Seven upper installation through holes 23 are provided on the bottom wall of the ring cavity 21 at the upper end of the rotor. The upper mounting through holes...

Embodiment 2

[0039] Embodiment two, the difference with embodiment one is: see Figure 7 , The lower mold 1 is provided with seven lower air extraction passages 14 . The inlet end 142 of each lower air extraction channel communicates with the lower installation through hole 12 respectively. The outlet end 141 of the lower air extraction channel is located on the radial side of the lower mold 1 . The curing section 421 of the lower vent hole is conical with a smaller opening area at the lower section and a larger opening area at the upper end. The opening area of the upper port of the lower vent hole curing section 421 is 0.3 square millimeters. The lower exhaust mesh 4 is provided with a lower air cavity 43 . The air outlets of all the lower exhaust holes 42 on the same lower exhaust mesh communicate with the lower air cavity 43 . The lower air chamber 43 is provided with a lower air chamber air outlet 431 . The air outlet 431 of the lower air cavity is butted with the inlet end 142...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com