Electric rotating machine

A technology for rotating electrical machines and rotating shafts, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as false detection of rotor position, and achieve the effect of reducing magnetic field strength and interference level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

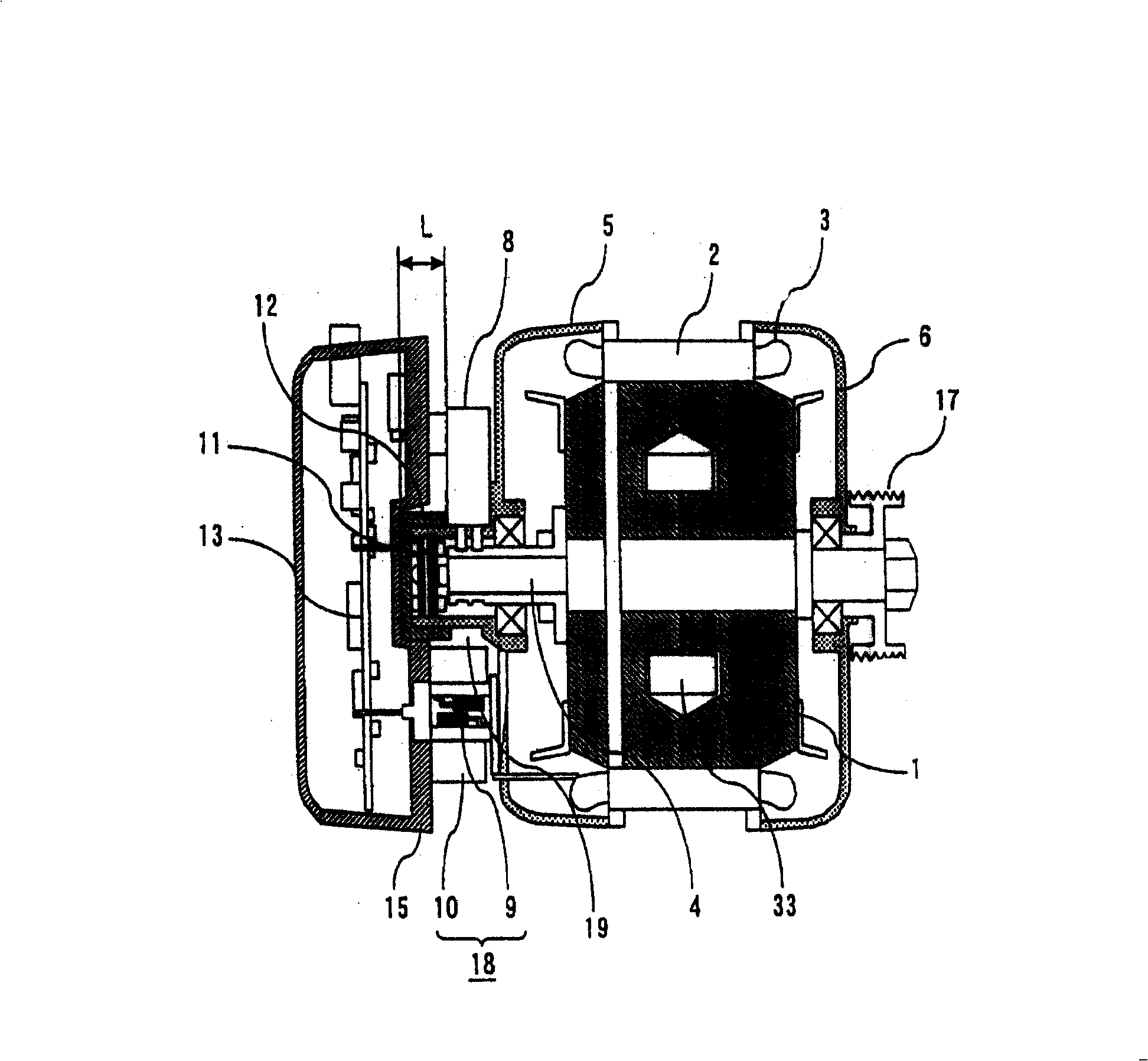

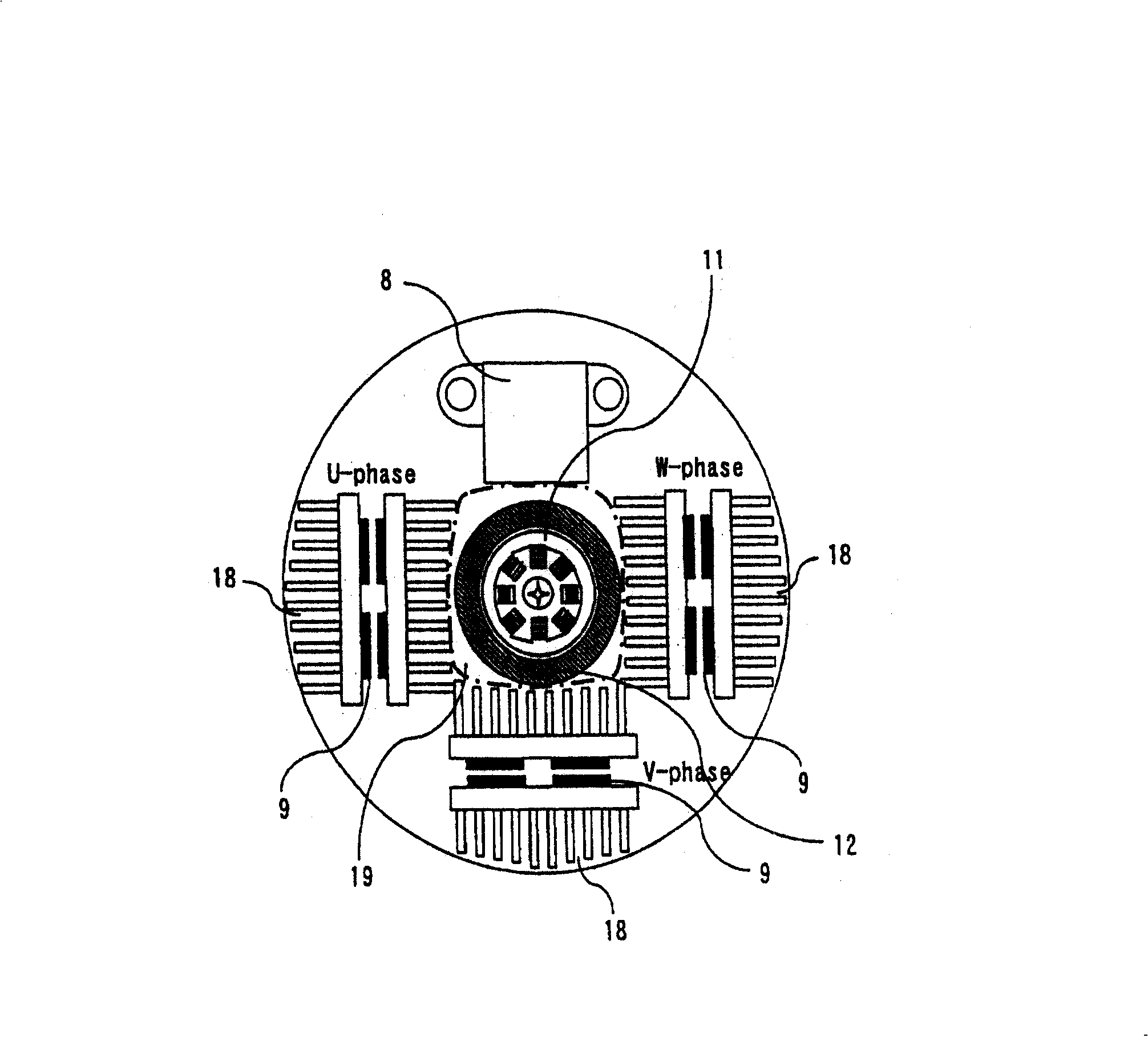

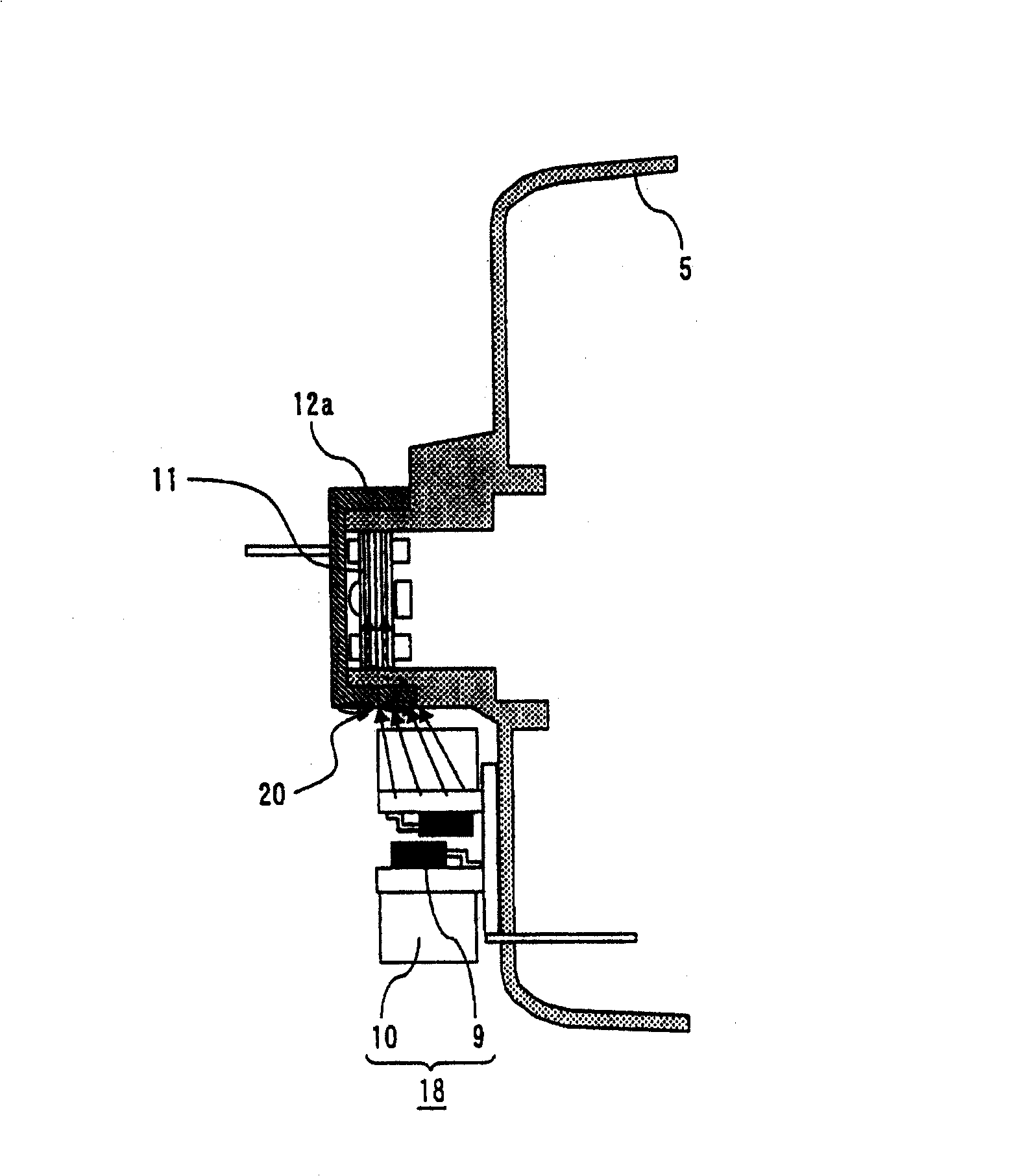

[0040] Embodiments of the present invention will be described below with reference to the drawings. Embodiments described below take as an example a structure of a control-device-integrated rotating electric machine in which a control device having a switching element unit for controlling current supplied to windings provided on a stator and a rotor is mounted on the rotating electric machine.

[0041] Embodiment 1

[0042] figure 1 is a schematic cross-sectional view showing Embodiment 1 of the rotating electric machine related to the present invention, figure 2 It is a side view of the periphery of the rotational position detection unit viewed from the axial direction. The rotating electrical machine in Embodiment 1 has: a stator 2 supported and fixed on end covers 5, 6; rotor 1. The stator 2 has a stator winding 3 and the rotor 1 has a rotor winding 33 . The pulley 17 is attached to the load side of the rotary shaft 4, and the pulley 17 is connected to a load not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com