Salient pole type linear motor and reciprocating type double-piston compressor

A linear motor and compressor technology, applied in the motor field, can solve the problems of lubricating oil contaminating compressed gas or fluid, affecting the overall system efficiency, and cylinder wall wear, etc., and achieving the effects of improving efficiency, low noise, and low mechanical wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

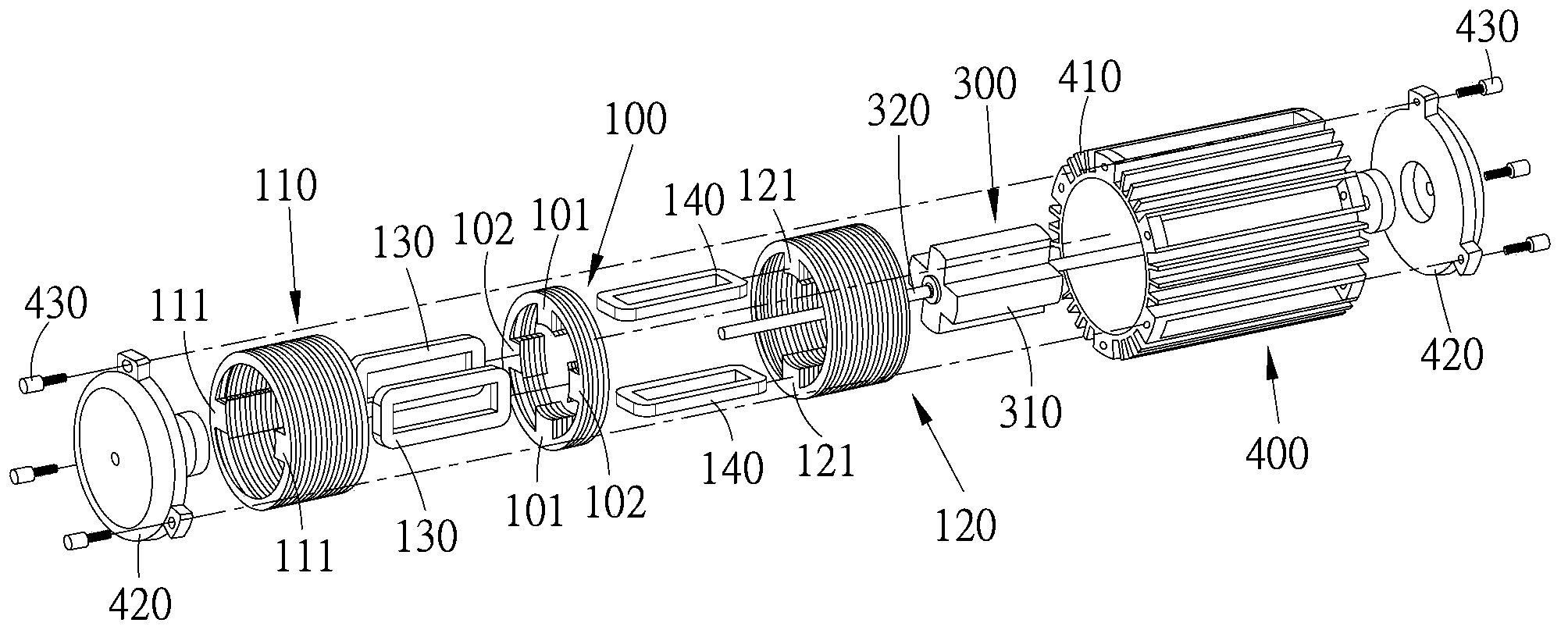

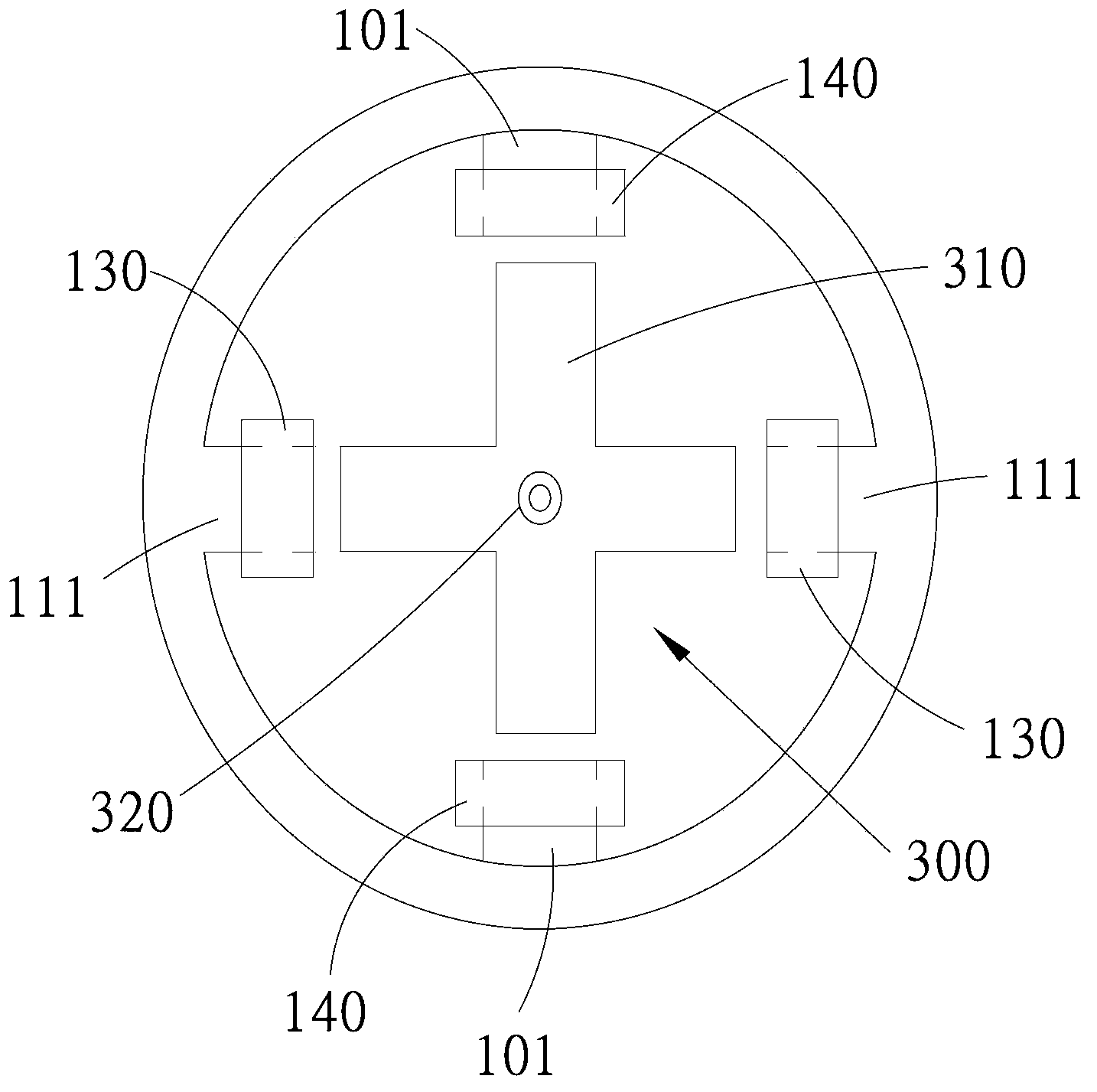

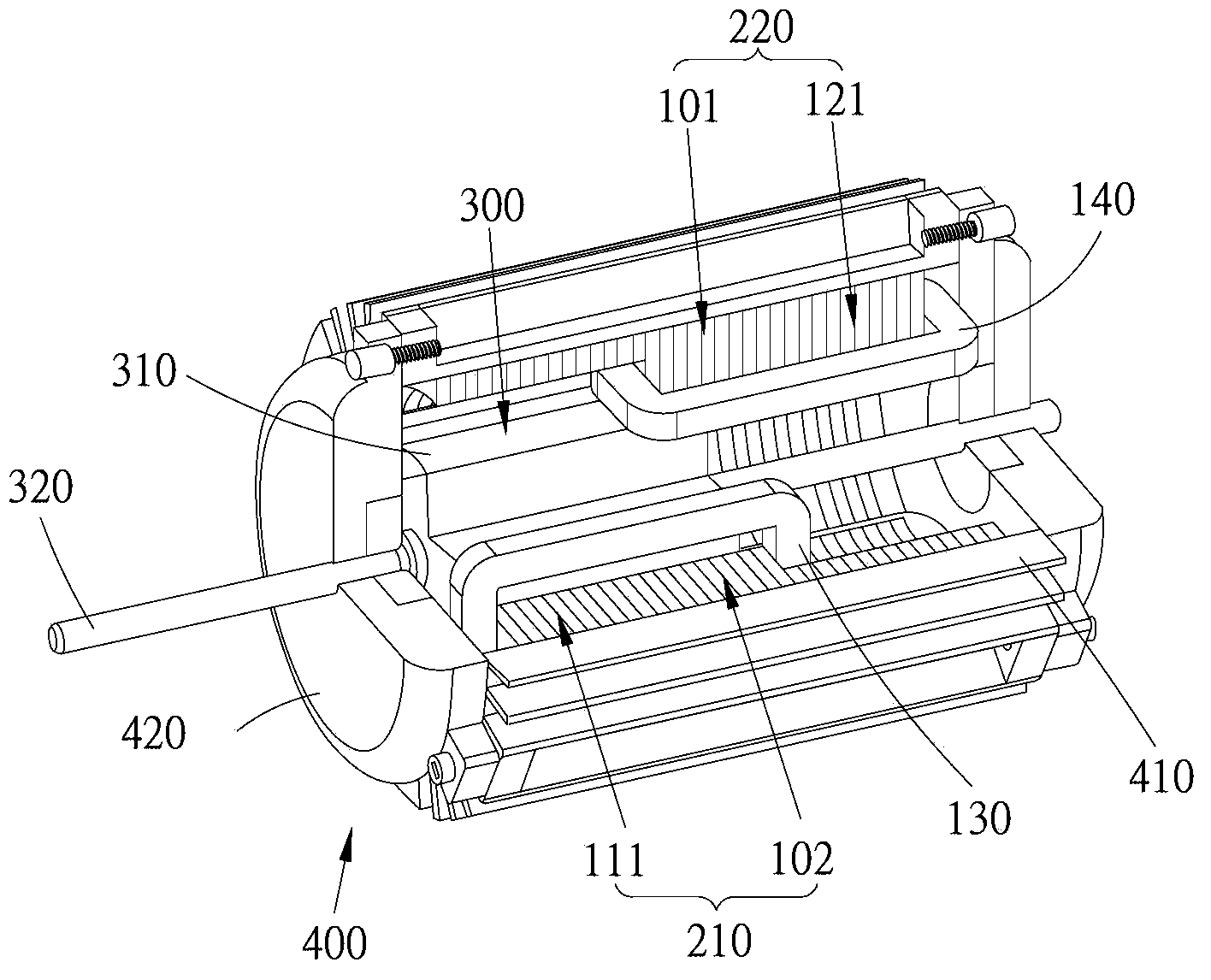

[0031] The embodiments of the salient-pole linear motor and the reciprocating dual-piston compressor according to the present invention will be described below with reference to the relevant drawings. For ease of understanding, the same components in the following embodiments are described with the same symbols.

[0032] In the salient pole linear motor of the present invention, front and rear stator core poles are arranged on the stator, and shaped coils are arranged on the magnetic poles. The front and rear coils are used to generate a magnetic field, and the characteristic that the closed magnetic force lines will follow the minimum reluctance path makes the mover move freely. A salient-pole type linear motor that moves in the direction of the minimum reluctance, thereby constituting linear motion. And use this salient pole type linear motor to drive the compressor designed with dual-piston two-way inlet and outlet fluid or compressed gas, to replace the traditional driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com