Radial airgap, transverse flux motor

A magnet and axial technology, applied in the field of electric-generator rotating machines, can solve the problems such as difficult to save costs, achieve the effect of improving performance characteristics and low magnetic core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

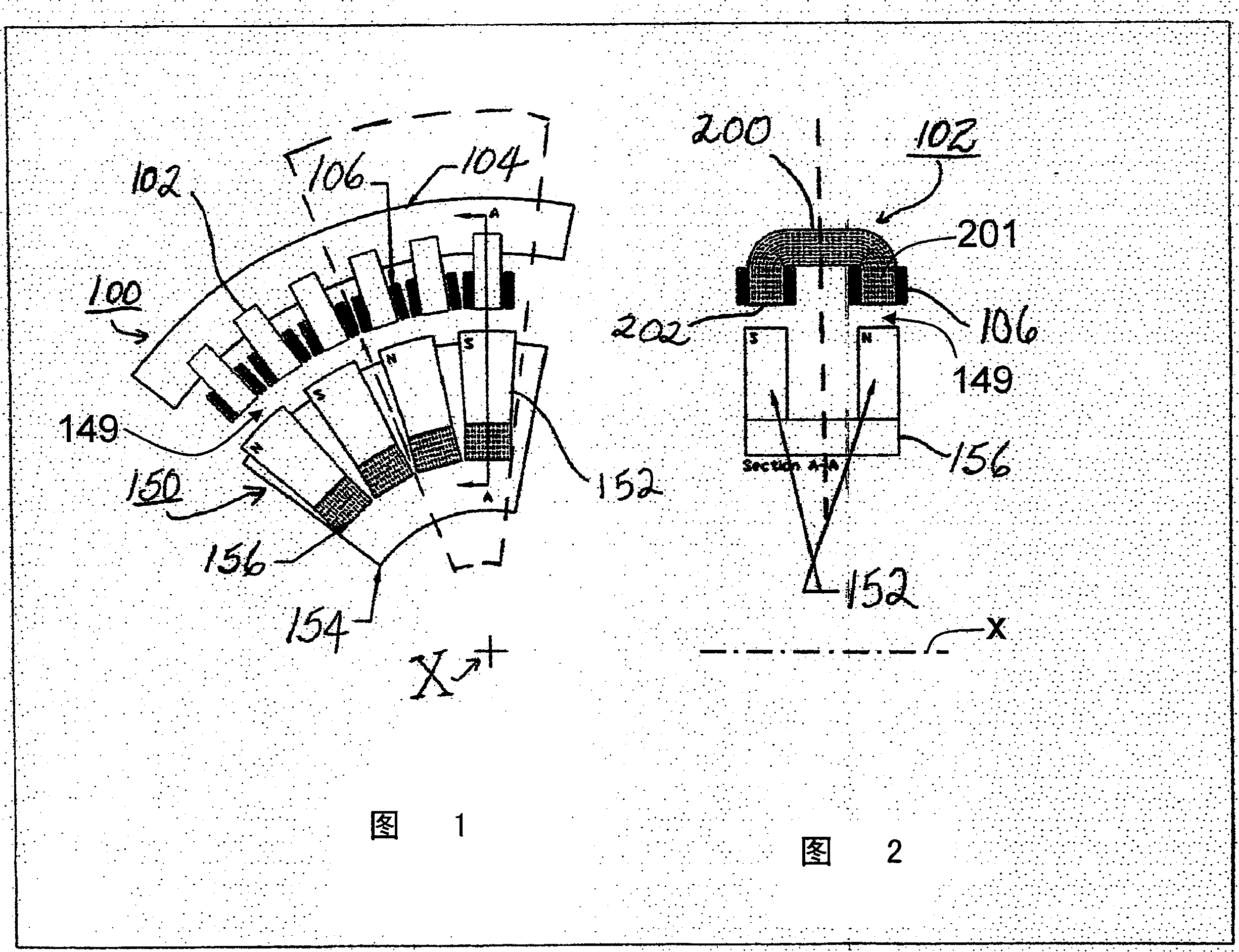

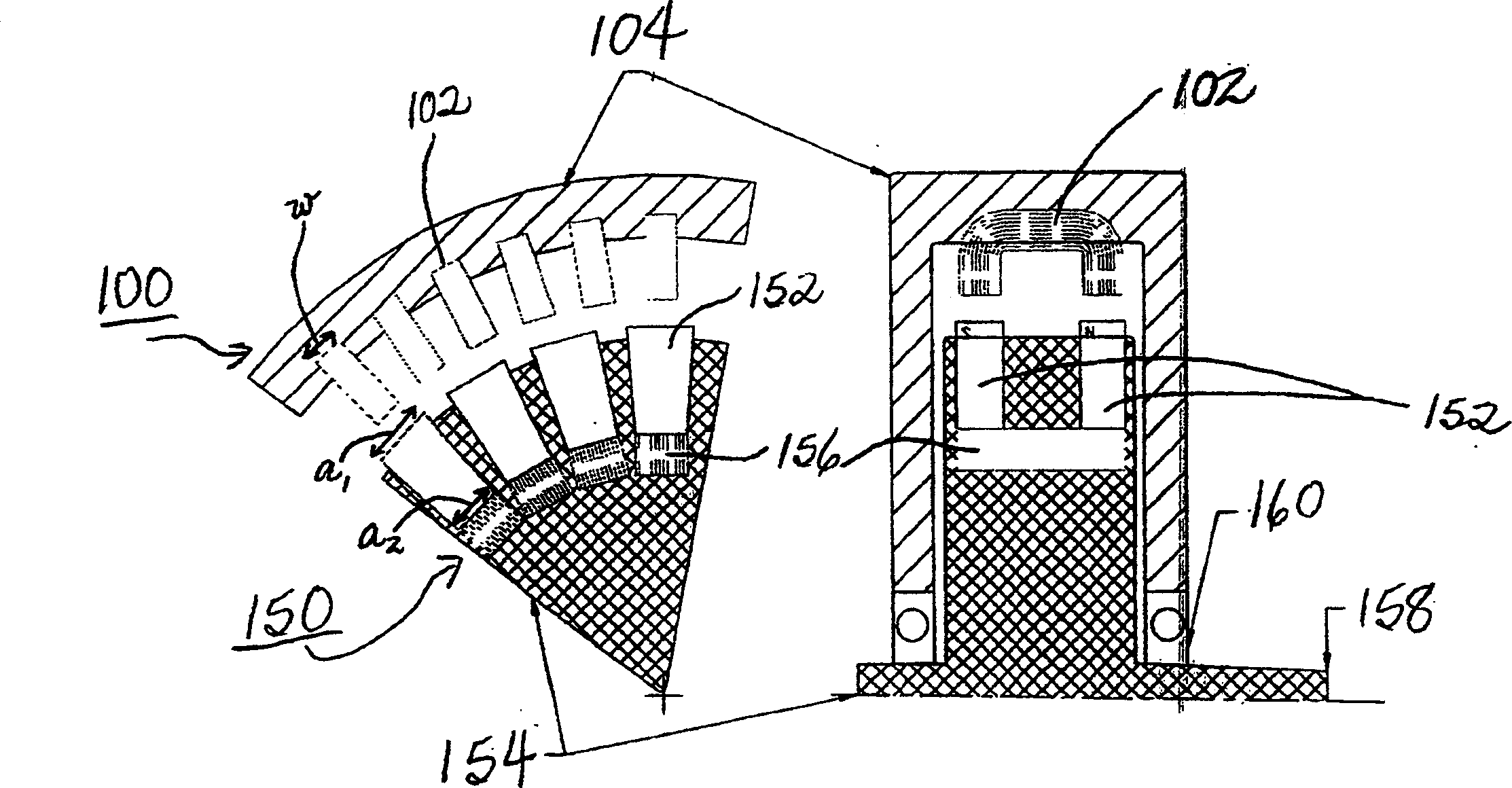

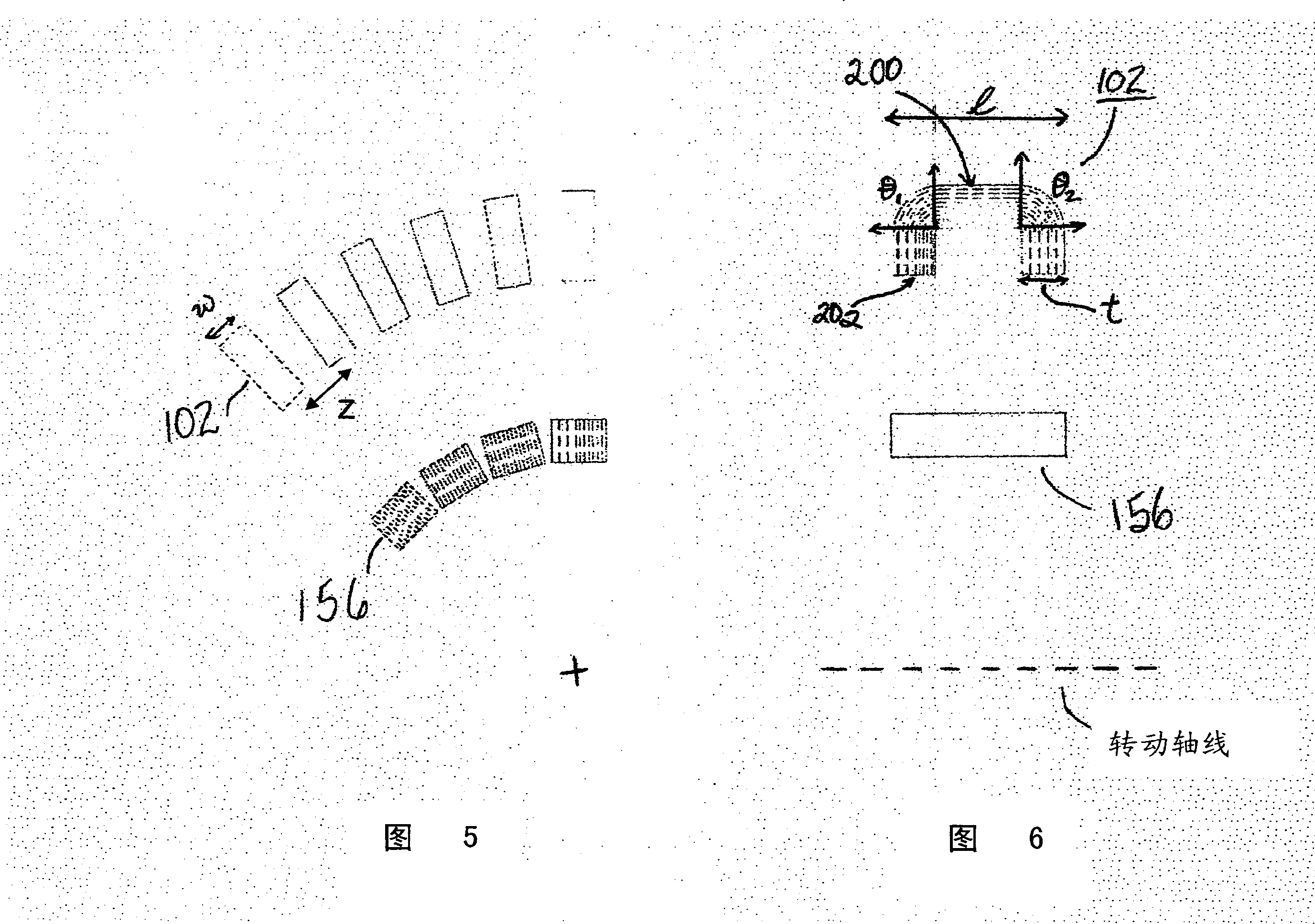

[0036] Hereinafter, preferred embodiments of the present invention will be described in more detail with reference to the accompanying drawings. The present invention provides a radial air gap, traversing magnet electrical device with a stator core made of low loss material. It is preferred that the stator core be made of thin strip or strip form material consisting mainly of amorphous or nanocrystalline metals, or grain-oriented or non-grain-oriented Fe-based materials, usually having a higher ratio than amorphous or nanocrystalline Materials of high saturation induction are generally referred to herein as "flux-enhanced Fe-based magnetic materials".

[0037] amorphous metal

[0038] Amorphous metals, also known as metallic glasses, are present in a variety of different compositions suitable for use in the motor of the present invention. Metallic glasses are generally formed from alloy melts of the desired composition, for example, by 6 Rapid quenching from the melt by coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com