Current transformer

A technology for current transformers and iron cores, applied in the direction of inductors, transformer/inductor cores, transformer/inductor coils/windings/connections, etc., which can solve the problem of easy saturation of output waveforms and distortion of secondary currents that will cause tailing , can not truly reflect the attenuation state of non-periodic components, and the current transformer cannot accurately transmit and change DC components, etc., to achieve the effect of eliminating tailing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

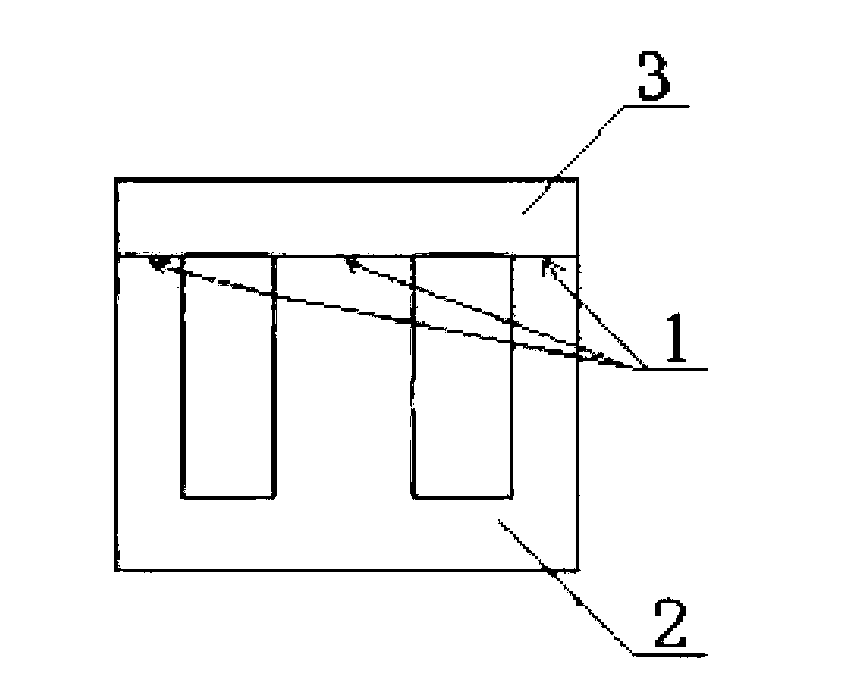

[0029] Such as figure 1 As shown, a current transformer includes an iron core, a primary winding and a secondary winding, wherein the cross-sectional area of the iron core is 0.5-3.5cm2, and at least one air gap 1 is provided on the iron core along the direction of the cutting magnetic force line; The number of turns of the winding is 1-25 turns, preferably 1-15 turns; the number of turns of the secondary winding is 10001-30000 turns, preferably 10001-20000 turns; in addition, the coil cross-sectional area of the primary winding is 0.5- 4mm 2 , preferably 1mm 2 , the coil diameter of the secondary winding is in the range of 0.05-0.3 mm, preferably 0.1 mm.

[0030] In this embodiment, a resistor is connected in parallel at both ends of the secondary winding, and the resistance of the resistor ranges from 1 ohm to 5000 ohm. In addition, the iron core can be composed of one or more of a stack of EI iron cores with air gaps, at least one pair of ED iron cores, at least one ...

Embodiment 2

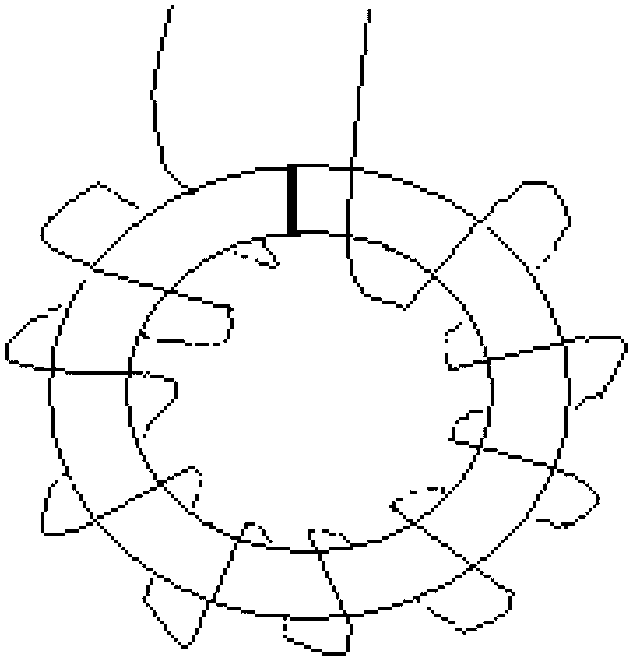

[0032] Such as Figure 7 and Figure 8 As shown, this embodiment is basically the same as Embodiment 1, except that the iron core used in this embodiment is an annular iron core, and the cross-sectional area of this annular iron core is 2cm 2 , the number of turns of the primary winding is 5 turns, the number of turns of the secondary winding is 15000 turns, and the coil cross-sectional area of the primary winding is 1.5mm 2 , the coil cross-sectional area of the secondary winding is 0.1mm 2 .

[0033] In the second embodiment, a resistor may be connected in parallel at both ends of the secondary winding, and the resistance value of the resistor ranges from 1 ohm to 5000 ohm. The iron core may consist of at least one pair of annular notched iron cores. Such as Figure 8 As shown, the present embodiment only adopts an annular iron core with an air gap 1, the outer diameter of the annular iron core is 18-40mm, the inner diameter is 12-30mm, and the thickness is 6-18mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com